How Vacuum Forming Revolutionizes Modular Construction Elements

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Construction: Evolution and Objectives

Vacuum forming has emerged as a transformative technology in the construction industry, revolutionizing the production of modular construction elements. This technique, which originated in the 1950s, has evolved significantly over the decades, adapting to the changing needs of the construction sector. Initially used for simple packaging and product casings, vacuum forming has grown to become an integral part of modern construction methodologies.

The evolution of vacuum forming in construction can be traced through several key phases. In its early applications, the technology was primarily used for creating lightweight, non-structural components such as decorative panels and interior fittings. As materials science advanced, the scope of vacuum-formed elements expanded to include more robust and functional parts, including insulation panels, roofing components, and facade elements.

A significant milestone in the technology's evolution was the development of high-performance thermoplastics and reinforced composites. These materials allowed for the creation of stronger, more durable vacuum-formed components capable of withstanding the rigors of construction environments. This advancement opened up new possibilities for prefabrication and modular construction, aligning with the industry's growing focus on off-site manufacturing and rapid assembly.

The objectives of vacuum forming in modern construction are multifaceted. Primarily, it aims to enhance efficiency in the production of modular elements, allowing for faster, more cost-effective manufacturing processes. By enabling the creation of complex shapes and designs with minimal material waste, vacuum forming supports the industry's sustainability goals. Additionally, the technology seeks to improve the overall quality and consistency of construction components, reducing variability and potential defects associated with traditional manufacturing methods.

Another key objective is to facilitate greater design flexibility and customization in construction projects. Vacuum forming allows architects and designers to create unique, bespoke elements that can be easily replicated at scale, bridging the gap between mass production and individualized design. This capability is particularly valuable in the context of modern architectural trends that emphasize distinctive, non-standard forms and structures.

Looking forward, the objectives of vacuum forming in construction are expanding to address emerging industry challenges. These include the development of smart, integrated components that incorporate sensors and other technologies, as well as the creation of ultra-lightweight, high-strength materials that can further reduce construction times and costs. The technology is also being explored for its potential in creating adaptive and responsive building elements, capable of changing shape or properties in response to environmental conditions or user needs.

The evolution of vacuum forming in construction can be traced through several key phases. In its early applications, the technology was primarily used for creating lightweight, non-structural components such as decorative panels and interior fittings. As materials science advanced, the scope of vacuum-formed elements expanded to include more robust and functional parts, including insulation panels, roofing components, and facade elements.

A significant milestone in the technology's evolution was the development of high-performance thermoplastics and reinforced composites. These materials allowed for the creation of stronger, more durable vacuum-formed components capable of withstanding the rigors of construction environments. This advancement opened up new possibilities for prefabrication and modular construction, aligning with the industry's growing focus on off-site manufacturing and rapid assembly.

The objectives of vacuum forming in modern construction are multifaceted. Primarily, it aims to enhance efficiency in the production of modular elements, allowing for faster, more cost-effective manufacturing processes. By enabling the creation of complex shapes and designs with minimal material waste, vacuum forming supports the industry's sustainability goals. Additionally, the technology seeks to improve the overall quality and consistency of construction components, reducing variability and potential defects associated with traditional manufacturing methods.

Another key objective is to facilitate greater design flexibility and customization in construction projects. Vacuum forming allows architects and designers to create unique, bespoke elements that can be easily replicated at scale, bridging the gap between mass production and individualized design. This capability is particularly valuable in the context of modern architectural trends that emphasize distinctive, non-standard forms and structures.

Looking forward, the objectives of vacuum forming in construction are expanding to address emerging industry challenges. These include the development of smart, integrated components that incorporate sensors and other technologies, as well as the creation of ultra-lightweight, high-strength materials that can further reduce construction times and costs. The technology is also being explored for its potential in creating adaptive and responsive building elements, capable of changing shape or properties in response to environmental conditions or user needs.

Market Demand for Modular Construction Solutions

The modular construction industry has experienced significant growth in recent years, driven by increasing demand for cost-effective, efficient, and sustainable building solutions. Vacuum forming technology has emerged as a revolutionary force in this sector, offering numerous advantages that align with market needs and industry trends.

The global modular construction market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is fueled by several factors, including urbanization, population growth, and the need for affordable housing solutions. Vacuum-formed modular construction elements are particularly well-positioned to meet these demands due to their versatility, durability, and cost-effectiveness.

In the residential sector, there is a growing demand for prefabricated homes that can be quickly assembled and customized to meet individual needs. Vacuum-formed components offer the flexibility to create a wide range of designs and finishes, appealing to homeowners seeking personalized living spaces. Additionally, the construction industry faces ongoing labor shortages, making efficient, off-site manufacturing processes like vacuum forming increasingly attractive.

The commercial and industrial sectors also show strong demand for modular construction solutions. Businesses are seeking ways to reduce construction time and costs while maintaining high-quality standards. Vacuum-formed elements can be used in various applications, from interior partitions to exterior cladding, offering a balance of aesthetics and functionality.

Sustainability is another key driver of market demand for modular construction solutions. Vacuum forming processes typically generate less waste compared to traditional construction methods, aligning with the growing emphasis on environmentally friendly building practices. The ability to recycle and reuse materials in vacuum forming further enhances its appeal to eco-conscious clients and developers.

The healthcare sector presents a significant opportunity for vacuum-formed modular construction elements. The need for rapid deployment of medical facilities, particularly in response to public health crises, has highlighted the importance of flexible and scalable building solutions. Vacuum-formed components can be quickly produced and assembled to create temporary or permanent healthcare structures, meeting urgent market demands.

As urbanization continues to accelerate, there is an increasing need for innovative solutions to address housing shortages in densely populated areas. Vacuum-formed modular construction elements offer the potential for vertical expansion and infill development, maximizing limited urban space. This aligns with the market trend towards compact, efficient living spaces in city centers.

In conclusion, the market demand for modular construction solutions, particularly those utilizing vacuum forming technology, is robust and diverse. From residential to commercial applications, the industry is poised for continued growth as it addresses key challenges in modern construction, including speed, cost-effectiveness, customization, and sustainability.

The global modular construction market is projected to expand rapidly, with estimates suggesting a compound annual growth rate (CAGR) of over 6% from 2021 to 2026. This growth is fueled by several factors, including urbanization, population growth, and the need for affordable housing solutions. Vacuum-formed modular construction elements are particularly well-positioned to meet these demands due to their versatility, durability, and cost-effectiveness.

In the residential sector, there is a growing demand for prefabricated homes that can be quickly assembled and customized to meet individual needs. Vacuum-formed components offer the flexibility to create a wide range of designs and finishes, appealing to homeowners seeking personalized living spaces. Additionally, the construction industry faces ongoing labor shortages, making efficient, off-site manufacturing processes like vacuum forming increasingly attractive.

The commercial and industrial sectors also show strong demand for modular construction solutions. Businesses are seeking ways to reduce construction time and costs while maintaining high-quality standards. Vacuum-formed elements can be used in various applications, from interior partitions to exterior cladding, offering a balance of aesthetics and functionality.

Sustainability is another key driver of market demand for modular construction solutions. Vacuum forming processes typically generate less waste compared to traditional construction methods, aligning with the growing emphasis on environmentally friendly building practices. The ability to recycle and reuse materials in vacuum forming further enhances its appeal to eco-conscious clients and developers.

The healthcare sector presents a significant opportunity for vacuum-formed modular construction elements. The need for rapid deployment of medical facilities, particularly in response to public health crises, has highlighted the importance of flexible and scalable building solutions. Vacuum-formed components can be quickly produced and assembled to create temporary or permanent healthcare structures, meeting urgent market demands.

As urbanization continues to accelerate, there is an increasing need for innovative solutions to address housing shortages in densely populated areas. Vacuum-formed modular construction elements offer the potential for vertical expansion and infill development, maximizing limited urban space. This aligns with the market trend towards compact, efficient living spaces in city centers.

In conclusion, the market demand for modular construction solutions, particularly those utilizing vacuum forming technology, is robust and diverse. From residential to commercial applications, the industry is poised for continued growth as it addresses key challenges in modern construction, including speed, cost-effectiveness, customization, and sustainability.

Current State and Challenges in Vacuum Forming Technology

Vacuum forming technology has made significant strides in recent years, particularly in its application to modular construction elements. The current state of this technology is characterized by a blend of established practices and innovative approaches, driven by the growing demand for efficient and cost-effective construction methods.

In the realm of modular construction, vacuum forming has emerged as a versatile and powerful technique. It allows for the rapid production of large, lightweight panels and components with complex geometries. This process has been refined to achieve higher precision and consistency, enabling the creation of interlocking modular elements that can be easily assembled on-site.

One of the key advancements in vacuum forming for construction is the development of high-performance thermoplastics and composite materials. These materials offer improved strength-to-weight ratios, enhanced durability, and better insulation properties compared to traditional construction materials. The ability to incorporate various additives and reinforcements into these materials has further expanded their potential applications in modular construction.

However, despite these advancements, the technology faces several challenges. One significant hurdle is the limitation on the size of components that can be produced. While vacuum forming can create large panels, there are practical limits to the dimensions of the forming machines and the handling of oversized elements. This constraint can impact the design flexibility and scalability of modular construction projects.

Another challenge lies in achieving uniform material distribution and thickness control, especially for complex shapes. Inconsistencies in material thickness can lead to structural weaknesses or aesthetic imperfections in the final product. Advanced software and simulation tools are being developed to address this issue, but further refinement is needed to ensure optimal results across a wide range of designs.

The integration of vacuum-formed elements with other construction materials and systems also presents challenges. Ensuring proper sealing, insulation, and structural integrity at the interfaces between vacuum-formed components and traditional building materials requires careful engineering and innovative connection solutions.

Furthermore, the environmental impact of vacuum forming in construction is a growing concern. While the process itself is relatively energy-efficient, the use of thermoplastics raises questions about sustainability and end-of-life recycling. The industry is actively exploring bio-based and recyclable materials to address these concerns, but widespread adoption remains a challenge.

Lastly, the regulatory landscape for vacuum-formed modular construction elements is still evolving. Ensuring compliance with building codes and standards, which were primarily developed for traditional construction methods, requires ongoing collaboration between industry stakeholders and regulatory bodies.

In the realm of modular construction, vacuum forming has emerged as a versatile and powerful technique. It allows for the rapid production of large, lightweight panels and components with complex geometries. This process has been refined to achieve higher precision and consistency, enabling the creation of interlocking modular elements that can be easily assembled on-site.

One of the key advancements in vacuum forming for construction is the development of high-performance thermoplastics and composite materials. These materials offer improved strength-to-weight ratios, enhanced durability, and better insulation properties compared to traditional construction materials. The ability to incorporate various additives and reinforcements into these materials has further expanded their potential applications in modular construction.

However, despite these advancements, the technology faces several challenges. One significant hurdle is the limitation on the size of components that can be produced. While vacuum forming can create large panels, there are practical limits to the dimensions of the forming machines and the handling of oversized elements. This constraint can impact the design flexibility and scalability of modular construction projects.

Another challenge lies in achieving uniform material distribution and thickness control, especially for complex shapes. Inconsistencies in material thickness can lead to structural weaknesses or aesthetic imperfections in the final product. Advanced software and simulation tools are being developed to address this issue, but further refinement is needed to ensure optimal results across a wide range of designs.

The integration of vacuum-formed elements with other construction materials and systems also presents challenges. Ensuring proper sealing, insulation, and structural integrity at the interfaces between vacuum-formed components and traditional building materials requires careful engineering and innovative connection solutions.

Furthermore, the environmental impact of vacuum forming in construction is a growing concern. While the process itself is relatively energy-efficient, the use of thermoplastics raises questions about sustainability and end-of-life recycling. The industry is actively exploring bio-based and recyclable materials to address these concerns, but widespread adoption remains a challenge.

Lastly, the regulatory landscape for vacuum-formed modular construction elements is still evolving. Ensuring compliance with building codes and standards, which were primarily developed for traditional construction methods, requires ongoing collaboration between industry stakeholders and regulatory bodies.

Existing Vacuum Forming Solutions for Construction

01 Vacuum forming techniques for modular construction elements

Vacuum forming is utilized to create modular construction elements with precise shapes and dimensions. This process involves heating thermoplastic sheets and using vacuum pressure to form them over molds, resulting in lightweight yet durable components for construction. The technique allows for efficient production of standardized building elements that can be easily assembled on-site.- Vacuum forming techniques for modular construction: Vacuum forming is used to create modular construction elements, allowing for efficient and cost-effective production of standardized building components. This process involves heating thermoplastic sheets and using vacuum pressure to form them into desired shapes, resulting in lightweight yet durable construction elements.

- Interlocking systems for modular elements: Modular construction elements often incorporate interlocking systems to facilitate easy assembly and disassembly. These systems may include tongue-and-groove connections, snap-fit mechanisms, or other innovative joining methods that enhance the structural integrity of the assembled modules while allowing for flexibility in design and reconfiguration.

- Materials selection for vacuum-formed modules: The choice of materials for vacuum-formed modular construction elements is crucial for performance and durability. Common materials include various thermoplastics, reinforced polymers, and composite materials that offer a balance of strength, weight, and weather resistance. Some formulations may also incorporate recycled materials to improve sustainability.

- Integration of insulation and utilities: Advanced vacuum-formed modular elements often integrate insulation and provisions for utilities within their design. This can include pre-formed channels for electrical wiring, plumbing, or HVAC systems, as well as built-in insulation layers to enhance energy efficiency in the final construction.

- Customization and adaptability of modular elements: Vacuum forming techniques allow for a high degree of customization in modular construction elements. This includes the ability to create elements with various surface textures, colors, and finishes, as well as the flexibility to produce modules in different sizes and shapes to meet specific architectural requirements or to adapt to different building designs.

02 Interlocking systems for modular construction

Modular construction elements are designed with interlocking systems to facilitate easy assembly and disassembly. These systems may include tongue-and-groove connections, snap-fit mechanisms, or other innovative joining methods. The interlocking design ensures structural stability while allowing for flexibility in construction and potential reconfiguration of buildings.Expand Specific Solutions03 Insulation and energy efficiency in modular elements

Vacuum-formed modular construction elements are engineered to incorporate insulation properties, enhancing the energy efficiency of buildings. This may involve the use of multi-layer materials or the integration of insulating cores within the elements during the forming process. The result is improved thermal performance and reduced energy consumption in completed structures.Expand Specific Solutions04 Customization and adaptability of modular components

Vacuum forming techniques allow for the creation of customizable modular construction elements that can be adapted to various architectural designs and requirements. This flexibility enables the production of elements with different sizes, shapes, and functionalities while maintaining the benefits of standardized manufacturing processes. The adaptability of these components supports diverse construction needs and aesthetic preferences.Expand Specific Solutions05 Integration of utilities and smart features

Advanced modular construction elements incorporate pre-installed utilities and smart features. During the vacuum forming process, channels or cavities can be created to accommodate electrical wiring, plumbing, or other building systems. Additionally, sensors or other smart technologies can be embedded within the elements, facilitating the creation of intelligent and connected building structures.Expand Specific Solutions

Key Players in Modular Construction and Vacuum Forming

The vacuum forming technology in modular construction is currently in a growth phase, with increasing market adoption and expanding applications. The global market for this technology is projected to grow significantly, driven by the demand for efficient and cost-effective construction methods. While the technology has matured considerably, there is still room for innovation and improvement. Companies like PolyCare Research Technology and Cuby Technologies are pioneering advanced vacuum forming techniques for modular construction elements, while established players such as Magna International and Changsha Yuanda Housing Industry Group are integrating this technology into their manufacturing processes. Universities like Tianjin University and Universidad Politécnica de Madrid are conducting research to further enhance the capabilities and applications of vacuum forming in construction.

PolyCare Research Technology GmbH Co. KG

Technical Solution: PolyCare has developed an innovative modular construction system using vacuum forming technology. Their process involves creating lightweight, high-strength polymer concrete elements through vacuum forming. This method allows for rapid production of customizable building components with excellent thermal and acoustic properties[1]. The company's technology enables the creation of interlocking building blocks that can be easily assembled on-site, significantly reducing construction time and labor costs[2]. PolyCare's vacuum-formed elements are also designed to be recyclable, promoting sustainability in the construction industry[3].

Strengths: Rapid production, customizable designs, improved thermal and acoustic properties, easy on-site assembly, and recyclability. Weaknesses: Potentially higher initial costs compared to traditional materials, limited long-term performance data in various climates.

Magna International, Inc.

Technical Solution: Magna International has applied vacuum forming technology to revolutionize the production of modular construction elements for the automotive industry. Their process involves using large-scale vacuum forming machines to create lightweight, yet durable interior and exterior components for vehicles[4]. This technology allows for the production of complex shapes and textures that would be difficult or impossible to achieve with traditional manufacturing methods. Magna's vacuum-formed components are designed to reduce vehicle weight, improve fuel efficiency, and enhance overall design flexibility[5]. The company has also developed advanced materials specifically formulated for vacuum forming, which offer improved strength-to-weight ratios and resistance to environmental factors[6].

Strengths: Lightweight components, complex shape capabilities, improved fuel efficiency, design flexibility. Weaknesses: Limited to specific automotive applications, potential for higher tooling costs for low-volume production.

Innovative Vacuum Forming Patents for Construction

Vacuum formed wall structure

PatentActiveZA201904640A

Innovation

- A vacuum-formed, continuous wall structure with integrally formed and pivotally connected sidewalls and rear wall, featuring vacuum-formed hinges that allow sidewalls to pivot relative to the rear wall, enabling easy assembly and configuration into a U-shaped cubicle with pivotable door-engaging panels and roof connection.

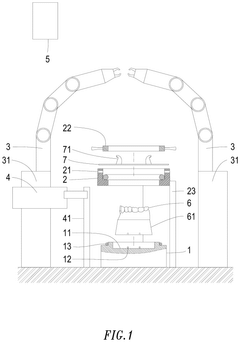

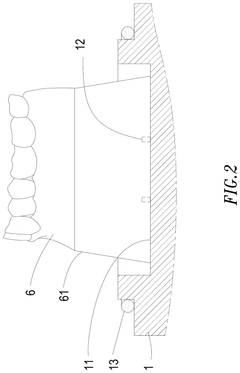

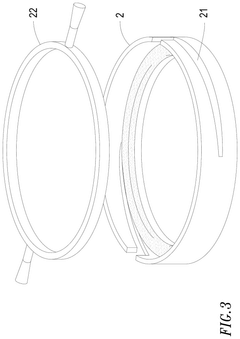

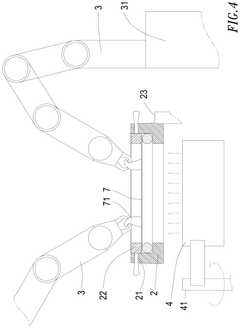

Vacuum forming method for membrane-like objects having protruding structures and forming apparatus thereof

PatentPendingUS20250042076A1

Innovation

- A computer simulation is used to pre-construct and position special structures on a membrane-like object, which is then transferred to a predetermined forming position using a controllable transfer device during the vacuum forming process, ensuring precise attachment to a mold.

Environmental Impact of Vacuum Forming in Construction

Vacuum forming in modular construction has significant environmental implications, both positive and negative. On the positive side, this technology contributes to waste reduction in the construction industry. By creating precise, pre-fabricated elements, vacuum forming minimizes on-site material waste, which is a common issue in traditional construction methods. The ability to produce exact quantities of needed components reduces overproduction and associated resource consumption.

Furthermore, the energy efficiency of buildings constructed using vacuum-formed elements can be superior to traditional methods. The precise fit and uniformity of these components can lead to better insulation and reduced thermal bridging, potentially lowering the energy requirements for heating and cooling throughout the building's lifecycle. This long-term energy saving can offset the initial energy investment in the manufacturing process.

However, the environmental impact of the materials used in vacuum forming must be considered. Many of the plastics and polymers commonly employed in this process are derived from non-renewable petroleum sources. The production of these materials can be energy-intensive and contribute to greenhouse gas emissions. Additionally, the end-of-life disposal of these components presents challenges, as not all materials used in vacuum forming are easily recyclable.

The transportation of vacuum-formed elements can have mixed environmental effects. While the lightweight nature of many vacuum-formed components can reduce fuel consumption during transport compared to heavier traditional materials, the potential for increased shipping distances due to centralized production facilities may offset these gains.

The durability and lifespan of vacuum-formed construction elements also play a role in their overall environmental impact. If these components prove to be more resilient and longer-lasting than traditional alternatives, they could reduce the need for frequent replacements and renovations, thereby conserving resources over time.

In terms of air quality, vacuum forming processes can release volatile organic compounds (VOCs) during production. While modern manufacturing facilities often have systems in place to mitigate these emissions, the potential environmental and health impacts should not be overlooked. On the other hand, the controlled factory environment where vacuum forming typically occurs can lead to better management of pollutants compared to on-site construction activities.

As the construction industry moves towards more sustainable practices, there is ongoing research into eco-friendly materials suitable for vacuum forming. Biodegradable plastics and recycled materials are being explored as alternatives to traditional petroleum-based polymers, which could significantly improve the environmental profile of vacuum-formed construction elements in the future.

Furthermore, the energy efficiency of buildings constructed using vacuum-formed elements can be superior to traditional methods. The precise fit and uniformity of these components can lead to better insulation and reduced thermal bridging, potentially lowering the energy requirements for heating and cooling throughout the building's lifecycle. This long-term energy saving can offset the initial energy investment in the manufacturing process.

However, the environmental impact of the materials used in vacuum forming must be considered. Many of the plastics and polymers commonly employed in this process are derived from non-renewable petroleum sources. The production of these materials can be energy-intensive and contribute to greenhouse gas emissions. Additionally, the end-of-life disposal of these components presents challenges, as not all materials used in vacuum forming are easily recyclable.

The transportation of vacuum-formed elements can have mixed environmental effects. While the lightweight nature of many vacuum-formed components can reduce fuel consumption during transport compared to heavier traditional materials, the potential for increased shipping distances due to centralized production facilities may offset these gains.

The durability and lifespan of vacuum-formed construction elements also play a role in their overall environmental impact. If these components prove to be more resilient and longer-lasting than traditional alternatives, they could reduce the need for frequent replacements and renovations, thereby conserving resources over time.

In terms of air quality, vacuum forming processes can release volatile organic compounds (VOCs) during production. While modern manufacturing facilities often have systems in place to mitigate these emissions, the potential environmental and health impacts should not be overlooked. On the other hand, the controlled factory environment where vacuum forming typically occurs can lead to better management of pollutants compared to on-site construction activities.

As the construction industry moves towards more sustainable practices, there is ongoing research into eco-friendly materials suitable for vacuum forming. Biodegradable plastics and recycled materials are being explored as alternatives to traditional petroleum-based polymers, which could significantly improve the environmental profile of vacuum-formed construction elements in the future.

Cost-Benefit Analysis of Vacuum Formed Modular Elements

The cost-benefit analysis of vacuum formed modular elements reveals significant advantages in terms of economic efficiency and construction productivity. Initial investment in vacuum forming equipment and molds can be substantial, but the long-term benefits often outweigh these upfront costs.

One of the primary cost advantages is the reduction in labor expenses. Vacuum forming allows for the rapid production of large, complex shapes with minimal manual intervention. This automation significantly decreases the man-hours required for manufacturing modular elements, leading to lower labor costs and increased output capacity.

Material costs also see a notable reduction. Vacuum forming typically uses thermoplastic sheets, which are generally less expensive than traditional construction materials like concrete or steel. The process also minimizes material waste, as excess plastic can often be recycled and reused in future production runs.

The speed of production is another crucial benefit. Vacuum forming can produce modular elements in a fraction of the time required for conventional methods. This rapid turnaround translates to shorter project timelines and reduced overall construction costs.

Durability and longevity of vacuum formed elements contribute to long-term cost savings. These components are resistant to weathering, corrosion, and UV radiation, reducing maintenance and replacement costs over the lifespan of the structure.

Transportation and installation costs are also favorably impacted. Vacuum formed modular elements are typically lighter than traditional materials, reducing shipping expenses and simplifying on-site handling. Their precise dimensions and interlocking designs often lead to faster, more efficient assembly processes.

However, there are some potential drawbacks to consider. The initial setup costs for vacuum forming facilities can be high, which may present a barrier to entry for smaller construction firms. Additionally, while the process is versatile, there are limitations to the sizes and complexities of shapes that can be produced, potentially necessitating multiple components for larger structures.

Energy consumption during the vacuum forming process is another factor to consider. The heating and forming of thermoplastic sheets require significant energy input, which can impact operational costs and environmental sustainability.

In conclusion, the cost-benefit analysis of vacuum formed modular elements generally favors their adoption in construction projects. The combination of reduced labor costs, material savings, increased production speed, and improved durability often results in a positive return on investment, particularly for large-scale or repetitive construction projects.

One of the primary cost advantages is the reduction in labor expenses. Vacuum forming allows for the rapid production of large, complex shapes with minimal manual intervention. This automation significantly decreases the man-hours required for manufacturing modular elements, leading to lower labor costs and increased output capacity.

Material costs also see a notable reduction. Vacuum forming typically uses thermoplastic sheets, which are generally less expensive than traditional construction materials like concrete or steel. The process also minimizes material waste, as excess plastic can often be recycled and reused in future production runs.

The speed of production is another crucial benefit. Vacuum forming can produce modular elements in a fraction of the time required for conventional methods. This rapid turnaround translates to shorter project timelines and reduced overall construction costs.

Durability and longevity of vacuum formed elements contribute to long-term cost savings. These components are resistant to weathering, corrosion, and UV radiation, reducing maintenance and replacement costs over the lifespan of the structure.

Transportation and installation costs are also favorably impacted. Vacuum formed modular elements are typically lighter than traditional materials, reducing shipping expenses and simplifying on-site handling. Their precise dimensions and interlocking designs often lead to faster, more efficient assembly processes.

However, there are some potential drawbacks to consider. The initial setup costs for vacuum forming facilities can be high, which may present a barrier to entry for smaller construction firms. Additionally, while the process is versatile, there are limitations to the sizes and complexities of shapes that can be produced, potentially necessitating multiple components for larger structures.

Energy consumption during the vacuum forming process is another factor to consider. The heating and forming of thermoplastic sheets require significant energy input, which can impact operational costs and environmental sustainability.

In conclusion, the cost-benefit analysis of vacuum formed modular elements generally favors their adoption in construction projects. The combination of reduced labor costs, material savings, increased production speed, and improved durability often results in a positive return on investment, particularly for large-scale or repetitive construction projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!