Role of Advanced Polymer Coatings in Vacuum Forming Products

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer Coating Evolution and Objectives

The evolution of polymer coatings in vacuum forming products has been a journey of continuous innovation and technological advancement. From basic protective layers to sophisticated multifunctional coatings, the industry has witnessed a remarkable transformation over the past few decades. Initially, polymer coatings were primarily used to enhance the durability and aesthetics of vacuum-formed products. However, as manufacturing processes and consumer demands evolved, so did the role and capabilities of these coatings.

In the early stages, polymer coatings were simple barrier layers, offering basic protection against environmental factors such as moisture, UV radiation, and chemical exposure. As research progressed, scientists and engineers began to explore more advanced formulations, incorporating additives and modifying polymer structures to achieve enhanced properties. This led to the development of coatings with improved adhesion, flexibility, and resistance to various forms of degradation.

The advent of nanotechnology marked a significant milestone in polymer coating evolution. Nanoparticles and nanostructures integrated into coating formulations opened up new possibilities for performance enhancement. These nano-enhanced coatings exhibited superior scratch resistance, self-healing properties, and even antimicrobial characteristics, expanding their application scope in vacuum-formed products across various industries.

Recent years have seen a shift towards smart and responsive polymer coatings. These advanced formulations can adapt to environmental stimuli, changing their properties in response to factors like temperature, pH, or light exposure. Such intelligent coatings have found applications in packaging, automotive components, and consumer electronics, where they provide dynamic protection and functionality.

The objectives of current and future polymer coating development for vacuum forming products are multifaceted. Firstly, there is a strong focus on sustainability, with efforts directed towards developing bio-based and biodegradable coating materials that maintain high performance standards. This aligns with global initiatives to reduce environmental impact and promote circular economy principles in manufacturing.

Another key objective is to enhance the integration of coatings with the vacuum forming process itself. Researchers are exploring ways to apply coatings during the forming stage, potentially reducing production steps and improving overall efficiency. This includes the development of in-mold coating techniques and the optimization of coating formulations for compatibility with high-temperature vacuum forming processes.

Furthermore, the industry aims to expand the functional capabilities of polymer coatings beyond traditional protective roles. This includes the development of coatings with embedded sensors for smart packaging applications, self-cleaning surfaces for low-maintenance products, and coatings that can improve the recyclability of vacuum-formed items. The ultimate goal is to transform polymer coatings from passive protective layers into active components that add significant value to the final product.

In the early stages, polymer coatings were simple barrier layers, offering basic protection against environmental factors such as moisture, UV radiation, and chemical exposure. As research progressed, scientists and engineers began to explore more advanced formulations, incorporating additives and modifying polymer structures to achieve enhanced properties. This led to the development of coatings with improved adhesion, flexibility, and resistance to various forms of degradation.

The advent of nanotechnology marked a significant milestone in polymer coating evolution. Nanoparticles and nanostructures integrated into coating formulations opened up new possibilities for performance enhancement. These nano-enhanced coatings exhibited superior scratch resistance, self-healing properties, and even antimicrobial characteristics, expanding their application scope in vacuum-formed products across various industries.

Recent years have seen a shift towards smart and responsive polymer coatings. These advanced formulations can adapt to environmental stimuli, changing their properties in response to factors like temperature, pH, or light exposure. Such intelligent coatings have found applications in packaging, automotive components, and consumer electronics, where they provide dynamic protection and functionality.

The objectives of current and future polymer coating development for vacuum forming products are multifaceted. Firstly, there is a strong focus on sustainability, with efforts directed towards developing bio-based and biodegradable coating materials that maintain high performance standards. This aligns with global initiatives to reduce environmental impact and promote circular economy principles in manufacturing.

Another key objective is to enhance the integration of coatings with the vacuum forming process itself. Researchers are exploring ways to apply coatings during the forming stage, potentially reducing production steps and improving overall efficiency. This includes the development of in-mold coating techniques and the optimization of coating formulations for compatibility with high-temperature vacuum forming processes.

Furthermore, the industry aims to expand the functional capabilities of polymer coatings beyond traditional protective roles. This includes the development of coatings with embedded sensors for smart packaging applications, self-cleaning surfaces for low-maintenance products, and coatings that can improve the recyclability of vacuum-formed items. The ultimate goal is to transform polymer coatings from passive protective layers into active components that add significant value to the final product.

Market Demand Analysis

The market demand for advanced polymer coatings in vacuum forming products has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for high-performance, durable, and cost-effective materials across various industries. The automotive sector, in particular, has emerged as a key driver of this demand, as manufacturers seek lightweight yet robust materials for interior and exterior components.

The packaging industry also plays a crucial role in fueling the market for advanced polymer coatings in vacuum forming. With the rise of e-commerce and changing consumer preferences, there is a growing demand for innovative packaging solutions that offer enhanced protection, improved aesthetics, and sustainability. Advanced polymer coatings provide these benefits, making them increasingly popular among packaging manufacturers.

In the medical and healthcare sectors, the demand for advanced polymer coatings in vacuum forming products has been steadily rising. The need for sterile, biocompatible, and chemically resistant materials in medical devices and equipment has led to increased adoption of these coatings. Additionally, the ongoing COVID-19 pandemic has further accelerated this trend, with a heightened focus on hygiene and infection control in healthcare settings.

The construction industry is another significant contributor to the market demand. Advanced polymer coatings are being increasingly used in vacuum-formed building materials, such as insulation panels, roofing components, and decorative elements. These coatings offer improved weather resistance, thermal insulation, and durability, making them attractive options for both residential and commercial construction projects.

Consumer electronics manufacturers are also turning to advanced polymer coatings for vacuum-formed components. The demand for sleek, lightweight, and durable devices has led to the adoption of these coatings in smartphone cases, laptop shells, and other electronic accessories. The ability of these coatings to provide scratch resistance, color stability, and enhanced aesthetics aligns well with consumer preferences in this sector.

The aerospace industry, although smaller in volume compared to other sectors, represents a high-value market for advanced polymer coatings in vacuum forming. The stringent requirements for lightweight, heat-resistant, and high-performance materials in aircraft interiors and components drive the demand for specialized coatings in this sector.

As environmental concerns continue to grow, there is an increasing demand for sustainable and eco-friendly coating solutions. This trend is pushing manufacturers to develop advanced polymer coatings that are free from harmful chemicals, have lower VOC emissions, and are recyclable or biodegradable. The market is responding to this demand by investing in research and development of bio-based and environmentally friendly coating technologies.

The packaging industry also plays a crucial role in fueling the market for advanced polymer coatings in vacuum forming. With the rise of e-commerce and changing consumer preferences, there is a growing demand for innovative packaging solutions that offer enhanced protection, improved aesthetics, and sustainability. Advanced polymer coatings provide these benefits, making them increasingly popular among packaging manufacturers.

In the medical and healthcare sectors, the demand for advanced polymer coatings in vacuum forming products has been steadily rising. The need for sterile, biocompatible, and chemically resistant materials in medical devices and equipment has led to increased adoption of these coatings. Additionally, the ongoing COVID-19 pandemic has further accelerated this trend, with a heightened focus on hygiene and infection control in healthcare settings.

The construction industry is another significant contributor to the market demand. Advanced polymer coatings are being increasingly used in vacuum-formed building materials, such as insulation panels, roofing components, and decorative elements. These coatings offer improved weather resistance, thermal insulation, and durability, making them attractive options for both residential and commercial construction projects.

Consumer electronics manufacturers are also turning to advanced polymer coatings for vacuum-formed components. The demand for sleek, lightweight, and durable devices has led to the adoption of these coatings in smartphone cases, laptop shells, and other electronic accessories. The ability of these coatings to provide scratch resistance, color stability, and enhanced aesthetics aligns well with consumer preferences in this sector.

The aerospace industry, although smaller in volume compared to other sectors, represents a high-value market for advanced polymer coatings in vacuum forming. The stringent requirements for lightweight, heat-resistant, and high-performance materials in aircraft interiors and components drive the demand for specialized coatings in this sector.

As environmental concerns continue to grow, there is an increasing demand for sustainable and eco-friendly coating solutions. This trend is pushing manufacturers to develop advanced polymer coatings that are free from harmful chemicals, have lower VOC emissions, and are recyclable or biodegradable. The market is responding to this demand by investing in research and development of bio-based and environmentally friendly coating technologies.

Current Challenges

The application of advanced polymer coatings in vacuum forming products faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is achieving consistent coating thickness across complex geometries. Vacuum-formed products often feature intricate shapes and varying surface contours, making it difficult to apply uniform coatings. This inconsistency can lead to areas of weakness or excessive material usage, compromising both product quality and cost-effectiveness.

Another critical challenge lies in the adhesion of polymer coatings to diverse substrate materials commonly used in vacuum forming. Different plastics and composites exhibit varying surface energies and chemical compositions, necessitating specialized coating formulations and application techniques. Ensuring strong, long-lasting adhesion across a range of substrates while maintaining the desired functional properties of the coating remains a complex task for manufacturers.

The high-temperature conditions inherent in the vacuum forming process pose additional challenges for polymer coatings. Many advanced coatings struggle to maintain their integrity and performance characteristics when subjected to the heat and pressure involved in shaping thermoplastic sheets. Developing heat-resistant formulations that can withstand these conditions without degradation or loss of functionality is an ongoing area of research and development.

Environmental concerns and regulatory pressures also present significant hurdles for the industry. Traditional coating technologies often rely on volatile organic compounds (VOCs) and other potentially harmful substances. Transitioning to more environmentally friendly, low-VOC or water-based coating systems while maintaining the required performance characteristics is a complex challenge that requires substantial investment in research and reformulation efforts.

Furthermore, the integration of advanced functionalities into polymer coatings for vacuum-formed products presents its own set of challenges. As industries demand coatings with enhanced properties such as antimicrobial resistance, self-healing capabilities, or smart responsive features, formulators must balance these advanced functionalities with the practical constraints of the vacuum forming process. Achieving this balance without compromising the core performance or increasing costs significantly remains a significant technical hurdle.

Lastly, the scalability and cost-effectiveness of advanced polymer coating technologies for high-volume production environments pose considerable challenges. Many cutting-edge coating solutions that show promise in laboratory settings face difficulties in scaling up to meet the demands of industrial-scale vacuum forming operations. Developing processes and equipment capable of applying these advanced coatings efficiently and economically in a production environment is crucial for their widespread adoption and commercial viability.

Another critical challenge lies in the adhesion of polymer coatings to diverse substrate materials commonly used in vacuum forming. Different plastics and composites exhibit varying surface energies and chemical compositions, necessitating specialized coating formulations and application techniques. Ensuring strong, long-lasting adhesion across a range of substrates while maintaining the desired functional properties of the coating remains a complex task for manufacturers.

The high-temperature conditions inherent in the vacuum forming process pose additional challenges for polymer coatings. Many advanced coatings struggle to maintain their integrity and performance characteristics when subjected to the heat and pressure involved in shaping thermoplastic sheets. Developing heat-resistant formulations that can withstand these conditions without degradation or loss of functionality is an ongoing area of research and development.

Environmental concerns and regulatory pressures also present significant hurdles for the industry. Traditional coating technologies often rely on volatile organic compounds (VOCs) and other potentially harmful substances. Transitioning to more environmentally friendly, low-VOC or water-based coating systems while maintaining the required performance characteristics is a complex challenge that requires substantial investment in research and reformulation efforts.

Furthermore, the integration of advanced functionalities into polymer coatings for vacuum-formed products presents its own set of challenges. As industries demand coatings with enhanced properties such as antimicrobial resistance, self-healing capabilities, or smart responsive features, formulators must balance these advanced functionalities with the practical constraints of the vacuum forming process. Achieving this balance without compromising the core performance or increasing costs significantly remains a significant technical hurdle.

Lastly, the scalability and cost-effectiveness of advanced polymer coating technologies for high-volume production environments pose considerable challenges. Many cutting-edge coating solutions that show promise in laboratory settings face difficulties in scaling up to meet the demands of industrial-scale vacuum forming operations. Developing processes and equipment capable of applying these advanced coatings efficiently and economically in a production environment is crucial for their widespread adoption and commercial viability.

Existing Coating Solutions

01 Polymer coatings with enhanced properties

Advanced polymer coatings are developed to improve various properties such as durability, chemical resistance, and thermal stability. These coatings often incorporate novel polymer blends or modified polymer structures to achieve superior performance in specific applications.- Polymer coatings with enhanced properties: Advanced polymer coatings are developed to enhance specific properties such as durability, chemical resistance, and thermal stability. These coatings often incorporate novel polymer blends or modified polymer structures to achieve superior performance in various applications.

- Nanocomposite polymer coatings: Nanocomposite polymer coatings incorporate nanomaterials to improve coating properties such as mechanical strength, barrier properties, and conductivity. These advanced coatings often utilize nanoparticles, nanotubes, or nanoplatelets dispersed within the polymer matrix.

- Environmentally friendly polymer coatings: Advanced polymer coatings are being developed with a focus on environmental sustainability. These coatings may include bio-based polymers, water-based formulations, or low-VOC systems to reduce environmental impact while maintaining high performance.

- Smart and responsive polymer coatings: Polymer coatings with responsive or adaptive properties are being developed for advanced applications. These coatings may change their properties in response to external stimuli such as temperature, pH, or light, enabling functionalities like self-healing or controlled release.

- Polymer coatings for electronic applications: Advanced polymer coatings are being developed for electronic and optoelectronic applications. These coatings may provide insulation, protection, or functional properties for electronic components, circuits, or displays.

02 Conductive polymer coatings

Electrically conductive polymer coatings are designed for applications in electronics, electromagnetic shielding, and antistatic protection. These coatings typically involve the use of intrinsically conductive polymers or polymer composites with conductive fillers.Expand Specific Solutions03 Environmentally friendly polymer coatings

Advanced polymer coatings are being developed with a focus on environmental sustainability. These include water-based formulations, bio-based polymers, and coatings with reduced volatile organic compound (VOC) content to minimize environmental impact.Expand Specific Solutions04 Self-healing polymer coatings

Innovative polymer coatings with self-healing properties are designed to repair minor damages automatically. These coatings often incorporate microcapsules or other mechanisms that release healing agents when the coating is damaged, extending the lifespan of the protected surface.Expand Specific Solutions05 Nanocomposite polymer coatings

Advanced polymer coatings incorporating nanoparticles or nanostructures are developed to enhance properties such as mechanical strength, barrier performance, and UV resistance. These nanocomposite coatings often exhibit synergistic effects between the polymer matrix and the nanoscale additives.Expand Specific Solutions

Key Industry Players

The advanced polymer coatings market for vacuum forming products is in a growth phase, driven by increasing demand across various industries. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is advancing rapidly, with companies like BASF, DuPont, and Wacker Chemie leading innovation. These industry giants are developing high-performance coatings with enhanced durability, chemical resistance, and sustainability features. Emerging players such as PhiChem Corp and Sokan New Materials are also contributing to market dynamism, particularly in Asia. The competitive landscape is characterized by a mix of established multinationals and specialized regional manufacturers, fostering both collaboration and competition in R&D efforts.

BASF Corp.

Technical Solution: BASF Corp. has developed advanced polymer coatings specifically designed for vacuum forming products. Their innovative approach involves the use of thermoplastic polyurethane (TPU) coatings that offer excellent flexibility and durability[1]. These coatings are engineered to withstand the high temperatures and mechanical stresses involved in the vacuum forming process. BASF's polymer coatings incorporate nanotechnology to enhance surface properties, resulting in improved scratch resistance and self-healing capabilities[2]. The company has also focused on developing eco-friendly formulations, reducing volatile organic compounds (VOCs) by up to 30% compared to traditional coatings[3]. BASF's coatings are designed to adhere strongly to various substrates, including plastics, metals, and composites, ensuring long-lasting protection and aesthetics for vacuum-formed products.

Strengths: Superior flexibility, durability, and adhesion to multiple substrates. Advanced nanotechnology for enhanced surface properties. Eco-friendly formulations with reduced VOCs. Weaknesses: Potentially higher cost compared to conventional coatings. May require specialized application equipment.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of high-performance polymer coatings tailored for vacuum forming applications. Their technology focuses on fluoropolymer-based coatings, such as Teflon™, which provide exceptional non-stick properties and chemical resistance[4]. DuPont's coatings are engineered to maintain their integrity under the high temperatures and pressures of vacuum forming processes. The company has introduced a novel cross-linking technology that enhances the coating's durability and extends its lifespan by up to 50% compared to standard formulations[5]. DuPont's coatings also feature advanced color stability, resisting fading and discoloration even under harsh UV exposure. Additionally, they have developed antimicrobial variants that inhibit bacterial growth on surfaces, making them ideal for medical and food packaging applications[6].

Strengths: Exceptional non-stick properties and chemical resistance. Enhanced durability and extended lifespan. Advanced color stability and UV resistance. Antimicrobial variants available. Weaknesses: Higher initial cost compared to standard coatings. May require specialized application techniques.

Innovative Polymer Formulations

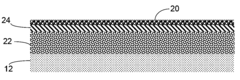

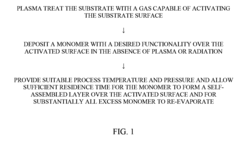

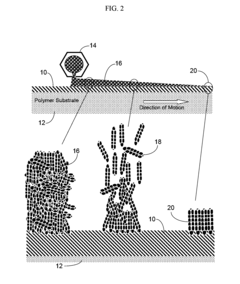

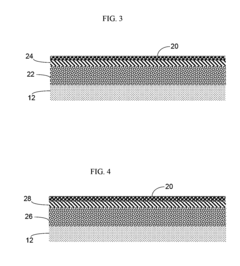

Self-assembled functional layers in multilayer structures

PatentActiveUS20120184165A1

Innovation

- A vacuum-based high-speed surface functionalization process using self-assembly of reactive-gas plasma-treated substrates with liquid functional monomers, forming an activated layer and allowing excess monomer to re-evaporate, enabling functionalization without radiation or plasma-induced polymerization, suitable for roll-to-roll processing.

Environmental Impact Assessment

The environmental impact of advanced polymer coatings in vacuum forming products is a critical consideration in the industry's sustainability efforts. These coatings, while offering numerous benefits in terms of product performance and durability, also present potential environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of advanced polymer coatings often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution and pose risks to worker health if not properly managed. However, recent advancements in coating technologies have led to the development of low-VOC and water-based formulations, significantly reducing environmental impact during production.

The application process of these coatings in vacuum forming also requires careful environmental consideration. Energy consumption during the coating and curing processes can be substantial, contributing to the carbon footprint of the final product. Manufacturers are increasingly adopting more energy-efficient technologies and processes to mitigate this impact, such as UV-curing systems and optimized thermal management in coating lines.

In the product use phase, advanced polymer coatings generally contribute positively to environmental sustainability. By enhancing the durability and longevity of vacuum-formed products, these coatings reduce the need for frequent replacements, thereby conserving resources and reducing waste. Additionally, some advanced coatings offer improved chemical resistance, preventing leaching of potentially harmful substances from the base material into the environment.

End-of-life considerations for vacuum-formed products with advanced polymer coatings present both challenges and opportunities. While these coatings can enhance the recyclability of products by protecting the base material from degradation, they may also complicate the recycling process. Some coatings may need to be removed before recycling, requiring additional processing steps. However, innovations in coating design are addressing this issue, with the development of easily separable or compatible coatings that do not hinder recycling efforts.

The environmental impact of these coatings extends beyond direct product-related factors. Their use in vacuum forming can lead to improved energy efficiency in various applications. For instance, in automotive and aerospace industries, lightweight components with advanced coatings can contribute to fuel efficiency, indirectly reducing carbon emissions over the product's lifetime.

As environmental regulations become more stringent globally, the polymer coating industry is responding with increased focus on eco-friendly formulations. This includes the development of bio-based and biodegradable coating materials, which promise to significantly reduce the environmental footprint of vacuum-formed products. These innovations not only address end-of-life concerns but also contribute to reducing dependence on fossil-fuel-derived raw materials.

During the production phase, the manufacturing of advanced polymer coatings often involves the use of volatile organic compounds (VOCs) and other potentially harmful chemicals. These substances can contribute to air pollution and pose risks to worker health if not properly managed. However, recent advancements in coating technologies have led to the development of low-VOC and water-based formulations, significantly reducing environmental impact during production.

The application process of these coatings in vacuum forming also requires careful environmental consideration. Energy consumption during the coating and curing processes can be substantial, contributing to the carbon footprint of the final product. Manufacturers are increasingly adopting more energy-efficient technologies and processes to mitigate this impact, such as UV-curing systems and optimized thermal management in coating lines.

In the product use phase, advanced polymer coatings generally contribute positively to environmental sustainability. By enhancing the durability and longevity of vacuum-formed products, these coatings reduce the need for frequent replacements, thereby conserving resources and reducing waste. Additionally, some advanced coatings offer improved chemical resistance, preventing leaching of potentially harmful substances from the base material into the environment.

End-of-life considerations for vacuum-formed products with advanced polymer coatings present both challenges and opportunities. While these coatings can enhance the recyclability of products by protecting the base material from degradation, they may also complicate the recycling process. Some coatings may need to be removed before recycling, requiring additional processing steps. However, innovations in coating design are addressing this issue, with the development of easily separable or compatible coatings that do not hinder recycling efforts.

The environmental impact of these coatings extends beyond direct product-related factors. Their use in vacuum forming can lead to improved energy efficiency in various applications. For instance, in automotive and aerospace industries, lightweight components with advanced coatings can contribute to fuel efficiency, indirectly reducing carbon emissions over the product's lifetime.

As environmental regulations become more stringent globally, the polymer coating industry is responding with increased focus on eco-friendly formulations. This includes the development of bio-based and biodegradable coating materials, which promise to significantly reduce the environmental footprint of vacuum-formed products. These innovations not only address end-of-life concerns but also contribute to reducing dependence on fossil-fuel-derived raw materials.

Cost-Benefit Analysis

The implementation of advanced polymer coatings in vacuum forming products presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the initial investment in research, development, and implementation of these coatings can be substantial. This includes expenses related to material sourcing, specialized equipment for coating application, and potential modifications to existing manufacturing processes. Additionally, there may be ongoing costs associated with quality control measures and potential increases in production time.

However, the benefits of utilizing advanced polymer coatings can often outweigh these initial costs. One of the primary advantages is the enhanced durability and longevity of vacuum-formed products. These coatings can significantly improve resistance to wear, abrasion, and chemical exposure, potentially extending the product lifecycle. This increased durability can lead to reduced replacement rates and lower long-term costs for both manufacturers and end-users.

Another significant benefit is the potential for improved product performance. Advanced polymer coatings can enhance surface properties, leading to better aesthetics, improved tactile feel, and increased functionality. For instance, in automotive applications, these coatings can provide better UV resistance and color stability, maintaining the appearance of interior components over time. In medical devices, specialized coatings can improve biocompatibility and reduce the risk of infections, potentially leading to better patient outcomes and reduced healthcare costs.

From a manufacturing perspective, the use of advanced coatings can sometimes simplify production processes. Certain coatings may allow for the use of less expensive base materials without compromising on final product quality. This can lead to overall cost reductions in raw materials and potentially offset the initial investment in coating technology.

Environmental considerations also play a role in the cost-benefit analysis. While some advanced coatings may have higher upfront environmental costs due to their production processes, they can contribute to sustainability efforts by extending product life and reducing waste. This aligns with growing consumer and regulatory demands for more environmentally friendly products, potentially opening up new market opportunities and improving brand perception.

In conclusion, while the implementation of advanced polymer coatings in vacuum forming products does involve significant upfront costs, the long-term benefits in terms of product quality, performance, and durability often justify the investment. Companies must carefully weigh these factors against their specific product requirements, market demands, and long-term strategic goals to determine the overall value proposition of incorporating these advanced coatings into their manufacturing processes.

However, the benefits of utilizing advanced polymer coatings can often outweigh these initial costs. One of the primary advantages is the enhanced durability and longevity of vacuum-formed products. These coatings can significantly improve resistance to wear, abrasion, and chemical exposure, potentially extending the product lifecycle. This increased durability can lead to reduced replacement rates and lower long-term costs for both manufacturers and end-users.

Another significant benefit is the potential for improved product performance. Advanced polymer coatings can enhance surface properties, leading to better aesthetics, improved tactile feel, and increased functionality. For instance, in automotive applications, these coatings can provide better UV resistance and color stability, maintaining the appearance of interior components over time. In medical devices, specialized coatings can improve biocompatibility and reduce the risk of infections, potentially leading to better patient outcomes and reduced healthcare costs.

From a manufacturing perspective, the use of advanced coatings can sometimes simplify production processes. Certain coatings may allow for the use of less expensive base materials without compromising on final product quality. This can lead to overall cost reductions in raw materials and potentially offset the initial investment in coating technology.

Environmental considerations also play a role in the cost-benefit analysis. While some advanced coatings may have higher upfront environmental costs due to their production processes, they can contribute to sustainability efforts by extending product life and reducing waste. This aligns with growing consumer and regulatory demands for more environmentally friendly products, potentially opening up new market opportunities and improving brand perception.

In conclusion, while the implementation of advanced polymer coatings in vacuum forming products does involve significant upfront costs, the long-term benefits in terms of product quality, performance, and durability often justify the investment. Companies must carefully weigh these factors against their specific product requirements, market demands, and long-term strategic goals to determine the overall value proposition of incorporating these advanced coatings into their manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!