Addressing Material Waste Management in Vacuum Forming Processes

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Waste Reduction Objectives

Vacuum forming waste reduction objectives focus on minimizing material waste and improving resource efficiency in the vacuum forming process. This technology aims to address the significant environmental and economic challenges posed by excessive material waste in the plastics industry. The primary goal is to develop innovative solutions that optimize material usage, reduce scrap rates, and enhance overall process efficiency.

One key objective is to improve material utilization through advanced design and engineering techniques. This involves optimizing product designs to minimize excess material, developing more efficient mold designs, and implementing computer-aided design (CAD) and simulation tools to predict and reduce potential waste areas. By refining these aspects, manufacturers can significantly decrease the amount of trim waste generated during the vacuum forming process.

Another critical objective is to enhance process control and automation. This includes implementing real-time monitoring systems, advanced sensors, and machine learning algorithms to optimize process parameters such as temperature, pressure, and forming time. By fine-tuning these variables, manufacturers can reduce defects, improve product quality, and minimize material waste due to rejected parts or production errors.

Recycling and reuse of waste materials form another crucial objective in vacuum forming waste reduction. This involves developing efficient in-house recycling systems to reprocess trim waste and rejected parts, as well as exploring innovative ways to incorporate recycled materials into new products without compromising quality or performance. Additionally, research into biodegradable and compostable materials for vacuum forming applications aims to reduce the environmental impact of waste that cannot be recycled.

Energy efficiency is also a key consideration in waste reduction objectives. By optimizing heating systems, reducing cycle times, and implementing energy recovery systems, manufacturers can minimize energy waste and improve the overall sustainability of the vacuum forming process. This not only reduces operational costs but also contributes to a lower carbon footprint.

Lastly, the development of closed-loop manufacturing systems represents a long-term objective in vacuum forming waste reduction. This holistic approach aims to create a circular economy within the manufacturing process, where waste is minimized, and resources are continuously reused or recycled. This may involve collaborations across the supply chain, from material suppliers to end-users, to create more sustainable and efficient production cycles.

One key objective is to improve material utilization through advanced design and engineering techniques. This involves optimizing product designs to minimize excess material, developing more efficient mold designs, and implementing computer-aided design (CAD) and simulation tools to predict and reduce potential waste areas. By refining these aspects, manufacturers can significantly decrease the amount of trim waste generated during the vacuum forming process.

Another critical objective is to enhance process control and automation. This includes implementing real-time monitoring systems, advanced sensors, and machine learning algorithms to optimize process parameters such as temperature, pressure, and forming time. By fine-tuning these variables, manufacturers can reduce defects, improve product quality, and minimize material waste due to rejected parts or production errors.

Recycling and reuse of waste materials form another crucial objective in vacuum forming waste reduction. This involves developing efficient in-house recycling systems to reprocess trim waste and rejected parts, as well as exploring innovative ways to incorporate recycled materials into new products without compromising quality or performance. Additionally, research into biodegradable and compostable materials for vacuum forming applications aims to reduce the environmental impact of waste that cannot be recycled.

Energy efficiency is also a key consideration in waste reduction objectives. By optimizing heating systems, reducing cycle times, and implementing energy recovery systems, manufacturers can minimize energy waste and improve the overall sustainability of the vacuum forming process. This not only reduces operational costs but also contributes to a lower carbon footprint.

Lastly, the development of closed-loop manufacturing systems represents a long-term objective in vacuum forming waste reduction. This holistic approach aims to create a circular economy within the manufacturing process, where waste is minimized, and resources are continuously reused or recycled. This may involve collaborations across the supply chain, from material suppliers to end-users, to create more sustainable and efficient production cycles.

Market Demand for Sustainable Manufacturing

The market demand for sustainable manufacturing practices, particularly in vacuum forming processes, has been steadily increasing in recent years. This surge is driven by a combination of environmental concerns, regulatory pressures, and consumer preferences for eco-friendly products. Companies across various industries, including packaging, automotive, and consumer goods, are actively seeking ways to reduce material waste and improve their sustainability profiles.

In the vacuum forming sector, the focus on material waste management is particularly acute. Traditional vacuum forming processes often generate significant amounts of waste, primarily in the form of trim scrap and rejected parts. This waste not only represents a financial loss for manufacturers but also contributes to environmental degradation. As a result, there is a growing demand for innovative solutions that can minimize material waste while maintaining or improving product quality and production efficiency.

The packaging industry, one of the largest users of vacuum forming technology, is at the forefront of this demand. With increasing public awareness of plastic pollution, packaging manufacturers are under pressure to adopt more sustainable practices. This has led to a rise in demand for vacuum forming processes that can utilize recycled materials, produce thinner and lighter products, and generate less waste during production.

Similarly, the automotive industry is experiencing a shift towards lightweight, fuel-efficient vehicles, driving demand for vacuum-formed components that are both durable and sustainably produced. Manufacturers in this sector are seeking solutions that can reduce material usage without compromising on part strength or performance.

The consumer goods sector is another key driver of demand for sustainable vacuum forming processes. Companies in this space are responding to consumer preferences for products with lower environmental footprints. This has created a market for vacuum-formed products made from bio-based or recycled materials, as well as those produced through waste-minimizing processes.

Regulatory pressures are also playing a significant role in shaping market demand. Many countries and regions have implemented or are considering regulations aimed at reducing plastic waste and promoting circular economy principles. These regulations are compelling manufacturers to invest in more sustainable production methods, including improved waste management in vacuum forming processes.

The economic benefits of waste reduction are further fueling market demand. Manufacturers are recognizing that minimizing material waste can lead to significant cost savings, both in terms of raw material costs and waste disposal expenses. This economic incentive is driving investment in technologies and processes that can optimize material usage and reduce waste in vacuum forming operations.

In the vacuum forming sector, the focus on material waste management is particularly acute. Traditional vacuum forming processes often generate significant amounts of waste, primarily in the form of trim scrap and rejected parts. This waste not only represents a financial loss for manufacturers but also contributes to environmental degradation. As a result, there is a growing demand for innovative solutions that can minimize material waste while maintaining or improving product quality and production efficiency.

The packaging industry, one of the largest users of vacuum forming technology, is at the forefront of this demand. With increasing public awareness of plastic pollution, packaging manufacturers are under pressure to adopt more sustainable practices. This has led to a rise in demand for vacuum forming processes that can utilize recycled materials, produce thinner and lighter products, and generate less waste during production.

Similarly, the automotive industry is experiencing a shift towards lightweight, fuel-efficient vehicles, driving demand for vacuum-formed components that are both durable and sustainably produced. Manufacturers in this sector are seeking solutions that can reduce material usage without compromising on part strength or performance.

The consumer goods sector is another key driver of demand for sustainable vacuum forming processes. Companies in this space are responding to consumer preferences for products with lower environmental footprints. This has created a market for vacuum-formed products made from bio-based or recycled materials, as well as those produced through waste-minimizing processes.

Regulatory pressures are also playing a significant role in shaping market demand. Many countries and regions have implemented or are considering regulations aimed at reducing plastic waste and promoting circular economy principles. These regulations are compelling manufacturers to invest in more sustainable production methods, including improved waste management in vacuum forming processes.

The economic benefits of waste reduction are further fueling market demand. Manufacturers are recognizing that minimizing material waste can lead to significant cost savings, both in terms of raw material costs and waste disposal expenses. This economic incentive is driving investment in technologies and processes that can optimize material usage and reduce waste in vacuum forming operations.

Current Challenges in Vacuum Forming Waste Management

Vacuum forming processes, while efficient for producing a wide range of plastic products, face significant challenges in material waste management. The industry is grappling with the environmental and economic impacts of excessive waste generation, which has become a pressing concern for manufacturers and stakeholders alike.

One of the primary challenges is the inherent material waste produced during the trimming process. After the plastic sheet is formed over the mold, excess material around the edges must be removed. This trimming waste, often referred to as "skeletal waste," can account for a substantial portion of the original sheet, sometimes up to 40-50% depending on the product design and sheet utilization efficiency.

Another significant issue is the generation of defective parts during production. Factors such as improper heating, inadequate vacuum pressure, or mold design flaws can lead to parts that do not meet quality standards. These rejected parts contribute to the overall waste stream and represent a loss of both material and energy resources invested in their production.

The variability in plastic sheet thickness also poses a challenge. To ensure adequate coverage and strength in the final product, manufacturers often use sheets that are thicker than necessary for certain areas of the product. This results in excess material usage and increased waste, particularly in products with complex geometries.

Recycling of vacuum forming waste presents its own set of challenges. While thermoplastics used in vacuum forming are theoretically recyclable, the process is complicated by the presence of different plastic types, additives, and potential contamination. Sorting and cleaning the waste to make it suitable for recycling can be labor-intensive and costly, deterring many manufacturers from implementing comprehensive recycling programs.

The industry also faces difficulties in implementing closed-loop recycling systems within production facilities. The reintroduction of recycled materials into the vacuum forming process can affect product quality and consistency, requiring careful management and potentially limiting the percentage of recycled content that can be used.

Lastly, there is a growing challenge in meeting increasingly stringent environmental regulations and customer demands for sustainable practices. Manufacturers are under pressure to reduce their environmental footprint, which includes minimizing waste generation and improving recycling rates. However, the costs associated with implementing advanced waste management technologies and processes can be prohibitive for smaller operations.

One of the primary challenges is the inherent material waste produced during the trimming process. After the plastic sheet is formed over the mold, excess material around the edges must be removed. This trimming waste, often referred to as "skeletal waste," can account for a substantial portion of the original sheet, sometimes up to 40-50% depending on the product design and sheet utilization efficiency.

Another significant issue is the generation of defective parts during production. Factors such as improper heating, inadequate vacuum pressure, or mold design flaws can lead to parts that do not meet quality standards. These rejected parts contribute to the overall waste stream and represent a loss of both material and energy resources invested in their production.

The variability in plastic sheet thickness also poses a challenge. To ensure adequate coverage and strength in the final product, manufacturers often use sheets that are thicker than necessary for certain areas of the product. This results in excess material usage and increased waste, particularly in products with complex geometries.

Recycling of vacuum forming waste presents its own set of challenges. While thermoplastics used in vacuum forming are theoretically recyclable, the process is complicated by the presence of different plastic types, additives, and potential contamination. Sorting and cleaning the waste to make it suitable for recycling can be labor-intensive and costly, deterring many manufacturers from implementing comprehensive recycling programs.

The industry also faces difficulties in implementing closed-loop recycling systems within production facilities. The reintroduction of recycled materials into the vacuum forming process can affect product quality and consistency, requiring careful management and potentially limiting the percentage of recycled content that can be used.

Lastly, there is a growing challenge in meeting increasingly stringent environmental regulations and customer demands for sustainable practices. Manufacturers are under pressure to reduce their environmental footprint, which includes minimizing waste generation and improving recycling rates. However, the costs associated with implementing advanced waste management technologies and processes can be prohibitive for smaller operations.

Existing Waste Management Solutions for Vacuum Forming

01 Material recycling and waste reduction

Vacuum forming processes can be optimized to reduce material waste through efficient recycling systems. This involves collecting and reprocessing scrap material from trimming and cutting operations, as well as implementing closed-loop systems to reuse materials within the manufacturing process. These techniques help minimize raw material consumption and reduce overall waste generation.- Optimization of material usage in vacuum forming: Techniques to reduce material waste in vacuum forming processes include precise control of material thickness, optimized mold design, and efficient sheet sizing. These methods help minimize excess material and improve overall efficiency of the forming process.

- Recycling and reuse of waste material: Implementing systems for collecting, processing, and reusing waste material from vacuum forming processes. This includes grinding or shredding of scrap material for reintegration into new products or as raw material for other manufacturing processes.

- Advanced forming techniques to reduce waste: Utilization of advanced forming techniques such as twin-sheet forming, multi-cavity molds, and selective heating to maximize material utilization and reduce waste in vacuum forming processes.

- Material selection and preparation: Careful selection of appropriate materials and proper preparation techniques, including pre-heating and conditioning, to minimize material waste during the vacuum forming process. This includes using materials with optimal forming characteristics and adjusting processing parameters accordingly.

- Process monitoring and control systems: Implementation of advanced monitoring and control systems to optimize vacuum forming processes in real-time. These systems can adjust parameters such as temperature, pressure, and forming speed to minimize material waste and improve overall efficiency.

02 Precision cutting and trimming techniques

Advanced cutting and trimming techniques can significantly reduce material waste in vacuum forming processes. This includes the use of computer-controlled cutting systems, laser cutting, and water jet cutting technologies. These methods allow for more precise and efficient material removal, minimizing excess waste and improving overall material utilization.Expand Specific Solutions03 Optimized mold design and material distribution

Improving mold design and material distribution can help reduce waste in vacuum forming processes. This involves using computer-aided design (CAD) and simulation tools to optimize material thickness and distribution, ensuring efficient use of raw materials. Additionally, multi-cavity molds and adjustable mold systems can maximize material utilization and minimize scrap generation.Expand Specific Solutions04 Alternative materials and composites

Incorporating alternative materials and composites in vacuum forming processes can lead to reduced waste and improved sustainability. This includes the use of biodegradable plastics, recycled materials, and composite materials that offer enhanced strength-to-weight ratios. These materials can help minimize waste generation while maintaining or improving product performance.Expand Specific Solutions05 Process monitoring and quality control

Implementing advanced process monitoring and quality control systems can help reduce material waste in vacuum forming processes. This includes the use of sensors, machine vision systems, and real-time data analysis to detect and correct issues during production. By minimizing defects and optimizing process parameters, these systems can significantly reduce material waste and improve overall efficiency.Expand Specific Solutions

Key Players in Sustainable Vacuum Forming Industry

The vacuum forming waste management sector is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding as industries seek sustainable solutions for material waste reduction. Technologically, the field is advancing rapidly, with companies like Tokyo Electron Ltd. and BYD Co., Ltd. leading innovation in process optimization and material recycling. Established players such as Toshiba Corp. and Hitachi Ltd. are leveraging their expertise to develop integrated waste management systems. Emerging companies like Wimao Oy and BurCell Technologies, Inc. are introducing novel approaches to material recovery and reuse, indicating a dynamic and competitive landscape with diverse technological maturity levels across different solution areas.

Hitachi Ltd.

Technical Solution: Hitachi has developed a comprehensive approach to addressing material waste in vacuum forming processes through their "Eco-Factories & Offices" initiative. They have implemented advanced robotics and automation systems that optimize material handling and reduce waste in vacuum forming production lines[9]. Hitachi's AI-powered predictive maintenance systems help prevent equipment failures that could lead to material waste. Their vacuum forming machines incorporate real-time monitoring and adjustment capabilities, ensuring optimal material usage throughout the production process. Additionally, Hitachi has developed recycling technologies that can process and reuse waste materials from vacuum forming operations, creating a closed-loop system within manufacturing facilities[10].

Strengths: Integrated approach combining automation, AI, and recycling technologies. Weaknesses: May require significant infrastructure changes for full implementation.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed several innovative approaches to address material waste in vacuum forming processes. Their researchers have created a novel adaptive mold technology that allows for the production of complex geometries with minimal material waste[7]. This system uses a matrix of adjustable pins to create customizable mold surfaces, reducing the need for disposable or single-use molds. Additionally, Fraunhofer has developed advanced simulation software that optimizes material distribution during the vacuum forming process, minimizing thinning and ensuring uniform wall thickness, which can reduce material waste by up to 30%[8]. They have also pioneered the use of recycled and bio-based materials in vacuum forming applications, contributing to a more circular economy in the packaging industry.

Strengths: Adaptive mold technology, advanced simulation software, and focus on sustainable materials. Weaknesses: Some technologies may require significant initial investment for implementation.

Innovative Approaches to Material Waste Reduction

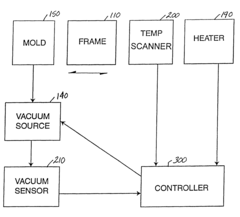

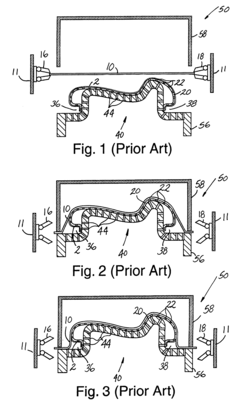

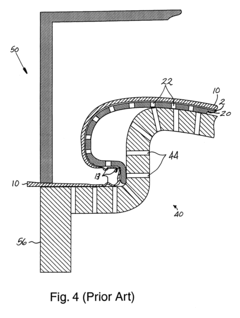

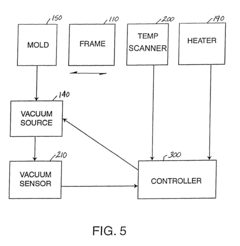

Process for controlling vacuum forming

PatentInactiveUS6517649B1

Innovation

- The introduction of a controlled vacuum system that uses a clamping device with a spring or hydraulic assist mechanism to manage sheet tension and a multi-staged vacuum, along with temperature and pressure sensors to monitor and adjust heating cycles and vacuum levels, ensuring a controlled draw and preventing deformation.

Process and apparatus for controlling vacuum forming

PatentWO2002026475A3

Innovation

- Spring-loaded rotatable bars compress the marginal portion of the material against the mold, controlling the release rate of the material during vacuum forming.

- The control unit dynamically adjusts vacuum pressure based on the inverse relationship with material temperature, reducing material defects.

- Real-time monitoring and control of temperature and vacuum parameters throughout the forming process.

Environmental Regulations Impact on Vacuum Forming

Environmental regulations have significantly impacted vacuum forming processes, particularly in the context of material waste management. These regulations, driven by growing environmental concerns, have forced manufacturers to reassess their production methods and waste handling practices.

In recent years, many countries have implemented stricter environmental policies targeting industrial waste reduction. For vacuum forming, this has led to increased scrutiny of material usage and disposal methods. Manufacturers are now required to adhere to more stringent waste management protocols, often necessitating substantial changes in their operations.

One key area of focus has been the reduction of plastic waste generated during the vacuum forming process. Regulations have pushed companies to implement more efficient material utilization techniques, such as optimizing sheet sizes and thicknesses to minimize offcuts. Additionally, there's a growing emphasis on recycling and reusing plastic waste within the production cycle, aligning with circular economy principles.

The introduction of Extended Producer Responsibility (EPR) schemes in various regions has further influenced vacuum forming practices. These regulations hold manufacturers accountable for the entire lifecycle of their products, including disposal. This has incentivized the development of more easily recyclable designs and the use of eco-friendly materials in vacuum forming applications.

Compliance with air quality regulations has also become a critical concern for vacuum forming operations. Volatile Organic Compound (VOC) emissions, often associated with certain plastics used in vacuum forming, are now subject to stricter controls. This has led to the adoption of low-VOC materials and improved ventilation systems in production facilities.

Water pollution regulations have similarly impacted the industry, particularly for manufacturers using water-based cooling systems. Stringent wastewater treatment requirements have prompted the development of closed-loop cooling systems and the implementation of more effective water recycling technologies in vacuum forming processes.

Energy efficiency regulations have also played a role in shaping vacuum forming practices. Many jurisdictions now mandate the use of energy-efficient equipment and processes, driving innovations in heating and forming technologies to reduce overall energy consumption.

These regulatory changes have not only influenced production methods but have also spurred innovation in the vacuum forming industry. Manufacturers are increasingly investing in research and development to create more sustainable processes and products, often leading to improved efficiency and cost-effectiveness in the long term.

In recent years, many countries have implemented stricter environmental policies targeting industrial waste reduction. For vacuum forming, this has led to increased scrutiny of material usage and disposal methods. Manufacturers are now required to adhere to more stringent waste management protocols, often necessitating substantial changes in their operations.

One key area of focus has been the reduction of plastic waste generated during the vacuum forming process. Regulations have pushed companies to implement more efficient material utilization techniques, such as optimizing sheet sizes and thicknesses to minimize offcuts. Additionally, there's a growing emphasis on recycling and reusing plastic waste within the production cycle, aligning with circular economy principles.

The introduction of Extended Producer Responsibility (EPR) schemes in various regions has further influenced vacuum forming practices. These regulations hold manufacturers accountable for the entire lifecycle of their products, including disposal. This has incentivized the development of more easily recyclable designs and the use of eco-friendly materials in vacuum forming applications.

Compliance with air quality regulations has also become a critical concern for vacuum forming operations. Volatile Organic Compound (VOC) emissions, often associated with certain plastics used in vacuum forming, are now subject to stricter controls. This has led to the adoption of low-VOC materials and improved ventilation systems in production facilities.

Water pollution regulations have similarly impacted the industry, particularly for manufacturers using water-based cooling systems. Stringent wastewater treatment requirements have prompted the development of closed-loop cooling systems and the implementation of more effective water recycling technologies in vacuum forming processes.

Energy efficiency regulations have also played a role in shaping vacuum forming practices. Many jurisdictions now mandate the use of energy-efficient equipment and processes, driving innovations in heating and forming technologies to reduce overall energy consumption.

These regulatory changes have not only influenced production methods but have also spurred innovation in the vacuum forming industry. Manufacturers are increasingly investing in research and development to create more sustainable processes and products, often leading to improved efficiency and cost-effectiveness in the long term.

Economic Implications of Waste Reduction Strategies

The economic implications of waste reduction strategies in vacuum forming processes are significant and multifaceted. Implementing effective waste management techniques can lead to substantial cost savings for manufacturers, primarily through reduced material consumption and decreased disposal expenses. By optimizing material usage, companies can lower their raw material procurement costs, which often constitute a significant portion of production expenses.

Furthermore, waste reduction strategies can enhance operational efficiency, resulting in improved productivity and reduced labor costs. Automated systems for material handling and recycling can minimize manual intervention, allowing for more streamlined production processes. This increased efficiency can lead to higher output rates and potentially lower per-unit production costs, enhancing overall profitability.

Environmental regulations and compliance requirements also play a crucial role in the economic considerations of waste management. As governments worldwide implement stricter environmental policies, companies that proactively adopt waste reduction strategies may avoid potential fines and penalties associated with non-compliance. Additionally, environmentally conscious practices can improve a company's reputation, potentially leading to increased market share and customer loyalty.

The implementation of waste reduction strategies often requires initial capital investment in new technologies or process modifications. However, the long-term economic benefits typically outweigh these upfront costs. Companies can expect to see a return on investment through reduced material costs, lower waste disposal fees, and improved operational efficiency. In some cases, government incentives or tax breaks for environmentally friendly practices can further offset implementation costs.

Waste reduction strategies can also open up new revenue streams for manufacturers. Recycled materials from the vacuum forming process can be sold to other industries or used in-house for different applications, creating additional value from what was previously considered waste. This circular economy approach not only generates extra income but also reduces the company's reliance on virgin materials, providing a hedge against raw material price fluctuations.

Lastly, the adoption of waste reduction strategies can position companies as industry leaders in sustainability, potentially attracting environmentally conscious investors and partners. This can lead to improved access to capital and strategic alliances, further strengthening the company's economic position in the long term.

Furthermore, waste reduction strategies can enhance operational efficiency, resulting in improved productivity and reduced labor costs. Automated systems for material handling and recycling can minimize manual intervention, allowing for more streamlined production processes. This increased efficiency can lead to higher output rates and potentially lower per-unit production costs, enhancing overall profitability.

Environmental regulations and compliance requirements also play a crucial role in the economic considerations of waste management. As governments worldwide implement stricter environmental policies, companies that proactively adopt waste reduction strategies may avoid potential fines and penalties associated with non-compliance. Additionally, environmentally conscious practices can improve a company's reputation, potentially leading to increased market share and customer loyalty.

The implementation of waste reduction strategies often requires initial capital investment in new technologies or process modifications. However, the long-term economic benefits typically outweigh these upfront costs. Companies can expect to see a return on investment through reduced material costs, lower waste disposal fees, and improved operational efficiency. In some cases, government incentives or tax breaks for environmentally friendly practices can further offset implementation costs.

Waste reduction strategies can also open up new revenue streams for manufacturers. Recycled materials from the vacuum forming process can be sold to other industries or used in-house for different applications, creating additional value from what was previously considered waste. This circular economy approach not only generates extra income but also reduces the company's reliance on virgin materials, providing a hedge against raw material price fluctuations.

Lastly, the adoption of waste reduction strategies can position companies as industry leaders in sustainability, potentially attracting environmentally conscious investors and partners. This can lead to improved access to capital and strategic alliances, further strengthening the company's economic position in the long term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!