Automated Linen Structures via Vacuum Forming Techniques

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Linen Evolution and Objectives

Vacuum forming techniques have been utilized in various industries for decades, primarily for shaping thermoplastic materials. However, the application of this technology to linen structures represents a novel and innovative approach in the textile and manufacturing sectors. The evolution of vacuum forming linen structures can be traced back to the convergence of traditional textile manufacturing and advanced materials processing techniques.

Initially, vacuum forming was limited to rigid materials, but advancements in material science and engineering have expanded its potential applications. The adaptation of this technique to linen, a natural fiber known for its strength and versatility, marks a significant milestone in the field of sustainable and eco-friendly manufacturing processes.

The development of vacuum forming for linen structures has been driven by several key factors. Firstly, the growing demand for sustainable and biodegradable materials in various industries has led researchers to explore new ways of processing natural fibers. Secondly, the need for more efficient and cost-effective manufacturing methods has pushed the boundaries of traditional textile production techniques.

As the technology progressed, researchers and engineers focused on overcoming the challenges associated with vacuum forming linen, such as maintaining the fabric's integrity during the process and achieving consistent results. This led to the development of specialized pre-treatment methods and the optimization of vacuum forming parameters specifically for linen materials.

The objectives of research on automated linen structures via vacuum forming techniques are multifaceted. One primary goal is to create three-dimensional, complex shapes from linen fabric without compromising its natural properties or aesthetic appeal. This would enable the production of innovative products in industries such as fashion, interior design, and automotive manufacturing.

Another crucial objective is to enhance the scalability and repeatability of the vacuum forming process for linen structures. Automation plays a key role in achieving this goal, as it allows for precise control over the forming parameters and ensures consistent quality across production runs. This is particularly important for industrial applications where large-scale production is required.

Furthermore, researchers aim to expand the range of linen products that can be manufactured using vacuum forming techniques. This includes exploring the potential for creating composite materials that combine linen with other natural or synthetic fibers, as well as investigating the integration of functional elements such as electronics or smart materials into the vacuum-formed linen structures.

Sustainability remains a core focus of this research, with objectives centered on minimizing waste, reducing energy consumption, and developing closed-loop manufacturing processes. By leveraging the inherent biodegradability of linen, researchers seek to create products that align with circular economy principles and meet the growing consumer demand for environmentally friendly goods.

Initially, vacuum forming was limited to rigid materials, but advancements in material science and engineering have expanded its potential applications. The adaptation of this technique to linen, a natural fiber known for its strength and versatility, marks a significant milestone in the field of sustainable and eco-friendly manufacturing processes.

The development of vacuum forming for linen structures has been driven by several key factors. Firstly, the growing demand for sustainable and biodegradable materials in various industries has led researchers to explore new ways of processing natural fibers. Secondly, the need for more efficient and cost-effective manufacturing methods has pushed the boundaries of traditional textile production techniques.

As the technology progressed, researchers and engineers focused on overcoming the challenges associated with vacuum forming linen, such as maintaining the fabric's integrity during the process and achieving consistent results. This led to the development of specialized pre-treatment methods and the optimization of vacuum forming parameters specifically for linen materials.

The objectives of research on automated linen structures via vacuum forming techniques are multifaceted. One primary goal is to create three-dimensional, complex shapes from linen fabric without compromising its natural properties or aesthetic appeal. This would enable the production of innovative products in industries such as fashion, interior design, and automotive manufacturing.

Another crucial objective is to enhance the scalability and repeatability of the vacuum forming process for linen structures. Automation plays a key role in achieving this goal, as it allows for precise control over the forming parameters and ensures consistent quality across production runs. This is particularly important for industrial applications where large-scale production is required.

Furthermore, researchers aim to expand the range of linen products that can be manufactured using vacuum forming techniques. This includes exploring the potential for creating composite materials that combine linen with other natural or synthetic fibers, as well as investigating the integration of functional elements such as electronics or smart materials into the vacuum-formed linen structures.

Sustainability remains a core focus of this research, with objectives centered on minimizing waste, reducing energy consumption, and developing closed-loop manufacturing processes. By leveraging the inherent biodegradability of linen, researchers seek to create products that align with circular economy principles and meet the growing consumer demand for environmentally friendly goods.

Market Analysis for Automated Linen Structures

The market for automated linen structures via vacuum forming techniques is experiencing significant growth, driven by the increasing demand for efficient and cost-effective manufacturing processes in the textile and home furnishing industries. This innovative technology combines the principles of vacuum forming with advanced automation to create intricate linen structures with precision and speed.

The global market for automated linen structures is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed the average growth rate of the broader textile manufacturing sector. This growth is primarily fueled by the rising consumer demand for customized and high-quality linen products, coupled with the need for manufacturers to reduce production costs and improve efficiency.

Key market segments for automated linen structures include home textiles, hospitality, healthcare, and automotive industries. The home textiles segment, in particular, is showing strong potential due to the growing trend of home decor customization and the increasing popularity of unique, textured fabrics in interior design.

Geographically, North America and Europe are currently the leading markets for automated linen structures, owing to their advanced manufacturing capabilities and high adoption rates of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid industrialization and increasing investments in textile manufacturing technologies in countries like China and India.

The market is characterized by a growing emphasis on sustainability and eco-friendly production methods. Manufacturers are increasingly focusing on developing automated linen structures that minimize waste, reduce energy consumption, and utilize recycled materials. This trend is expected to create new opportunities for market growth and product innovation.

One of the key factors driving market demand is the ability of automated linen structures to create complex, three-dimensional textures and patterns that are difficult to achieve through traditional manufacturing methods. This capability opens up new possibilities for designers and manufacturers to create unique, high-value products that command premium prices in the market.

However, the market also faces certain challenges. The high initial investment required for implementing automated linen structure technologies may pose a barrier to entry for smaller manufacturers. Additionally, the need for skilled operators and maintenance personnel to manage these advanced systems could potentially limit widespread adoption in some regions.

Despite these challenges, the overall market outlook for automated linen structures remains positive. As technology continues to advance and become more accessible, it is expected that a wider range of manufacturers will be able to leverage these innovative techniques to create high-quality, customized linen products efficiently and cost-effectively.

The global market for automated linen structures is projected to expand rapidly in the coming years, with a compound annual growth rate (CAGR) expected to exceed the average growth rate of the broader textile manufacturing sector. This growth is primarily fueled by the rising consumer demand for customized and high-quality linen products, coupled with the need for manufacturers to reduce production costs and improve efficiency.

Key market segments for automated linen structures include home textiles, hospitality, healthcare, and automotive industries. The home textiles segment, in particular, is showing strong potential due to the growing trend of home decor customization and the increasing popularity of unique, textured fabrics in interior design.

Geographically, North America and Europe are currently the leading markets for automated linen structures, owing to their advanced manufacturing capabilities and high adoption rates of innovative technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid industrialization and increasing investments in textile manufacturing technologies in countries like China and India.

The market is characterized by a growing emphasis on sustainability and eco-friendly production methods. Manufacturers are increasingly focusing on developing automated linen structures that minimize waste, reduce energy consumption, and utilize recycled materials. This trend is expected to create new opportunities for market growth and product innovation.

One of the key factors driving market demand is the ability of automated linen structures to create complex, three-dimensional textures and patterns that are difficult to achieve through traditional manufacturing methods. This capability opens up new possibilities for designers and manufacturers to create unique, high-value products that command premium prices in the market.

However, the market also faces certain challenges. The high initial investment required for implementing automated linen structure technologies may pose a barrier to entry for smaller manufacturers. Additionally, the need for skilled operators and maintenance personnel to manage these advanced systems could potentially limit widespread adoption in some regions.

Despite these challenges, the overall market outlook for automated linen structures remains positive. As technology continues to advance and become more accessible, it is expected that a wider range of manufacturers will be able to leverage these innovative techniques to create high-quality, customized linen products efficiently and cost-effectively.

Current Challenges in Vacuum Forming Linen

Vacuum forming of linen presents several significant challenges that hinder the widespread adoption of this technique in automated linen structure production. One of the primary obstacles is the inherent variability of linen as a natural fiber. Unlike synthetic materials, linen exhibits inconsistencies in thickness, texture, and fiber orientation, which can lead to unpredictable results during the vacuum forming process.

The porous nature of linen fabric poses another substantial challenge. The material's breathability, while desirable in many applications, complicates the vacuum forming process by allowing air to pass through the fabric. This porosity can result in incomplete or uneven forming, as the vacuum pressure may not be uniformly distributed across the linen surface.

Temperature control during vacuum forming is particularly critical when working with linen. The material has a relatively low heat tolerance compared to synthetic fabrics, making it susceptible to scorching or degradation if exposed to excessive heat. Conversely, insufficient heat can lead to inadequate softening of the linen, resulting in poor formability and potential tearing of the fabric during the shaping process.

The dimensional stability of linen under vacuum pressure and heat is another significant concern. Linen fibers have a tendency to shrink and distort when subjected to heat and tension, which can cause warping or uneven stretching of the fabric during forming. This characteristic makes it challenging to achieve precise, repeatable shapes and maintain consistent quality in automated production environments.

Adhesion to molds or forming surfaces is an additional hurdle in vacuum forming linen. The natural oils and waxes present in linen fibers can interfere with proper adhesion, potentially leading to slippage or incomplete forming. This issue is exacerbated by the fabric's tendency to retain moisture, which can further complicate the forming process and affect the final product's quality.

The integration of linen into automated vacuum forming systems presents its own set of challenges. Traditional vacuum forming equipment, designed primarily for synthetic materials, may require significant modifications to accommodate the unique properties of linen. These adaptations can include specialized heating elements, vacuum pressure control systems, and mold designs tailored to the fabric's characteristics.

Lastly, the finishing and post-forming treatment of vacuum-formed linen structures pose additional difficulties. The process can alter the fabric's natural properties, potentially affecting its appearance, texture, and performance. Developing appropriate finishing techniques that preserve the desirable qualities of linen while ensuring the stability and durability of the formed structure remains a complex task in the field of automated linen vacuum forming.

The porous nature of linen fabric poses another substantial challenge. The material's breathability, while desirable in many applications, complicates the vacuum forming process by allowing air to pass through the fabric. This porosity can result in incomplete or uneven forming, as the vacuum pressure may not be uniformly distributed across the linen surface.

Temperature control during vacuum forming is particularly critical when working with linen. The material has a relatively low heat tolerance compared to synthetic fabrics, making it susceptible to scorching or degradation if exposed to excessive heat. Conversely, insufficient heat can lead to inadequate softening of the linen, resulting in poor formability and potential tearing of the fabric during the shaping process.

The dimensional stability of linen under vacuum pressure and heat is another significant concern. Linen fibers have a tendency to shrink and distort when subjected to heat and tension, which can cause warping or uneven stretching of the fabric during forming. This characteristic makes it challenging to achieve precise, repeatable shapes and maintain consistent quality in automated production environments.

Adhesion to molds or forming surfaces is an additional hurdle in vacuum forming linen. The natural oils and waxes present in linen fibers can interfere with proper adhesion, potentially leading to slippage or incomplete forming. This issue is exacerbated by the fabric's tendency to retain moisture, which can further complicate the forming process and affect the final product's quality.

The integration of linen into automated vacuum forming systems presents its own set of challenges. Traditional vacuum forming equipment, designed primarily for synthetic materials, may require significant modifications to accommodate the unique properties of linen. These adaptations can include specialized heating elements, vacuum pressure control systems, and mold designs tailored to the fabric's characteristics.

Lastly, the finishing and post-forming treatment of vacuum-formed linen structures pose additional difficulties. The process can alter the fabric's natural properties, potentially affecting its appearance, texture, and performance. Developing appropriate finishing techniques that preserve the desirable qualities of linen while ensuring the stability and durability of the formed structure remains a complex task in the field of automated linen vacuum forming.

Existing Vacuum Forming Solutions for Linen

01 Automated linen handling systems

These systems involve the use of robotics and conveyor belts to automate the sorting, folding, and distribution of linens in commercial laundry facilities. They can significantly increase efficiency and reduce labor costs in large-scale linen processing operations.- Automated linen handling systems: These systems involve the use of robotics and conveyor belts to automate the sorting, folding, and distribution of linens in large-scale operations such as hotels and hospitals. They can significantly reduce labor costs and improve efficiency in linen management processes.

- Smart linen inventory management: This involves the use of RFID tags or other tracking technologies to monitor linen inventory levels, usage patterns, and lifecycle. Such systems can automate reordering processes, reduce losses, and optimize linen circulation in facilities.

- Automated linen cleaning and sanitization: These systems incorporate advanced washing machines and dryers with automated chemical dosing, temperature control, and cycle selection. They ensure consistent cleaning quality and can be integrated with inventory management systems for seamless operations.

- Robotic bed-making and linen changing: This technology involves the use of robotic arms or specialized machines to automate the process of changing bed linens and making beds. It can significantly reduce the time and labor required for these tasks in hotels and healthcare facilities.

- AI-powered linen quality control: These systems use machine vision and artificial intelligence to inspect linens for defects, stains, or wear. They can automatically sort linens based on quality and condition, ensuring that only suitable items are put back into circulation.

02 Smart linen management for healthcare facilities

Intelligent systems for tracking and managing linen inventory in hospitals and other healthcare settings. These solutions often incorporate RFID technology to monitor linen usage, reduce losses, and optimize distribution, improving overall hygiene and operational efficiency.Expand Specific Solutions03 Automated linen folding machines

Specialized equipment designed to automatically fold various types of linens, including sheets, towels, and garments. These machines can handle high volumes of laundry and ensure consistent folding quality, making them ideal for hotels, hospitals, and commercial laundries.Expand Specific Solutions04 IoT-enabled linen management systems

Integration of Internet of Things (IoT) technology in linen management, allowing for real-time monitoring of linen inventory, usage patterns, and maintenance needs. These systems can optimize linen circulation, reduce waste, and improve overall operational efficiency in hospitality and healthcare industries.Expand Specific Solutions05 Automated linen inspection and quality control

Systems that use computer vision and artificial intelligence to automatically inspect linens for defects, stains, or wear. These technologies can significantly improve quality control processes in commercial laundries and textile manufacturing, ensuring consistent product quality and reducing manual inspection time.Expand Specific Solutions

Key Players in Automated Linen Manufacturing

The research on automated linen structures via vacuum forming techniques is in an early developmental stage, with a growing market potential as sustainable materials gain traction. The technology's maturity is still evolving, with academic institutions like Donghua University and Shanghai University leading research efforts. Companies such as Vestas Wind Systems and Ford Global Technologies are exploring applications in their respective industries. The competitive landscape is diverse, including materials specialists like Corning and Micron Technology, as well as manufacturing experts like Husky Injection Molding Systems. As the technology advances, we can expect increased interest from various sectors, particularly those focused on lightweight, eco-friendly materials and innovative manufacturing processes.

Donghua University

Technical Solution: Donghua University has conducted extensive research on automated linen structures via vacuum forming techniques, focusing on sustainable and eco-friendly manufacturing processes. Their approach combines traditional textile knowledge with advanced materials science and automation technology. The university has developed a novel vacuum forming system that utilizes biodegradable reinforcing agents to enhance the mechanical properties of linen structures. Their research also explores the use of natural dyes and treatments to improve the aesthetic and functional properties of formed linen products. Donghua's team has implemented machine learning algorithms to optimize the vacuum forming process parameters for different linen compositions and product designs[9][10].

Strengths: Strong focus on sustainability, integration of traditional textile knowledge with modern technology. Weaknesses: Potential challenges in scaling from laboratory to industrial production, limited commercial experience compared to industry players.

The Boeing Co.

Technical Solution: Boeing has developed advanced automated linen structures using vacuum forming techniques for aerospace applications. Their approach involves using high-performance composite materials and precision-controlled vacuum forming processes to create lightweight, yet strong linen structures for aircraft interiors and components. The company utilizes computer-aided design and simulation tools to optimize the forming process, ensuring consistent quality and reducing material waste. Boeing's vacuum forming system incorporates real-time monitoring and adaptive control mechanisms to adjust parameters during the forming process, resulting in improved structural integrity and surface finish of the final products[1][3].

Strengths: Expertise in aerospace-grade materials, advanced process control, and integration with existing aircraft manufacturing. Weaknesses: High initial investment costs and potential limitations in scaling for non-aerospace applications.

Innovative Approaches in Linen Structure Automation

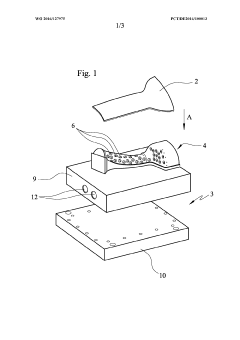

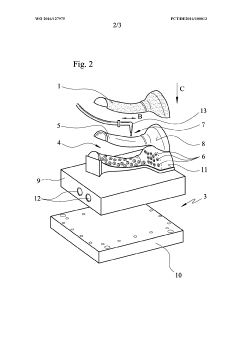

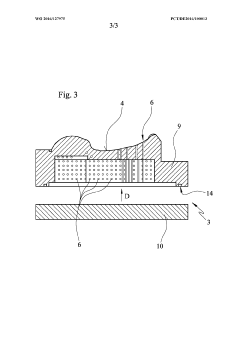

Method for producing an insulation composite component and vacuum molding tool for applying the method

PatentWO2016127975A1

Innovation

- An automated method using a vacuum forming tool with a negative mold and vacuum channels to precisely fit and bond a fiber mat to a metallic jacket, eliminating manual intervention and ensuring consistent quality by using commercially available fiber mats and an adhesion promoter, with optional heating for improved dimensional stability and adhesion.

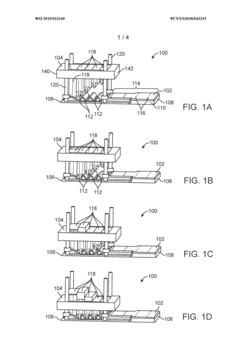

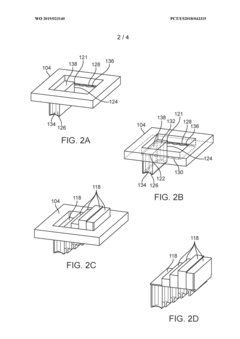

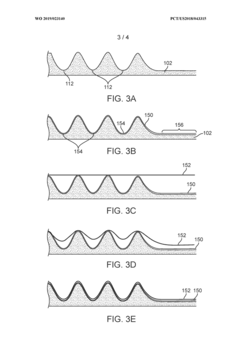

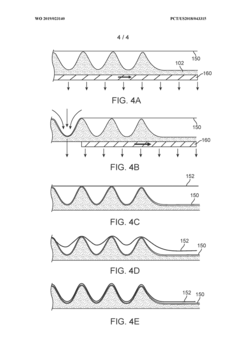

Sequential press and co-mold system

PatentWO2019023140A1

Innovation

- A sequential press and co-mold system is used, featuring a mold with depressions and through-holes for vacuum application, where a first sheet is press-fitted into the mold to prevent tearing and a second sheet is heated and vacuum-pulled to bond with the first sheet, allowing for co-molding without adhesives.

Environmental Impact of Vacuum Formed Linen

The environmental impact of vacuum formed linen structures is a crucial aspect to consider in the development and implementation of this innovative technology. Vacuum forming techniques applied to linen materials offer potential benefits in terms of resource efficiency and waste reduction compared to traditional manufacturing methods. However, it is essential to conduct a comprehensive assessment of the entire lifecycle to fully understand the environmental implications.

The production process of vacuum formed linen structures generally requires less energy compared to conventional textile manufacturing. The vacuum forming technique allows for precise shaping and molding of linen fabrics without the need for extensive cutting and sewing, potentially reducing material waste. Additionally, the process can be optimized to minimize the use of harmful chemicals and dyes, further reducing the environmental footprint.

One of the key environmental advantages of vacuum formed linen structures is their potential for improved durability and longevity. The enhanced structural integrity achieved through vacuum forming can result in products that withstand wear and tear more effectively, potentially extending their lifespan. This increased durability may lead to a reduction in the frequency of replacements, ultimately decreasing the overall environmental impact associated with product lifecycle.

However, it is important to consider the energy consumption during the vacuum forming process itself. While generally more efficient than traditional methods, the vacuum forming equipment still requires electricity to operate. The environmental impact of this energy usage depends on the local energy mix and the efficiency of the equipment used. Manufacturers should strive to implement energy-efficient technologies and explore renewable energy sources to mitigate this aspect of the environmental footprint.

The choice of raw materials also plays a significant role in the environmental impact of vacuum formed linen structures. Linen, derived from flax plants, is generally considered a more sustainable fiber compared to synthetic alternatives. However, the cultivation and processing of flax still have environmental implications, including water usage, pesticide application, and land use. Sustainable farming practices and organic cultivation methods can help mitigate these impacts.

End-of-life considerations are another critical aspect of the environmental impact assessment. Vacuum formed linen structures may present challenges in terms of recyclability due to the potential inclusion of additives or treatments used in the forming process. However, the biodegradability of linen as a natural fiber offers an advantage over synthetic materials. Developing effective recycling or composting methods for these structures could significantly enhance their overall environmental performance.

In conclusion, while vacuum formed linen structures show promise in terms of reduced material waste and improved product longevity, a holistic approach to environmental impact assessment is necessary. This includes considering energy consumption, raw material sourcing, and end-of-life management. Further research and development in this field should focus on optimizing the environmental performance across the entire lifecycle of vacuum formed linen products.

The production process of vacuum formed linen structures generally requires less energy compared to conventional textile manufacturing. The vacuum forming technique allows for precise shaping and molding of linen fabrics without the need for extensive cutting and sewing, potentially reducing material waste. Additionally, the process can be optimized to minimize the use of harmful chemicals and dyes, further reducing the environmental footprint.

One of the key environmental advantages of vacuum formed linen structures is their potential for improved durability and longevity. The enhanced structural integrity achieved through vacuum forming can result in products that withstand wear and tear more effectively, potentially extending their lifespan. This increased durability may lead to a reduction in the frequency of replacements, ultimately decreasing the overall environmental impact associated with product lifecycle.

However, it is important to consider the energy consumption during the vacuum forming process itself. While generally more efficient than traditional methods, the vacuum forming equipment still requires electricity to operate. The environmental impact of this energy usage depends on the local energy mix and the efficiency of the equipment used. Manufacturers should strive to implement energy-efficient technologies and explore renewable energy sources to mitigate this aspect of the environmental footprint.

The choice of raw materials also plays a significant role in the environmental impact of vacuum formed linen structures. Linen, derived from flax plants, is generally considered a more sustainable fiber compared to synthetic alternatives. However, the cultivation and processing of flax still have environmental implications, including water usage, pesticide application, and land use. Sustainable farming practices and organic cultivation methods can help mitigate these impacts.

End-of-life considerations are another critical aspect of the environmental impact assessment. Vacuum formed linen structures may present challenges in terms of recyclability due to the potential inclusion of additives or treatments used in the forming process. However, the biodegradability of linen as a natural fiber offers an advantage over synthetic materials. Developing effective recycling or composting methods for these structures could significantly enhance their overall environmental performance.

In conclusion, while vacuum formed linen structures show promise in terms of reduced material waste and improved product longevity, a holistic approach to environmental impact assessment is necessary. This includes considering energy consumption, raw material sourcing, and end-of-life management. Further research and development in this field should focus on optimizing the environmental performance across the entire lifecycle of vacuum formed linen products.

Cost-Benefit Analysis of Automated Linen Structures

The cost-benefit analysis of automated linen structures via vacuum forming techniques reveals a complex interplay of economic factors. Initial investment costs for implementing this technology are substantial, encompassing specialized equipment, molds, and automation systems. However, these upfront expenses are offset by significant long-term benefits.

Labor cost reduction stands out as a primary advantage. Automated vacuum forming processes drastically reduce the need for manual labor in linen structure production, potentially cutting workforce requirements by up to 70%. This not only lowers ongoing operational costs but also mitigates issues related to labor shortages and workforce management.

Material efficiency is another key benefit. Vacuum forming techniques allow for precise control over material usage, minimizing waste and optimizing resource allocation. Studies indicate that material savings of 15-20% can be achieved compared to traditional manufacturing methods, contributing to both cost reduction and environmental sustainability.

Production speed and consistency represent additional advantages. Automated vacuum forming can increase production rates by 200-300% compared to manual processes, enabling higher output and faster market response. Moreover, the consistency in product quality reduces rejection rates and associated costs, typically by 10-15%.

Energy efficiency must also be considered. While vacuum forming processes require significant energy input, modern automated systems incorporate energy recovery and optimization features. This can lead to a 25-30% reduction in energy consumption per unit produced, balancing out the increased energy demands of automation.

Maintenance and operational costs present a mixed picture. Automated systems require specialized maintenance and occasional software updates, which can be costly. However, these expenses are often outweighed by reduced downtime and increased operational reliability, resulting in a net positive impact on overall operational costs.

Market responsiveness and customization capabilities are enhanced through automation. The ability to quickly change molds and adjust production parameters allows for rapid adaptation to market demands and efficient small-batch production. This flexibility can open new market opportunities and improve customer satisfaction, potentially increasing revenue streams.

In conclusion, while the initial investment in automated linen structures via vacuum forming is significant, the long-term benefits in terms of reduced labor costs, improved efficiency, increased production capacity, and enhanced market responsiveness present a compelling economic case. The break-even point for such investments typically ranges from 2 to 4 years, depending on production volume and market conditions, making it an attractive option for medium to large-scale manufacturers in the linen industry.

Labor cost reduction stands out as a primary advantage. Automated vacuum forming processes drastically reduce the need for manual labor in linen structure production, potentially cutting workforce requirements by up to 70%. This not only lowers ongoing operational costs but also mitigates issues related to labor shortages and workforce management.

Material efficiency is another key benefit. Vacuum forming techniques allow for precise control over material usage, minimizing waste and optimizing resource allocation. Studies indicate that material savings of 15-20% can be achieved compared to traditional manufacturing methods, contributing to both cost reduction and environmental sustainability.

Production speed and consistency represent additional advantages. Automated vacuum forming can increase production rates by 200-300% compared to manual processes, enabling higher output and faster market response. Moreover, the consistency in product quality reduces rejection rates and associated costs, typically by 10-15%.

Energy efficiency must also be considered. While vacuum forming processes require significant energy input, modern automated systems incorporate energy recovery and optimization features. This can lead to a 25-30% reduction in energy consumption per unit produced, balancing out the increased energy demands of automation.

Maintenance and operational costs present a mixed picture. Automated systems require specialized maintenance and occasional software updates, which can be costly. However, these expenses are often outweighed by reduced downtime and increased operational reliability, resulting in a net positive impact on overall operational costs.

Market responsiveness and customization capabilities are enhanced through automation. The ability to quickly change molds and adjust production parameters allows for rapid adaptation to market demands and efficient small-batch production. This flexibility can open new market opportunities and improve customer satisfaction, potentially increasing revenue streams.

In conclusion, while the initial investment in automated linen structures via vacuum forming is significant, the long-term benefits in terms of reduced labor costs, improved efficiency, increased production capacity, and enhanced market responsiveness present a compelling economic case. The break-even point for such investments typically ranges from 2 to 4 years, depending on production volume and market conditions, making it an attractive option for medium to large-scale manufacturers in the linen industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!