Vacuum Forming as a Method for Complex Medical Models

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming in Medical Modeling: Background and Objectives

Vacuum forming has emerged as a promising technique in the field of medical modeling, offering a unique approach to creating complex anatomical replicas. This method, rooted in the plastics industry, has found its way into medical applications due to its ability to produce accurate, cost-effective, and customizable models. The evolution of vacuum forming in medical contexts can be traced back to the late 20th century, coinciding with advancements in medical imaging technologies and the growing demand for patient-specific anatomical models.

The primary objective of utilizing vacuum forming in medical modeling is to enhance the accuracy and accessibility of anatomical representations for various medical purposes. These include surgical planning, medical education, patient communication, and prosthetic design. By leveraging the principles of thermoplastic deformation, vacuum forming allows for the creation of detailed, three-dimensional models that closely mimic the intricate structures of human anatomy.

The technology's progression in the medical field has been driven by several factors. Firstly, the increasing sophistication of medical imaging techniques, such as CT and MRI scans, has provided more detailed and precise anatomical data. This has, in turn, enabled the creation of more accurate molds for vacuum forming. Secondly, advancements in materials science have led to the development of biocompatible and sterilizable thermoplastics, expanding the potential applications of vacuum-formed models in clinical settings.

As the field continues to evolve, researchers and medical professionals are exploring new frontiers in vacuum forming for medical modeling. Current trends include the integration of 3D printing technologies to create more complex molds, the development of multi-material vacuum forming techniques for enhanced realism, and the exploration of biodegradable materials for sustainable medical model production.

The adoption of vacuum forming in medical modeling aligns with the broader trend towards personalized medicine and patient-specific interventions. By providing cost-effective means to produce customized anatomical models, this technology has the potential to democratize access to advanced medical planning and education tools. Furthermore, it offers a bridge between traditional manufacturing techniques and cutting-edge medical technologies, paving the way for innovative approaches in healthcare delivery and medical device development.

The primary objective of utilizing vacuum forming in medical modeling is to enhance the accuracy and accessibility of anatomical representations for various medical purposes. These include surgical planning, medical education, patient communication, and prosthetic design. By leveraging the principles of thermoplastic deformation, vacuum forming allows for the creation of detailed, three-dimensional models that closely mimic the intricate structures of human anatomy.

The technology's progression in the medical field has been driven by several factors. Firstly, the increasing sophistication of medical imaging techniques, such as CT and MRI scans, has provided more detailed and precise anatomical data. This has, in turn, enabled the creation of more accurate molds for vacuum forming. Secondly, advancements in materials science have led to the development of biocompatible and sterilizable thermoplastics, expanding the potential applications of vacuum-formed models in clinical settings.

As the field continues to evolve, researchers and medical professionals are exploring new frontiers in vacuum forming for medical modeling. Current trends include the integration of 3D printing technologies to create more complex molds, the development of multi-material vacuum forming techniques for enhanced realism, and the exploration of biodegradable materials for sustainable medical model production.

The adoption of vacuum forming in medical modeling aligns with the broader trend towards personalized medicine and patient-specific interventions. By providing cost-effective means to produce customized anatomical models, this technology has the potential to democratize access to advanced medical planning and education tools. Furthermore, it offers a bridge between traditional manufacturing techniques and cutting-edge medical technologies, paving the way for innovative approaches in healthcare delivery and medical device development.

Market Analysis for Complex Medical Models

The market for complex medical models is experiencing significant growth, driven by advancements in medical technology and the increasing demand for personalized healthcare solutions. These models play a crucial role in various medical applications, including surgical planning, medical education, and patient communication. The global market for medical models is projected to expand at a robust rate over the coming years, with a particular emphasis on complex, patient-specific models.

One of the key factors driving market growth is the rising prevalence of chronic diseases and complex medical conditions that require intricate surgical interventions. As healthcare providers seek to improve patient outcomes and reduce surgical risks, the demand for accurate and detailed medical models has surged. These models enable surgeons to plan and practice complex procedures, leading to improved surgical precision and reduced operating times.

The medical education sector represents another significant market segment for complex medical models. Medical schools and training institutions are increasingly incorporating realistic anatomical models into their curricula to enhance the learning experience for students and practitioners. This trend is expected to continue as the importance of hands-on training in medical education becomes more widely recognized.

Technological advancements in imaging techniques, such as high-resolution CT and MRI scans, have also contributed to the market's growth. These imaging modalities provide the detailed data necessary for creating highly accurate and patient-specific medical models. As a result, the market has seen an increase in demand for sophisticated 3D printing and manufacturing technologies capable of producing these intricate models.

Geographically, North America and Europe currently dominate the market for complex medical models, owing to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in this market as healthcare spending increases and awareness of the benefits of medical modeling grows.

The market is characterized by a mix of established medical device manufacturers and specialized 3D printing companies. Key players are focusing on developing more cost-effective and efficient manufacturing processes to meet the growing demand for complex medical models. Vacuum forming, as a potential method for producing these models, could offer advantages in terms of speed and cost-effectiveness, potentially disrupting the current market dynamics.

Despite the positive growth outlook, challenges such as high production costs and regulatory hurdles persist. However, ongoing research and development efforts, including the exploration of novel manufacturing techniques like vacuum forming, are expected to address these challenges and further drive market expansion in the coming years.

One of the key factors driving market growth is the rising prevalence of chronic diseases and complex medical conditions that require intricate surgical interventions. As healthcare providers seek to improve patient outcomes and reduce surgical risks, the demand for accurate and detailed medical models has surged. These models enable surgeons to plan and practice complex procedures, leading to improved surgical precision and reduced operating times.

The medical education sector represents another significant market segment for complex medical models. Medical schools and training institutions are increasingly incorporating realistic anatomical models into their curricula to enhance the learning experience for students and practitioners. This trend is expected to continue as the importance of hands-on training in medical education becomes more widely recognized.

Technological advancements in imaging techniques, such as high-resolution CT and MRI scans, have also contributed to the market's growth. These imaging modalities provide the detailed data necessary for creating highly accurate and patient-specific medical models. As a result, the market has seen an increase in demand for sophisticated 3D printing and manufacturing technologies capable of producing these intricate models.

Geographically, North America and Europe currently dominate the market for complex medical models, owing to their advanced healthcare infrastructure and higher adoption rates of innovative medical technologies. However, emerging economies in Asia-Pacific and Latin America are expected to witness rapid growth in this market as healthcare spending increases and awareness of the benefits of medical modeling grows.

The market is characterized by a mix of established medical device manufacturers and specialized 3D printing companies. Key players are focusing on developing more cost-effective and efficient manufacturing processes to meet the growing demand for complex medical models. Vacuum forming, as a potential method for producing these models, could offer advantages in terms of speed and cost-effectiveness, potentially disrupting the current market dynamics.

Despite the positive growth outlook, challenges such as high production costs and regulatory hurdles persist. However, ongoing research and development efforts, including the exploration of novel manufacturing techniques like vacuum forming, are expected to address these challenges and further drive market expansion in the coming years.

Current Challenges in Vacuum Forming for Medical Applications

Vacuum forming has emerged as a promising method for creating complex medical models, but it faces several significant challenges in its application to the medical field. One of the primary obstacles is achieving the required level of precision and detail necessary for accurate medical representations. The intricate anatomical structures and subtle surface features of human organs and tissues demand a level of resolution that pushes the limits of current vacuum forming technology.

Material selection poses another critical challenge. The materials used in vacuum forming must not only be suitable for the forming process but also meet stringent medical standards for biocompatibility, sterilization, and durability. Finding materials that can withstand the heat and pressure of the vacuum forming process while maintaining the necessary properties for medical use is an ongoing area of research and development.

The complexity of medical geometries often leads to issues with undercuts and deep recesses, which are difficult to reproduce accurately using traditional vacuum forming techniques. This limitation can result in models that lack the fidelity required for certain medical applications, such as surgical planning or medical education. Overcoming these geometric constraints requires innovative approaches to mold design and forming processes.

Consistency and repeatability in production are also significant concerns. Medical models often need to be produced in small batches with high consistency, which can be challenging to achieve with vacuum forming. Variations in temperature, pressure, and material properties can lead to inconsistencies between batches, potentially affecting the reliability of the models for medical use.

The scalability of vacuum forming for medical applications is another area of concern. While the process is well-suited for producing larger quantities of simpler shapes, scaling up production for complex medical models while maintaining quality and cost-effectiveness remains a challenge. This is particularly relevant when considering the diverse range of medical models required for different specialties and procedures.

Additionally, the integration of vacuum-formed medical models with other technologies, such as 3D printing or embedded sensors, presents both opportunities and challenges. Developing hybrid manufacturing processes that combine the strengths of vacuum forming with other advanced technologies could potentially address some of the current limitations, but this integration is still in its early stages and requires further research and development.

Lastly, the regulatory landscape for medical models produced through vacuum forming is still evolving. Ensuring compliance with medical device regulations and obtaining necessary certifications for vacuum-formed medical models can be a complex and time-consuming process, potentially slowing down the adoption of this technology in clinical settings.

Material selection poses another critical challenge. The materials used in vacuum forming must not only be suitable for the forming process but also meet stringent medical standards for biocompatibility, sterilization, and durability. Finding materials that can withstand the heat and pressure of the vacuum forming process while maintaining the necessary properties for medical use is an ongoing area of research and development.

The complexity of medical geometries often leads to issues with undercuts and deep recesses, which are difficult to reproduce accurately using traditional vacuum forming techniques. This limitation can result in models that lack the fidelity required for certain medical applications, such as surgical planning or medical education. Overcoming these geometric constraints requires innovative approaches to mold design and forming processes.

Consistency and repeatability in production are also significant concerns. Medical models often need to be produced in small batches with high consistency, which can be challenging to achieve with vacuum forming. Variations in temperature, pressure, and material properties can lead to inconsistencies between batches, potentially affecting the reliability of the models for medical use.

The scalability of vacuum forming for medical applications is another area of concern. While the process is well-suited for producing larger quantities of simpler shapes, scaling up production for complex medical models while maintaining quality and cost-effectiveness remains a challenge. This is particularly relevant when considering the diverse range of medical models required for different specialties and procedures.

Additionally, the integration of vacuum-formed medical models with other technologies, such as 3D printing or embedded sensors, presents both opportunities and challenges. Developing hybrid manufacturing processes that combine the strengths of vacuum forming with other advanced technologies could potentially address some of the current limitations, but this integration is still in its early stages and requires further research and development.

Lastly, the regulatory landscape for medical models produced through vacuum forming is still evolving. Ensuring compliance with medical device regulations and obtaining necessary certifications for vacuum-formed medical models can be a complex and time-consuming process, potentially slowing down the adoption of this technology in clinical settings.

Existing Vacuum Forming Techniques for Medical Models

01 Complexity in software development for vacuum forming

Software development for vacuum forming processes involves complex algorithms and systems to optimize the forming process. This includes modeling of material behavior, simulation of heat transfer, and prediction of final product shape. Advanced software solutions are developed to handle these complexities and improve the efficiency of vacuum forming operations.- Complexity in software development and testing: Vacuum forming complexity in software development involves intricate processes for creating, testing, and optimizing software systems. This includes managing complex algorithms, handling large datasets, and ensuring system reliability across various scenarios. Advanced testing methodologies are employed to identify and resolve issues in complex software environments.

- Vacuum forming in manufacturing processes: The complexity of vacuum forming in manufacturing involves designing and implementing sophisticated systems for shaping materials using vacuum pressure. This process requires precise control of temperature, pressure, and material properties to achieve desired product shapes and qualities. Advanced techniques are used to optimize the forming process for various materials and complex geometries.

- Data processing and analysis in complex systems: Handling complexity in data processing and analysis involves developing advanced algorithms and methodologies to extract meaningful insights from large, complex datasets. This includes techniques for data mining, pattern recognition, and predictive modeling in various fields such as finance, healthcare, and scientific research.

- Complexity in communication systems and networks: Addressing complexity in communication systems and networks involves designing and implementing sophisticated protocols and architectures to ensure efficient and secure data transmission. This includes managing complex routing algorithms, optimizing network performance, and handling large-scale distributed systems.

- Complexity in medical imaging and diagnostics: Managing complexity in medical imaging and diagnostics involves developing advanced techniques for capturing, processing, and analyzing complex biological data. This includes implementing sophisticated image reconstruction algorithms, enhancing visualization methods, and integrating multiple imaging modalities for improved diagnostic accuracy.

02 Vacuum forming process control and optimization

Controlling and optimizing the vacuum forming process involves managing multiple variables such as temperature, pressure, and material properties. Complex systems are developed to monitor and adjust these parameters in real-time, ensuring consistent product quality and reducing waste. This may include the use of sensors, feedback loops, and adaptive control algorithms.Expand Specific Solutions03 Material complexity in vacuum forming

The behavior of different materials during the vacuum forming process adds complexity to the operation. Various materials exhibit unique characteristics in terms of stretching, shrinking, and cooling rates. Addressing these material-specific challenges requires sophisticated modeling and testing methods to achieve desired product specifications.Expand Specific Solutions04 Mold design complexity for vacuum forming

Designing molds for vacuum forming involves intricate considerations of part geometry, material flow, and cooling patterns. Complex mold designs may incorporate features such as undercuts, textured surfaces, or multi-part assemblies. Advanced CAD/CAM systems and simulation tools are used to address these design challenges and optimize mold performance.Expand Specific Solutions05 Integration of vacuum forming with other manufacturing processes

Integrating vacuum forming with other manufacturing processes, such as trimming, assembly, or surface treatment, adds complexity to the overall production system. This integration requires careful planning, synchronization of different processes, and development of specialized handling and transfer mechanisms to ensure efficient and seamless production flow.Expand Specific Solutions

Key Players in Medical Model Manufacturing

The research on vacuum forming for complex medical models is in a growth phase, with increasing market size driven by demand for personalized healthcare solutions. The technology's maturity is advancing rapidly, with key players like GE Precision Healthcare, Brainlab AG, and Carestream Health leading innovation. Universities such as Zhejiang University and Rice University contribute to academic research, while companies like Koninklijke Philips NV and Bio-Rad Laboratories bring industry expertise. The competitive landscape is diverse, including medical technology firms, research institutions, and specialized manufacturers, indicating a dynamic and evolving field with significant potential for further development and application in healthcare.

GE Precision Healthcare LLC

Technical Solution: GE Precision Healthcare LLC has developed advanced vacuum forming techniques for creating complex medical models. Their approach utilizes high-precision 3D printing to create molds, which are then used in a vacuum forming process to produce accurate anatomical replicas. This method allows for the creation of patient-specific models with intricate details, such as vascular structures and organ surfaces[1]. The company has also integrated their vacuum forming process with imaging technologies, enabling the production of models directly from CT or MRI scans[2]. This integration streamlines the workflow and improves the accuracy of the final models, making them suitable for surgical planning and medical education[3].

Strengths: High precision, integration with medical imaging, and ability to produce patient-specific models. Weaknesses: Potentially higher cost compared to traditional methods and limited to thermoplastic materials.

Brainlab AG

Technical Solution: Brainlab AG has innovated in the field of vacuum forming for medical models by developing a hybrid approach that combines 3D printing and vacuum forming. Their process involves creating a 3D printed core structure that is then encased in a vacuum-formed outer layer[4]. This method allows for the production of models with both rigid and flexible components, mimicking the complex structures of human anatomy more accurately. Brainlab's technology also incorporates radiopaque materials into the vacuum forming process, enabling the creation of models that can be visualized under X-ray or CT imaging[5]. This feature is particularly useful for surgical planning and intraoperative guidance.

Strengths: Ability to create multi-material models and compatibility with medical imaging. Weaknesses: More complex production process and potentially longer manufacturing time.

Innovations in Materials for Medical Vacuum Forming

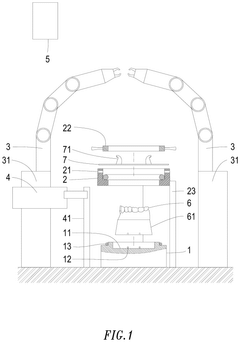

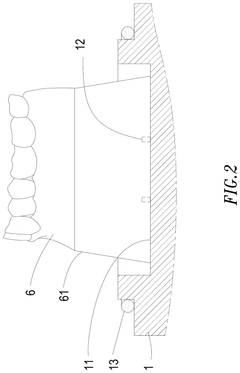

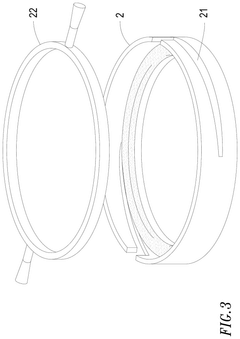

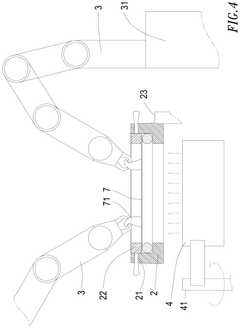

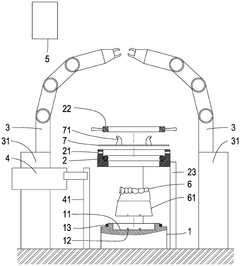

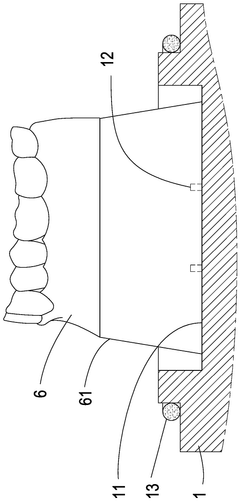

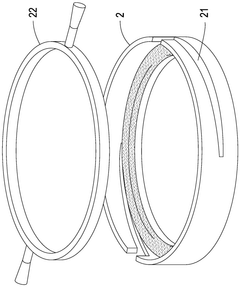

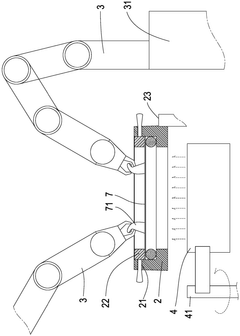

Vacuum forming method for membrane-like objects having protruding structures and forming apparatus thereof

PatentPendingUS20250042076A1

Innovation

- A computer simulation is used to pre-construct and position special structures on a membrane-like object, which is then transferred to a predetermined forming position using a controllable transfer device during the vacuum forming process, ensuring precise attachment to a mold.

Vacuum forming method for membrane-like substance containing raised structure body and forming device thereof

PatentPendingEP4506141A1

Innovation

- A computer simulation is used to construct and pre-displace special structures on a membrane-like object before vacuum forming, utilizing a controllable transfer device to move the structures to predetermined positions on the mold during the softening of the membrane, ensuring precise formation.

Regulatory Compliance for Medical Model Manufacturing

Regulatory compliance is a critical aspect of medical model manufacturing, especially when utilizing vacuum forming techniques for complex medical models. The process must adhere to stringent guidelines set by regulatory bodies such as the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) in Europe. These regulations ensure the safety, efficacy, and quality of medical models used in various applications, including surgical planning, medical education, and patient communication.

One of the primary regulatory considerations for vacuum-formed medical models is the classification of the device. Depending on the intended use and risk level, these models may fall under different regulatory categories, each with its own set of requirements. For instance, models used for diagnostic purposes or surgical planning may be classified as Class II medical devices, requiring more rigorous controls and potentially a 510(k) premarket notification in the United States.

Material selection is another crucial aspect of regulatory compliance. The materials used in vacuum forming for medical models must be biocompatible and meet specific standards, such as ISO 10993 for biological evaluation of medical devices. This ensures that the materials do not pose any health risks when in contact with human tissues or fluids. Additionally, manufacturers must maintain detailed documentation on material sourcing, processing, and quality control measures.

Quality management systems (QMS) play a vital role in ensuring regulatory compliance throughout the manufacturing process. Manufacturers of vacuum-formed medical models should implement and maintain a QMS that aligns with international standards such as ISO 13485 for medical devices. This system should cover all aspects of production, from design and development to final product release and post-market surveillance.

Traceability and documentation are essential components of regulatory compliance. Manufacturers must maintain comprehensive records of the entire production process, including design specifications, material sourcing, manufacturing parameters, and quality control tests. This documentation is crucial for demonstrating compliance during regulatory audits and for facilitating product recalls if necessary.

Risk management is another critical aspect of regulatory compliance for medical model manufacturing. Manufacturers must conduct thorough risk assessments and implement appropriate mitigation strategies to ensure the safety and effectiveness of their products. This includes identifying potential hazards associated with the vacuum forming process, such as material degradation or dimensional inaccuracies, and implementing controls to minimize these risks.

Labeling and packaging requirements must also be carefully considered to meet regulatory standards. Medical models should be clearly labeled with relevant information, including intended use, warnings, and storage conditions. Packaging must protect the integrity of the model during transportation and storage while maintaining sterility if required.

In conclusion, regulatory compliance for vacuum-formed complex medical models involves a multifaceted approach that encompasses device classification, material selection, quality management, documentation, risk management, and labeling. Manufacturers must stay abreast of evolving regulations and standards to ensure continued compliance and market access for their products.

One of the primary regulatory considerations for vacuum-formed medical models is the classification of the device. Depending on the intended use and risk level, these models may fall under different regulatory categories, each with its own set of requirements. For instance, models used for diagnostic purposes or surgical planning may be classified as Class II medical devices, requiring more rigorous controls and potentially a 510(k) premarket notification in the United States.

Material selection is another crucial aspect of regulatory compliance. The materials used in vacuum forming for medical models must be biocompatible and meet specific standards, such as ISO 10993 for biological evaluation of medical devices. This ensures that the materials do not pose any health risks when in contact with human tissues or fluids. Additionally, manufacturers must maintain detailed documentation on material sourcing, processing, and quality control measures.

Quality management systems (QMS) play a vital role in ensuring regulatory compliance throughout the manufacturing process. Manufacturers of vacuum-formed medical models should implement and maintain a QMS that aligns with international standards such as ISO 13485 for medical devices. This system should cover all aspects of production, from design and development to final product release and post-market surveillance.

Traceability and documentation are essential components of regulatory compliance. Manufacturers must maintain comprehensive records of the entire production process, including design specifications, material sourcing, manufacturing parameters, and quality control tests. This documentation is crucial for demonstrating compliance during regulatory audits and for facilitating product recalls if necessary.

Risk management is another critical aspect of regulatory compliance for medical model manufacturing. Manufacturers must conduct thorough risk assessments and implement appropriate mitigation strategies to ensure the safety and effectiveness of their products. This includes identifying potential hazards associated with the vacuum forming process, such as material degradation or dimensional inaccuracies, and implementing controls to minimize these risks.

Labeling and packaging requirements must also be carefully considered to meet regulatory standards. Medical models should be clearly labeled with relevant information, including intended use, warnings, and storage conditions. Packaging must protect the integrity of the model during transportation and storage while maintaining sterility if required.

In conclusion, regulatory compliance for vacuum-formed complex medical models involves a multifaceted approach that encompasses device classification, material selection, quality management, documentation, risk management, and labeling. Manufacturers must stay abreast of evolving regulations and standards to ensure continued compliance and market access for their products.

Cost-Benefit Analysis of Vacuum Forming in Healthcare

Vacuum forming has emerged as a promising method for creating complex medical models, offering a unique balance of cost-effectiveness and precision. In the healthcare sector, where budgets are often constrained and the demand for accurate anatomical representations is high, this technique presents significant potential for cost savings and improved patient outcomes.

The initial investment in vacuum forming equipment is relatively low compared to other manufacturing methods such as 3D printing or injection molding. A basic vacuum forming setup can be acquired for a fraction of the cost of industrial-grade 3D printers, making it accessible to a wider range of healthcare facilities, including smaller clinics and educational institutions.

Material costs for vacuum forming are also competitive. Thermoplastic sheets used in the process are generally less expensive than specialized 3D printing filaments or resins. This cost advantage becomes particularly apparent when producing larger quantities of models, as the per-unit cost decreases significantly with scale.

Labor costs associated with vacuum forming are generally lower than those of more complex manufacturing processes. The technique requires less specialized training and can be performed by technicians rather than highly skilled operators, reducing ongoing operational expenses.

However, the cost-benefit analysis must also consider the limitations of vacuum forming. While suitable for many applications, it may not achieve the same level of detail as high-end 3D printing for certain intricate anatomical structures. In such cases, the cost savings must be weighed against the potential need for supplementary modeling techniques.

The time efficiency of vacuum forming contributes to its cost-effectiveness. The rapid production cycle allows for quick turnaround times, potentially reducing patient wait times and improving overall healthcare delivery efficiency. This speed can translate to cost savings in terms of reduced hospital stays and more efficient use of medical staff time.

Maintenance costs for vacuum forming equipment are generally lower than those for more complex manufacturing systems. The simplicity of the machinery results in fewer breakdowns and easier repairs, contributing to long-term cost savings and reliability.

In terms of material waste, vacuum forming is relatively efficient, especially when compared to subtractive manufacturing methods. This efficiency not only reduces material costs but also aligns with sustainability goals, which are increasingly important in healthcare settings.

The versatility of vacuum forming allows for the production of a wide range of medical models using the same equipment, from basic anatomical representations to patient-specific surgical guides. This adaptability enhances the cost-benefit ratio by increasing the utility of the initial investment across various medical applications.

The initial investment in vacuum forming equipment is relatively low compared to other manufacturing methods such as 3D printing or injection molding. A basic vacuum forming setup can be acquired for a fraction of the cost of industrial-grade 3D printers, making it accessible to a wider range of healthcare facilities, including smaller clinics and educational institutions.

Material costs for vacuum forming are also competitive. Thermoplastic sheets used in the process are generally less expensive than specialized 3D printing filaments or resins. This cost advantage becomes particularly apparent when producing larger quantities of models, as the per-unit cost decreases significantly with scale.

Labor costs associated with vacuum forming are generally lower than those of more complex manufacturing processes. The technique requires less specialized training and can be performed by technicians rather than highly skilled operators, reducing ongoing operational expenses.

However, the cost-benefit analysis must also consider the limitations of vacuum forming. While suitable for many applications, it may not achieve the same level of detail as high-end 3D printing for certain intricate anatomical structures. In such cases, the cost savings must be weighed against the potential need for supplementary modeling techniques.

The time efficiency of vacuum forming contributes to its cost-effectiveness. The rapid production cycle allows for quick turnaround times, potentially reducing patient wait times and improving overall healthcare delivery efficiency. This speed can translate to cost savings in terms of reduced hospital stays and more efficient use of medical staff time.

Maintenance costs for vacuum forming equipment are generally lower than those for more complex manufacturing systems. The simplicity of the machinery results in fewer breakdowns and easier repairs, contributing to long-term cost savings and reliability.

In terms of material waste, vacuum forming is relatively efficient, especially when compared to subtractive manufacturing methods. This efficiency not only reduces material costs but also aligns with sustainability goals, which are increasingly important in healthcare settings.

The versatility of vacuum forming allows for the production of a wide range of medical models using the same equipment, from basic anatomical representations to patient-specific surgical guides. This adaptability enhances the cost-benefit ratio by increasing the utility of the initial investment across various medical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!