How Smart Sensors Enhance Vacuum Forming Stages

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Sensor Evolution in Vacuum Forming

The evolution of smart sensors in vacuum forming has been a transformative journey, significantly enhancing the efficiency and precision of the manufacturing process. Initially, vacuum forming relied on basic pressure and temperature sensors to monitor the process. These early sensors provided limited data, often requiring manual interpretation and adjustments.

As technology advanced, the integration of more sophisticated sensors began to revolutionize the vacuum forming industry. The introduction of infrared temperature sensors allowed for more accurate and real-time monitoring of sheet temperature, crucial for achieving optimal forming conditions. Pressure sensors evolved to provide more granular data on vacuum levels, enabling finer control over the forming process.

The advent of smart sensors marked a significant leap forward. These sensors not only collected data but also incorporated processing capabilities, allowing for on-the-spot analysis and decision-making. Smart thickness sensors, for instance, could continuously monitor material thickness during the forming process, adjusting parameters in real-time to maintain consistency and quality.

Another milestone in sensor evolution was the development of multi-parameter sensors. These devices could simultaneously measure various aspects of the forming process, such as temperature, pressure, and material flow. This holistic approach to data collection provided a more comprehensive understanding of the forming dynamics, leading to improved product quality and reduced waste.

The integration of wireless technology into smart sensors further enhanced their utility in vacuum forming. Wireless sensors could be placed in previously inaccessible areas of the forming machine, providing data from critical points without the limitations of wired connections. This advancement not only improved data collection but also simplified machine setup and maintenance.

Recent years have seen the emergence of AI-enhanced smart sensors in vacuum forming. These cutting-edge devices utilize machine learning algorithms to analyze historical and real-time data, predicting potential issues before they occur and suggesting optimal process parameters. This predictive capability has significantly reduced downtime and improved overall production efficiency.

The latest frontier in smart sensor evolution for vacuum forming is the development of nano-sensors. These microscopic devices can be embedded directly into the forming materials, providing unprecedented insights into material behavior at the molecular level during the forming process. While still in the experimental stage, nano-sensors promise to revolutionize material science in vacuum forming, potentially leading to the development of new, high-performance materials tailored for specific forming applications.

As technology advanced, the integration of more sophisticated sensors began to revolutionize the vacuum forming industry. The introduction of infrared temperature sensors allowed for more accurate and real-time monitoring of sheet temperature, crucial for achieving optimal forming conditions. Pressure sensors evolved to provide more granular data on vacuum levels, enabling finer control over the forming process.

The advent of smart sensors marked a significant leap forward. These sensors not only collected data but also incorporated processing capabilities, allowing for on-the-spot analysis and decision-making. Smart thickness sensors, for instance, could continuously monitor material thickness during the forming process, adjusting parameters in real-time to maintain consistency and quality.

Another milestone in sensor evolution was the development of multi-parameter sensors. These devices could simultaneously measure various aspects of the forming process, such as temperature, pressure, and material flow. This holistic approach to data collection provided a more comprehensive understanding of the forming dynamics, leading to improved product quality and reduced waste.

The integration of wireless technology into smart sensors further enhanced their utility in vacuum forming. Wireless sensors could be placed in previously inaccessible areas of the forming machine, providing data from critical points without the limitations of wired connections. This advancement not only improved data collection but also simplified machine setup and maintenance.

Recent years have seen the emergence of AI-enhanced smart sensors in vacuum forming. These cutting-edge devices utilize machine learning algorithms to analyze historical and real-time data, predicting potential issues before they occur and suggesting optimal process parameters. This predictive capability has significantly reduced downtime and improved overall production efficiency.

The latest frontier in smart sensor evolution for vacuum forming is the development of nano-sensors. These microscopic devices can be embedded directly into the forming materials, providing unprecedented insights into material behavior at the molecular level during the forming process. While still in the experimental stage, nano-sensors promise to revolutionize material science in vacuum forming, potentially leading to the development of new, high-performance materials tailored for specific forming applications.

Market Demand Analysis

The market demand for smart sensors in vacuum forming processes has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for enhanced efficiency, quality control, and automation in manufacturing industries. Vacuum forming, a widely used technique in packaging, automotive, and consumer goods production, has traditionally relied on manual monitoring and adjustments. However, the integration of smart sensors is revolutionizing this process, offering real-time data collection, analysis, and process optimization.

In the packaging industry, which accounts for a substantial portion of vacuum forming applications, there is a growing demand for sensors that can monitor and control temperature, pressure, and material thickness. These sensors enable manufacturers to produce more consistent and higher-quality packaging materials while reducing waste and energy consumption. The food and beverage sector, in particular, is showing keen interest in smart sensor technologies that can ensure food safety and extend shelf life through precise packaging control.

The automotive industry is another major driver of market demand for smart sensors in vacuum forming. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing use of vacuum-formed components in car interiors and exteriors. Smart sensors play a crucial role in ensuring the dimensional accuracy and structural integrity of these parts, meeting the stringent quality standards of the automotive sector.

Consumer electronics and appliance manufacturers are also contributing to the growing demand for smart sensor-enhanced vacuum forming. These industries require precise control over the forming process to create complex shapes and maintain tight tolerances for device casings and panels. Smart sensors enable real-time adjustments during the forming process, resulting in higher yields and reduced defect rates.

The healthcare and medical device industry is emerging as a significant market for smart sensor applications in vacuum forming. The production of medical packaging, disposable medical devices, and customized orthopedic products demands extremely high precision and consistency. Smart sensors provide the necessary monitoring and control capabilities to meet these exacting requirements, ensuring product safety and regulatory compliance.

As Industry 4.0 and smart manufacturing concepts gain traction globally, the demand for data-driven process control in vacuum forming is expected to accelerate. Manufacturers are increasingly looking for integrated sensor systems that can seamlessly connect with their existing industrial IoT infrastructure, providing valuable insights for predictive maintenance and process optimization.

The market for smart sensors in vacuum forming is also being propelled by the growing emphasis on sustainability and energy efficiency. Sensors that can optimize material usage, reduce energy consumption, and minimize waste are becoming increasingly attractive to manufacturers looking to reduce their environmental footprint and operational costs.

In the packaging industry, which accounts for a substantial portion of vacuum forming applications, there is a growing demand for sensors that can monitor and control temperature, pressure, and material thickness. These sensors enable manufacturers to produce more consistent and higher-quality packaging materials while reducing waste and energy consumption. The food and beverage sector, in particular, is showing keen interest in smart sensor technologies that can ensure food safety and extend shelf life through precise packaging control.

The automotive industry is another major driver of market demand for smart sensors in vacuum forming. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is an increasing use of vacuum-formed components in car interiors and exteriors. Smart sensors play a crucial role in ensuring the dimensional accuracy and structural integrity of these parts, meeting the stringent quality standards of the automotive sector.

Consumer electronics and appliance manufacturers are also contributing to the growing demand for smart sensor-enhanced vacuum forming. These industries require precise control over the forming process to create complex shapes and maintain tight tolerances for device casings and panels. Smart sensors enable real-time adjustments during the forming process, resulting in higher yields and reduced defect rates.

The healthcare and medical device industry is emerging as a significant market for smart sensor applications in vacuum forming. The production of medical packaging, disposable medical devices, and customized orthopedic products demands extremely high precision and consistency. Smart sensors provide the necessary monitoring and control capabilities to meet these exacting requirements, ensuring product safety and regulatory compliance.

As Industry 4.0 and smart manufacturing concepts gain traction globally, the demand for data-driven process control in vacuum forming is expected to accelerate. Manufacturers are increasingly looking for integrated sensor systems that can seamlessly connect with their existing industrial IoT infrastructure, providing valuable insights for predictive maintenance and process optimization.

The market for smart sensors in vacuum forming is also being propelled by the growing emphasis on sustainability and energy efficiency. Sensors that can optimize material usage, reduce energy consumption, and minimize waste are becoming increasingly attractive to manufacturers looking to reduce their environmental footprint and operational costs.

Current Challenges in Vacuum Forming Sensing

Vacuum forming is a widely used manufacturing process in various industries, but it faces several challenges when it comes to sensing and monitoring. One of the primary issues is the lack of real-time feedback during the forming process. Traditional methods often rely on post-production quality checks, which can lead to material waste and inefficiencies.

The integration of smart sensors into vacuum forming stages presents a significant opportunity to address these challenges. However, implementing effective sensing solutions is not without its difficulties. The high-temperature environment of vacuum forming can pose problems for sensor durability and accuracy. Many conventional sensors are not designed to withstand the heat and pressure involved in the process, limiting their applicability.

Another challenge lies in the complexity of data interpretation. While sensors can collect vast amounts of data, translating this information into actionable insights requires sophisticated algorithms and data analysis techniques. Many manufacturers struggle to develop or implement these advanced analytical capabilities, hindering their ability to fully leverage sensor technology.

The variability of materials used in vacuum forming further complicates sensing efforts. Different plastics and composites behave uniquely under heat and pressure, necessitating adaptive sensing solutions. Current sensor technologies often lack the versatility to accurately monitor a wide range of materials without recalibration or replacement.

Space constraints within vacuum forming machinery present another obstacle. Integrating sensors without disrupting the forming process or compromising the quality of the final product can be challenging. This limitation often forces engineers to make trade-offs between sensor placement and manufacturing efficiency.

The cost of implementing comprehensive sensing systems remains a significant barrier for many manufacturers, especially small and medium-sized enterprises. High-quality sensors, data processing equipment, and the necessary software can represent a substantial investment, which may be difficult to justify without clear evidence of return on investment.

Lastly, there is a notable skills gap in the industry when it comes to operating and maintaining advanced sensing systems. Many operators and technicians are not trained in interpreting sensor data or troubleshooting sophisticated monitoring equipment. This lack of expertise can lead to underutilization of sensing capabilities or misinterpretation of data, potentially negating the benefits of smart sensor integration.

Addressing these challenges is crucial for advancing the state of vacuum forming technology. As the industry moves towards more automated and precise manufacturing processes, overcoming these sensing hurdles will be key to improving product quality, reducing waste, and enhancing overall production efficiency.

The integration of smart sensors into vacuum forming stages presents a significant opportunity to address these challenges. However, implementing effective sensing solutions is not without its difficulties. The high-temperature environment of vacuum forming can pose problems for sensor durability and accuracy. Many conventional sensors are not designed to withstand the heat and pressure involved in the process, limiting their applicability.

Another challenge lies in the complexity of data interpretation. While sensors can collect vast amounts of data, translating this information into actionable insights requires sophisticated algorithms and data analysis techniques. Many manufacturers struggle to develop or implement these advanced analytical capabilities, hindering their ability to fully leverage sensor technology.

The variability of materials used in vacuum forming further complicates sensing efforts. Different plastics and composites behave uniquely under heat and pressure, necessitating adaptive sensing solutions. Current sensor technologies often lack the versatility to accurately monitor a wide range of materials without recalibration or replacement.

Space constraints within vacuum forming machinery present another obstacle. Integrating sensors without disrupting the forming process or compromising the quality of the final product can be challenging. This limitation often forces engineers to make trade-offs between sensor placement and manufacturing efficiency.

The cost of implementing comprehensive sensing systems remains a significant barrier for many manufacturers, especially small and medium-sized enterprises. High-quality sensors, data processing equipment, and the necessary software can represent a substantial investment, which may be difficult to justify without clear evidence of return on investment.

Lastly, there is a notable skills gap in the industry when it comes to operating and maintaining advanced sensing systems. Many operators and technicians are not trained in interpreting sensor data or troubleshooting sophisticated monitoring equipment. This lack of expertise can lead to underutilization of sensing capabilities or misinterpretation of data, potentially negating the benefits of smart sensor integration.

Addressing these challenges is crucial for advancing the state of vacuum forming technology. As the industry moves towards more automated and precise manufacturing processes, overcoming these sensing hurdles will be key to improving product quality, reducing waste, and enhancing overall production efficiency.

Existing Smart Sensor Solutions

01 Enhanced sensor data processing and analysis

Advanced algorithms and machine learning techniques are employed to improve the processing and analysis of sensor data. This enhancement allows for more accurate interpretation of sensor readings, noise reduction, and the extraction of meaningful insights from complex data streams.- Integration of AI and machine learning in smart sensors: Smart sensors are being enhanced with artificial intelligence and machine learning capabilities. This integration allows for more sophisticated data analysis, pattern recognition, and predictive capabilities. These advanced sensors can adapt to changing environments, improve accuracy, and provide more meaningful insights from collected data.

- Improved energy efficiency and power management: Enhancements in smart sensor technology focus on reducing power consumption and improving energy efficiency. This includes the development of low-power sensors, energy harvesting techniques, and optimized power management systems. These advancements enable longer battery life and the potential for self-powered sensors in various applications.

- Enhanced connectivity and communication protocols: Smart sensors are being improved with advanced connectivity features and communication protocols. This includes the integration of wireless technologies, IoT compatibility, and support for various network standards. These enhancements enable seamless data transmission, real-time monitoring, and improved interoperability with other devices and systems.

- Miniaturization and improved form factors: Advancements in smart sensor technology focus on miniaturization and the development of more compact form factors. This includes the use of nanotechnology, MEMS (Micro-Electro-Mechanical Systems), and advanced manufacturing techniques. These improvements allow for the integration of sensors into smaller devices and enable new applications in various fields.

- Multi-sensor fusion and data integration: Smart sensor enhancements involve the integration of multiple sensing modalities and data fusion techniques. This approach combines data from various sensors to provide more comprehensive and accurate information. Multi-sensor fusion enables improved situational awareness, enhanced decision-making capabilities, and more robust sensing systems across different applications.

02 Integration of multiple sensor types

Smart sensor systems are enhanced by integrating various types of sensors, such as environmental, motion, and biometric sensors. This multi-sensor approach provides a more comprehensive and accurate understanding of the monitored environment or subject, enabling more sophisticated applications and decision-making processes.Expand Specific Solutions03 Improved energy efficiency and power management

Advancements in power management techniques and low-power components enhance the energy efficiency of smart sensors. This improvement extends battery life, enables long-term deployment in remote locations, and supports the development of self-powered or energy-harvesting sensor systems.Expand Specific Solutions04 Enhanced connectivity and communication protocols

Smart sensors are equipped with improved wireless communication capabilities and protocols, enabling seamless integration with IoT networks and cloud platforms. This enhancement facilitates real-time data transmission, remote monitoring, and the creation of large-scale sensor networks for various applications.Expand Specific Solutions05 Advanced calibration and self-diagnostic features

Smart sensors incorporate sophisticated calibration techniques and self-diagnostic capabilities. These features ensure long-term accuracy, reduce maintenance requirements, and enable sensors to adapt to changing environmental conditions or detect potential malfunctions autonomously.Expand Specific Solutions

Key Industry Players

The smart sensor market for vacuum forming is in a growth phase, driven by increasing demand for automation and quality control in manufacturing. The market size is expanding rapidly, with projections indicating significant growth over the next few years. Technologically, smart sensors for vacuum forming are advancing, with companies like Samsung Electronics, ULVAC, and NEC Corp leading innovation. These firms are developing more sophisticated sensors with improved accuracy, real-time monitoring capabilities, and integration with IoT systems. However, the technology is still evolving, with opportunities for further enhancements in areas such as miniaturization, energy efficiency, and data analytics integration.

ULVAC, Inc.

Technical Solution: ULVAC has developed advanced smart sensor technologies to enhance vacuum forming stages. Their approach integrates multiple sensor types, including pressure, temperature, and gas composition sensors, to provide real-time monitoring and control of the vacuum forming process. The system utilizes machine learning algorithms to analyze sensor data and optimize process parameters dynamically. This results in improved product quality, reduced material waste, and increased energy efficiency. ULVAC's smart sensors can detect minute changes in vacuum levels and adjust the process accordingly, ensuring consistent results across production runs[1][3]. The company has also implemented IoT connectivity, allowing for remote monitoring and predictive maintenance of vacuum forming equipment.

Strengths: Comprehensive sensor integration, real-time process optimization, and IoT connectivity. Weaknesses: Potentially high initial implementation costs and requires specialized training for operators.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a range of MEMS-based smart sensors for vacuum forming applications. Their technology focuses on miniaturization and energy efficiency, making it ideal for integration into compact vacuum forming systems. Murata's sensors utilize piezoelectric elements to detect minute pressure changes and vibrations during the forming process. The company has also developed wireless sensor networks that can be easily retrofitted to existing vacuum forming equipment, providing a cost-effective upgrade path for manufacturers[6]. Murata's smart sensors are particularly effective in detecting and preventing material thinning and webbing issues in complex mold geometries.

Strengths: Compact design, energy-efficient operation, and easy retrofit capabilities. Weaknesses: May have limited range compared to larger sensor systems in industrial-scale applications.

Innovative Sensor Designs

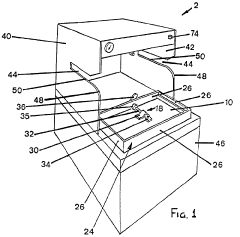

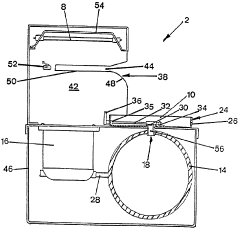

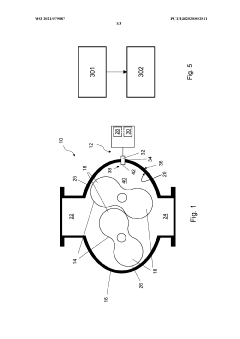

A vacuum forming machine in which vacuum is automatically initiated upon delivery of the sheet to the machine

PatentInactiveGB2248579A

Innovation

- A simplified vacuum forming machine design featuring a holder that moves from a heating position to a forming position automatically operates the valve, creating a vacuum to shape the plastic sheet, with a spring-biased valve plate and guide means for easy operation and reduced manual intervention.

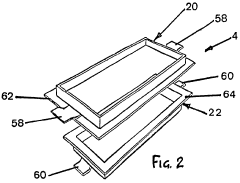

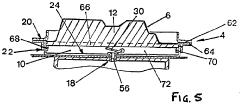

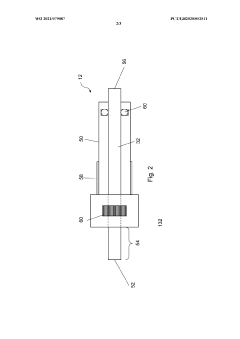

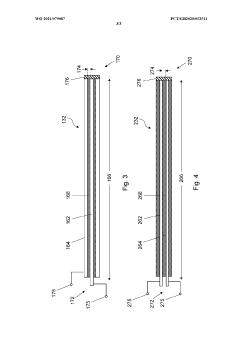

Sensor assembly

PatentWO2021079087A1

Innovation

- A sensor assembly with a probe forming an incomplete circuit that completes only when engaged by a moving part, producing a signal to activate a shut-down process or alert, reducing data output and allowing for reduced supervision and maintenance, featuring a low-volume data output and cost-effective design.

Regulatory Compliance for Smart Manufacturing

Regulatory compliance is a critical aspect of smart manufacturing, particularly when implementing smart sensors in vacuum forming processes. As industries increasingly adopt advanced technologies, they must navigate a complex landscape of regulations to ensure safety, quality, and environmental protection.

In the context of vacuum forming enhanced by smart sensors, manufacturers must adhere to various standards and regulations. These include safety regulations such as OSHA (Occupational Safety and Health Administration) guidelines in the United States, which mandate the proper use and maintenance of equipment to prevent workplace accidents. Smart sensors can play a crucial role in meeting these requirements by providing real-time monitoring of machine operations and environmental conditions.

Quality control regulations, such as ISO 9001 standards, are also relevant to smart manufacturing processes. Smart sensors in vacuum forming can contribute to compliance by ensuring consistent product quality through precise monitoring of temperature, pressure, and material properties. This data-driven approach aligns with the ISO's emphasis on measurable quality management systems.

Environmental regulations, including those related to energy efficiency and waste reduction, are increasingly important in manufacturing. Smart sensors can help companies comply with these regulations by optimizing energy consumption during the vacuum forming process and minimizing material waste through precise control and predictive maintenance.

Data privacy and security regulations, such as GDPR in Europe or CCPA in California, must be considered when implementing smart sensor systems. These regulations govern the collection, storage, and use of data generated by smart manufacturing processes. Manufacturers must ensure that their sensor networks and data management practices comply with these privacy laws.

Industry-specific regulations may also apply, depending on the end-use of vacuum-formed products. For example, in the food packaging industry, FDA regulations in the United States or EFSA guidelines in Europe dictate material safety and hygiene standards. Smart sensors can aid in compliance by monitoring and documenting production conditions that affect food safety.

Compliance with electromagnetic compatibility (EMC) regulations is essential when integrating smart sensors into vacuum forming equipment. These regulations ensure that electronic devices do not interfere with each other or with other electrical systems in the manufacturing environment.

As smart manufacturing technologies evolve, regulatory frameworks are also adapting. Manufacturers must stay informed about emerging regulations related to artificial intelligence, machine learning, and Internet of Things (IoT) devices, as these may impact the use of smart sensors in vacuum forming processes.

To ensure comprehensive regulatory compliance, manufacturers should implement robust quality management systems, conduct regular audits, and maintain detailed documentation of their smart manufacturing processes. This approach not only helps in meeting current regulations but also positions companies to adapt to future regulatory changes in the rapidly evolving landscape of smart manufacturing.

In the context of vacuum forming enhanced by smart sensors, manufacturers must adhere to various standards and regulations. These include safety regulations such as OSHA (Occupational Safety and Health Administration) guidelines in the United States, which mandate the proper use and maintenance of equipment to prevent workplace accidents. Smart sensors can play a crucial role in meeting these requirements by providing real-time monitoring of machine operations and environmental conditions.

Quality control regulations, such as ISO 9001 standards, are also relevant to smart manufacturing processes. Smart sensors in vacuum forming can contribute to compliance by ensuring consistent product quality through precise monitoring of temperature, pressure, and material properties. This data-driven approach aligns with the ISO's emphasis on measurable quality management systems.

Environmental regulations, including those related to energy efficiency and waste reduction, are increasingly important in manufacturing. Smart sensors can help companies comply with these regulations by optimizing energy consumption during the vacuum forming process and minimizing material waste through precise control and predictive maintenance.

Data privacy and security regulations, such as GDPR in Europe or CCPA in California, must be considered when implementing smart sensor systems. These regulations govern the collection, storage, and use of data generated by smart manufacturing processes. Manufacturers must ensure that their sensor networks and data management practices comply with these privacy laws.

Industry-specific regulations may also apply, depending on the end-use of vacuum-formed products. For example, in the food packaging industry, FDA regulations in the United States or EFSA guidelines in Europe dictate material safety and hygiene standards. Smart sensors can aid in compliance by monitoring and documenting production conditions that affect food safety.

Compliance with electromagnetic compatibility (EMC) regulations is essential when integrating smart sensors into vacuum forming equipment. These regulations ensure that electronic devices do not interfere with each other or with other electrical systems in the manufacturing environment.

As smart manufacturing technologies evolve, regulatory frameworks are also adapting. Manufacturers must stay informed about emerging regulations related to artificial intelligence, machine learning, and Internet of Things (IoT) devices, as these may impact the use of smart sensors in vacuum forming processes.

To ensure comprehensive regulatory compliance, manufacturers should implement robust quality management systems, conduct regular audits, and maintain detailed documentation of their smart manufacturing processes. This approach not only helps in meeting current regulations but also positions companies to adapt to future regulatory changes in the rapidly evolving landscape of smart manufacturing.

Energy Efficiency Improvements

Smart sensors play a crucial role in enhancing energy efficiency throughout the vacuum forming process. By integrating advanced sensing technologies, manufacturers can significantly reduce energy consumption while maintaining or even improving product quality. These sensors provide real-time data on various parameters, enabling precise control and optimization of energy usage across different stages of the vacuum forming process.

One of the primary areas where smart sensors contribute to energy efficiency is in temperature management. Vacuum forming requires precise heating of thermoplastic sheets, and traditional methods often result in overheating or uneven heat distribution. Smart temperature sensors, such as infrared arrays or thermocouples, can continuously monitor the sheet temperature across its entire surface. This data allows for dynamic adjustment of heating elements, ensuring that only the necessary amount of energy is used to achieve the desired temperature profile.

Pressure sensors are another key component in improving energy efficiency. By accurately measuring the vacuum pressure during the forming stage, these sensors enable fine-tuning of the vacuum pumps. This optimization prevents excessive energy consumption from overworking the pumps while still maintaining the required forming pressure. Additionally, pressure sensors can detect leaks or inefficiencies in the system, allowing for prompt maintenance and preventing energy waste.

Motion and position sensors contribute to energy savings by optimizing the movement of machine components. These sensors ensure that actuators and mechanical parts operate with minimal energy expenditure, moving only as much as necessary to complete the forming process. By reducing unnecessary motion and optimizing cycle times, the overall energy consumption of the vacuum forming machine is decreased.

Smart power monitoring sensors integrated into the vacuum forming equipment provide valuable insights into energy usage patterns. These sensors can identify peak consumption periods, standby power draw, and inefficiencies in individual components. By analyzing this data, manufacturers can implement targeted energy-saving strategies, such as scheduling high-energy operations during off-peak hours or upgrading specific components to more energy-efficient alternatives.

The integration of these smart sensors with advanced control systems and machine learning algorithms further enhances energy efficiency. Predictive maintenance algorithms can analyze sensor data to anticipate equipment failures or performance degradation, scheduling maintenance before issues lead to increased energy consumption. Additionally, machine learning models can optimize process parameters in real-time, continuously adjusting settings to maintain the best balance between product quality and energy efficiency.

By leveraging smart sensor technology, vacuum forming processes can achieve significant reductions in energy consumption, often ranging from 15% to 30% compared to traditional methods. This not only reduces operational costs but also aligns with sustainability goals and regulatory requirements for energy efficiency in manufacturing. As sensor technology continues to advance, the potential for further energy optimization in vacuum forming processes remains promising, driving the industry towards more sustainable and efficient production methods.

One of the primary areas where smart sensors contribute to energy efficiency is in temperature management. Vacuum forming requires precise heating of thermoplastic sheets, and traditional methods often result in overheating or uneven heat distribution. Smart temperature sensors, such as infrared arrays or thermocouples, can continuously monitor the sheet temperature across its entire surface. This data allows for dynamic adjustment of heating elements, ensuring that only the necessary amount of energy is used to achieve the desired temperature profile.

Pressure sensors are another key component in improving energy efficiency. By accurately measuring the vacuum pressure during the forming stage, these sensors enable fine-tuning of the vacuum pumps. This optimization prevents excessive energy consumption from overworking the pumps while still maintaining the required forming pressure. Additionally, pressure sensors can detect leaks or inefficiencies in the system, allowing for prompt maintenance and preventing energy waste.

Motion and position sensors contribute to energy savings by optimizing the movement of machine components. These sensors ensure that actuators and mechanical parts operate with minimal energy expenditure, moving only as much as necessary to complete the forming process. By reducing unnecessary motion and optimizing cycle times, the overall energy consumption of the vacuum forming machine is decreased.

Smart power monitoring sensors integrated into the vacuum forming equipment provide valuable insights into energy usage patterns. These sensors can identify peak consumption periods, standby power draw, and inefficiencies in individual components. By analyzing this data, manufacturers can implement targeted energy-saving strategies, such as scheduling high-energy operations during off-peak hours or upgrading specific components to more energy-efficient alternatives.

The integration of these smart sensors with advanced control systems and machine learning algorithms further enhances energy efficiency. Predictive maintenance algorithms can analyze sensor data to anticipate equipment failures or performance degradation, scheduling maintenance before issues lead to increased energy consumption. Additionally, machine learning models can optimize process parameters in real-time, continuously adjusting settings to maintain the best balance between product quality and energy efficiency.

By leveraging smart sensor technology, vacuum forming processes can achieve significant reductions in energy consumption, often ranging from 15% to 30% compared to traditional methods. This not only reduces operational costs but also aligns with sustainability goals and regulatory requirements for energy efficiency in manufacturing. As sensor technology continues to advance, the potential for further energy optimization in vacuum forming processes remains promising, driving the industry towards more sustainable and efficient production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!