Overcoming Challenges in Vacuum Forming High-Strength Materials

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Evolution and Objectives

Vacuum forming has evolved significantly since its inception in the 1940s, transforming from a simple thermoforming process to a sophisticated manufacturing technique capable of producing complex, high-strength components. The journey of vacuum forming technology reflects the broader trends in materials science and manufacturing innovation, driven by the increasing demand for lightweight, durable, and cost-effective products across various industries.

Initially, vacuum forming was primarily used for creating simple plastic packaging and disposable items. However, as the technology matured, its applications expanded to include more demanding sectors such as automotive, aerospace, and medical device manufacturing. This expansion necessitated the development of more advanced materials and processing techniques to meet the stringent requirements of these industries.

The evolution of vacuum forming has been marked by several key milestones. The introduction of twin-sheet forming in the 1960s allowed for the creation of hollow parts, significantly expanding the range of possible applications. The 1980s saw the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, which greatly improved the precision and repeatability of the vacuum forming process.

In recent years, the focus has shifted towards overcoming the challenges associated with forming high-strength materials. This shift is driven by the growing need for lightweight yet robust components in industries such as automotive and aerospace, where fuel efficiency and performance are paramount. The ability to vacuum form high-strength materials such as advanced thermoplastics, fiber-reinforced composites, and even certain metals has become a key objective for researchers and manufacturers alike.

The primary objectives in the field of vacuum forming high-strength materials are multifaceted. First and foremost is the goal of achieving consistent, high-quality parts with minimal defects such as thinning, wrinkling, or incomplete forming. This requires a deep understanding of material behavior under high temperatures and pressures, as well as precise control over the forming process parameters.

Another critical objective is to expand the range of formable high-strength materials. This includes developing new material formulations that combine high strength with the necessary thermoforming characteristics, as well as adapting existing high-strength materials for vacuum forming processes. Researchers are also exploring hybrid materials and multi-layer structures to achieve optimal combinations of strength, weight, and formability.

Improving energy efficiency and reducing cycle times are also key objectives in the evolution of vacuum forming technology for high-strength materials. This involves developing more efficient heating systems, optimizing cooling strategies, and implementing advanced process control algorithms to minimize energy consumption and maximize throughput.

As the technology continues to evolve, the ultimate goal is to position vacuum forming as a viable and competitive manufacturing process for producing high-strength, complex-geometry parts at scale. This requires not only technical advancements but also a focus on cost-effectiveness and integration with other manufacturing processes and Industry 4.0 technologies.

Initially, vacuum forming was primarily used for creating simple plastic packaging and disposable items. However, as the technology matured, its applications expanded to include more demanding sectors such as automotive, aerospace, and medical device manufacturing. This expansion necessitated the development of more advanced materials and processing techniques to meet the stringent requirements of these industries.

The evolution of vacuum forming has been marked by several key milestones. The introduction of twin-sheet forming in the 1960s allowed for the creation of hollow parts, significantly expanding the range of possible applications. The 1980s saw the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, which greatly improved the precision and repeatability of the vacuum forming process.

In recent years, the focus has shifted towards overcoming the challenges associated with forming high-strength materials. This shift is driven by the growing need for lightweight yet robust components in industries such as automotive and aerospace, where fuel efficiency and performance are paramount. The ability to vacuum form high-strength materials such as advanced thermoplastics, fiber-reinforced composites, and even certain metals has become a key objective for researchers and manufacturers alike.

The primary objectives in the field of vacuum forming high-strength materials are multifaceted. First and foremost is the goal of achieving consistent, high-quality parts with minimal defects such as thinning, wrinkling, or incomplete forming. This requires a deep understanding of material behavior under high temperatures and pressures, as well as precise control over the forming process parameters.

Another critical objective is to expand the range of formable high-strength materials. This includes developing new material formulations that combine high strength with the necessary thermoforming characteristics, as well as adapting existing high-strength materials for vacuum forming processes. Researchers are also exploring hybrid materials and multi-layer structures to achieve optimal combinations of strength, weight, and formability.

Improving energy efficiency and reducing cycle times are also key objectives in the evolution of vacuum forming technology for high-strength materials. This involves developing more efficient heating systems, optimizing cooling strategies, and implementing advanced process control algorithms to minimize energy consumption and maximize throughput.

As the technology continues to evolve, the ultimate goal is to position vacuum forming as a viable and competitive manufacturing process for producing high-strength, complex-geometry parts at scale. This requires not only technical advancements but also a focus on cost-effectiveness and integration with other manufacturing processes and Industry 4.0 technologies.

High-Strength Materials Market Analysis

The high-strength materials market has experienced significant growth in recent years, driven by increasing demand across various industries such as automotive, aerospace, construction, and consumer electronics. These materials, including advanced alloys, composites, and engineered plastics, offer superior mechanical properties and performance characteristics compared to traditional materials.

In the automotive sector, the push for lightweight vehicles to improve fuel efficiency and reduce emissions has led to a surge in demand for high-strength materials. Advanced high-strength steels (AHSS) and aluminum alloys are increasingly being used in vehicle structures, body panels, and components. The aerospace industry also relies heavily on high-strength materials to enhance aircraft performance and fuel efficiency, with titanium alloys and carbon fiber reinforced polymers (CFRP) being key materials in this sector.

The construction industry has embraced high-strength materials for their ability to create more durable and resilient structures. High-strength concrete and advanced steel alloys are being used in skyscrapers, bridges, and other infrastructure projects to improve structural integrity and longevity. In the consumer electronics sector, high-strength materials such as chemically strengthened glass and advanced polymers are essential for producing durable and lightweight devices.

Market analysis indicates that the global high-strength materials market is poised for continued growth. Factors contributing to this growth include ongoing technological advancements, increasing focus on sustainability, and the need for materials that can withstand extreme conditions in various applications. The market is also benefiting from the growing adoption of additive manufacturing techniques, which enable the production of complex geometries using high-strength materials.

Regionally, North America and Europe have traditionally been the largest markets for high-strength materials, owing to their well-established automotive and aerospace industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, infrastructure development, and the expansion of manufacturing capabilities in countries like China and India.

Despite the positive outlook, the high-strength materials market faces challenges such as high production costs, complex manufacturing processes, and the need for specialized equipment and expertise. These factors can limit adoption, particularly in price-sensitive industries or regions. Additionally, the market is subject to fluctuations in raw material prices and supply chain disruptions, which can impact profitability and production schedules.

Looking ahead, the high-strength materials market is expected to continue evolving, with ongoing research and development efforts focused on improving material properties, reducing production costs, and expanding applications. The integration of nanotechnology and the development of bio-based high-strength materials are emerging trends that could reshape the market landscape in the coming years.

In the automotive sector, the push for lightweight vehicles to improve fuel efficiency and reduce emissions has led to a surge in demand for high-strength materials. Advanced high-strength steels (AHSS) and aluminum alloys are increasingly being used in vehicle structures, body panels, and components. The aerospace industry also relies heavily on high-strength materials to enhance aircraft performance and fuel efficiency, with titanium alloys and carbon fiber reinforced polymers (CFRP) being key materials in this sector.

The construction industry has embraced high-strength materials for their ability to create more durable and resilient structures. High-strength concrete and advanced steel alloys are being used in skyscrapers, bridges, and other infrastructure projects to improve structural integrity and longevity. In the consumer electronics sector, high-strength materials such as chemically strengthened glass and advanced polymers are essential for producing durable and lightweight devices.

Market analysis indicates that the global high-strength materials market is poised for continued growth. Factors contributing to this growth include ongoing technological advancements, increasing focus on sustainability, and the need for materials that can withstand extreme conditions in various applications. The market is also benefiting from the growing adoption of additive manufacturing techniques, which enable the production of complex geometries using high-strength materials.

Regionally, North America and Europe have traditionally been the largest markets for high-strength materials, owing to their well-established automotive and aerospace industries. However, the Asia-Pacific region is emerging as a significant market, driven by rapid industrialization, infrastructure development, and the expansion of manufacturing capabilities in countries like China and India.

Despite the positive outlook, the high-strength materials market faces challenges such as high production costs, complex manufacturing processes, and the need for specialized equipment and expertise. These factors can limit adoption, particularly in price-sensitive industries or regions. Additionally, the market is subject to fluctuations in raw material prices and supply chain disruptions, which can impact profitability and production schedules.

Looking ahead, the high-strength materials market is expected to continue evolving, with ongoing research and development efforts focused on improving material properties, reducing production costs, and expanding applications. The integration of nanotechnology and the development of bio-based high-strength materials are emerging trends that could reshape the market landscape in the coming years.

Vacuum Forming Limitations for High-Strength Materials

Vacuum forming is a widely used manufacturing process for shaping thermoplastic sheets into various products. However, when it comes to high-strength materials, this technique faces significant limitations. The primary challenge lies in the material's inherent resistance to deformation, which is essential for achieving the desired shape during the vacuum forming process.

One of the main limitations is the difficulty in achieving uniform thickness distribution across the formed part. High-strength materials tend to resist stretching, leading to uneven thinning in areas of deep draws or complex geometries. This can result in weak spots or compromised structural integrity in the final product, potentially affecting its performance and durability.

Temperature control presents another critical challenge in vacuum forming high-strength materials. These materials often require higher processing temperatures to become pliable enough for forming. However, maintaining precise temperature control throughout the process is crucial, as overheating can lead to material degradation or loss of mechanical properties, while insufficient heating may result in incomplete forming or surface defects.

The cooling rate of high-strength materials also poses a limitation. Rapid cooling can induce internal stresses within the material, potentially leading to warping, dimensional instability, or reduced mechanical strength in the finished part. Controlling the cooling rate to ensure uniform solidification without compromising the material's properties is a delicate balance that requires careful process optimization.

Tooling design and material selection for molds present additional challenges. High-strength materials often require more robust and heat-resistant tooling to withstand the higher processing temperatures and pressures. This can significantly increase tooling costs and limit the economic viability of vacuum forming for certain high-strength material applications.

Furthermore, the surface finish of vacuum-formed high-strength parts may be compromised due to the material's resistance to conforming to fine mold details. This can result in reduced aesthetic quality or the need for additional post-processing steps, increasing production time and costs.

The limited formability of high-strength materials also restricts the complexity of shapes that can be achieved through vacuum forming. Deep draws, sharp corners, and intricate geometries may be difficult or impossible to produce without risking material failure or excessive thinning.

In conclusion, while vacuum forming offers many advantages in plastic processing, its application to high-strength materials is constrained by several technical limitations. Overcoming these challenges requires innovative approaches in material science, process engineering, and tooling design to expand the capabilities of vacuum forming for high-performance applications.

One of the main limitations is the difficulty in achieving uniform thickness distribution across the formed part. High-strength materials tend to resist stretching, leading to uneven thinning in areas of deep draws or complex geometries. This can result in weak spots or compromised structural integrity in the final product, potentially affecting its performance and durability.

Temperature control presents another critical challenge in vacuum forming high-strength materials. These materials often require higher processing temperatures to become pliable enough for forming. However, maintaining precise temperature control throughout the process is crucial, as overheating can lead to material degradation or loss of mechanical properties, while insufficient heating may result in incomplete forming or surface defects.

The cooling rate of high-strength materials also poses a limitation. Rapid cooling can induce internal stresses within the material, potentially leading to warping, dimensional instability, or reduced mechanical strength in the finished part. Controlling the cooling rate to ensure uniform solidification without compromising the material's properties is a delicate balance that requires careful process optimization.

Tooling design and material selection for molds present additional challenges. High-strength materials often require more robust and heat-resistant tooling to withstand the higher processing temperatures and pressures. This can significantly increase tooling costs and limit the economic viability of vacuum forming for certain high-strength material applications.

Furthermore, the surface finish of vacuum-formed high-strength parts may be compromised due to the material's resistance to conforming to fine mold details. This can result in reduced aesthetic quality or the need for additional post-processing steps, increasing production time and costs.

The limited formability of high-strength materials also restricts the complexity of shapes that can be achieved through vacuum forming. Deep draws, sharp corners, and intricate geometries may be difficult or impossible to produce without risking material failure or excessive thinning.

In conclusion, while vacuum forming offers many advantages in plastic processing, its application to high-strength materials is constrained by several technical limitations. Overcoming these challenges requires innovative approaches in material science, process engineering, and tooling design to expand the capabilities of vacuum forming for high-performance applications.

Current Solutions for High-Strength Material Forming

01 Improving vacuum forming strength through material selection

Selecting appropriate materials with high tensile strength and formability can significantly enhance the strength of vacuum-formed products. This includes using reinforced plastics, composite materials, or specially formulated thermoplastics that maintain their structural integrity during and after the forming process.- Improving vacuum forming strength through material selection: Selecting appropriate materials with high tensile strength and formability can significantly enhance the strength of vacuum formed products. This includes using reinforced plastics, composite materials, or specially formulated thermoplastics that maintain their structural integrity during and after the forming process.

- Optimizing vacuum forming process parameters: Adjusting process parameters such as temperature, pressure, and forming speed can improve the strength of vacuum formed parts. Precise control of these variables ensures optimal material flow and distribution, resulting in stronger and more uniform products.

- Enhancing mold design for improved strength: Innovative mold designs, including the use of reinforced or multi-part molds, can contribute to increased strength in vacuum formed products. Proper mold design ensures even material distribution and reduces weak points in the final product.

- Incorporating reinforcement techniques: Various reinforcement techniques can be applied to enhance the strength of vacuum formed parts. These may include adding ribs, gussets, or using sandwich structures to improve overall structural integrity without significantly increasing weight.

- Utilizing advanced testing and simulation methods: Employing advanced testing and simulation techniques allows for the prediction and optimization of vacuum formed part strength. Finite element analysis and other computational methods can be used to identify potential weak points and optimize design before production.

02 Optimizing vacuum forming process parameters

Adjusting process parameters such as temperature, pressure, and forming speed can improve the strength of vacuum-formed parts. Precise control of these variables ensures optimal material flow and distribution, resulting in stronger and more uniform products.Expand Specific Solutions03 Enhancing mold design for improved strength

Innovative mold designs, including the use of reinforced or multi-part molds, can contribute to increased strength in vacuum-formed products. Proper mold design ensures even material distribution and reduces weak points in the final product.Expand Specific Solutions04 Incorporating reinforcement techniques

Implementing reinforcement techniques such as ribbing, embossing, or adding structural elements during the vacuum forming process can significantly enhance the strength of the final product. These methods provide additional support and rigidity to the formed parts.Expand Specific Solutions05 Utilizing advanced testing and analysis methods

Employing sophisticated testing and analysis techniques, including finite element analysis and non-destructive testing, helps in predicting and improving the strength of vacuum-formed parts. These methods allow for optimization of design and process parameters before production.Expand Specific Solutions

Key Players in Vacuum Forming Industry

The vacuum forming of high-strength materials is currently in a growth phase, with increasing market demand driven by industries such as aerospace, automotive, and medical devices. The global market size for this technology is expanding, estimated to reach several billion dollars in the coming years. Technologically, the process is advancing rapidly, with companies like Applied Materials, Tokyo Electron, and ASML Netherlands BV leading innovations in equipment and processes. Established players such as Schuler Pressen and Mitsubishi Gas Chemical are also contributing to the field's development. While the technology is maturing, challenges remain in achieving consistent quality and cost-effectiveness for complex high-strength materials, indicating room for further advancements and market growth.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL CORP. has developed advanced high-strength steel (AHSS) grades specifically designed for vacuum forming processes. Their technology involves precise control of microstructure and alloying elements to achieve optimal formability while maintaining high strength. The company utilizes a combination of hot stamping and vacuum forming techniques, where the steel is heated to its austenitic phase before being rapidly cooled and formed in a vacuum environment[1]. This process allows for complex geometries and tight tolerances in high-strength components. Additionally, NIPPON STEEL has implemented surface treatments and coatings that enhance the material's resistance to thinning during deep drawing operations under vacuum conditions[3].

Strengths: Excellent combination of strength and formability, ability to produce complex shapes. Weaknesses: Higher production costs, potential for springback in certain geometries.

Schuler Pressen GmbH & Co. KG

Technical Solution: Schuler Pressen has developed a vacuum-assisted hydroforming technology for high-strength materials. Their system uses a flexible membrane and hydraulic pressure in combination with a vacuum chamber to form complex shapes from high-strength sheet metals. The process begins by creating a vacuum between the sheet metal and the die, which helps to eliminate air pockets and improve material flow. Hydraulic pressure is then applied to the opposite side of the sheet, causing it to conform to the die shape[5]. This method allows for more uniform material distribution and reduces the risk of wrinkling or tearing in high-strength materials. Schuler has also implemented adaptive pressure control systems that adjust forming parameters in real-time based on material behavior[6].

Strengths: Enables forming of complex shapes with high-strength materials, reduces material waste. Weaknesses: Higher initial equipment costs, longer cycle times compared to traditional stamping.

Innovative Approaches in Vacuum Forming Technology

Composite articles

PatentInactiveEP0713845A2

Innovation

- A vacuum forming method employing a dispersion with anhydrous crystalline minerals, such as Wollastonite, as the major solid constituent, along with a binder system and optional fillers, to create a composite article with enhanced thermal resistance and insulation.

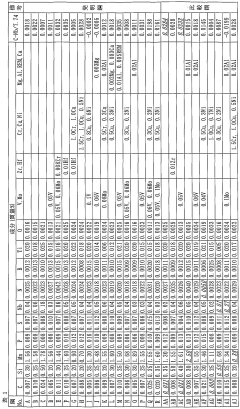

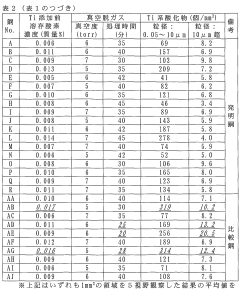

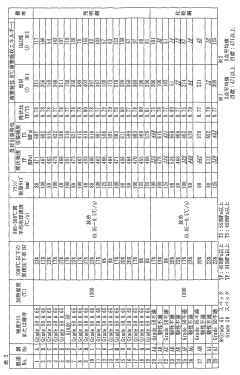

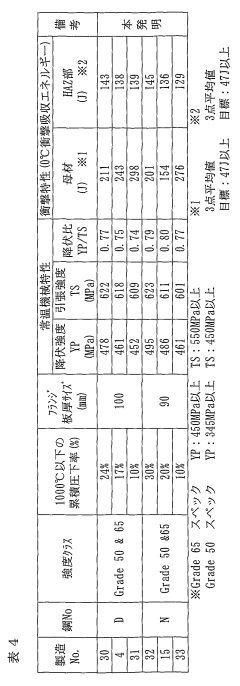

High-strength thick steel products excellent in toughness and weldability, high-strength ultra-thick h shape steel and processes for manufacturing both

PatentWO2010013358A1

Innovation

- A method to produce steel with enhanced strength, toughness, and durability by controlling heat treatment and adding a small amount of carbon, along with specific elemental compositions and vacuum gas processing, to limit particle dispersion and oxide formation, ensuring excellent mechanical properties without hot rolling treatment.

Material Science Advancements for Vacuum Forming

Recent advancements in material science have significantly impacted the field of vacuum forming, particularly in addressing the challenges associated with high-strength materials. These developments have focused on enhancing the formability, durability, and overall performance of materials used in vacuum forming processes.

One of the key areas of progress has been in the development of advanced polymer composites. These materials combine the lightweight properties of polymers with the strength and stiffness of reinforcing fibers, such as carbon or glass. By carefully engineering the composition and structure of these composites, researchers have created materials that can withstand the high stresses involved in vacuum forming while maintaining their shape and integrity.

Nanotechnology has also played a crucial role in improving material properties for vacuum forming. The incorporation of nanoparticles into polymer matrices has led to enhanced mechanical strength, thermal stability, and barrier properties. For instance, the addition of nano-clays to thermoplastics has resulted in materials with improved heat resistance and reduced gas permeability, making them ideal for vacuum-formed packaging applications.

Another significant advancement has been the development of smart materials that can respond to external stimuli. Shape memory polymers, for example, can be deformed at high temperatures and then return to their original shape when cooled. This property has opened up new possibilities for creating complex, three-dimensional structures through vacuum forming that were previously difficult or impossible to achieve.

Surface modification techniques have also evolved to address adhesion issues in vacuum forming. Plasma treatment and chemical functionalization methods have been refined to improve the bonding between different layers in multi-material structures, enhancing the overall strength and durability of vacuum-formed products.

Furthermore, the integration of computational modeling and simulation tools has revolutionized material design for vacuum forming. These tools allow researchers to predict material behavior under various forming conditions, optimize material compositions, and develop new alloys or polymer blends tailored specifically for vacuum forming applications.

Biodegradable and sustainable materials have gained significant attention in recent years. Researchers have made strides in developing bio-based polymers and composites that can be effectively vacuum formed while offering environmentally friendly alternatives to traditional petroleum-based plastics.

These advancements in material science have not only expanded the range of materials suitable for vacuum forming but have also improved the quality, functionality, and sustainability of vacuum-formed products across various industries, from automotive to medical devices.

One of the key areas of progress has been in the development of advanced polymer composites. These materials combine the lightweight properties of polymers with the strength and stiffness of reinforcing fibers, such as carbon or glass. By carefully engineering the composition and structure of these composites, researchers have created materials that can withstand the high stresses involved in vacuum forming while maintaining their shape and integrity.

Nanotechnology has also played a crucial role in improving material properties for vacuum forming. The incorporation of nanoparticles into polymer matrices has led to enhanced mechanical strength, thermal stability, and barrier properties. For instance, the addition of nano-clays to thermoplastics has resulted in materials with improved heat resistance and reduced gas permeability, making them ideal for vacuum-formed packaging applications.

Another significant advancement has been the development of smart materials that can respond to external stimuli. Shape memory polymers, for example, can be deformed at high temperatures and then return to their original shape when cooled. This property has opened up new possibilities for creating complex, three-dimensional structures through vacuum forming that were previously difficult or impossible to achieve.

Surface modification techniques have also evolved to address adhesion issues in vacuum forming. Plasma treatment and chemical functionalization methods have been refined to improve the bonding between different layers in multi-material structures, enhancing the overall strength and durability of vacuum-formed products.

Furthermore, the integration of computational modeling and simulation tools has revolutionized material design for vacuum forming. These tools allow researchers to predict material behavior under various forming conditions, optimize material compositions, and develop new alloys or polymer blends tailored specifically for vacuum forming applications.

Biodegradable and sustainable materials have gained significant attention in recent years. Researchers have made strides in developing bio-based polymers and composites that can be effectively vacuum formed while offering environmentally friendly alternatives to traditional petroleum-based plastics.

These advancements in material science have not only expanded the range of materials suitable for vacuum forming but have also improved the quality, functionality, and sustainability of vacuum-formed products across various industries, from automotive to medical devices.

Environmental Impact of Vacuum Forming Processes

Vacuum forming processes, while efficient for shaping high-strength materials, have significant environmental implications that warrant careful consideration. The primary environmental concerns stem from energy consumption, material waste, and emissions associated with the manufacturing process.

Energy usage is a major factor in the environmental impact of vacuum forming. The process requires substantial electrical power to heat materials to their forming temperature and operate vacuum pumps. This energy demand contributes to greenhouse gas emissions when sourced from non-renewable energy sources. Implementing energy-efficient heating systems and exploring renewable energy options can help mitigate this impact.

Material waste is another critical environmental issue. While vacuum forming is generally more efficient than some alternative manufacturing methods, it still produces waste in the form of excess material trimmed from formed parts. This waste, particularly when working with high-strength materials, may not be easily recyclable due to the specialized nature of these materials. Developing more efficient material utilization strategies and improving recycling technologies for high-strength materials are essential steps in reducing this environmental burden.

Emissions from the vacuum forming process also pose environmental challenges. When heating certain high-strength materials, volatile organic compounds (VOCs) and other potentially harmful substances may be released. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities. Implementing effective ventilation systems and exploring low-emission materials are crucial for minimizing these impacts.

Water usage in vacuum forming, while not as significant as in some other manufacturing processes, still contributes to the overall environmental footprint. Water is often used for cooling molds and formed parts. Implementing closed-loop cooling systems and water recycling technologies can help reduce water consumption and associated environmental impacts.

The disposal of end-of-life vacuum-formed products made from high-strength materials presents another environmental challenge. Many of these materials are not biodegradable and may persist in the environment for extended periods. Developing effective recycling and upcycling strategies for these products is crucial for minimizing their long-term environmental impact.

To address these environmental concerns, the industry is exploring various sustainable practices. These include the use of bio-based and recyclable high-strength materials, implementation of energy recovery systems, and adoption of lean manufacturing principles to minimize waste. Additionally, life cycle assessment (LCA) studies are being conducted to comprehensively evaluate the environmental impact of vacuum-formed products from raw material extraction to end-of-life disposal.

Energy usage is a major factor in the environmental impact of vacuum forming. The process requires substantial electrical power to heat materials to their forming temperature and operate vacuum pumps. This energy demand contributes to greenhouse gas emissions when sourced from non-renewable energy sources. Implementing energy-efficient heating systems and exploring renewable energy options can help mitigate this impact.

Material waste is another critical environmental issue. While vacuum forming is generally more efficient than some alternative manufacturing methods, it still produces waste in the form of excess material trimmed from formed parts. This waste, particularly when working with high-strength materials, may not be easily recyclable due to the specialized nature of these materials. Developing more efficient material utilization strategies and improving recycling technologies for high-strength materials are essential steps in reducing this environmental burden.

Emissions from the vacuum forming process also pose environmental challenges. When heating certain high-strength materials, volatile organic compounds (VOCs) and other potentially harmful substances may be released. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities. Implementing effective ventilation systems and exploring low-emission materials are crucial for minimizing these impacts.

Water usage in vacuum forming, while not as significant as in some other manufacturing processes, still contributes to the overall environmental footprint. Water is often used for cooling molds and formed parts. Implementing closed-loop cooling systems and water recycling technologies can help reduce water consumption and associated environmental impacts.

The disposal of end-of-life vacuum-formed products made from high-strength materials presents another environmental challenge. Many of these materials are not biodegradable and may persist in the environment for extended periods. Developing effective recycling and upcycling strategies for these products is crucial for minimizing their long-term environmental impact.

To address these environmental concerns, the industry is exploring various sustainable practices. These include the use of bio-based and recyclable high-strength materials, implementation of energy recovery systems, and adoption of lean manufacturing principles to minimize waste. Additionally, life cycle assessment (LCA) studies are being conducted to comprehensively evaluate the environmental impact of vacuum-formed products from raw material extraction to end-of-life disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!