Tracking Material Deformation Using Vacuum Forming Simulations

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Simulation Background and Objectives

Vacuum forming is a thermoforming process that has been widely used in manufacturing for decades. It involves heating a plastic sheet until it becomes pliable, then using vacuum suction to draw the softened material onto a mold. This technique has found applications in various industries, including packaging, automotive, aerospace, and consumer goods production. As the demand for more complex and precise parts increases, the need for accurate simulation of the vacuum forming process has become paramount.

The evolution of vacuum forming technology can be traced back to the 1940s, with significant advancements occurring in the 1960s and 1970s. Initially, the process relied heavily on trial and error, with manufacturers often producing multiple prototypes before achieving the desired result. This approach was time-consuming, costly, and inefficient. The advent of computer-aided design (CAD) and finite element analysis (FEA) in the 1980s and 1990s marked a turning point, enabling rudimentary simulations of the forming process.

In recent years, the focus has shifted towards developing more sophisticated simulation tools that can accurately predict material behavior during vacuum forming. These simulations aim to model the complex interactions between heat transfer, material properties, and mechanical deformation. The primary objective is to create virtual prototypes that closely mimic real-world results, thereby reducing the need for physical prototyping and optimizing the manufacturing process.

Tracking material deformation using vacuum forming simulations represents a critical advancement in this field. It allows manufacturers to visualize and analyze how materials stretch, thin, and conform to mold geometries under various process conditions. This capability is crucial for ensuring part quality, optimizing material usage, and identifying potential defects before production begins.

The main goals of vacuum forming simulation in tracking material deformation include:

1. Accurately predicting material thickness distribution across the formed part.

2. Identifying areas of excessive thinning or potential failure.

3. Optimizing process parameters such as heating time, vacuum pressure, and mold design.

4. Reducing the number of physical prototypes required for product development.

5. Improving overall product quality and consistency.

6. Minimizing material waste and production costs.

As the technology continues to evolve, researchers and industry professionals are working towards developing more accurate models that account for the viscoelastic behavior of polymers, non-uniform temperature distributions, and complex mold geometries. The integration of machine learning and artificial intelligence is expected to further enhance the predictive capabilities of these simulations, paving the way for more efficient and innovative vacuum forming processes in the future.

The evolution of vacuum forming technology can be traced back to the 1940s, with significant advancements occurring in the 1960s and 1970s. Initially, the process relied heavily on trial and error, with manufacturers often producing multiple prototypes before achieving the desired result. This approach was time-consuming, costly, and inefficient. The advent of computer-aided design (CAD) and finite element analysis (FEA) in the 1980s and 1990s marked a turning point, enabling rudimentary simulations of the forming process.

In recent years, the focus has shifted towards developing more sophisticated simulation tools that can accurately predict material behavior during vacuum forming. These simulations aim to model the complex interactions between heat transfer, material properties, and mechanical deformation. The primary objective is to create virtual prototypes that closely mimic real-world results, thereby reducing the need for physical prototyping and optimizing the manufacturing process.

Tracking material deformation using vacuum forming simulations represents a critical advancement in this field. It allows manufacturers to visualize and analyze how materials stretch, thin, and conform to mold geometries under various process conditions. This capability is crucial for ensuring part quality, optimizing material usage, and identifying potential defects before production begins.

The main goals of vacuum forming simulation in tracking material deformation include:

1. Accurately predicting material thickness distribution across the formed part.

2. Identifying areas of excessive thinning or potential failure.

3. Optimizing process parameters such as heating time, vacuum pressure, and mold design.

4. Reducing the number of physical prototypes required for product development.

5. Improving overall product quality and consistency.

6. Minimizing material waste and production costs.

As the technology continues to evolve, researchers and industry professionals are working towards developing more accurate models that account for the viscoelastic behavior of polymers, non-uniform temperature distributions, and complex mold geometries. The integration of machine learning and artificial intelligence is expected to further enhance the predictive capabilities of these simulations, paving the way for more efficient and innovative vacuum forming processes in the future.

Market Analysis for Vacuum Forming Simulation Tools

The market for vacuum forming simulation tools is experiencing significant growth, driven by the increasing demand for efficient and cost-effective manufacturing processes across various industries. These tools play a crucial role in optimizing product design, reducing material waste, and improving overall production efficiency in sectors such as automotive, aerospace, packaging, and consumer goods.

The global market for vacuum forming simulation software is expected to expand at a steady pace over the next five years. This growth is primarily attributed to the rising adoption of digital manufacturing technologies and the increasing emphasis on sustainable production practices. Manufacturers are increasingly recognizing the value of simulation tools in reducing time-to-market and minimizing production errors, leading to substantial cost savings.

In terms of regional distribution, North America and Europe currently dominate the market for vacuum forming simulation tools. This is largely due to the presence of established manufacturing industries and early adoption of advanced technologies in these regions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expanding manufacturing sector in countries like China, India, and South Korea.

The market is characterized by a mix of large, established software companies and specialized niche players. Major CAD/CAM software providers are incorporating vacuum forming simulation capabilities into their comprehensive product suites, while specialized firms are focusing on developing highly accurate and industry-specific simulation tools.

Key market drivers include the increasing complexity of product designs, stringent quality standards, and the need for rapid prototyping. As manufacturers strive to produce more intricate and customized products, the demand for advanced simulation tools that can accurately predict material behavior during the vacuum forming process is on the rise.

The integration of artificial intelligence and machine learning technologies into vacuum forming simulation tools is emerging as a significant trend. These advancements are enabling more accurate predictions of material deformation and optimizing process parameters, further enhancing the value proposition of these tools.

Despite the positive outlook, the market faces challenges such as the high initial investment required for advanced simulation software and the need for skilled personnel to operate these tools effectively. However, the long-term benefits in terms of reduced material waste, improved product quality, and increased production efficiency are expected to outweigh these initial barriers.

The global market for vacuum forming simulation software is expected to expand at a steady pace over the next five years. This growth is primarily attributed to the rising adoption of digital manufacturing technologies and the increasing emphasis on sustainable production practices. Manufacturers are increasingly recognizing the value of simulation tools in reducing time-to-market and minimizing production errors, leading to substantial cost savings.

In terms of regional distribution, North America and Europe currently dominate the market for vacuum forming simulation tools. This is largely due to the presence of established manufacturing industries and early adoption of advanced technologies in these regions. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by the expanding manufacturing sector in countries like China, India, and South Korea.

The market is characterized by a mix of large, established software companies and specialized niche players. Major CAD/CAM software providers are incorporating vacuum forming simulation capabilities into their comprehensive product suites, while specialized firms are focusing on developing highly accurate and industry-specific simulation tools.

Key market drivers include the increasing complexity of product designs, stringent quality standards, and the need for rapid prototyping. As manufacturers strive to produce more intricate and customized products, the demand for advanced simulation tools that can accurately predict material behavior during the vacuum forming process is on the rise.

The integration of artificial intelligence and machine learning technologies into vacuum forming simulation tools is emerging as a significant trend. These advancements are enabling more accurate predictions of material deformation and optimizing process parameters, further enhancing the value proposition of these tools.

Despite the positive outlook, the market faces challenges such as the high initial investment required for advanced simulation software and the need for skilled personnel to operate these tools effectively. However, the long-term benefits in terms of reduced material waste, improved product quality, and increased production efficiency are expected to outweigh these initial barriers.

Current Challenges in Material Deformation Tracking

Tracking material deformation during vacuum forming processes presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary difficulties lies in the complex nature of material behavior under the influence of heat and pressure. Materials used in vacuum forming, such as thermoplastics, exhibit non-linear and time-dependent properties, making accurate prediction and simulation of their deformation a formidable task.

The high-speed nature of the vacuum forming process further complicates the tracking of material deformation. As the material is rapidly heated and stretched over a mold, capturing real-time data on its changing shape and thickness becomes extremely challenging. Traditional sensing technologies often struggle to keep pace with the rapid deformation, leading to incomplete or inaccurate data collection.

Another significant challenge is the variability in material properties and process conditions. Factors such as temperature distribution, material composition, and even ambient conditions can significantly affect the deformation process. This variability makes it difficult to develop universally applicable models and simulations, necessitating a more adaptive and robust approach to tracking material deformation.

The interaction between the material and the mold surface introduces additional complexities. Friction, adhesion, and heat transfer at the material-mold interface can significantly influence the deformation process. Accurately modeling and simulating these interactions remains a considerable challenge, particularly when dealing with complex mold geometries or textured surfaces.

Furthermore, the multi-physics nature of the vacuum forming process poses a significant challenge for simulation and tracking efforts. The process involves simultaneous heat transfer, fluid dynamics (air flow), and structural mechanics (material deformation). Integrating these diverse physical phenomena into a cohesive and computationally efficient simulation model is a complex undertaking that continues to challenge researchers in the field.

The need for real-time feedback and control during the vacuum forming process adds another layer of complexity to the challenge of tracking material deformation. Developing systems that can not only accurately track deformation but also provide instantaneous feedback for process optimization remains an active area of research and development.

Lastly, the validation of simulation models against real-world data presents its own set of challenges. Obtaining accurate experimental data for comparison with simulations is often difficult due to the limitations of current measurement technologies and the inherent variability of the vacuum forming process. This gap between simulation and reality continues to be a significant hurdle in advancing the field of material deformation tracking in vacuum forming simulations.

The high-speed nature of the vacuum forming process further complicates the tracking of material deformation. As the material is rapidly heated and stretched over a mold, capturing real-time data on its changing shape and thickness becomes extremely challenging. Traditional sensing technologies often struggle to keep pace with the rapid deformation, leading to incomplete or inaccurate data collection.

Another significant challenge is the variability in material properties and process conditions. Factors such as temperature distribution, material composition, and even ambient conditions can significantly affect the deformation process. This variability makes it difficult to develop universally applicable models and simulations, necessitating a more adaptive and robust approach to tracking material deformation.

The interaction between the material and the mold surface introduces additional complexities. Friction, adhesion, and heat transfer at the material-mold interface can significantly influence the deformation process. Accurately modeling and simulating these interactions remains a considerable challenge, particularly when dealing with complex mold geometries or textured surfaces.

Furthermore, the multi-physics nature of the vacuum forming process poses a significant challenge for simulation and tracking efforts. The process involves simultaneous heat transfer, fluid dynamics (air flow), and structural mechanics (material deformation). Integrating these diverse physical phenomena into a cohesive and computationally efficient simulation model is a complex undertaking that continues to challenge researchers in the field.

The need for real-time feedback and control during the vacuum forming process adds another layer of complexity to the challenge of tracking material deformation. Developing systems that can not only accurately track deformation but also provide instantaneous feedback for process optimization remains an active area of research and development.

Lastly, the validation of simulation models against real-world data presents its own set of challenges. Obtaining accurate experimental data for comparison with simulations is often difficult due to the limitations of current measurement technologies and the inherent variability of the vacuum forming process. This gap between simulation and reality continues to be a significant hurdle in advancing the field of material deformation tracking in vacuum forming simulations.

Existing Material Deformation Tracking Solutions

01 Simulation methods for vacuum forming processes

Various simulation methods are employed to predict material deformation during vacuum forming. These methods include finite element analysis, computational fluid dynamics, and numerical modeling techniques. Simulations help optimize process parameters, predict material behavior, and improve product quality.- Simulation of material deformation in vacuum forming: Advanced simulation techniques are used to model and predict material deformation during the vacuum forming process. These simulations take into account factors such as material properties, temperature, and applied forces to accurately represent how the material will behave when subjected to vacuum pressure. This allows for optimization of the forming process and prediction of potential issues before physical production.

- Temperature control and heating simulation: Simulations incorporate temperature control and heating elements to accurately model the thermal behavior of materials during vacuum forming. This includes simulating the heating of the material to its forming temperature, as well as the cooling process after forming. Proper temperature simulation is crucial for predicting material flow and final product quality.

- Material property analysis for vacuum forming: Simulations analyze various material properties such as elasticity, plasticity, and viscosity to accurately predict how different materials will deform under vacuum pressure. This analysis helps in selecting the most suitable materials for specific vacuum forming applications and optimizing process parameters to achieve desired results.

- Mold design optimization using simulations: Vacuum forming simulations are used to optimize mold designs by predicting how materials will interact with different mold geometries. This includes analyzing draft angles, undercuts, and other design features to ensure proper material flow and minimize defects in the final product. Simulations help in iterating and refining mold designs before physical prototyping.

- Real-time monitoring and adaptive control: Advanced simulation systems incorporate real-time monitoring and adaptive control features. These systems continuously compare actual forming processes with simulated results, allowing for immediate adjustments to process parameters. This ensures that the physical vacuum forming process closely matches the optimized simulations, resulting in improved product quality and consistency.

02 Material property considerations in vacuum forming simulations

Accurate simulation of vacuum forming processes requires consideration of material properties such as viscoelasticity, thermal conductivity, and strain rate sensitivity. These properties influence how materials deform under vacuum and heat, affecting the final product shape and quality.Expand Specific Solutions03 Temperature effects on material deformation

Temperature plays a crucial role in vacuum forming simulations. The heating and cooling phases of the process significantly affect material behavior and deformation. Simulations account for temperature distribution, heat transfer, and thermal gradients to accurately predict material flow and final part geometry.Expand Specific Solutions04 Multi-layer material deformation modeling

Simulations for vacuum forming of multi-layer materials require specialized approaches to account for the interaction between layers. These models consider factors such as interfacial adhesion, differential thermal expansion, and varying material properties to predict deformation accurately.Expand Specific Solutions05 Real-time monitoring and adaptive simulation techniques

Advanced vacuum forming simulations incorporate real-time monitoring and adaptive techniques. These methods use sensor data to adjust simulation parameters dynamically, improving accuracy and allowing for process optimization during production. This approach helps in predicting and mitigating defects caused by material deformation.Expand Specific Solutions

Key Players in Vacuum Forming Simulation Industry

The competitive landscape for "Tracking Material Deformation Using Vacuum Forming Simulations" is in an early development stage, with a growing market potential as industries seek more precise manufacturing processes. The technology's maturity is still evolving, with key players like Sumitomo Rubber Industries, Mitsubishi Heavy Industries, and Siemens Medical Solutions USA leading research efforts. Academic institutions such as Northwestern Polytechnical University and Nanjing University of Aeronautics & Astronautics are contributing to advancements in this field. The market size is expected to expand as the technology finds applications in automotive, aerospace, and medical industries, driven by the need for improved material performance and cost-effective production methods.

Velo3D US, Inc.

Technical Solution: Velo3D has developed a specialized simulation platform for tracking material deformation in additive manufacturing processes, which has been adapted for vacuum forming applications. Their approach utilizes a voxel-based simulation method that allows for high-resolution tracking of material deformation at multiple scales[8]. The system incorporates advanced material models that account for non-linear and anisotropic behaviors often encountered in complex forming processes[10]. Velo3D's platform also features a unique optimization algorithm that can suggest modifications to part geometry or process parameters to minimize unwanted deformation during vacuum forming[12].

Strengths: High-resolution voxel-based simulation, advanced material modeling capabilities. Weaknesses: May be less suited for very large-scale forming processes, potentially high computational requirements.

Imetrum Ltd.

Technical Solution: Imetrum Ltd. has developed a cutting-edge non-contact measurement system specifically designed for tracking material deformation in vacuum forming processes. Their approach combines high-resolution video extensometry with advanced image processing algorithms to provide real-time, full-field strain measurements during the forming process[13]. The system integrates seamlessly with finite element simulation software, allowing for direct comparison between predicted and measured deformation patterns[15]. Imetrum's technology also includes a unique feature for tracking multiple layers in composite materials, providing insights into inter-layer interactions during vacuum forming[17].

Strengths: High-precision non-contact measurement, real-time full-field strain analysis. Weaknesses: May require line-of-sight access to the forming area, potential limitations in measuring opaque materials.

Core Innovations in Deformation Simulation Techniques

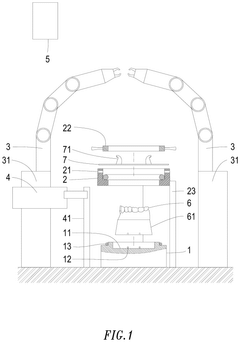

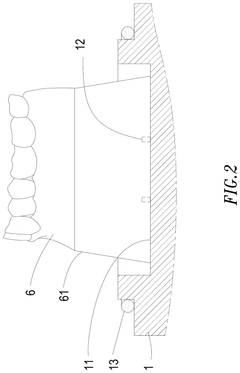

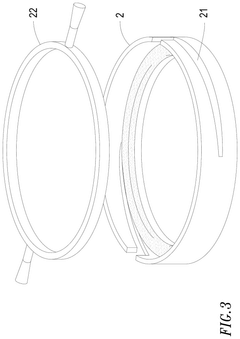

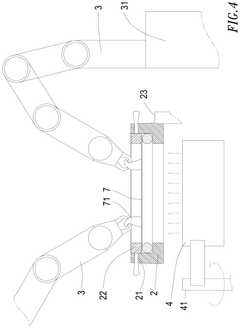

Vacuum forming method for membrane-like objects having protruding structures and forming apparatus thereof

PatentPendingUS20250042076A1

Innovation

- A computer simulation is used to pre-construct and position special structures on a membrane-like object, which is then transferred to a predetermined forming position using a controllable transfer device during the vacuum forming process, ensuring precise attachment to a mold.

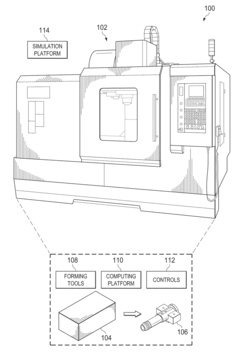

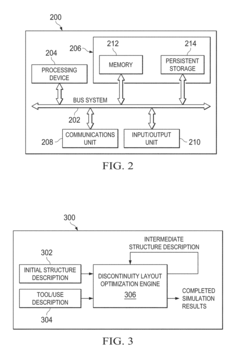

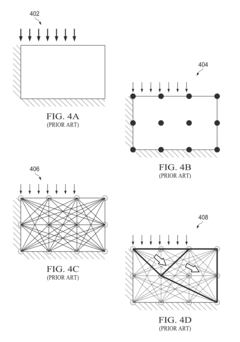

Apparatus and method for simulating machining and other forming operations

PatentActiveUS20180173829A1

Innovation

- The use of discontinuity layout optimization (DLO) to simulate material deformation by evaluating and predicting shear planes, calculating deformed shapes, and repeating these processes iteratively to model material removal during forming operations, allowing for more accurate and efficient prediction of CNC manufacturing machine behaviors.

Environmental Impact of Vacuum Forming Processes

Vacuum forming processes, while efficient for manufacturing various plastic products, have significant environmental implications that warrant careful consideration. The primary environmental concerns stem from the materials used, energy consumption, and waste generation associated with these processes.

The most notable environmental impact of vacuum forming is related to the raw materials utilized. Predominantly, vacuum forming relies on thermoplastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). These materials are derived from non-renewable fossil fuels, contributing to resource depletion and greenhouse gas emissions during their production. Moreover, many of these plastics are not biodegradable, leading to long-term environmental persistence and potential pollution if not properly managed at the end of their lifecycle.

Energy consumption is another critical factor in the environmental footprint of vacuum forming processes. The heating of plastic sheets to their forming temperature requires substantial energy input, often derived from fossil fuel sources. This energy demand contributes to carbon dioxide emissions and other greenhouse gases, exacerbating climate change concerns. Additionally, the operation of vacuum pumps and cooling systems further increases the overall energy requirements of the process.

Waste generation is an inherent challenge in vacuum forming. The trimming of excess material from formed parts produces plastic scrap, which, if not recycled, can contribute to landfill waste. While many thermoplastics used in vacuum forming are theoretically recyclable, the practical implementation of recycling programs faces obstacles such as contamination and the degradation of material properties through repeated processing cycles.

Water usage in vacuum forming, although not as significant as in some other manufacturing processes, still presents environmental considerations. Cooling systems may require substantial amounts of water, and the potential for water pollution through the release of plastic particles or additives during the manufacturing process exists.

The environmental impact extends beyond the immediate production phase to the entire lifecycle of vacuum-formed products. The durability and lightweight nature of many vacuum-formed items can lead to increased transportation efficiency and potentially longer product lifespans. However, these benefits must be weighed against the end-of-life challenges posed by plastic products, including their persistence in ecosystems and the growing concern over microplastic pollution.

Efforts to mitigate the environmental impact of vacuum forming processes are ongoing. These include the development of bio-based and biodegradable plastics as alternatives to traditional petroleum-based materials, improvements in energy efficiency through advanced heating and cooling technologies, and the implementation of closed-loop recycling systems within manufacturing facilities. Additionally, design strategies that minimize material usage and facilitate easy recycling at the end of product life are being explored to enhance the sustainability of vacuum-formed products.

The most notable environmental impact of vacuum forming is related to the raw materials utilized. Predominantly, vacuum forming relies on thermoplastics such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). These materials are derived from non-renewable fossil fuels, contributing to resource depletion and greenhouse gas emissions during their production. Moreover, many of these plastics are not biodegradable, leading to long-term environmental persistence and potential pollution if not properly managed at the end of their lifecycle.

Energy consumption is another critical factor in the environmental footprint of vacuum forming processes. The heating of plastic sheets to their forming temperature requires substantial energy input, often derived from fossil fuel sources. This energy demand contributes to carbon dioxide emissions and other greenhouse gases, exacerbating climate change concerns. Additionally, the operation of vacuum pumps and cooling systems further increases the overall energy requirements of the process.

Waste generation is an inherent challenge in vacuum forming. The trimming of excess material from formed parts produces plastic scrap, which, if not recycled, can contribute to landfill waste. While many thermoplastics used in vacuum forming are theoretically recyclable, the practical implementation of recycling programs faces obstacles such as contamination and the degradation of material properties through repeated processing cycles.

Water usage in vacuum forming, although not as significant as in some other manufacturing processes, still presents environmental considerations. Cooling systems may require substantial amounts of water, and the potential for water pollution through the release of plastic particles or additives during the manufacturing process exists.

The environmental impact extends beyond the immediate production phase to the entire lifecycle of vacuum-formed products. The durability and lightweight nature of many vacuum-formed items can lead to increased transportation efficiency and potentially longer product lifespans. However, these benefits must be weighed against the end-of-life challenges posed by plastic products, including their persistence in ecosystems and the growing concern over microplastic pollution.

Efforts to mitigate the environmental impact of vacuum forming processes are ongoing. These include the development of bio-based and biodegradable plastics as alternatives to traditional petroleum-based materials, improvements in energy efficiency through advanced heating and cooling technologies, and the implementation of closed-loop recycling systems within manufacturing facilities. Additionally, design strategies that minimize material usage and facilitate easy recycling at the end of product life are being explored to enhance the sustainability of vacuum-formed products.

Integration with Advanced Manufacturing Systems

The integration of vacuum forming simulations for tracking material deformation with advanced manufacturing systems represents a significant leap forward in precision manufacturing and quality control. This integration enables real-time monitoring and adjustment of the vacuum forming process, leading to improved product quality, reduced waste, and increased production efficiency.

Advanced manufacturing systems, such as Industry 4.0 and smart factories, rely heavily on data-driven decision-making and process optimization. By incorporating vacuum forming simulations into these systems, manufacturers can create a digital twin of the production process. This digital representation allows for predictive modeling of material behavior under various forming conditions, enabling proactive adjustments to process parameters before issues arise.

The integration process typically involves connecting simulation software with manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. This connection facilitates the flow of data between the simulation environment and the physical production line. Sensors and actuators on the vacuum forming equipment provide real-time data on temperature, pressure, and material properties, which are then fed into the simulation model.

Machine learning algorithms can be employed to continuously refine the simulation model based on actual production data. This adaptive approach ensures that the digital twin remains accurate over time, even as equipment ages or material properties change. The result is a self-optimizing production system that can automatically adjust process parameters to maintain optimal product quality.

One of the key benefits of this integration is the ability to perform virtual prototyping and process optimization. Manufacturers can test different material compositions, forming temperatures, and vacuum pressures in the simulation environment before committing to physical production runs. This capability significantly reduces the time and cost associated with traditional trial-and-error methods of process development.

Furthermore, the integration of vacuum forming simulations with advanced manufacturing systems enables enhanced quality control measures. By comparing real-time production data with simulation predictions, manufacturers can quickly identify deviations from expected material behavior. This early detection of potential defects allows for immediate corrective action, reducing scrap rates and improving overall product consistency.

As the technology continues to evolve, we can expect to see even tighter integration between simulation tools and physical production systems. Future developments may include augmented reality interfaces that overlay simulation data onto physical products, allowing operators to visualize material stress and deformation in real-time. Additionally, the use of artificial intelligence for autonomous decision-making in the production process will likely become more prevalent, further optimizing the vacuum forming process.

Advanced manufacturing systems, such as Industry 4.0 and smart factories, rely heavily on data-driven decision-making and process optimization. By incorporating vacuum forming simulations into these systems, manufacturers can create a digital twin of the production process. This digital representation allows for predictive modeling of material behavior under various forming conditions, enabling proactive adjustments to process parameters before issues arise.

The integration process typically involves connecting simulation software with manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. This connection facilitates the flow of data between the simulation environment and the physical production line. Sensors and actuators on the vacuum forming equipment provide real-time data on temperature, pressure, and material properties, which are then fed into the simulation model.

Machine learning algorithms can be employed to continuously refine the simulation model based on actual production data. This adaptive approach ensures that the digital twin remains accurate over time, even as equipment ages or material properties change. The result is a self-optimizing production system that can automatically adjust process parameters to maintain optimal product quality.

One of the key benefits of this integration is the ability to perform virtual prototyping and process optimization. Manufacturers can test different material compositions, forming temperatures, and vacuum pressures in the simulation environment before committing to physical production runs. This capability significantly reduces the time and cost associated with traditional trial-and-error methods of process development.

Furthermore, the integration of vacuum forming simulations with advanced manufacturing systems enables enhanced quality control measures. By comparing real-time production data with simulation predictions, manufacturers can quickly identify deviations from expected material behavior. This early detection of potential defects allows for immediate corrective action, reducing scrap rates and improving overall product consistency.

As the technology continues to evolve, we can expect to see even tighter integration between simulation tools and physical production systems. Future developments may include augmented reality interfaces that overlay simulation data onto physical products, allowing operators to visualize material stress and deformation in real-time. Additionally, the use of artificial intelligence for autonomous decision-making in the production process will likely become more prevalent, further optimizing the vacuum forming process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!