Use of Biodegradable Polymers in Vacuum Forming Processes

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Polymers in Vacuum Forming: Background and Objectives

Biodegradable polymers have emerged as a promising solution to address the growing environmental concerns associated with conventional plastics. The use of these materials in vacuum forming processes represents a significant advancement in sustainable manufacturing practices. This technological approach aims to combine the versatility of vacuum forming with the eco-friendly properties of biodegradable polymers, offering a potential pathway to reduce plastic waste and environmental impact.

The development of biodegradable polymers for vacuum forming applications has its roots in the broader field of sustainable materials science. Over the past few decades, researchers and industry professionals have been exploring alternatives to traditional petroleum-based plastics, driven by increasing awareness of plastic pollution and the need for more environmentally responsible production methods. Biodegradable polymers, derived from renewable resources or engineered to decompose naturally, have gained traction as a viable solution.

Vacuum forming, a well-established thermoforming technique, has been widely used in various industries for producing plastic products. The process involves heating a plastic sheet until it becomes pliable, then using vacuum pressure to conform the sheet to a mold. The integration of biodegradable polymers into this process presents both opportunities and challenges, as these materials often have different thermal and mechanical properties compared to conventional plastics.

The primary objective of utilizing biodegradable polymers in vacuum forming is to create products that maintain the desired functionality and quality while significantly reducing environmental impact. This goal encompasses several key aspects, including the development of biodegradable polymer formulations suitable for vacuum forming, optimization of processing parameters, and ensuring the final products meet performance standards across various applications.

Another critical objective is to address the end-of-life considerations for vacuum-formed biodegradable products. This involves designing materials that can effectively degrade under specific environmental conditions without leaving harmful residues. Additionally, there is a focus on creating closed-loop systems where these products can be composted or recycled, further minimizing their environmental footprint.

The technological evolution in this field is driven by the need to overcome existing limitations of biodegradable polymers, such as thermal stability, mechanical strength, and processability. Researchers are exploring various approaches, including polymer blending, nanotechnology, and chemical modifications, to enhance the properties of biodegradable materials for vacuum forming applications.

As the technology progresses, there is a growing emphasis on scalability and cost-effectiveness. The aim is to develop solutions that can be readily adopted by industries, making sustainable vacuum forming processes economically viable and competitive with traditional plastic manufacturing methods. This technological trajectory aligns with global sustainability goals and the increasing demand for environmentally friendly products across various sectors.

The development of biodegradable polymers for vacuum forming applications has its roots in the broader field of sustainable materials science. Over the past few decades, researchers and industry professionals have been exploring alternatives to traditional petroleum-based plastics, driven by increasing awareness of plastic pollution and the need for more environmentally responsible production methods. Biodegradable polymers, derived from renewable resources or engineered to decompose naturally, have gained traction as a viable solution.

Vacuum forming, a well-established thermoforming technique, has been widely used in various industries for producing plastic products. The process involves heating a plastic sheet until it becomes pliable, then using vacuum pressure to conform the sheet to a mold. The integration of biodegradable polymers into this process presents both opportunities and challenges, as these materials often have different thermal and mechanical properties compared to conventional plastics.

The primary objective of utilizing biodegradable polymers in vacuum forming is to create products that maintain the desired functionality and quality while significantly reducing environmental impact. This goal encompasses several key aspects, including the development of biodegradable polymer formulations suitable for vacuum forming, optimization of processing parameters, and ensuring the final products meet performance standards across various applications.

Another critical objective is to address the end-of-life considerations for vacuum-formed biodegradable products. This involves designing materials that can effectively degrade under specific environmental conditions without leaving harmful residues. Additionally, there is a focus on creating closed-loop systems where these products can be composted or recycled, further minimizing their environmental footprint.

The technological evolution in this field is driven by the need to overcome existing limitations of biodegradable polymers, such as thermal stability, mechanical strength, and processability. Researchers are exploring various approaches, including polymer blending, nanotechnology, and chemical modifications, to enhance the properties of biodegradable materials for vacuum forming applications.

As the technology progresses, there is a growing emphasis on scalability and cost-effectiveness. The aim is to develop solutions that can be readily adopted by industries, making sustainable vacuum forming processes economically viable and competitive with traditional plastic manufacturing methods. This technological trajectory aligns with global sustainability goals and the increasing demand for environmentally friendly products across various sectors.

Market Analysis for Eco-Friendly Packaging Solutions

The market for eco-friendly packaging solutions has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. The global biodegradable packaging market is expected to reach $21.7 billion by 2025, with a compound annual growth rate of 17.4% from 2020 to 2025. This growth is primarily fueled by the rising demand for sustainable packaging options across various industries, including food and beverage, personal care, and healthcare.

Consumer preferences have shifted towards environmentally responsible products, with a survey indicating that 74% of consumers are willing to pay more for sustainable packaging. This trend has prompted major retailers and brands to commit to using more eco-friendly packaging materials, creating a substantial market opportunity for biodegradable polymers in vacuum forming processes.

The food and beverage industry represents the largest market segment for eco-friendly packaging, accounting for approximately 42% of the total market share. This sector's demand is driven by the need for biodegradable food containers, trays, and wraps that can maintain product freshness while reducing environmental impact. The personal care and cosmetics industry follows closely, with a growing demand for sustainable packaging solutions for products such as shampoo bottles, cosmetic containers, and disposable razors.

Geographically, Europe leads the market for eco-friendly packaging solutions, followed by North America and the Asia-Pacific region. European countries have implemented stringent regulations on single-use plastics, which has accelerated the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

Key market drivers include government regulations banning or restricting single-use plastics, corporate sustainability initiatives, and consumer demand for environmentally friendly products. However, challenges such as higher production costs and limited waste management infrastructure for biodegradable materials persist. The cost of biodegradable polymers remains 20-100% higher than conventional plastics, depending on the specific material and application.

Competitive landscape analysis reveals that the market is fragmented, with several key players and numerous small to medium-sized enterprises. Major companies in this space are investing heavily in research and development to improve the performance and cost-effectiveness of biodegradable polymers for vacuum forming processes. Collaborations between material suppliers, packaging manufacturers, and end-users are becoming increasingly common to develop tailored solutions that meet specific industry needs.

Consumer preferences have shifted towards environmentally responsible products, with a survey indicating that 74% of consumers are willing to pay more for sustainable packaging. This trend has prompted major retailers and brands to commit to using more eco-friendly packaging materials, creating a substantial market opportunity for biodegradable polymers in vacuum forming processes.

The food and beverage industry represents the largest market segment for eco-friendly packaging, accounting for approximately 42% of the total market share. This sector's demand is driven by the need for biodegradable food containers, trays, and wraps that can maintain product freshness while reducing environmental impact. The personal care and cosmetics industry follows closely, with a growing demand for sustainable packaging solutions for products such as shampoo bottles, cosmetic containers, and disposable razors.

Geographically, Europe leads the market for eco-friendly packaging solutions, followed by North America and the Asia-Pacific region. European countries have implemented stringent regulations on single-use plastics, which has accelerated the adoption of biodegradable alternatives. The Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing disposable income, and growing environmental consciousness in countries like China and India.

Key market drivers include government regulations banning or restricting single-use plastics, corporate sustainability initiatives, and consumer demand for environmentally friendly products. However, challenges such as higher production costs and limited waste management infrastructure for biodegradable materials persist. The cost of biodegradable polymers remains 20-100% higher than conventional plastics, depending on the specific material and application.

Competitive landscape analysis reveals that the market is fragmented, with several key players and numerous small to medium-sized enterprises. Major companies in this space are investing heavily in research and development to improve the performance and cost-effectiveness of biodegradable polymers for vacuum forming processes. Collaborations between material suppliers, packaging manufacturers, and end-users are becoming increasingly common to develop tailored solutions that meet specific industry needs.

Current Challenges in Biodegradable Vacuum Forming

The integration of biodegradable polymers into vacuum forming processes presents several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is the limited thermal stability of many biodegradable polymers. These materials often have lower melting points and narrower processing windows compared to traditional petroleum-based plastics, making them more susceptible to degradation during the heating phase of vacuum forming.

Another critical challenge lies in achieving consistent and uniform thickness distribution across the formed product. Biodegradable polymers typically exhibit different flow characteristics and melt viscosities, which can lead to uneven material distribution during the forming process. This inconsistency can result in weak spots or areas of excessive thickness, compromising the structural integrity and functionality of the final product.

The moisture sensitivity of many biodegradable polymers poses additional complications. These materials tend to absorb moisture from the environment, which can cause processing issues such as bubbling, blistering, or incomplete forming. Proper drying procedures and moisture control become crucial steps in the manufacturing process, adding complexity and potentially increasing production time and costs.

Adhesion to molds and release properties present further challenges in biodegradable vacuum forming. Some biodegradable polymers may stick to mold surfaces more readily than conventional plastics, necessitating the use of specialized release agents or surface treatments. This can impact the surface quality of the formed parts and may require additional post-processing steps.

The mechanical properties of biodegradable polymers in vacuum-formed products often fall short of those achieved with traditional plastics. Issues such as lower impact resistance, reduced flexibility, and potential brittleness can limit the application range of these materials, particularly in demanding environments or for products requiring specific performance characteristics.

Cost considerations remain a significant barrier to widespread adoption. Biodegradable polymers are generally more expensive than their petroleum-based counterparts, and the additional processing requirements can further increase production costs. This economic factor often deters manufacturers from transitioning to more sustainable materials, especially in price-sensitive markets.

Lastly, the biodegradability of these polymers can be a double-edged sword in vacuum forming applications. While beneficial for end-of-life disposal, the susceptibility to degradation can lead to shorter shelf life and reduced durability of the formed products. Balancing the desired biodegradability with adequate product lifespan and performance remains a complex challenge for manufacturers and material scientists alike.

Another critical challenge lies in achieving consistent and uniform thickness distribution across the formed product. Biodegradable polymers typically exhibit different flow characteristics and melt viscosities, which can lead to uneven material distribution during the forming process. This inconsistency can result in weak spots or areas of excessive thickness, compromising the structural integrity and functionality of the final product.

The moisture sensitivity of many biodegradable polymers poses additional complications. These materials tend to absorb moisture from the environment, which can cause processing issues such as bubbling, blistering, or incomplete forming. Proper drying procedures and moisture control become crucial steps in the manufacturing process, adding complexity and potentially increasing production time and costs.

Adhesion to molds and release properties present further challenges in biodegradable vacuum forming. Some biodegradable polymers may stick to mold surfaces more readily than conventional plastics, necessitating the use of specialized release agents or surface treatments. This can impact the surface quality of the formed parts and may require additional post-processing steps.

The mechanical properties of biodegradable polymers in vacuum-formed products often fall short of those achieved with traditional plastics. Issues such as lower impact resistance, reduced flexibility, and potential brittleness can limit the application range of these materials, particularly in demanding environments or for products requiring specific performance characteristics.

Cost considerations remain a significant barrier to widespread adoption. Biodegradable polymers are generally more expensive than their petroleum-based counterparts, and the additional processing requirements can further increase production costs. This economic factor often deters manufacturers from transitioning to more sustainable materials, especially in price-sensitive markets.

Lastly, the biodegradability of these polymers can be a double-edged sword in vacuum forming applications. While beneficial for end-of-life disposal, the susceptibility to degradation can lead to shorter shelf life and reduced durability of the formed products. Balancing the desired biodegradability with adequate product lifespan and performance remains a complex challenge for manufacturers and material scientists alike.

Existing Biodegradable Vacuum Forming Techniques

01 Synthesis and composition of biodegradable polymers

Various methods and compositions for synthesizing biodegradable polymers are explored. These include the development of novel polymer blends, copolymers, and composites with enhanced biodegradability and improved mechanical properties. The focus is on creating materials that can degrade naturally in the environment while maintaining their functional characteristics during use.- Synthesis and composition of biodegradable polymers: Various methods and compositions for synthesizing biodegradable polymers are explored. These include the development of novel polymer blends, copolymers, and composites with enhanced biodegradability and improved mechanical properties. The focus is on creating materials that can degrade naturally in the environment while maintaining their functional characteristics during use.

- Applications of biodegradable polymers in medical field: Biodegradable polymers find extensive use in medical applications, particularly in drug delivery systems and tissue engineering. These polymers are designed to degrade safely within the body, allowing for controlled release of drugs or supporting tissue growth before being absorbed. The research focuses on improving biocompatibility and tailoring degradation rates for specific medical needs.

- Biodegradable polymers for packaging and consumer goods: The development of biodegradable polymers for packaging materials and consumer products is a growing area of research. These materials aim to replace traditional plastics in various applications, reducing environmental impact. The focus is on creating polymers that maintain necessary properties such as strength and barrier protection while ensuring complete biodegradation after disposal.

- Modification and enhancement of biodegradable polymers: Research efforts are directed towards modifying and enhancing the properties of existing biodegradable polymers. This includes the incorporation of additives, surface treatments, and the development of novel processing techniques to improve mechanical strength, thermal stability, and degradation characteristics. The goal is to expand the range of applications for these environmentally friendly materials.

- Biodegradable polymers from renewable resources: The production of biodegradable polymers from renewable resources is an emerging field of study. This involves the use of plant-based materials, agricultural waste, and other sustainable sources to create eco-friendly polymers. The research aims to develop cost-effective and scalable processes for producing these materials, reducing dependence on petroleum-based plastics.

02 Applications of biodegradable polymers in medical field

Biodegradable polymers find extensive use in medical applications, particularly in drug delivery systems and tissue engineering. These polymers are designed to degrade safely within the body, allowing for controlled release of drugs or supporting tissue growth before being absorbed. Research focuses on optimizing polymer properties for specific medical uses.Expand Specific Solutions03 Biodegradable polymers for packaging and consumer products

The development of biodegradable polymers for packaging materials and consumer products aims to reduce environmental impact. These polymers are designed to break down naturally after use, addressing issues of plastic pollution. Research in this area focuses on improving the durability and shelf-life of products while ensuring complete biodegradability.Expand Specific Solutions04 Modification and enhancement of biodegradable polymer properties

Techniques for modifying and enhancing the properties of biodegradable polymers are explored to improve their performance in various applications. This includes methods for increasing tensile strength, improving thermal stability, and enhancing biodegradation rates. The goal is to create versatile biodegradable materials that can compete with traditional non-biodegradable plastics.Expand Specific Solutions05 Environmental impact and biodegradation studies of polymers

Research into the environmental impact and biodegradation processes of various polymers is crucial for developing truly sustainable materials. Studies focus on understanding degradation mechanisms in different environments, assessing the ecological effects of degradation byproducts, and developing standardized testing methods for biodegradability claims.Expand Specific Solutions

Key Players in Biodegradable Polymer Manufacturing

The biodegradable polymers market in vacuum forming processes is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding, with a projected CAGR of 15-20% over the next five years. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech. Co., Ltd. and Plantic Technologies Ltd. leading innovation. BASF Corp. and CJ CheilJedang Corp. are also making significant strides in developing high-performance biodegradable materials. While the technology is maturing, challenges remain in matching the performance and cost-effectiveness of traditional plastics, indicating room for further development and market growth.

Plantic Technologies Ltd.

Technical Solution: Plantic Technologies specializes in developing and manufacturing biopolymer materials derived from non-GMO, high-amylose corn starch. Their Plantic® R1 material is specifically designed for thermoforming and vacuum forming applications[3]. The material offers excellent barrier properties, particularly against oxygen, making it suitable for food packaging. Plantic has developed a unique process that allows for the creation of multi-layer structures, combining the benefits of biopolymers with conventional plastics to enhance overall performance[4]. The company's technology enables the production of trays and containers with up to 80% renewable content, significantly reducing the carbon footprint of packaging products.

Strengths: High renewable content, excellent oxygen barrier properties, and compatibility with existing thermoforming equipment. Weaknesses: May have limitations in moisture-sensitive applications and potentially higher cost compared to conventional plastics.

BASF Corp.

Technical Solution: BASF Corp. has developed ecovio®, a biodegradable and compostable plastic certified for industrial composting. For vacuum forming processes, ecovio® offers excellent thermoforming properties and high temperature resistance[1]. The material consists of the biodegradable copolyester ecoflex® and polylactic acid (PLA), making it suitable for various packaging applications. BASF has also introduced ecovio® EA, specifically designed for agricultural films, which can be plowed into the soil after use and biodegrade without leaving harmful residues[2]. The company's continuous research focuses on improving the material's performance in different forming processes, including vacuum forming, to meet diverse industry needs.

Strengths: Wide range of applications, certified compostability, and good thermoforming properties. Weaknesses: May have higher production costs compared to conventional plastics and limited shelf life in certain conditions.

Innovations in Biodegradable Polymer Formulations

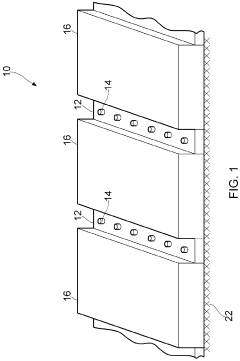

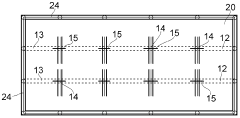

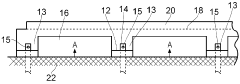

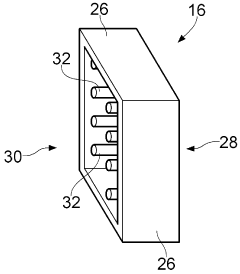

Environmentally degradable void former

PatentInactiveNZ589460A

Innovation

- A void forming apparatus using biodegradable polymers that support the concrete slab until it cures, then degrades to create a cavity for soil expansion, isolating the slab from ground movements and preventing damage.

Biodegradable polymer

PatentInactiveUS7326743B2

Innovation

- A process involving a mixture of starch, modified starch, a water-soluble polymer, polyol plasticizer, and a C12-22 fatty acid or salt, processed within specific temperature ranges to prevent foaming and allow for thermoforming without water removal, resulting in biodegradable polymers suitable for packaging trays and films.

Environmental Impact Assessment

The use of biodegradable polymers in vacuum forming processes presents a significant opportunity to reduce the environmental impact of plastic manufacturing. This assessment examines the potential benefits and challenges associated with this innovative approach.

Biodegradable polymers offer a promising alternative to conventional plastics, as they can decompose naturally in the environment, reducing long-term pollution and waste accumulation. When applied to vacuum forming processes, these materials can significantly decrease the ecological footprint of product packaging and disposable items.

One of the primary environmental benefits is the reduction of plastic waste in landfills and oceans. Biodegradable polymers can break down into harmless compounds, such as water, carbon dioxide, and biomass, within months to years, depending on the specific polymer and environmental conditions. This characteristic helps mitigate the persistent pollution issues associated with traditional plastics, which can take hundreds of years to degrade.

Furthermore, the production of biodegradable polymers often requires less energy and generates fewer greenhouse gas emissions compared to conventional plastic manufacturing. Many biodegradable polymers are derived from renewable resources, such as corn starch or sugarcane, which can be replenished naturally. This shift towards bio-based materials contributes to a more sustainable and circular economy.

However, the environmental impact of biodegradable polymers in vacuum forming is not without challenges. The degradation process of these materials may release methane, a potent greenhouse gas, if not properly managed in anaerobic environments like landfills. Additionally, the increased demand for bio-based raw materials could potentially lead to land-use changes and competition with food crops, raising concerns about food security and biodiversity.

The end-of-life management of biodegradable polymer products also requires careful consideration. While these materials can decompose in industrial composting facilities, many regions lack the necessary infrastructure to process them effectively. Improper disposal or mixing with conventional plastics in recycling streams can complicate waste management efforts and potentially contaminate recycled plastic streams.

To maximize the environmental benefits of biodegradable polymers in vacuum forming, it is crucial to implement comprehensive life cycle assessments. These evaluations should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life disposal. By understanding the full environmental impact, manufacturers can make informed decisions to optimize their processes and minimize negative effects.

In conclusion, the use of biodegradable polymers in vacuum forming processes offers significant potential for reducing environmental impact. However, realizing these benefits requires careful material selection, process optimization, and the development of appropriate waste management infrastructure. As technology advances and awareness grows, the integration of biodegradable polymers in vacuum forming can contribute to a more sustainable future for plastic manufacturing and product packaging.

Biodegradable polymers offer a promising alternative to conventional plastics, as they can decompose naturally in the environment, reducing long-term pollution and waste accumulation. When applied to vacuum forming processes, these materials can significantly decrease the ecological footprint of product packaging and disposable items.

One of the primary environmental benefits is the reduction of plastic waste in landfills and oceans. Biodegradable polymers can break down into harmless compounds, such as water, carbon dioxide, and biomass, within months to years, depending on the specific polymer and environmental conditions. This characteristic helps mitigate the persistent pollution issues associated with traditional plastics, which can take hundreds of years to degrade.

Furthermore, the production of biodegradable polymers often requires less energy and generates fewer greenhouse gas emissions compared to conventional plastic manufacturing. Many biodegradable polymers are derived from renewable resources, such as corn starch or sugarcane, which can be replenished naturally. This shift towards bio-based materials contributes to a more sustainable and circular economy.

However, the environmental impact of biodegradable polymers in vacuum forming is not without challenges. The degradation process of these materials may release methane, a potent greenhouse gas, if not properly managed in anaerobic environments like landfills. Additionally, the increased demand for bio-based raw materials could potentially lead to land-use changes and competition with food crops, raising concerns about food security and biodiversity.

The end-of-life management of biodegradable polymer products also requires careful consideration. While these materials can decompose in industrial composting facilities, many regions lack the necessary infrastructure to process them effectively. Improper disposal or mixing with conventional plastics in recycling streams can complicate waste management efforts and potentially contaminate recycled plastic streams.

To maximize the environmental benefits of biodegradable polymers in vacuum forming, it is crucial to implement comprehensive life cycle assessments. These evaluations should consider factors such as raw material sourcing, production processes, transportation, use phase, and end-of-life disposal. By understanding the full environmental impact, manufacturers can make informed decisions to optimize their processes and minimize negative effects.

In conclusion, the use of biodegradable polymers in vacuum forming processes offers significant potential for reducing environmental impact. However, realizing these benefits requires careful material selection, process optimization, and the development of appropriate waste management infrastructure. As technology advances and awareness grows, the integration of biodegradable polymers in vacuum forming can contribute to a more sustainable future for plastic manufacturing and product packaging.

Regulatory Framework for Biodegradable Packaging

The regulatory framework for biodegradable packaging is a complex and evolving landscape that plays a crucial role in the adoption and implementation of sustainable packaging solutions, including those involving biodegradable polymers in vacuum forming processes. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the World Trade Organization (WTO) have established guidelines and standards to promote sustainable packaging practices and reduce plastic waste.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging materials, including biodegradable plastics. The EU has also introduced the Single-Use Plastics Directive (EU) 2019/904, which aims to reduce the environmental impact of certain plastic products and promote the use of sustainable alternatives. These regulations have significant implications for the use of biodegradable polymers in vacuum forming processes, as they encourage the development and adoption of more environmentally friendly packaging solutions.

In the United States, the regulatory landscape is more fragmented, with both federal and state-level regulations impacting biodegradable packaging. The Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California and Washington, have implemented their own regulations on biodegradable plastics, often requiring specific certifications or standards to be met.

Many countries have introduced or are in the process of implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including packaging. These regulations incentivize the use of biodegradable materials in packaging applications, potentially driving innovation in vacuum forming processes using biodegradable polymers.

Certification standards play a crucial role in the regulatory framework for biodegradable packaging. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria offer certifications for compostable and biodegradable materials, which are often referenced in regulations and used by manufacturers to demonstrate compliance. These standards typically assess factors such as biodegradation rate, ecotoxicity, and the absence of harmful residues.

As the use of biodegradable polymers in vacuum forming processes continues to evolve, it is likely that regulatory frameworks will adapt to address new challenges and opportunities. This may include the development of more specific standards for biodegradable materials used in vacuum forming, as well as regulations addressing the end-of-life management of these products. Manufacturers and researchers working with biodegradable polymers in vacuum forming processes must stay informed about these regulatory developments to ensure compliance and capitalize on emerging opportunities in the sustainable packaging market.

In the European Union, the Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging materials, including biodegradable plastics. The EU has also introduced the Single-Use Plastics Directive (EU) 2019/904, which aims to reduce the environmental impact of certain plastic products and promote the use of sustainable alternatives. These regulations have significant implications for the use of biodegradable polymers in vacuum forming processes, as they encourage the development and adoption of more environmentally friendly packaging solutions.

In the United States, the regulatory landscape is more fragmented, with both federal and state-level regulations impacting biodegradable packaging. The Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. Several states, such as California and Washington, have implemented their own regulations on biodegradable plastics, often requiring specific certifications or standards to be met.

Many countries have introduced or are in the process of implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their products, including packaging. These regulations incentivize the use of biodegradable materials in packaging applications, potentially driving innovation in vacuum forming processes using biodegradable polymers.

Certification standards play a crucial role in the regulatory framework for biodegradable packaging. Organizations such as the Biodegradable Products Institute (BPI) and TÜV Austria offer certifications for compostable and biodegradable materials, which are often referenced in regulations and used by manufacturers to demonstrate compliance. These standards typically assess factors such as biodegradation rate, ecotoxicity, and the absence of harmful residues.

As the use of biodegradable polymers in vacuum forming processes continues to evolve, it is likely that regulatory frameworks will adapt to address new challenges and opportunities. This may include the development of more specific standards for biodegradable materials used in vacuum forming, as well as regulations addressing the end-of-life management of these products. Manufacturers and researchers working with biodegradable polymers in vacuum forming processes must stay informed about these regulatory developments to ensure compliance and capitalize on emerging opportunities in the sustainable packaging market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!