Vacuum Forming in Next-Gen Transportation Interior Design

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Evolution in Transportation Interiors

Vacuum forming has undergone significant evolution in transportation interior design since its inception in the 1950s. Initially used for simple, flat components, the technology has progressively advanced to create complex, three-dimensional parts that are integral to modern vehicle interiors. The early stages of vacuum forming in transportation were characterized by limited material options and basic shapes, primarily used for dashboard components and door panels.

As materials science progressed, the range of thermoplastics suitable for vacuum forming expanded, allowing for greater design flexibility and improved performance characteristics. The 1970s and 1980s saw the introduction of high-impact polystyrene (HIPS) and acrylonitrile butadiene styrene (ABS), which became staples in automotive interior manufacturing due to their durability and aesthetic appeal.

The 1990s marked a significant leap in vacuum forming technology with the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These technologies enabled more precise mold creation and better control over the forming process, resulting in higher quality and more intricate interior components. This period also saw the integration of in-mold texturing, allowing for a wider range of surface finishes without secondary operations.

The turn of the millennium brought about a focus on lightweight materials and sustainability in transportation design. Vacuum forming adapted to these trends with the development of thinner gauge materials and the incorporation of recycled plastics. Advanced twin-sheet forming techniques emerged, allowing for the creation of hollow parts with complex geometries, ideal for armrests and console components.

Recent years have witnessed the integration of smart materials and embedded electronics into vacuum-formed parts. This has led to the production of interactive surfaces and integrated lighting systems within interior panels. The use of multi-layer forming techniques has also grown, enabling the creation of parts with varying properties across different sections, such as soft-touch surfaces combined with rigid structural elements.

Today, vacuum forming in transportation interiors is at the forefront of rapid prototyping and mass customization. 3D printing technologies are being used to create molds quickly and cost-effectively, allowing for faster design iterations and personalized interior components. The industry is also exploring the use of bio-based and biodegradable plastics in vacuum forming, aligning with the growing demand for sustainable transportation solutions.

As we look to the future, vacuum forming is poised to play a crucial role in the development of next-generation transportation interiors. The technology is evolving to meet the demands of electric and autonomous vehicles, with a focus on creating adaptable, multifunctional spaces that can transform based on passenger needs. Innovations in material science and forming processes continue to push the boundaries of what is possible, promising even more sophisticated and sustainable interior solutions for the vehicles of tomorrow.

As materials science progressed, the range of thermoplastics suitable for vacuum forming expanded, allowing for greater design flexibility and improved performance characteristics. The 1970s and 1980s saw the introduction of high-impact polystyrene (HIPS) and acrylonitrile butadiene styrene (ABS), which became staples in automotive interior manufacturing due to their durability and aesthetic appeal.

The 1990s marked a significant leap in vacuum forming technology with the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These technologies enabled more precise mold creation and better control over the forming process, resulting in higher quality and more intricate interior components. This period also saw the integration of in-mold texturing, allowing for a wider range of surface finishes without secondary operations.

The turn of the millennium brought about a focus on lightweight materials and sustainability in transportation design. Vacuum forming adapted to these trends with the development of thinner gauge materials and the incorporation of recycled plastics. Advanced twin-sheet forming techniques emerged, allowing for the creation of hollow parts with complex geometries, ideal for armrests and console components.

Recent years have witnessed the integration of smart materials and embedded electronics into vacuum-formed parts. This has led to the production of interactive surfaces and integrated lighting systems within interior panels. The use of multi-layer forming techniques has also grown, enabling the creation of parts with varying properties across different sections, such as soft-touch surfaces combined with rigid structural elements.

Today, vacuum forming in transportation interiors is at the forefront of rapid prototyping and mass customization. 3D printing technologies are being used to create molds quickly and cost-effectively, allowing for faster design iterations and personalized interior components. The industry is also exploring the use of bio-based and biodegradable plastics in vacuum forming, aligning with the growing demand for sustainable transportation solutions.

As we look to the future, vacuum forming is poised to play a crucial role in the development of next-generation transportation interiors. The technology is evolving to meet the demands of electric and autonomous vehicles, with a focus on creating adaptable, multifunctional spaces that can transform based on passenger needs. Innovations in material science and forming processes continue to push the boundaries of what is possible, promising even more sophisticated and sustainable interior solutions for the vehicles of tomorrow.

Market Demand for Lightweight Interior Components

The demand for lightweight interior components in next-generation transportation design has been steadily increasing, driven by the automotive industry's push for improved fuel efficiency and reduced emissions. Vacuum forming technology plays a crucial role in meeting this demand, offering a cost-effective and versatile method for producing lightweight, durable interior parts.

In the automotive sector, the global market for lightweight materials is projected to grow significantly, with a particular focus on interior components. This growth is fueled by stringent regulations on vehicle emissions and fuel economy standards worldwide. Manufacturers are increasingly turning to vacuum-formed parts to replace heavier traditional materials, resulting in weight reductions of up to 30% for certain interior components.

The aerospace industry is another key driver of demand for lightweight interior components. With the rising costs of fuel and the need to reduce carbon footprints, airlines are seeking ways to minimize aircraft weight without compromising safety or comfort. Vacuum-formed interior panels, overhead bins, and seating components offer substantial weight savings, translating to improved fuel efficiency and reduced operating costs.

The rail transportation sector is also embracing lightweight solutions for interior design. As high-speed rail networks expand globally, there is a growing need for interior components that can withstand high speeds while maintaining passenger comfort. Vacuum-formed panels and seating elements provide an ideal balance of strength, weight reduction, and design flexibility.

In the marine industry, lightweight interior components are gaining traction in both commercial and recreational vessels. Vacuum-formed parts offer excellent resistance to moisture and corrosion, making them ideal for marine environments. The ability to create complex shapes and textures through vacuum forming allows designers to create aesthetically pleasing interiors while reducing overall vessel weight.

The electric vehicle (EV) market is emerging as a significant driver for lightweight interior components. As EV manufacturers strive to extend battery range, every gram of weight savings becomes crucial. Vacuum-formed interior parts contribute to this goal while allowing for the integration of smart features and sustainable materials, aligning with the eco-friendly ethos of electric vehicles.

Consumer preferences are also shaping the demand for lightweight interior components. Modern travelers expect vehicles and transportation modes to be not only efficient but also comfortable and aesthetically pleasing. Vacuum forming enables the creation of sleek, modern designs with smooth contours and integrated functionalities, meeting these evolving consumer expectations.

As the transportation industry continues to evolve, the demand for lightweight interior components produced through vacuum forming is expected to grow further. This technology's ability to combine weight reduction with design flexibility, cost-effectiveness, and sustainability makes it a key enabler in the development of next-generation transportation interiors across various sectors.

In the automotive sector, the global market for lightweight materials is projected to grow significantly, with a particular focus on interior components. This growth is fueled by stringent regulations on vehicle emissions and fuel economy standards worldwide. Manufacturers are increasingly turning to vacuum-formed parts to replace heavier traditional materials, resulting in weight reductions of up to 30% for certain interior components.

The aerospace industry is another key driver of demand for lightweight interior components. With the rising costs of fuel and the need to reduce carbon footprints, airlines are seeking ways to minimize aircraft weight without compromising safety or comfort. Vacuum-formed interior panels, overhead bins, and seating components offer substantial weight savings, translating to improved fuel efficiency and reduced operating costs.

The rail transportation sector is also embracing lightweight solutions for interior design. As high-speed rail networks expand globally, there is a growing need for interior components that can withstand high speeds while maintaining passenger comfort. Vacuum-formed panels and seating elements provide an ideal balance of strength, weight reduction, and design flexibility.

In the marine industry, lightweight interior components are gaining traction in both commercial and recreational vessels. Vacuum-formed parts offer excellent resistance to moisture and corrosion, making them ideal for marine environments. The ability to create complex shapes and textures through vacuum forming allows designers to create aesthetically pleasing interiors while reducing overall vessel weight.

The electric vehicle (EV) market is emerging as a significant driver for lightweight interior components. As EV manufacturers strive to extend battery range, every gram of weight savings becomes crucial. Vacuum-formed interior parts contribute to this goal while allowing for the integration of smart features and sustainable materials, aligning with the eco-friendly ethos of electric vehicles.

Consumer preferences are also shaping the demand for lightweight interior components. Modern travelers expect vehicles and transportation modes to be not only efficient but also comfortable and aesthetically pleasing. Vacuum forming enables the creation of sleek, modern designs with smooth contours and integrated functionalities, meeting these evolving consumer expectations.

As the transportation industry continues to evolve, the demand for lightweight interior components produced through vacuum forming is expected to grow further. This technology's ability to combine weight reduction with design flexibility, cost-effectiveness, and sustainability makes it a key enabler in the development of next-generation transportation interiors across various sectors.

Current Challenges in Vacuum Forming Technology

Vacuum forming technology, while widely used in transportation interior design, faces several significant challenges that hinder its full potential in next-generation applications. One of the primary issues is the limited material selection suitable for vacuum forming processes. Traditional thermoplastics used in this technique often lack the advanced properties required for modern transportation interiors, such as enhanced durability, fire resistance, and eco-friendliness.

Another major challenge lies in achieving complex geometries and intricate details. As transportation interior designs become increasingly sophisticated, vacuum forming struggles to produce sharp edges, deep undercuts, and fine textures that are often desired in contemporary aesthetics. This limitation can result in compromised design integrity and reduced visual appeal of the final product.

The thickness consistency of vacuum-formed parts also presents a significant hurdle. Uneven material distribution during the forming process can lead to weak spots or excess material in certain areas, affecting both the structural integrity and the overall quality of the components. This issue becomes particularly critical in safety-related applications within transportation interiors.

Energy efficiency and sustainability concerns pose additional challenges to vacuum forming technology. The process typically requires substantial energy input for heating and forming, which can contribute to increased carbon footprints and operational costs. As the transportation industry moves towards more sustainable practices, the energy-intensive nature of vacuum forming becomes a point of contention.

Automation and integration with other manufacturing processes represent another area of difficulty. While vacuum forming itself is relatively straightforward, incorporating it seamlessly into automated production lines and combining it with other fabrication techniques can be complex. This integration challenge can lead to inefficiencies in production and increased manufacturing times.

The scalability of vacuum forming for mass production in transportation applications also presents obstacles. Balancing the need for high-volume output with maintaining consistent quality across large production runs can be challenging, especially when dealing with the diverse range of components required in modern vehicle interiors.

Lastly, the industry faces challenges in terms of tooling costs and flexibility. While vacuum forming molds are generally less expensive than those used in injection molding, creating and modifying tools for new designs or iterations can still be time-consuming and costly. This can limit the ability to rapidly prototype and iterate on designs, potentially slowing down innovation in transportation interior development.

Another major challenge lies in achieving complex geometries and intricate details. As transportation interior designs become increasingly sophisticated, vacuum forming struggles to produce sharp edges, deep undercuts, and fine textures that are often desired in contemporary aesthetics. This limitation can result in compromised design integrity and reduced visual appeal of the final product.

The thickness consistency of vacuum-formed parts also presents a significant hurdle. Uneven material distribution during the forming process can lead to weak spots or excess material in certain areas, affecting both the structural integrity and the overall quality of the components. This issue becomes particularly critical in safety-related applications within transportation interiors.

Energy efficiency and sustainability concerns pose additional challenges to vacuum forming technology. The process typically requires substantial energy input for heating and forming, which can contribute to increased carbon footprints and operational costs. As the transportation industry moves towards more sustainable practices, the energy-intensive nature of vacuum forming becomes a point of contention.

Automation and integration with other manufacturing processes represent another area of difficulty. While vacuum forming itself is relatively straightforward, incorporating it seamlessly into automated production lines and combining it with other fabrication techniques can be complex. This integration challenge can lead to inefficiencies in production and increased manufacturing times.

The scalability of vacuum forming for mass production in transportation applications also presents obstacles. Balancing the need for high-volume output with maintaining consistent quality across large production runs can be challenging, especially when dealing with the diverse range of components required in modern vehicle interiors.

Lastly, the industry faces challenges in terms of tooling costs and flexibility. While vacuum forming molds are generally less expensive than those used in injection molding, creating and modifying tools for new designs or iterations can still be time-consuming and costly. This can limit the ability to rapidly prototype and iterate on designs, potentially slowing down innovation in transportation interior development.

Existing Vacuum Forming Solutions for Interiors

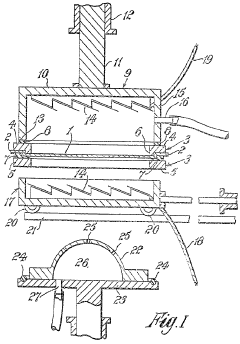

01 Vacuum forming apparatus design

Innovations in vacuum forming machine design focus on improving efficiency and product quality. This includes advancements in heating systems, mold design, and vacuum application methods. These improvements allow for more precise control over the forming process, resulting in better-quality products and increased production speeds.- Vacuum forming apparatus design: Innovations in vacuum forming apparatus design focus on improving efficiency and product quality. These designs may include specialized heating elements, adjustable mold supports, and advanced vacuum systems to enhance the forming process. Some designs incorporate features for better temperature control and uniform material distribution.

- Material handling and preparation: Techniques for handling and preparing materials for vacuum forming are crucial for achieving optimal results. This includes methods for preheating thermoplastic sheets, controlling material thickness, and ensuring proper positioning of the material before forming. Some approaches focus on reducing waste and improving material utilization.

- Mold design and fabrication: Advancements in mold design and fabrication for vacuum forming processes aim to improve product quality and reduce cycle times. This includes the use of novel materials for mold construction, innovative cooling systems, and designs that facilitate easy part removal. Some approaches focus on creating molds for complex geometries or large-scale products.

- Process control and automation: Developments in process control and automation for vacuum forming focus on enhancing precision, repeatability, and efficiency. This includes the integration of sensors, computerized control systems, and real-time monitoring technologies. Some innovations aim to optimize cycle times, reduce energy consumption, and minimize operator intervention.

- Post-forming operations and finishing: Techniques for post-forming operations and finishing of vacuum-formed products are essential for achieving desired final product characteristics. This includes methods for trimming, surface treatment, and assembly of formed parts. Some approaches focus on integrating these operations into the main production line to improve overall efficiency.

02 Materials for vacuum forming

Various materials are used in vacuum forming processes, including thermoplastics and composite materials. Research focuses on developing new materials with improved properties such as heat resistance, flexibility, and durability. These advancements expand the range of products that can be manufactured using vacuum forming techniques.Expand Specific Solutions03 Mold design and fabrication

Innovations in mold design and fabrication techniques are crucial for vacuum forming. This includes the use of advanced materials for mold construction, improved cooling systems, and the integration of complex geometries. These developments allow for the production of more intricate and precise parts while reducing cycle times.Expand Specific Solutions04 Process control and automation

Advancements in process control and automation systems for vacuum forming machines enhance productivity and consistency. This includes the integration of sensors, real-time monitoring, and adaptive control algorithms. These technologies allow for more precise control over forming parameters, resulting in improved product quality and reduced waste.Expand Specific Solutions05 Specialized vacuum forming techniques

Development of specialized vacuum forming techniques for specific applications or industries. This includes methods for forming large-scale parts, multi-layer composites, or integrating additional features during the forming process. These specialized techniques expand the capabilities of vacuum forming and open up new applications in various industries.Expand Specific Solutions

Key Players in Transportation Interior Manufacturing

The vacuum forming technology in next-generation transportation interior design is in a growth phase, with increasing market size driven by demand for lightweight, cost-effective, and customizable interior components. The global market for automotive interior materials is projected to reach $54.8 billion by 2027, with vacuum forming playing a significant role. Technologically, the process is mature but evolving, with companies like Valeo Thermal Systems, TS TECH, and Brose Fahrzeugteile leading innovations. Major automotive manufacturers such as Volkswagen, Ford, and Honda are integrating advanced vacuum forming techniques into their production processes, indicating widespread adoption and ongoing refinement of this technology across the industry.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative vacuum forming process for next-generation transportation interior design. Their approach utilizes advanced thermoplastic materials and precision-controlled vacuum forming equipment to create complex, lightweight interior components. The process incorporates real-time temperature and pressure monitoring to ensure optimal material distribution and surface finish[1]. Ford's method also integrates recyclable materials, reducing environmental impact while maintaining high-quality aesthetics. The company has implemented a modular design strategy, allowing for easy customization and efficient production of various interior elements[3]. Additionally, Ford has developed a proprietary surface treatment technique that enhances the durability and tactile properties of vacuum-formed components, addressing common wear issues in high-touch areas of vehicle interiors[5].

Strengths: Efficient production of complex shapes, lightweight components, improved customization options, and enhanced durability. Weaknesses: Potentially higher initial tooling costs and limitations in material thickness for certain applications.

Volkswagen AG

Technical Solution: Volkswagen has pioneered a multi-layer vacuum forming technique for next-generation transportation interiors. This method combines different materials in a single forming process, allowing for the creation of components with varying properties across their surface. The company utilizes advanced CAD/CAM systems to optimize mold design and material placement, resulting in highly precise and repeatable parts[2]. Volkswagen's process incorporates smart sensors within the vacuum forming equipment to adjust parameters in real-time, ensuring consistent quality across production runs. The company has also developed a unique surface texturing method that can be applied during the vacuum forming process, eliminating the need for secondary finishing operations[4]. Furthermore, Volkswagen's approach includes the use of bio-based and recycled materials, aligning with sustainability goals while maintaining high performance standards[6].

Strengths: Multi-material capabilities, high precision and consistency, integrated texturing, and sustainable material options. Weaknesses: Potentially higher equipment costs and complexity in process control for multi-layer forming.

Innovative Vacuum Forming Techniques Analysis

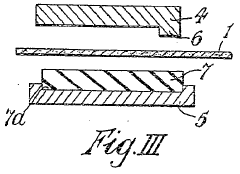

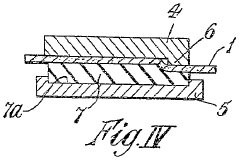

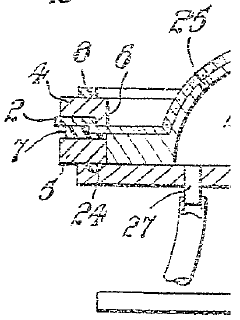

Improvements in vacuum forming of shaped articles

PatentInactiveGB1003031A

Innovation

- The method involves heating the sheet while reducing pressure on the upper surface to maintain a substantially planar configuration, using peripheral clamping means and heating units, and an open-sided box-like member for air evacuation, ensuring uniform heating and minimizing sagging. The clamping system includes a composite framework with a resilient rubber strip and abutment to secure the sheet.

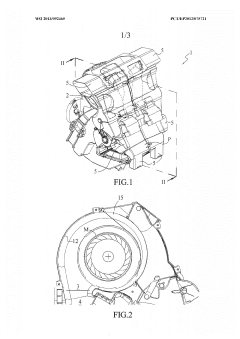

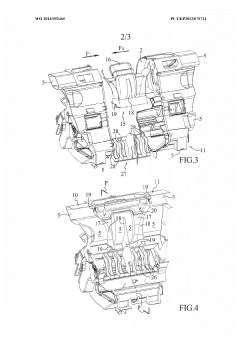

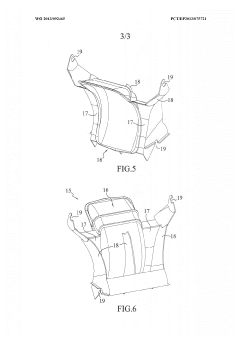

Heating, ventilation and/or air-conditioning unit casing for motor vehicle passenger compartment

PatentWO2013092465A1

Innovation

- The implementation of an internal partition element within the casing that forms part of both the volute and distribution channels, allowing for a compact design by nesting the volute within the distribution channels, and the use of two casings that form an outer casing with the partition element, enabling easier manufacturing and assembly.

Sustainability in Vacuum Formed Interiors

Sustainability in vacuum formed interiors has become a critical focus in the next-generation transportation design landscape. As environmental concerns continue to shape industry practices, manufacturers are increasingly adopting eco-friendly approaches to interior production. Vacuum forming, a versatile and cost-effective method, is being reimagined to align with sustainability goals.

One of the primary sustainability initiatives in vacuum forming is the use of recycled and recyclable materials. Manufacturers are exploring alternatives to traditional petroleum-based plastics, such as bio-based polymers derived from renewable resources. These materials not only reduce the carbon footprint of the production process but also ensure that the end-of-life disposal of interior components has minimal environmental impact.

Energy efficiency in the vacuum forming process is another area of significant improvement. Advanced machinery and optimized production techniques have led to reduced energy consumption during the forming process. Additionally, the integration of renewable energy sources in manufacturing facilities further minimizes the environmental impact of interior production.

Waste reduction strategies have been implemented throughout the vacuum forming lifecycle. Computer-aided design and simulation tools enable manufacturers to optimize material usage and reduce scrap. Moreover, closed-loop recycling systems are being developed to reintegrate production waste back into the manufacturing process, creating a more circular economy within the industry.

The durability and longevity of vacuum formed interiors contribute to their sustainability profile. By creating components that withstand the rigors of daily use and maintain their aesthetic appeal over time, manufacturers reduce the need for frequent replacements, thereby conserving resources and minimizing waste.

Innovations in surface treatments and finishes for vacuum formed parts are also advancing sustainability efforts. Water-based and low-VOC (Volatile Organic Compound) coatings are replacing solvent-based alternatives, reducing harmful emissions and improving air quality both during production and throughout the product's lifecycle.

As the transportation industry shifts towards electric and autonomous vehicles, the role of sustainable vacuum formed interiors becomes even more crucial. Lightweight materials and designs produced through vacuum forming contribute to overall vehicle efficiency, extending range and reducing energy consumption.

The integration of smart materials and technologies in vacuum formed interiors opens new avenues for sustainability. Self-cleaning surfaces, temperature-regulating materials, and components with built-in sensors for predictive maintenance all contribute to reducing the environmental impact of vehicle interiors over their lifespan.

One of the primary sustainability initiatives in vacuum forming is the use of recycled and recyclable materials. Manufacturers are exploring alternatives to traditional petroleum-based plastics, such as bio-based polymers derived from renewable resources. These materials not only reduce the carbon footprint of the production process but also ensure that the end-of-life disposal of interior components has minimal environmental impact.

Energy efficiency in the vacuum forming process is another area of significant improvement. Advanced machinery and optimized production techniques have led to reduced energy consumption during the forming process. Additionally, the integration of renewable energy sources in manufacturing facilities further minimizes the environmental impact of interior production.

Waste reduction strategies have been implemented throughout the vacuum forming lifecycle. Computer-aided design and simulation tools enable manufacturers to optimize material usage and reduce scrap. Moreover, closed-loop recycling systems are being developed to reintegrate production waste back into the manufacturing process, creating a more circular economy within the industry.

The durability and longevity of vacuum formed interiors contribute to their sustainability profile. By creating components that withstand the rigors of daily use and maintain their aesthetic appeal over time, manufacturers reduce the need for frequent replacements, thereby conserving resources and minimizing waste.

Innovations in surface treatments and finishes for vacuum formed parts are also advancing sustainability efforts. Water-based and low-VOC (Volatile Organic Compound) coatings are replacing solvent-based alternatives, reducing harmful emissions and improving air quality both during production and throughout the product's lifecycle.

As the transportation industry shifts towards electric and autonomous vehicles, the role of sustainable vacuum formed interiors becomes even more crucial. Lightweight materials and designs produced through vacuum forming contribute to overall vehicle efficiency, extending range and reducing energy consumption.

The integration of smart materials and technologies in vacuum formed interiors opens new avenues for sustainability. Self-cleaning surfaces, temperature-regulating materials, and components with built-in sensors for predictive maintenance all contribute to reducing the environmental impact of vehicle interiors over their lifespan.

Material Innovations for Vacuum Forming

The vacuum forming process in next-generation transportation interior design is witnessing significant advancements in material innovations. These developments are driven by the need for lightweight, durable, and sustainable materials that can meet the stringent requirements of modern vehicle interiors.

One of the key areas of innovation is in the development of high-performance thermoplastics. These materials offer improved heat resistance, dimensional stability, and surface finish quality, making them ideal for vacuum forming applications in transportation interiors. Advanced polymers such as polycarbonate blends and modified acrylonitrile butadiene styrene (ABS) are being engineered to withstand the harsh conditions inside vehicles while maintaining their aesthetic appeal.

Composite materials are also gaining traction in vacuum forming for transportation interiors. Fiber-reinforced plastics, particularly those incorporating carbon or glass fibers, provide exceptional strength-to-weight ratios. These composites allow for the creation of complex shapes and structures that were previously difficult to achieve with traditional materials, enabling designers to push the boundaries of interior aesthetics and functionality.

Sustainable materials are becoming increasingly important in the automotive industry, and this trend is reflected in vacuum forming innovations. Bio-based plastics derived from renewable resources such as corn starch or sugarcane are being developed and refined for use in interior components. These materials not only reduce the carbon footprint of vehicle production but also offer comparable performance to their petroleum-based counterparts.

Nanotechnology is playing a crucial role in enhancing the properties of materials used in vacuum forming. Nanoparticle additives can significantly improve the mechanical strength, thermal stability, and flame retardancy of plastics without adding substantial weight. This technology enables the creation of thinner, lighter components that meet or exceed safety and performance standards.

Smart materials are emerging as a frontier in vacuum forming for transportation interiors. These materials can change their properties in response to external stimuli such as temperature, light, or electrical current. For example, thermochromic plastics that change color with temperature variations can be used to create dynamic interior elements that enhance the user experience and provide visual feedback on environmental conditions.

Advancements in material science are also focusing on improving the recyclability and end-of-life management of vacuum-formed components. New additives and polymer formulations are being developed to facilitate easier separation and recycling of multi-material parts, addressing the growing demand for circular economy solutions in the automotive sector.

One of the key areas of innovation is in the development of high-performance thermoplastics. These materials offer improved heat resistance, dimensional stability, and surface finish quality, making them ideal for vacuum forming applications in transportation interiors. Advanced polymers such as polycarbonate blends and modified acrylonitrile butadiene styrene (ABS) are being engineered to withstand the harsh conditions inside vehicles while maintaining their aesthetic appeal.

Composite materials are also gaining traction in vacuum forming for transportation interiors. Fiber-reinforced plastics, particularly those incorporating carbon or glass fibers, provide exceptional strength-to-weight ratios. These composites allow for the creation of complex shapes and structures that were previously difficult to achieve with traditional materials, enabling designers to push the boundaries of interior aesthetics and functionality.

Sustainable materials are becoming increasingly important in the automotive industry, and this trend is reflected in vacuum forming innovations. Bio-based plastics derived from renewable resources such as corn starch or sugarcane are being developed and refined for use in interior components. These materials not only reduce the carbon footprint of vehicle production but also offer comparable performance to their petroleum-based counterparts.

Nanotechnology is playing a crucial role in enhancing the properties of materials used in vacuum forming. Nanoparticle additives can significantly improve the mechanical strength, thermal stability, and flame retardancy of plastics without adding substantial weight. This technology enables the creation of thinner, lighter components that meet or exceed safety and performance standards.

Smart materials are emerging as a frontier in vacuum forming for transportation interiors. These materials can change their properties in response to external stimuli such as temperature, light, or electrical current. For example, thermochromic plastics that change color with temperature variations can be used to create dynamic interior elements that enhance the user experience and provide visual feedback on environmental conditions.

Advancements in material science are also focusing on improving the recyclability and end-of-life management of vacuum-formed components. New additives and polymer formulations are being developed to facilitate easier separation and recycling of multi-material parts, addressing the growing demand for circular economy solutions in the automotive sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!