Innovations in Lighting Components Through Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Lighting: Background and Objectives

Vacuum forming has been a cornerstone in manufacturing for decades, but its application in lighting components represents a significant leap forward in both design and functionality. This technology, which involves heating a plastic sheet and forming it over a mold using vacuum suction, has found renewed relevance in the lighting industry due to its versatility and cost-effectiveness.

The evolution of vacuum forming in lighting can be traced back to the mid-20th century when plastics began to replace traditional materials in various industries. However, it is only in recent years that this technique has been refined to meet the exacting standards of modern lighting design. The push for energy-efficient and aesthetically pleasing lighting solutions has driven manufacturers to explore innovative production methods, with vacuum forming emerging as a frontrunner.

The primary objective of implementing vacuum forming in lighting components is to achieve a balance between form and function. This technique allows for the creation of complex shapes and textures that were previously difficult or impossible to produce using traditional methods. By enabling the production of lightweight yet durable components, vacuum forming addresses the growing demand for sustainable and energy-efficient lighting solutions.

Another key goal is to streamline the manufacturing process, reducing production time and costs without compromising on quality. Vacuum forming offers the advantage of rapid prototyping and the ability to produce small to medium-sized batches economically, making it an attractive option for both established lighting manufacturers and innovative startups.

The technology landscape surrounding vacuum forming in lighting is characterized by continuous improvement in materials and processes. Recent advancements include the development of high-performance thermoplastics that offer enhanced optical properties and durability. These materials can withstand the high temperatures associated with modern lighting technologies while maintaining their structural integrity and aesthetic appeal.

Looking ahead, the trajectory of vacuum forming in lighting components is closely aligned with broader trends in sustainable manufacturing and smart lighting systems. The industry is moving towards more integrated designs where vacuum-formed components not only serve as protective housings but also as active elements in light distribution and heat management.

As we delve deeper into the potential of vacuum forming in lighting, it becomes clear that this technology is not just about replicating existing designs more efficiently. It opens up new possibilities for creating lighting fixtures that are not only functional but also serve as artistic statements in their own right. The challenge and opportunity lie in fully leveraging this technology to push the boundaries of what is possible in lighting design and manufacturing.

The evolution of vacuum forming in lighting can be traced back to the mid-20th century when plastics began to replace traditional materials in various industries. However, it is only in recent years that this technique has been refined to meet the exacting standards of modern lighting design. The push for energy-efficient and aesthetically pleasing lighting solutions has driven manufacturers to explore innovative production methods, with vacuum forming emerging as a frontrunner.

The primary objective of implementing vacuum forming in lighting components is to achieve a balance between form and function. This technique allows for the creation of complex shapes and textures that were previously difficult or impossible to produce using traditional methods. By enabling the production of lightweight yet durable components, vacuum forming addresses the growing demand for sustainable and energy-efficient lighting solutions.

Another key goal is to streamline the manufacturing process, reducing production time and costs without compromising on quality. Vacuum forming offers the advantage of rapid prototyping and the ability to produce small to medium-sized batches economically, making it an attractive option for both established lighting manufacturers and innovative startups.

The technology landscape surrounding vacuum forming in lighting is characterized by continuous improvement in materials and processes. Recent advancements include the development of high-performance thermoplastics that offer enhanced optical properties and durability. These materials can withstand the high temperatures associated with modern lighting technologies while maintaining their structural integrity and aesthetic appeal.

Looking ahead, the trajectory of vacuum forming in lighting components is closely aligned with broader trends in sustainable manufacturing and smart lighting systems. The industry is moving towards more integrated designs where vacuum-formed components not only serve as protective housings but also as active elements in light distribution and heat management.

As we delve deeper into the potential of vacuum forming in lighting, it becomes clear that this technology is not just about replicating existing designs more efficiently. It opens up new possibilities for creating lighting fixtures that are not only functional but also serve as artistic statements in their own right. The challenge and opportunity lie in fully leveraging this technology to push the boundaries of what is possible in lighting design and manufacturing.

Market Analysis for Vacuum Formed Lighting Components

The market for vacuum formed lighting components has experienced significant growth in recent years, driven by the increasing demand for innovative and cost-effective lighting solutions across various industries. This market segment has emerged as a crucial part of the broader lighting industry, offering unique advantages in terms of design flexibility, weight reduction, and production efficiency.

The automotive sector represents a major market for vacuum formed lighting components, with a growing emphasis on lightweight materials and complex designs in vehicle lighting systems. As automakers strive to improve fuel efficiency and reduce emissions, the adoption of vacuum formed components in headlights, taillights, and interior lighting has increased substantially. This trend is expected to continue as electric vehicles gain market share, further driving the demand for lightweight and energy-efficient lighting solutions.

In the architectural and commercial lighting sectors, vacuum formed components have gained traction due to their ability to create unique, customized designs at a lower cost compared to traditional manufacturing methods. The hospitality industry, in particular, has shown a strong interest in these components for creating distinctive lighting fixtures that enhance the ambiance of hotels, restaurants, and entertainment venues.

The residential lighting market has also embraced vacuum formed components, particularly in the DIY and home improvement segments. Consumers are increasingly seeking affordable yet stylish lighting options, and vacuum formed products offer an attractive balance between aesthetics and cost-effectiveness.

From a geographical perspective, North America and Europe currently lead the market for vacuum formed lighting components, owing to their well-established automotive and lighting industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

The market is characterized by a mix of large, established lighting manufacturers and smaller, specialized vacuum forming companies. This diversity has led to a competitive landscape that fosters innovation and drives down costs. As the technology continues to evolve, we can expect to see further advancements in materials and production techniques, potentially expanding the application of vacuum formed components in new lighting segments.

Environmental concerns and sustainability initiatives are also shaping the market. The ability to use recycled materials in vacuum forming processes aligns well with the growing demand for eco-friendly lighting solutions. This aspect is likely to become increasingly important as consumers and regulators focus on reducing the environmental impact of lighting products.

The automotive sector represents a major market for vacuum formed lighting components, with a growing emphasis on lightweight materials and complex designs in vehicle lighting systems. As automakers strive to improve fuel efficiency and reduce emissions, the adoption of vacuum formed components in headlights, taillights, and interior lighting has increased substantially. This trend is expected to continue as electric vehicles gain market share, further driving the demand for lightweight and energy-efficient lighting solutions.

In the architectural and commercial lighting sectors, vacuum formed components have gained traction due to their ability to create unique, customized designs at a lower cost compared to traditional manufacturing methods. The hospitality industry, in particular, has shown a strong interest in these components for creating distinctive lighting fixtures that enhance the ambiance of hotels, restaurants, and entertainment venues.

The residential lighting market has also embraced vacuum formed components, particularly in the DIY and home improvement segments. Consumers are increasingly seeking affordable yet stylish lighting options, and vacuum formed products offer an attractive balance between aesthetics and cost-effectiveness.

From a geographical perspective, North America and Europe currently lead the market for vacuum formed lighting components, owing to their well-established automotive and lighting industries. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India.

The market is characterized by a mix of large, established lighting manufacturers and smaller, specialized vacuum forming companies. This diversity has led to a competitive landscape that fosters innovation and drives down costs. As the technology continues to evolve, we can expect to see further advancements in materials and production techniques, potentially expanding the application of vacuum formed components in new lighting segments.

Environmental concerns and sustainability initiatives are also shaping the market. The ability to use recycled materials in vacuum forming processes aligns well with the growing demand for eco-friendly lighting solutions. This aspect is likely to become increasingly important as consumers and regulators focus on reducing the environmental impact of lighting products.

Current Challenges in Vacuum Forming for Lighting

Vacuum forming has become an integral process in the production of lighting components, offering numerous advantages such as cost-effectiveness, design flexibility, and rapid prototyping capabilities. However, as the lighting industry continues to evolve and demand more sophisticated products, several challenges have emerged in the application of vacuum forming for lighting components.

One of the primary challenges is achieving consistent wall thickness across complex geometries. Lighting fixtures often require intricate designs with varying depths and contours, which can lead to uneven material distribution during the vacuum forming process. This inconsistency can result in weak spots, light leakage, or compromised structural integrity of the final product. Manufacturers are constantly striving to develop techniques and materials that can maintain uniform thickness even in complex molds.

Another significant challenge lies in the limited material options suitable for vacuum forming in lighting applications. While thermoplastics like ABS and PETG are commonly used, they may not always meet the stringent requirements for heat resistance, UV stability, and optical properties needed in modern lighting solutions. The industry is actively seeking advanced materials that can withstand high temperatures from LED light sources while maintaining optical clarity and longevity.

Surface finish quality presents another hurdle in vacuum forming for lighting components. Achieving a high-gloss or perfectly smooth surface can be difficult, especially for larger parts or those with intricate details. Imperfections such as orange peel texture or subtle marks from the mold can detract from the aesthetic appeal of the lighting fixture. Post-processing techniques are often required, adding time and cost to the production process.

The challenge of incorporating additional features or inserts during the vacuum forming process is also noteworthy. Lighting components frequently require mounting points, wire channels, or reflective surfaces that are ideally integrated during formation. However, the nature of vacuum forming makes it challenging to embed these elements without compromising the integrity of the formed part or the efficiency of the production process.

Sustainability concerns have also come to the forefront of challenges in vacuum forming for lighting. As the industry moves towards more environmentally friendly practices, there is a growing need for recyclable or biodegradable materials that can still meet the performance requirements of lighting components. Balancing these ecological considerations with the technical demands of the product remains a significant challenge for manufacturers.

Lastly, the scalability of vacuum forming for large production runs while maintaining consistency and quality is an ongoing challenge. As lighting designs become more complex and customized, ensuring repeatability across thousands of units without compromising on detail or structural integrity becomes increasingly difficult. This challenge is particularly acute when dealing with large-scale architectural lighting projects that demand both uniformity and precision.

One of the primary challenges is achieving consistent wall thickness across complex geometries. Lighting fixtures often require intricate designs with varying depths and contours, which can lead to uneven material distribution during the vacuum forming process. This inconsistency can result in weak spots, light leakage, or compromised structural integrity of the final product. Manufacturers are constantly striving to develop techniques and materials that can maintain uniform thickness even in complex molds.

Another significant challenge lies in the limited material options suitable for vacuum forming in lighting applications. While thermoplastics like ABS and PETG are commonly used, they may not always meet the stringent requirements for heat resistance, UV stability, and optical properties needed in modern lighting solutions. The industry is actively seeking advanced materials that can withstand high temperatures from LED light sources while maintaining optical clarity and longevity.

Surface finish quality presents another hurdle in vacuum forming for lighting components. Achieving a high-gloss or perfectly smooth surface can be difficult, especially for larger parts or those with intricate details. Imperfections such as orange peel texture or subtle marks from the mold can detract from the aesthetic appeal of the lighting fixture. Post-processing techniques are often required, adding time and cost to the production process.

The challenge of incorporating additional features or inserts during the vacuum forming process is also noteworthy. Lighting components frequently require mounting points, wire channels, or reflective surfaces that are ideally integrated during formation. However, the nature of vacuum forming makes it challenging to embed these elements without compromising the integrity of the formed part or the efficiency of the production process.

Sustainability concerns have also come to the forefront of challenges in vacuum forming for lighting. As the industry moves towards more environmentally friendly practices, there is a growing need for recyclable or biodegradable materials that can still meet the performance requirements of lighting components. Balancing these ecological considerations with the technical demands of the product remains a significant challenge for manufacturers.

Lastly, the scalability of vacuum forming for large production runs while maintaining consistency and quality is an ongoing challenge. As lighting designs become more complex and customized, ensuring repeatability across thousands of units without compromising on detail or structural integrity becomes increasingly difficult. This challenge is particularly acute when dealing with large-scale architectural lighting projects that demand both uniformity and precision.

Existing Vacuum Forming Solutions for Lighting Components

01 Advanced LED lighting systems

Innovations in LED lighting components focus on improving efficiency, color rendering, and controllability. These advancements include the development of smart LED drivers, integration of sensors for adaptive lighting, and the use of advanced materials to enhance light output and thermal management.- Advanced LED lighting systems: Innovations in LED lighting components focus on improving efficiency, color rendering, and controllability. These advancements include the development of smart LED drivers, integration of sensors for adaptive lighting, and the use of advanced materials to enhance light output and thermal management.

- Optical component innovations: New designs in optical components such as lenses, reflectors, and diffusers are enhancing light distribution and efficiency. These innovations include micro-optic structures, advanced coating technologies, and novel materials that improve light extraction and beam shaping capabilities.

- Smart lighting control systems: Advancements in lighting control systems incorporate IoT technologies, machine learning algorithms, and advanced sensors. These innovations enable features such as occupancy-based lighting, daylight harvesting, and integration with building management systems for improved energy efficiency and user comfort.

- Energy-efficient power supplies: Innovations in power supply components for lighting systems focus on improving energy efficiency, reducing size, and enhancing reliability. These advancements include the development of high-frequency switching power supplies, resonant converters, and integrated circuit solutions for LED drivers.

- Sustainable and eco-friendly lighting materials: Research and development efforts are focused on creating sustainable and environmentally friendly lighting components. This includes the use of recyclable materials, biodegradable plastics, and low-impact manufacturing processes for various lighting components, as well as the development of mercury-free light sources.

02 Optical component innovations

New designs in optical components such as lenses, reflectors, and diffusers are enhancing light distribution and efficiency. These innovations include micro-optic structures, advanced coating technologies, and novel materials that improve light extraction and beam shaping capabilities.Expand Specific Solutions03 Smart lighting control systems

Advancements in lighting control systems incorporate IoT technologies, machine learning algorithms, and advanced sensors. These innovations enable features such as occupancy-based lighting, daylight harvesting, and integration with building management systems for improved energy efficiency and user comfort.Expand Specific Solutions04 Energy-efficient power supplies and drivers

Innovations in power supply and driver technologies focus on improving energy efficiency, reducing size, and enhancing compatibility with various lighting systems. These advancements include the development of high-frequency drivers, resonant converters, and intelligent power management systems.Expand Specific Solutions05 Sustainable and eco-friendly lighting solutions

Development of lighting components using sustainable materials, recyclable designs, and energy-efficient technologies. These innovations aim to reduce environmental impact through the use of biodegradable materials, modular designs for easy repair and upgrade, and the integration of renewable energy sources.Expand Specific Solutions

Key Players in Vacuum Formed Lighting Industry

The vacuum forming technology for lighting components is in a growth phase, with increasing market size and evolving technical maturity. The industry is experiencing rapid innovation, driven by demand for energy-efficient and customizable lighting solutions. Key players like Signify Holding BV, Zumtobel Lighting GmbH, and Opple Lighting Co., Ltd. are investing heavily in R&D to improve manufacturing processes and product performance. Companies such as OSRAM Opto Semiconductors GmbH and Seoul Semiconductor Co., Ltd. are focusing on advanced LED technologies, while others like Evonik Industries AG are developing specialized materials for vacuum forming applications. This competitive landscape is fostering technological advancements and expanding market opportunities in the lighting industry.

ams-Osram International GmbH

Technical Solution: ams-Osram has developed innovative lighting components using vacuum forming techniques. Their approach involves creating ultra-thin, flexible OLED panels that can be molded into various shapes and forms. The company utilizes a proprietary vacuum thermoforming process to shape the OLED panels without compromising their performance or lifespan. This technology allows for the creation of curved, three-dimensional lighting surfaces that can be integrated seamlessly into automotive interiors, architectural designs, and consumer electronics[1][3]. The vacuum forming process enables the production of lightweight, energy-efficient lighting solutions with uniform illumination and minimal heat generation. ams-Osram has also developed specialized optical films and coatings that enhance the light output and durability of these formed OLED panels[5].

Strengths: Ability to create flexible, curved lighting surfaces; energy-efficient; seamless integration into various applications. Weaknesses: Higher production costs compared to traditional lighting; limited color options in some applications.

Signify Holding BV

Technical Solution: Signify has pioneered vacuum forming techniques in LED lighting components, particularly for their Philips brand. Their innovation focuses on creating lightweight, durable, and highly customizable lighting fixtures. The company employs a vacuum-assisted injection molding process to produce complex LED housings and reflectors with precise optical properties. This method allows for the creation of intricate shapes and textures that enhance light distribution and aesthetic appeal. Signify's vacuum-formed components incorporate advanced thermal management systems, ensuring optimal LED performance and longevity[2]. The company has also developed eco-friendly materials specifically designed for vacuum forming, reducing the environmental impact of their lighting products[4]. Additionally, Signify's process enables the integration of smart lighting features directly into the formed components, facilitating the production of IoT-ready lighting solutions[6].

Strengths: High customization potential; excellent thermal management; integration of smart features. Weaknesses: Initial tooling costs can be high; limitations in material choices for certain applications.

Innovative Vacuum Forming Techniques for Lighting

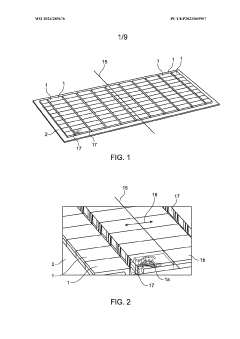

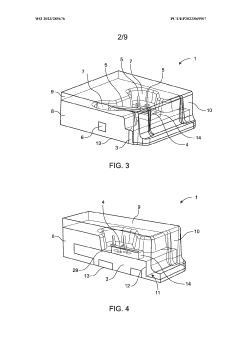

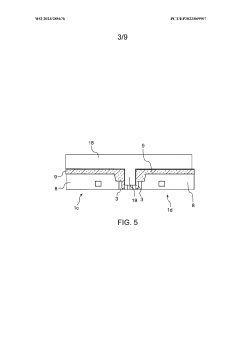

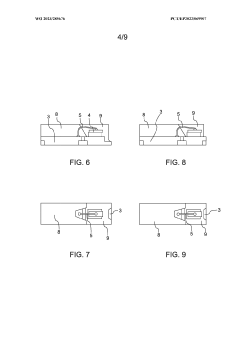

Encapsulation of side-emitting laser packages by means of vacuum injection molding

PatentWO2023285676A1

Innovation

- A light-emitting component with a cap produced by vacuum injection molding, allowing for a distance of less than 200 μm between the light exit surface and the semiconductor element's emission surface, which improves surface quality and enables precise positioning for enhanced beam quality and reduced risk of detachment.

Manufacturing apparatus and manufacturing method of lighting device

PatentInactiveEP2230703A3

Innovation

- A manufacturing apparatus with a vacuum chamber and exhaust system set to a reduced-pressure or high vacuum state, featuring multiple deposition chambers for forming electrodes, light-emitting units, and sealing films, allowing for sequential transfer and sealing of substrates within the same vacuum environment, enabling high-speed film formation and efficient material use.

Environmental Impact of Vacuum Formed Lighting Components

The environmental impact of vacuum formed lighting components is a crucial consideration in the evolving landscape of sustainable manufacturing. Vacuum forming, as a process for creating lighting components, offers several environmental advantages over traditional manufacturing methods. One of the primary benefits is the reduced material waste associated with this technique. Unlike subtractive manufacturing processes, vacuum forming utilizes only the necessary amount of material, minimizing excess and reducing the overall environmental footprint of production.

Energy efficiency is another significant factor in assessing the environmental impact of vacuum formed lighting components. The process typically requires less energy compared to injection molding or other high-pressure forming techniques. This reduced energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint for manufacturers adopting this technology. Additionally, the equipment used in vacuum forming generally has a longer lifespan and requires less maintenance, further contributing to resource conservation.

The choice of materials in vacuum forming also plays a crucial role in its environmental impact. Many vacuum formed lighting components utilize thermoplastics, which are often recyclable. This characteristic aligns with circular economy principles, allowing for the potential reuse or repurposing of materials at the end of the product's life cycle. Some manufacturers are exploring bio-based and biodegradable plastics for vacuum forming, further reducing the environmental impact of these components.

Transportation and logistics also factor into the environmental assessment of vacuum formed lighting components. The lightweight nature of these components, compared to traditional materials like metal or glass, can lead to reduced fuel consumption and emissions during transportation. Furthermore, the ability to nest or stack vacuum formed components efficiently during shipping can optimize space utilization, potentially reducing the number of shipments required.

However, it's important to note that the environmental impact is not uniformly positive. The use of plastics, even when recyclable, still raises concerns about long-term environmental persistence and potential microplastic pollution. The recycling infrastructure and practices in different regions can significantly affect the actual end-of-life environmental impact of these components. Additionally, the durability and lifespan of vacuum formed lighting components compared to alternatives made from more robust materials should be considered in a comprehensive environmental assessment.

As the lighting industry continues to evolve, there is growing emphasis on life cycle assessments for vacuum formed components. These assessments consider the environmental impact from raw material extraction through manufacturing, use, and disposal. Such comprehensive analyses are crucial for making informed decisions about material selection, design optimization, and end-of-life strategies for vacuum formed lighting components, ensuring that innovations in this field contribute positively to overall environmental sustainability.

Energy efficiency is another significant factor in assessing the environmental impact of vacuum formed lighting components. The process typically requires less energy compared to injection molding or other high-pressure forming techniques. This reduced energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint for manufacturers adopting this technology. Additionally, the equipment used in vacuum forming generally has a longer lifespan and requires less maintenance, further contributing to resource conservation.

The choice of materials in vacuum forming also plays a crucial role in its environmental impact. Many vacuum formed lighting components utilize thermoplastics, which are often recyclable. This characteristic aligns with circular economy principles, allowing for the potential reuse or repurposing of materials at the end of the product's life cycle. Some manufacturers are exploring bio-based and biodegradable plastics for vacuum forming, further reducing the environmental impact of these components.

Transportation and logistics also factor into the environmental assessment of vacuum formed lighting components. The lightweight nature of these components, compared to traditional materials like metal or glass, can lead to reduced fuel consumption and emissions during transportation. Furthermore, the ability to nest or stack vacuum formed components efficiently during shipping can optimize space utilization, potentially reducing the number of shipments required.

However, it's important to note that the environmental impact is not uniformly positive. The use of plastics, even when recyclable, still raises concerns about long-term environmental persistence and potential microplastic pollution. The recycling infrastructure and practices in different regions can significantly affect the actual end-of-life environmental impact of these components. Additionally, the durability and lifespan of vacuum formed lighting components compared to alternatives made from more robust materials should be considered in a comprehensive environmental assessment.

As the lighting industry continues to evolve, there is growing emphasis on life cycle assessments for vacuum formed components. These assessments consider the environmental impact from raw material extraction through manufacturing, use, and disposal. Such comprehensive analyses are crucial for making informed decisions about material selection, design optimization, and end-of-life strategies for vacuum formed lighting components, ensuring that innovations in this field contribute positively to overall environmental sustainability.

Cost-Benefit Analysis of Vacuum Forming in Lighting

The cost-benefit analysis of vacuum forming in lighting reveals significant advantages that make it an attractive manufacturing process for lighting components. Initial investment in vacuum forming equipment can be substantial, ranging from $5,000 to $100,000 depending on the scale and sophistication of the machinery. However, this upfront cost is often offset by the long-term savings in production expenses.

One of the primary benefits of vacuum forming is its ability to produce complex shapes and designs with minimal material waste. This process typically results in material savings of 15-25% compared to traditional injection molding methods. Additionally, the tooling costs for vacuum forming are considerably lower, often 50-70% less than those required for injection molding. This makes vacuum forming particularly cost-effective for small to medium production runs, where the high tooling costs of injection molding may not be justified.

Labor costs associated with vacuum forming are generally lower due to the simplified production process. A single operator can often manage multiple vacuum forming machines, reducing the need for extensive manual labor. This automation potential leads to an estimated 30-40% reduction in labor costs compared to more labor-intensive manufacturing methods.

Energy consumption is another area where vacuum forming demonstrates cost advantages. The process requires less energy than injection molding, with studies indicating energy savings of up to 25-35%. This not only reduces operational costs but also aligns with sustainability goals, potentially leading to additional benefits such as tax incentives or improved brand perception.

The versatility of vacuum forming allows for rapid prototyping and design iterations, significantly reducing time-to-market for new lighting products. This agility can result in a competitive advantage and increased market share, indirectly contributing to the overall cost-benefit analysis.

However, it's important to consider the limitations of vacuum forming. While suitable for many lighting components, it may not be appropriate for all applications, particularly those requiring high precision or extreme durability. The cost-benefit ratio may also vary depending on the specific materials used and the complexity of the designs.

In conclusion, the cost-benefit analysis of vacuum forming in lighting production generally favors its adoption, especially for businesses looking to balance quality, flexibility, and cost-effectiveness. The initial investment is often justified by the long-term savings in material, labor, and energy costs, as well as the strategic advantages of faster product development cycles.

One of the primary benefits of vacuum forming is its ability to produce complex shapes and designs with minimal material waste. This process typically results in material savings of 15-25% compared to traditional injection molding methods. Additionally, the tooling costs for vacuum forming are considerably lower, often 50-70% less than those required for injection molding. This makes vacuum forming particularly cost-effective for small to medium production runs, where the high tooling costs of injection molding may not be justified.

Labor costs associated with vacuum forming are generally lower due to the simplified production process. A single operator can often manage multiple vacuum forming machines, reducing the need for extensive manual labor. This automation potential leads to an estimated 30-40% reduction in labor costs compared to more labor-intensive manufacturing methods.

Energy consumption is another area where vacuum forming demonstrates cost advantages. The process requires less energy than injection molding, with studies indicating energy savings of up to 25-35%. This not only reduces operational costs but also aligns with sustainability goals, potentially leading to additional benefits such as tax incentives or improved brand perception.

The versatility of vacuum forming allows for rapid prototyping and design iterations, significantly reducing time-to-market for new lighting products. This agility can result in a competitive advantage and increased market share, indirectly contributing to the overall cost-benefit analysis.

However, it's important to consider the limitations of vacuum forming. While suitable for many lighting components, it may not be appropriate for all applications, particularly those requiring high precision or extreme durability. The cost-benefit ratio may also vary depending on the specific materials used and the complexity of the designs.

In conclusion, the cost-benefit analysis of vacuum forming in lighting production generally favors its adoption, especially for businesses looking to balance quality, flexibility, and cost-effectiveness. The initial investment is often justified by the long-term savings in material, labor, and energy costs, as well as the strategic advantages of faster product development cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!