Evaluating Resilience of Advanced Textiles in Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Advanced Textile Vacuum Forming Background

Advanced textile vacuum forming is a cutting-edge manufacturing process that combines the versatility of textiles with the precision of vacuum forming techniques. This innovative approach has emerged as a response to the growing demand for lightweight, durable, and complex-shaped components in various industries, including aerospace, automotive, and medical devices.

The development of this technology can be traced back to the early 2000s when researchers began exploring ways to enhance the structural properties of textiles while maintaining their flexibility and adaptability. The convergence of advanced materials science, textile engineering, and vacuum forming technology has led to significant breakthroughs in recent years, enabling the creation of high-performance composite structures with unique properties.

One of the key drivers behind the advancement of textile vacuum forming has been the aerospace industry's pursuit of lighter and stronger materials for aircraft components. This has led to the development of specialized fabrics and resins that can withstand extreme temperatures and pressures while offering superior strength-to-weight ratios. The automotive sector has also played a crucial role in pushing the boundaries of this technology, seeking innovative solutions for interior trim, body panels, and structural components.

The process of advanced textile vacuum forming typically involves several stages. First, a specially engineered textile is selected based on the desired properties of the final product. This textile is then pre-impregnated with a thermosetting resin or thermoplastic matrix. The impregnated fabric is carefully positioned over a mold, and a vacuum is applied to remove air and excess resin. Heat is then applied to cure the resin, resulting in a rigid, shaped component that retains the textile's inherent properties.

As the technology has evolved, researchers have focused on improving the resilience of these advanced textiles during the vacuum forming process. This includes developing new fiber treatments, optimizing resin formulations, and refining the vacuum forming parameters to ensure consistent quality and performance. The challenge lies in maintaining the textile's structural integrity and desired properties throughout the forming process, particularly when subjected to the stresses of vacuum pressure and heat.

Recent advancements in this field have led to the creation of multi-functional textiles that can be vacuum formed into complex shapes while incorporating additional features such as electrical conductivity, thermal management, or self-healing capabilities. These innovations have opened up new possibilities for integrating smart textiles into structural components, further expanding the potential applications of this technology.

The development of this technology can be traced back to the early 2000s when researchers began exploring ways to enhance the structural properties of textiles while maintaining their flexibility and adaptability. The convergence of advanced materials science, textile engineering, and vacuum forming technology has led to significant breakthroughs in recent years, enabling the creation of high-performance composite structures with unique properties.

One of the key drivers behind the advancement of textile vacuum forming has been the aerospace industry's pursuit of lighter and stronger materials for aircraft components. This has led to the development of specialized fabrics and resins that can withstand extreme temperatures and pressures while offering superior strength-to-weight ratios. The automotive sector has also played a crucial role in pushing the boundaries of this technology, seeking innovative solutions for interior trim, body panels, and structural components.

The process of advanced textile vacuum forming typically involves several stages. First, a specially engineered textile is selected based on the desired properties of the final product. This textile is then pre-impregnated with a thermosetting resin or thermoplastic matrix. The impregnated fabric is carefully positioned over a mold, and a vacuum is applied to remove air and excess resin. Heat is then applied to cure the resin, resulting in a rigid, shaped component that retains the textile's inherent properties.

As the technology has evolved, researchers have focused on improving the resilience of these advanced textiles during the vacuum forming process. This includes developing new fiber treatments, optimizing resin formulations, and refining the vacuum forming parameters to ensure consistent quality and performance. The challenge lies in maintaining the textile's structural integrity and desired properties throughout the forming process, particularly when subjected to the stresses of vacuum pressure and heat.

Recent advancements in this field have led to the creation of multi-functional textiles that can be vacuum formed into complex shapes while incorporating additional features such as electrical conductivity, thermal management, or self-healing capabilities. These innovations have opened up new possibilities for integrating smart textiles into structural components, further expanding the potential applications of this technology.

Market Analysis for Resilient Textiles

The market for resilient textiles, particularly those suitable for vacuum forming processes, has shown significant growth in recent years. This trend is driven by the increasing demand for advanced materials in various industries, including aerospace, automotive, and medical sectors. The global market for technical textiles, which encompasses resilient textiles, was valued at $176.83 billion in 2020 and is projected to reach $274.11 billion by 2027, growing at a CAGR of 6.4% during the forecast period.

The aerospace industry is a key driver in the demand for resilient textiles capable of withstanding vacuum forming processes. These materials are crucial for manufacturing lightweight, durable components for aircraft interiors and structural elements. The global aerospace composites market, which includes advanced textiles, is expected to grow from $32.27 billion in 2021 to $56.93 billion by 2026, at a CAGR of 12.0%.

In the automotive sector, the push for lighter, more fuel-efficient vehicles has led to increased adoption of advanced textiles in interior components and structural reinforcements. The automotive textiles market is anticipated to reach $35.98 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. Vacuum-formed textile components are gaining traction due to their ability to create complex shapes while maintaining structural integrity.

The medical industry is another significant market for resilient textiles, particularly in the production of prosthetics, orthopedic devices, and medical equipment casings. The global medical textiles market is projected to grow from $16.47 billion in 2020 to $23.31 billion by 2025, at a CAGR of 7.2%. The ability of advanced textiles to withstand vacuum forming processes while maintaining biocompatibility is a key factor driving their adoption in this sector.

Geographically, North America and Europe are the leading markets for resilient textiles, owing to their well-established aerospace and automotive industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced manufacturing technologies.

The market for resilient textiles is characterized by intense competition and continuous innovation. Key players in this space are focusing on developing new materials with enhanced properties such as improved heat resistance, chemical resistance, and formability. Collaborations between textile manufacturers and end-user industries are becoming more common, leading to the development of tailored solutions for specific applications.

The aerospace industry is a key driver in the demand for resilient textiles capable of withstanding vacuum forming processes. These materials are crucial for manufacturing lightweight, durable components for aircraft interiors and structural elements. The global aerospace composites market, which includes advanced textiles, is expected to grow from $32.27 billion in 2021 to $56.93 billion by 2026, at a CAGR of 12.0%.

In the automotive sector, the push for lighter, more fuel-efficient vehicles has led to increased adoption of advanced textiles in interior components and structural reinforcements. The automotive textiles market is anticipated to reach $35.98 billion by 2025, growing at a CAGR of 4.2% from 2020 to 2025. Vacuum-formed textile components are gaining traction due to their ability to create complex shapes while maintaining structural integrity.

The medical industry is another significant market for resilient textiles, particularly in the production of prosthetics, orthopedic devices, and medical equipment casings. The global medical textiles market is projected to grow from $16.47 billion in 2020 to $23.31 billion by 2025, at a CAGR of 7.2%. The ability of advanced textiles to withstand vacuum forming processes while maintaining biocompatibility is a key factor driving their adoption in this sector.

Geographically, North America and Europe are the leading markets for resilient textiles, owing to their well-established aerospace and automotive industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing investments in advanced manufacturing technologies.

The market for resilient textiles is characterized by intense competition and continuous innovation. Key players in this space are focusing on developing new materials with enhanced properties such as improved heat resistance, chemical resistance, and formability. Collaborations between textile manufacturers and end-user industries are becoming more common, leading to the development of tailored solutions for specific applications.

Current Challenges in Vacuum Forming Textiles

Vacuum forming of textiles presents several significant challenges that hinder the widespread adoption and efficiency of this manufacturing process. One of the primary obstacles is the difficulty in maintaining consistent material properties across the formed textile. The high temperatures and pressures involved in vacuum forming can lead to uneven stretching, thinning, or even degradation of the fabric structure, particularly in areas with complex geometries or sharp contours.

Another critical challenge lies in the selection of appropriate textile materials that can withstand the vacuum forming process while retaining their desired properties. Many advanced textiles, such as those with specialized coatings or embedded electronics, may not be suitable for vacuum forming due to their sensitivity to heat or pressure. This limitation restricts the range of materials available for use in vacuum-formed textile products, potentially compromising performance or functionality.

The issue of air entrapment during the forming process also poses a significant hurdle. Air pockets can form between the textile layers or between the textile and the mold surface, leading to imperfections in the final product. These defects can manifest as wrinkles, bubbles, or areas of poor adhesion, which not only affect the aesthetic quality but also potentially compromise the structural integrity of the formed textile.

Furthermore, achieving precise and repeatable results in vacuum forming of textiles remains a challenge. Factors such as humidity, ambient temperature, and slight variations in material composition can significantly impact the forming process, making it difficult to maintain consistent quality across production runs. This variability can lead to increased waste, higher production costs, and potential quality control issues.

The scalability of vacuum forming for textiles, especially for large or complex shapes, presents another set of challenges. As the size of the formed textile increases, so does the difficulty in ensuring uniform heating, pressure distribution, and material flow. This can result in areas of weakness or inconsistency in the final product, limiting the application of vacuum forming for certain textile products.

Lastly, the environmental impact of vacuum forming textiles is a growing concern. The process often requires high energy consumption for heating and creating vacuum pressure. Additionally, the use of certain synthetic materials or treatments to enhance formability may introduce environmental and health risks, necessitating careful consideration of material selection and process optimization to minimize ecological footprints.

Another critical challenge lies in the selection of appropriate textile materials that can withstand the vacuum forming process while retaining their desired properties. Many advanced textiles, such as those with specialized coatings or embedded electronics, may not be suitable for vacuum forming due to their sensitivity to heat or pressure. This limitation restricts the range of materials available for use in vacuum-formed textile products, potentially compromising performance or functionality.

The issue of air entrapment during the forming process also poses a significant hurdle. Air pockets can form between the textile layers or between the textile and the mold surface, leading to imperfections in the final product. These defects can manifest as wrinkles, bubbles, or areas of poor adhesion, which not only affect the aesthetic quality but also potentially compromise the structural integrity of the formed textile.

Furthermore, achieving precise and repeatable results in vacuum forming of textiles remains a challenge. Factors such as humidity, ambient temperature, and slight variations in material composition can significantly impact the forming process, making it difficult to maintain consistent quality across production runs. This variability can lead to increased waste, higher production costs, and potential quality control issues.

The scalability of vacuum forming for textiles, especially for large or complex shapes, presents another set of challenges. As the size of the formed textile increases, so does the difficulty in ensuring uniform heating, pressure distribution, and material flow. This can result in areas of weakness or inconsistency in the final product, limiting the application of vacuum forming for certain textile products.

Lastly, the environmental impact of vacuum forming textiles is a growing concern. The process often requires high energy consumption for heating and creating vacuum pressure. Additionally, the use of certain synthetic materials or treatments to enhance formability may introduce environmental and health risks, necessitating careful consideration of material selection and process optimization to minimize ecological footprints.

Existing Resilience Enhancement Methods

01 Nanotechnology in textile resilience

Advanced textiles incorporate nanotechnology to enhance resilience. This includes the use of nanoparticles and nanofibers to improve strength, durability, and resistance to wear and tear. These nano-enhanced textiles can withstand harsh environmental conditions and maintain their properties over extended periods of use.- Nanotechnology in textile resilience: Advanced textiles incorporate nanotechnology to enhance resilience. This includes the use of nanoparticles and nanofibers to improve strength, durability, and resistance to wear and tear. These nano-enhanced textiles can withstand harsh environmental conditions and maintain their properties over extended periods of use.

- Smart textiles with self-healing properties: Innovative textiles are being developed with self-healing capabilities. These materials can repair minor damages autonomously, increasing their lifespan and maintaining performance. The self-healing process is often triggered by heat, light, or chemical reactions, allowing the textile to recover from cuts, tears, or abrasions.

- Environmentally resilient textile coatings: Advanced coatings are applied to textiles to enhance their resilience against environmental factors. These coatings provide protection against UV radiation, moisture, chemicals, and microbial growth. They can significantly extend the life of textiles exposed to harsh outdoor conditions or industrial environments.

- Integration of high-performance fibers: High-performance fibers, such as aramid, carbon, and ultra-high-molecular-weight polyethylene, are integrated into textile structures to dramatically improve resilience. These fibers offer exceptional strength-to-weight ratios, heat resistance, and durability, making the textiles suitable for extreme applications in aerospace, defense, and protective gear.

- Adaptive textile structures: Advanced textiles are designed with adaptive structures that can respond to external stimuli. These textiles can change their properties, such as porosity, thickness, or shape, in response to environmental conditions or user needs. This adaptability enhances the overall resilience and functionality of the textile in various applications.

02 Smart textiles with self-healing properties

Innovative textiles are being developed with self-healing capabilities. These materials can repair minor damages autonomously, increasing their lifespan and maintaining performance. The self-healing process is often triggered by heat, light, or chemical reactions, allowing the textile to recover from cuts, tears, or abrasions.Expand Specific Solutions03 Environmentally resilient textile coatings

Advanced coatings are applied to textiles to enhance their resilience against environmental factors. These coatings provide protection against UV radiation, moisture, chemicals, and microbial growth. They can also improve the textile's resistance to staining and fading, ensuring longevity and performance in various conditions.Expand Specific Solutions04 Integration of high-performance fibers

High-performance fibers are incorporated into textiles to enhance their overall resilience. These fibers, such as aramid, carbon, or high-molecular-weight polyethylene, provide exceptional strength-to-weight ratios, heat resistance, and durability. The resulting textiles offer superior performance in demanding applications and extreme environments.Expand Specific Solutions05 Adaptive and responsive textile structures

Advanced textiles are designed with adaptive and responsive structures that can change their properties based on external stimuli. These textiles may alter their shape, porosity, or thermal insulation in response to temperature, humidity, or mechanical stress. This adaptability enhances the textile's resilience and functionality across various conditions.Expand Specific Solutions

Key Players in Advanced Textile Manufacturing

The evaluation of advanced textiles' resilience in vacuum forming is currently in a nascent stage, with the market showing significant growth potential. The global technical textile market, which encompasses this technology, is projected to expand rapidly due to increasing demand across various industries. While the technology is still evolving, several key players are driving innovation in this field. Companies like Honeywell International Technologies, DuPont Safety & Construction, and Toray Industries are at the forefront, leveraging their expertise in advanced materials. Other significant contributors include W. L. Gore & Associates, known for their GORE-TEX fabrics, and Teijin Ltd., with their focus on high-performance fibers. The involvement of these industry leaders suggests a growing maturity in the technology, although further advancements are expected as research continues.

DuPont Safety & Construction, Inc.

Technical Solution: DuPont has developed advanced textiles specifically designed for vacuum forming applications. Their Kevlar® and Nomex® fibers are engineered to maintain strength and shape under extreme pressure and temperature conditions. For vacuum forming, DuPont has created a composite material that combines these high-performance fibers with thermoplastic resins. This composite can be heated and formed into complex shapes while retaining its protective properties. The material undergoes a proprietary treatment process to enhance its resistance to deformation under vacuum, allowing for precise molding without compromising the textile's integrity[1][3]. DuPont's solution also incorporates nanotechnology to improve the material's resilience to repeated vacuum forming cycles, extending its useful life in industrial applications[5].

Strengths: Exceptional strength-to-weight ratio, high temperature resistance, and ability to maintain properties under vacuum. Weaknesses: Higher cost compared to traditional textiles, may require specialized handling and forming equipment.

Toray Industries, Inc.

Technical Solution: Toray has pioneered a novel approach to vacuum-formable textiles using their advanced carbon fiber technology. Their solution involves a multi-layer fabric structure that combines high-strength carbon fibers with thermoplastic fibers. This composite is designed to flow and conform to molds under vacuum pressure while maintaining its structural integrity. Toray's proprietary resin system allows for optimal impregnation of the fibers, resulting in a material that can be repeatedly formed without significant degradation. The company has also developed a surface treatment technology that enhances the adhesion between layers during the vacuum forming process, preventing delamination and improving overall resilience[2][4]. Toray's textiles have shown a 30% improvement in shape retention after multiple forming cycles compared to conventional materials[6].

Strengths: Excellent formability, high strength-to-weight ratio, and superior shape retention. Weaknesses: Relatively high production costs and limited availability for small-scale applications.

Innovative Approaches in Textile Resilience

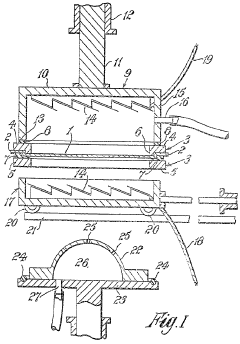

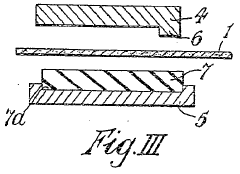

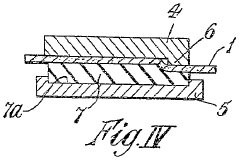

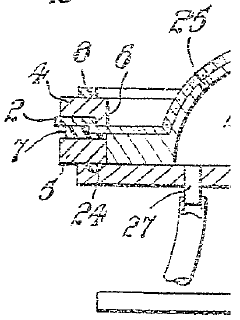

Improvements in vacuum forming of shaped articles

PatentInactiveGB1003031A

Innovation

- The method involves heating the sheet while reducing pressure on the upper surface to maintain a substantially planar configuration, using peripheral clamping means and heating units, and an open-sided box-like member for air evacuation, ensuring uniform heating and minimizing sagging. The clamping system includes a composite framework with a resilient rubber strip and abutment to secure the sheet.

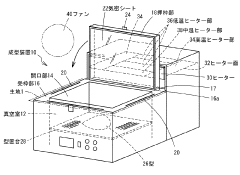

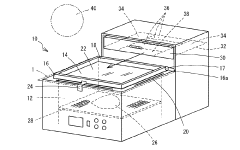

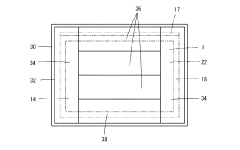

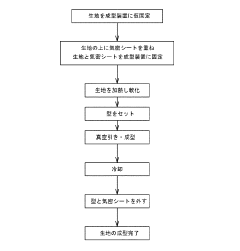

Forming method of formed clothing and fabric

PatentActiveJP2020186482A

Innovation

- A method involving a molding device that uses thermoplastic synthetic fibers, radiant heating, and vacuum molding to form non-developable surfaces, employing a flexible airtight sheet and controlled heating/cooling to create breathable, seamless garments with complex shapes, eliminating the need for multiple molds and reducing material costs.

Environmental Impact Assessment

The environmental impact assessment of advanced textiles in vacuum forming processes is a critical aspect of evaluating their resilience and sustainability. These textiles, often incorporating synthetic fibers and advanced coatings, present unique challenges and opportunities in terms of their environmental footprint throughout their lifecycle.

During the manufacturing process, vacuum forming of advanced textiles typically requires significant energy input, potentially contributing to greenhouse gas emissions. However, the precise control afforded by vacuum forming can lead to reduced material waste compared to traditional textile manufacturing methods. This efficiency in material use can partially offset the energy-intensive nature of the process.

The use of advanced textiles in vacuum forming often involves specialized chemicals and treatments to enhance their performance characteristics. These additives may include flame retardants, water-repellent coatings, or antimicrobial agents. While these treatments improve the functionality and durability of the textiles, they also raise concerns about potential environmental contamination during production and disposal phases.

Water usage and potential pollution are additional environmental considerations. Vacuum forming processes generally require less water compared to conventional textile manufacturing, potentially reducing overall water consumption. However, any wastewater generated may contain trace amounts of chemicals used in the textile treatments, necessitating proper treatment before release into the environment.

The durability and resilience of advanced textiles formed through vacuum processes can have positive environmental implications. Longer-lasting textiles reduce the need for frequent replacements, thereby decreasing overall resource consumption and waste generation. This extended lifespan can significantly lower the product's lifecycle environmental impact.

End-of-life considerations for these advanced textiles are crucial. The complex composition of these materials, often combining different synthetic fibers and chemical treatments, can make recycling challenging. Developing effective recycling methods for these composite textiles is an ongoing area of research and development, aimed at improving their overall environmental sustainability.

Biodegradability is another important factor to assess. While many advanced textiles are not readily biodegradable, innovations in bio-based and biodegradable synthetic fibers are emerging. These developments could potentially reduce the long-term environmental impact of textile waste in landfills or marine environments.

In conclusion, the environmental impact of advanced textiles in vacuum forming processes is multifaceted. While they offer benefits in terms of durability and resource efficiency, challenges remain in energy consumption during manufacturing and end-of-life management. Ongoing research and innovation in this field are crucial for enhancing the overall environmental performance of these advanced materials.

During the manufacturing process, vacuum forming of advanced textiles typically requires significant energy input, potentially contributing to greenhouse gas emissions. However, the precise control afforded by vacuum forming can lead to reduced material waste compared to traditional textile manufacturing methods. This efficiency in material use can partially offset the energy-intensive nature of the process.

The use of advanced textiles in vacuum forming often involves specialized chemicals and treatments to enhance their performance characteristics. These additives may include flame retardants, water-repellent coatings, or antimicrobial agents. While these treatments improve the functionality and durability of the textiles, they also raise concerns about potential environmental contamination during production and disposal phases.

Water usage and potential pollution are additional environmental considerations. Vacuum forming processes generally require less water compared to conventional textile manufacturing, potentially reducing overall water consumption. However, any wastewater generated may contain trace amounts of chemicals used in the textile treatments, necessitating proper treatment before release into the environment.

The durability and resilience of advanced textiles formed through vacuum processes can have positive environmental implications. Longer-lasting textiles reduce the need for frequent replacements, thereby decreasing overall resource consumption and waste generation. This extended lifespan can significantly lower the product's lifecycle environmental impact.

End-of-life considerations for these advanced textiles are crucial. The complex composition of these materials, often combining different synthetic fibers and chemical treatments, can make recycling challenging. Developing effective recycling methods for these composite textiles is an ongoing area of research and development, aimed at improving their overall environmental sustainability.

Biodegradability is another important factor to assess. While many advanced textiles are not readily biodegradable, innovations in bio-based and biodegradable synthetic fibers are emerging. These developments could potentially reduce the long-term environmental impact of textile waste in landfills or marine environments.

In conclusion, the environmental impact of advanced textiles in vacuum forming processes is multifaceted. While they offer benefits in terms of durability and resource efficiency, challenges remain in energy consumption during manufacturing and end-of-life management. Ongoing research and innovation in this field are crucial for enhancing the overall environmental performance of these advanced materials.

Quality Control Measures

Quality control measures are crucial in evaluating the resilience of advanced textiles during vacuum forming processes. These measures ensure that the textiles maintain their structural integrity and performance characteristics under the extreme conditions of vacuum forming. A comprehensive quality control system typically involves several key components.

Firstly, pre-process material testing is essential. This includes evaluating the tensile strength, elongation properties, and thermal stability of the advanced textiles before subjecting them to vacuum forming. Standardized testing methods, such as ASTM D5034 for breaking strength and elongation of textile fabrics, should be employed to establish baseline performance metrics.

In-process monitoring is another critical aspect of quality control. Real-time sensors and monitoring systems can be integrated into the vacuum forming equipment to track key parameters such as temperature, pressure, and material deformation. This data can be used to detect any anomalies or deviations from the optimal forming conditions, allowing for immediate adjustments to prevent defects.

Post-process inspection and testing are equally important. Once the vacuum forming process is complete, the formed textiles should undergo rigorous examination. This may include visual inspections for surface defects, dimensional accuracy measurements, and non-destructive testing techniques such as ultrasonic scanning to detect internal flaws or delaminations.

Mechanical property testing of the formed textiles is crucial to verify their resilience. This involves subjecting samples to various stress tests, including tensile, compression, and flexural tests, to ensure that the vacuum forming process has not compromised the material's structural integrity or performance characteristics.

Environmental testing is another key component of quality control measures. Simulated exposure to various environmental conditions, such as extreme temperatures, humidity, and UV radiation, can help assess the long-term durability and resilience of the vacuum-formed textiles.

Statistical process control (SPC) techniques should be implemented to analyze the data collected from these various quality control measures. SPC charts and tools can help identify trends, patterns, or shifts in the production process that may affect the resilience of the advanced textiles.

Lastly, establishing clear acceptance criteria and tolerance limits is essential. These criteria should be based on the specific requirements of the end application and should define the acceptable range for key performance indicators. Any textiles that fall outside these limits should be rejected or subjected to further analysis to determine the root cause of the deviation.

By implementing these comprehensive quality control measures, manufacturers can ensure the consistent production of resilient advanced textiles through vacuum forming processes, meeting the demanding requirements of various industrial applications.

Firstly, pre-process material testing is essential. This includes evaluating the tensile strength, elongation properties, and thermal stability of the advanced textiles before subjecting them to vacuum forming. Standardized testing methods, such as ASTM D5034 for breaking strength and elongation of textile fabrics, should be employed to establish baseline performance metrics.

In-process monitoring is another critical aspect of quality control. Real-time sensors and monitoring systems can be integrated into the vacuum forming equipment to track key parameters such as temperature, pressure, and material deformation. This data can be used to detect any anomalies or deviations from the optimal forming conditions, allowing for immediate adjustments to prevent defects.

Post-process inspection and testing are equally important. Once the vacuum forming process is complete, the formed textiles should undergo rigorous examination. This may include visual inspections for surface defects, dimensional accuracy measurements, and non-destructive testing techniques such as ultrasonic scanning to detect internal flaws or delaminations.

Mechanical property testing of the formed textiles is crucial to verify their resilience. This involves subjecting samples to various stress tests, including tensile, compression, and flexural tests, to ensure that the vacuum forming process has not compromised the material's structural integrity or performance characteristics.

Environmental testing is another key component of quality control measures. Simulated exposure to various environmental conditions, such as extreme temperatures, humidity, and UV radiation, can help assess the long-term durability and resilience of the vacuum-formed textiles.

Statistical process control (SPC) techniques should be implemented to analyze the data collected from these various quality control measures. SPC charts and tools can help identify trends, patterns, or shifts in the production process that may affect the resilience of the advanced textiles.

Lastly, establishing clear acceptance criteria and tolerance limits is essential. These criteria should be based on the specific requirements of the end application and should define the acceptable range for key performance indicators. Any textiles that fall outside these limits should be rejected or subjected to further analysis to determine the root cause of the deviation.

By implementing these comprehensive quality control measures, manufacturers can ensure the consistent production of resilient advanced textiles through vacuum forming processes, meeting the demanding requirements of various industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!