The Role of Digital Twins in Vacuum Forming Optimization

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Digital Twin Background

Digital twins have emerged as a transformative technology in various industries, offering a virtual representation of physical assets, processes, or systems. In the context of vacuum forming optimization, digital twins play a crucial role in enhancing efficiency, reducing costs, and improving product quality. The concept of digital twins originated in the aerospace industry in the early 2000s but has since expanded to numerous sectors, including manufacturing, healthcare, and urban planning.

At its core, a digital twin is a dynamic, virtual model that mirrors a real-world entity or system. It continuously collects data from its physical counterpart through sensors and IoT devices, enabling real-time monitoring, analysis, and simulation. This technology allows for predictive maintenance, performance optimization, and informed decision-making based on accurate, up-to-date information.

In vacuum forming, digital twins can revolutionize the production process by creating a virtual replica of the entire manufacturing line. This includes the vacuum forming machine, molds, materials, and environmental conditions. By integrating data from various sources, such as temperature sensors, pressure gauges, and material properties, the digital twin provides a comprehensive view of the forming process.

The evolution of digital twin technology has been driven by advancements in several key areas. These include the Internet of Things (IoT), which enables seamless data collection and transmission; artificial intelligence and machine learning algorithms that process and analyze vast amounts of data; and cloud computing, which provides the necessary storage and computational power for complex simulations.

In vacuum forming optimization, digital twins offer numerous benefits. They allow manufacturers to simulate different scenarios and optimize process parameters without the need for physical prototyping or trial runs. This significantly reduces material waste, energy consumption, and production time. Additionally, digital twins can predict potential issues before they occur, enabling proactive maintenance and minimizing downtime.

The integration of digital twins in vacuum forming also facilitates continuous improvement. By analyzing historical data and performance metrics, manufacturers can identify patterns and trends that lead to better product quality and increased efficiency. This data-driven approach enables informed decision-making and helps in refining production strategies over time.

As the technology continues to mature, we can expect to see even more sophisticated applications of digital twins in vacuum forming. Future developments may include enhanced real-time collaboration capabilities, allowing teams to work on virtual prototypes simultaneously, regardless of their physical location. Additionally, the integration of augmented reality (AR) and virtual reality (VR) technologies with digital twins could provide immersive experiences for training, troubleshooting, and design optimization in vacuum forming processes.

At its core, a digital twin is a dynamic, virtual model that mirrors a real-world entity or system. It continuously collects data from its physical counterpart through sensors and IoT devices, enabling real-time monitoring, analysis, and simulation. This technology allows for predictive maintenance, performance optimization, and informed decision-making based on accurate, up-to-date information.

In vacuum forming, digital twins can revolutionize the production process by creating a virtual replica of the entire manufacturing line. This includes the vacuum forming machine, molds, materials, and environmental conditions. By integrating data from various sources, such as temperature sensors, pressure gauges, and material properties, the digital twin provides a comprehensive view of the forming process.

The evolution of digital twin technology has been driven by advancements in several key areas. These include the Internet of Things (IoT), which enables seamless data collection and transmission; artificial intelligence and machine learning algorithms that process and analyze vast amounts of data; and cloud computing, which provides the necessary storage and computational power for complex simulations.

In vacuum forming optimization, digital twins offer numerous benefits. They allow manufacturers to simulate different scenarios and optimize process parameters without the need for physical prototyping or trial runs. This significantly reduces material waste, energy consumption, and production time. Additionally, digital twins can predict potential issues before they occur, enabling proactive maintenance and minimizing downtime.

The integration of digital twins in vacuum forming also facilitates continuous improvement. By analyzing historical data and performance metrics, manufacturers can identify patterns and trends that lead to better product quality and increased efficiency. This data-driven approach enables informed decision-making and helps in refining production strategies over time.

As the technology continues to mature, we can expect to see even more sophisticated applications of digital twins in vacuum forming. Future developments may include enhanced real-time collaboration capabilities, allowing teams to work on virtual prototypes simultaneously, regardless of their physical location. Additionally, the integration of augmented reality (AR) and virtual reality (VR) technologies with digital twins could provide immersive experiences for training, troubleshooting, and design optimization in vacuum forming processes.

Market Demand Analysis

The market demand for digital twins in vacuum forming optimization is experiencing significant growth, driven by the increasing need for efficiency, quality improvement, and cost reduction in manufacturing processes. As industries seek to enhance their competitiveness and adapt to Industry 4.0 trends, the integration of digital twin technology in vacuum forming has become a focal point for many businesses.

The vacuum forming industry, which encompasses a wide range of applications from packaging to automotive components, is witnessing a surge in demand for more sophisticated and precise production methods. Digital twins offer a compelling solution by providing real-time virtual representations of physical assets and processes. This technology enables manufacturers to simulate, analyze, and optimize vacuum forming operations without the need for costly physical prototypes or production interruptions.

One of the primary drivers of market demand is the potential for substantial cost savings. By leveraging digital twins, companies can identify inefficiencies, reduce material waste, and minimize energy consumption in vacuum forming processes. This not only leads to immediate financial benefits but also aligns with growing sustainability initiatives across industries.

Quality control is another critical factor fueling the adoption of digital twins in vacuum forming. The technology allows for predictive maintenance, early detection of potential defects, and continuous improvement of product quality. As consumer expectations and regulatory standards become more stringent, manufacturers are increasingly turning to digital twin solutions to ensure consistent, high-quality output.

The automotive and aerospace sectors are particularly strong drivers of market demand for digital twin technology in vacuum forming. These industries require complex, precision-engineered components that must meet strict performance and safety standards. Digital twins enable manufacturers to optimize the vacuum forming process for intricate parts, reducing development time and improving overall product performance.

Furthermore, the push towards customization and small-batch production is creating new opportunities for digital twin applications in vacuum forming. The technology's ability to quickly adapt and optimize processes for different product specifications makes it invaluable for manufacturers looking to offer more personalized products without sacrificing efficiency.

As the global manufacturing landscape continues to evolve, the demand for digital twins in vacuum forming optimization is expected to grow substantially. This trend is further supported by advancements in related technologies such as IoT sensors, big data analytics, and machine learning, which enhance the capabilities and accuracy of digital twin models. Companies that invest in these technologies are likely to gain a significant competitive advantage in the rapidly changing manufacturing environment.

The vacuum forming industry, which encompasses a wide range of applications from packaging to automotive components, is witnessing a surge in demand for more sophisticated and precise production methods. Digital twins offer a compelling solution by providing real-time virtual representations of physical assets and processes. This technology enables manufacturers to simulate, analyze, and optimize vacuum forming operations without the need for costly physical prototypes or production interruptions.

One of the primary drivers of market demand is the potential for substantial cost savings. By leveraging digital twins, companies can identify inefficiencies, reduce material waste, and minimize energy consumption in vacuum forming processes. This not only leads to immediate financial benefits but also aligns with growing sustainability initiatives across industries.

Quality control is another critical factor fueling the adoption of digital twins in vacuum forming. The technology allows for predictive maintenance, early detection of potential defects, and continuous improvement of product quality. As consumer expectations and regulatory standards become more stringent, manufacturers are increasingly turning to digital twin solutions to ensure consistent, high-quality output.

The automotive and aerospace sectors are particularly strong drivers of market demand for digital twin technology in vacuum forming. These industries require complex, precision-engineered components that must meet strict performance and safety standards. Digital twins enable manufacturers to optimize the vacuum forming process for intricate parts, reducing development time and improving overall product performance.

Furthermore, the push towards customization and small-batch production is creating new opportunities for digital twin applications in vacuum forming. The technology's ability to quickly adapt and optimize processes for different product specifications makes it invaluable for manufacturers looking to offer more personalized products without sacrificing efficiency.

As the global manufacturing landscape continues to evolve, the demand for digital twins in vacuum forming optimization is expected to grow substantially. This trend is further supported by advancements in related technologies such as IoT sensors, big data analytics, and machine learning, which enhance the capabilities and accuracy of digital twin models. Companies that invest in these technologies are likely to gain a significant competitive advantage in the rapidly changing manufacturing environment.

Current Challenges

The integration of digital twins in vacuum forming optimization faces several significant challenges that hinder widespread adoption and full realization of its potential. One primary obstacle is the complexity of accurately modeling the vacuum forming process in a digital environment. The process involves intricate interactions between heat transfer, material properties, and fluid dynamics, making it difficult to create a comprehensive and precise digital representation.

Data acquisition and integration pose another substantial challenge. Vacuum forming processes often lack sufficient sensors and data collection systems to provide real-time, high-fidelity information necessary for creating and maintaining an accurate digital twin. This data scarcity limits the ability to synchronize the physical and virtual models effectively, potentially reducing the reliability of simulations and predictions.

The computational demands of running complex simulations in real-time present a significant hurdle. Digital twins for vacuum forming require substantial processing power to handle the multiphysics simulations involved, which can be costly and may introduce latency issues in decision-making processes. This challenge is particularly acute for smaller manufacturers with limited resources for high-performance computing infrastructure.

Interoperability between different software systems and platforms is another critical issue. Digital twins often require integration with various enterprise systems, such as manufacturing execution systems (MES) and enterprise resource planning (ERP) software. Ensuring seamless data exchange and compatibility between these diverse systems can be technically challenging and resource-intensive.

The dynamic nature of material properties during the vacuum forming process adds another layer of complexity. Materials undergo significant changes in their physical characteristics as they are heated and formed, which can be difficult to model accurately in a digital environment. This variability can lead to discrepancies between the digital twin and the actual physical process, potentially compromising the reliability of optimization efforts.

Lastly, there is a notable skills gap in the industry. Implementing and maintaining digital twins for vacuum forming optimization requires a unique blend of expertise in manufacturing processes, materials science, data analytics, and software engineering. Many organizations struggle to find or develop talent with this multidisciplinary skill set, which can slow down adoption and limit the effectiveness of digital twin implementations.

Addressing these challenges will be crucial for advancing the role of digital twins in vacuum forming optimization. Overcoming these hurdles will require collaborative efforts from industry, academia, and technology providers to develop more sophisticated modeling techniques, improve data collection and integration capabilities, and enhance the accessibility and usability of digital twin technologies in the vacuum forming domain.

Data acquisition and integration pose another substantial challenge. Vacuum forming processes often lack sufficient sensors and data collection systems to provide real-time, high-fidelity information necessary for creating and maintaining an accurate digital twin. This data scarcity limits the ability to synchronize the physical and virtual models effectively, potentially reducing the reliability of simulations and predictions.

The computational demands of running complex simulations in real-time present a significant hurdle. Digital twins for vacuum forming require substantial processing power to handle the multiphysics simulations involved, which can be costly and may introduce latency issues in decision-making processes. This challenge is particularly acute for smaller manufacturers with limited resources for high-performance computing infrastructure.

Interoperability between different software systems and platforms is another critical issue. Digital twins often require integration with various enterprise systems, such as manufacturing execution systems (MES) and enterprise resource planning (ERP) software. Ensuring seamless data exchange and compatibility between these diverse systems can be technically challenging and resource-intensive.

The dynamic nature of material properties during the vacuum forming process adds another layer of complexity. Materials undergo significant changes in their physical characteristics as they are heated and formed, which can be difficult to model accurately in a digital environment. This variability can lead to discrepancies between the digital twin and the actual physical process, potentially compromising the reliability of optimization efforts.

Lastly, there is a notable skills gap in the industry. Implementing and maintaining digital twins for vacuum forming optimization requires a unique blend of expertise in manufacturing processes, materials science, data analytics, and software engineering. Many organizations struggle to find or develop talent with this multidisciplinary skill set, which can slow down adoption and limit the effectiveness of digital twin implementations.

Addressing these challenges will be crucial for advancing the role of digital twins in vacuum forming optimization. Overcoming these hurdles will require collaborative efforts from industry, academia, and technology providers to develop more sophisticated modeling techniques, improve data collection and integration capabilities, and enhance the accessibility and usability of digital twin technologies in the vacuum forming domain.

Existing Solutions

01 Real-time optimization of digital twins

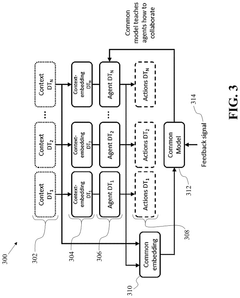

Digital twin optimization involves real-time monitoring and adjustment of virtual models to improve system performance. This approach uses advanced algorithms and data analytics to continuously update the digital twin, ensuring it accurately reflects the physical counterpart and enables proactive decision-making for enhanced efficiency and productivity.- Real-time optimization of digital twins: Digital twin optimization involves real-time data analysis and adjustment of virtual models to improve system performance. This approach enables continuous monitoring, predictive maintenance, and adaptive control strategies for complex systems, enhancing efficiency and reducing downtime.

- Machine learning integration for digital twin optimization: Incorporating machine learning algorithms into digital twin models enhances their predictive capabilities and optimization potential. These AI-driven techniques enable more accurate simulations, pattern recognition, and autonomous decision-making processes, leading to improved system performance and resource allocation.

- Multi-objective optimization in digital twin systems: Digital twin optimization often involves balancing multiple competing objectives, such as cost reduction, energy efficiency, and performance enhancement. Advanced algorithms and decision support tools are employed to find optimal trade-offs and solutions that satisfy diverse requirements in complex systems.

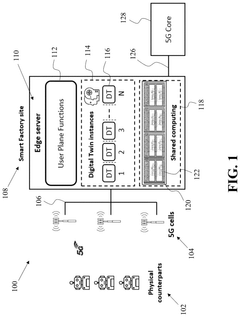

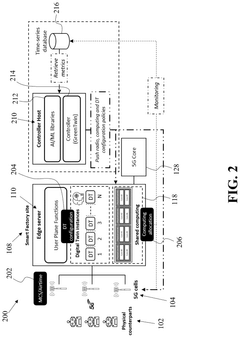

- Edge computing for digital twin optimization: Leveraging edge computing technologies in digital twin optimization enables faster data processing, reduced latency, and improved real-time decision-making. This approach enhances the responsiveness and efficiency of digital twin models, particularly in distributed or remote systems.

- Cybersecurity in optimized digital twin systems: As digital twin optimization involves sensitive data and critical system controls, robust cybersecurity measures are essential. This includes implementing encryption, access control, and threat detection mechanisms to protect the integrity and confidentiality of digital twin models and their associated optimization processes.

02 Machine learning integration for digital twin enhancement

Incorporating machine learning algorithms into digital twin systems allows for more accurate predictions and optimizations. These AI-powered models can analyze complex data patterns, adapt to changing conditions, and provide insights for improving the performance of both the digital twin and its physical counterpart.Expand Specific Solutions03 Multi-domain digital twin optimization

This approach focuses on optimizing digital twins across multiple domains or systems simultaneously. By considering the interactions and interdependencies between different components or processes, it enables holistic optimization strategies that can lead to significant improvements in overall system performance and efficiency.Expand Specific Solutions04 Edge computing for digital twin optimization

Leveraging edge computing technologies to optimize digital twins allows for faster processing and reduced latency. This approach enables real-time data analysis and decision-making at the edge of the network, improving the responsiveness and efficiency of digital twin systems in various applications.Expand Specific Solutions05 Predictive maintenance using optimized digital twins

Optimized digital twins can be used to enhance predictive maintenance strategies. By accurately simulating equipment behavior and analyzing historical data, these systems can predict potential failures, optimize maintenance schedules, and reduce downtime, leading to improved operational efficiency and cost savings.Expand Specific Solutions

Key Industry Players

The digital twin technology in vacuum forming optimization is in its early development stage, with a growing market potential as industries seek to enhance manufacturing efficiency. The market size is expanding, driven by the increasing adoption of Industry 4.0 technologies. While the concept is promising, the technology's maturity varies among key players. Companies like Siemens AG and International Business Machines Corp. are at the forefront, leveraging their extensive experience in digital solutions. Applied Materials, Inc. and Lam Research Corp. are also making strides in this field, particularly in semiconductor manufacturing applications. Other players like Robert Bosch GmbH and SK Innovation Co., Ltd. are exploring digital twin implementations in their respective industries, contributing to the technology's evolution and diversification.

Applied Materials, Inc.

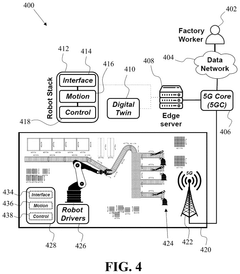

Technical Solution: Applied Materials has developed a digital twin solution specifically tailored for vacuum forming in semiconductor manufacturing. Their approach focuses on creating high-fidelity virtual models of vacuum forming processes used in chip production. The digital twin incorporates advanced physics-based simulations and real-time data from sensors to optimize parameters such as temperature distribution, gas flow, and pressure gradients[7]. Applied Materials' solution utilizes machine learning algorithms to predict and prevent defects in the vacuum forming process, significantly improving yield rates in semiconductor manufacturing. The company's digital twin also supports virtual experimentation, allowing engineers to test new process recipes and materials without disrupting production[9].

Strengths: Highly specialized for semiconductor manufacturing, advanced physics-based simulations. Weaknesses: May have limited applicability outside of the semiconductor industry.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive digital twin solution for vacuum forming optimization. Their approach integrates real-time data from sensors, historical process information, and advanced simulation models to create a virtual representation of the entire vacuum forming process. This digital twin enables predictive maintenance, process optimization, and quality control improvements[1]. Siemens' solution incorporates machine learning algorithms that continuously analyze data to identify patterns and optimize process parameters, resulting in reduced material waste and improved energy efficiency[3]. The company's digital twin platform also supports virtual commissioning, allowing manufacturers to test and validate process changes in a risk-free virtual environment before implementation[5].

Strengths: Comprehensive integration of multiple data sources, advanced simulation capabilities, and machine learning-driven optimization. Weaknesses: May require significant initial investment and expertise to implement fully.

Core Innovations

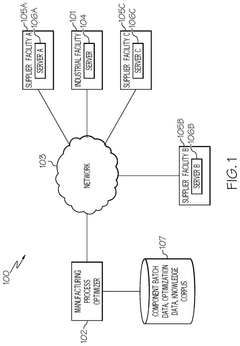

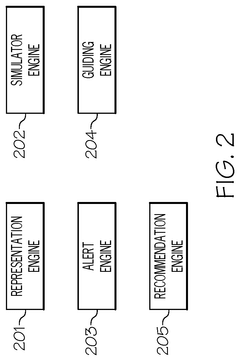

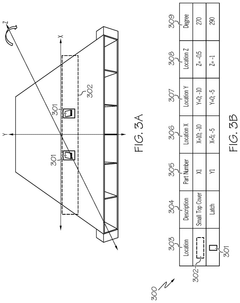

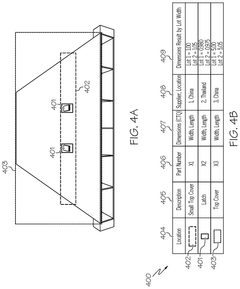

Optimizing a manufacturing process of a physical product using a virtual environment

PatentPendingUS20240394429A1

Innovation

- A computer-implemented method that generates a digital representation of component batches and creates a digital twin simulation to identify potential defects in a virtual environment, allowing for alerts and recommendations to prevent assembly issues.

Energy consumption optimization in digital twin applications

PatentPendingUS20240319774A1

Innovation

- A computer-implemented method that receives input metrics from digital twins, determines updated configurations including radio, computing, and digital twin configurations to reduce power consumption, and provides these configurations through APIs, leveraging delay budgets to optimize energy use and resource allocation.

Implementation Strategies

Implementing digital twins in vacuum forming optimization requires a strategic approach to ensure successful integration and maximum benefits. A phased implementation strategy is often recommended, starting with a pilot project to demonstrate the concept's value and identify potential challenges. This initial phase should focus on a specific aspect of the vacuum forming process, such as mold design or temperature control, allowing for targeted data collection and analysis.

Once the pilot project proves successful, a gradual expansion to other areas of the vacuum forming process can be undertaken. This step-by-step approach allows for continuous learning and refinement of the digital twin model. It is crucial to establish a robust data infrastructure to support the digital twin, including sensors for real-time data collection, secure data storage systems, and high-speed networks for data transmission.

Collaboration between IT specialists, process engineers, and vacuum forming experts is essential for effective implementation. Cross-functional teams should be formed to ensure that the digital twin accurately represents the physical process and addresses key optimization opportunities. Regular training sessions and workshops can help staff understand the digital twin concept and its applications in vacuum forming.

Integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) systems is another critical aspect of implementation. This integration enables a holistic view of the production process and facilitates data-driven decision-making across the organization. Cloud-based solutions can offer scalability and flexibility, allowing for easier updates and maintenance of the digital twin model.

Continuous validation and calibration of the digital twin model are necessary to maintain its accuracy and relevance. This involves comparing simulation results with real-world data and making adjustments as needed. Implementing a feedback loop that incorporates machine learning algorithms can enable the digital twin to improve its predictive capabilities over time.

Finally, establishing key performance indicators (KPIs) to measure the impact of the digital twin on vacuum forming optimization is crucial. These KPIs may include reduced material waste, improved product quality, increased energy efficiency, and shortened production cycles. Regular assessment of these metrics will help justify the investment in digital twin technology and guide future optimization efforts.

Once the pilot project proves successful, a gradual expansion to other areas of the vacuum forming process can be undertaken. This step-by-step approach allows for continuous learning and refinement of the digital twin model. It is crucial to establish a robust data infrastructure to support the digital twin, including sensors for real-time data collection, secure data storage systems, and high-speed networks for data transmission.

Collaboration between IT specialists, process engineers, and vacuum forming experts is essential for effective implementation. Cross-functional teams should be formed to ensure that the digital twin accurately represents the physical process and addresses key optimization opportunities. Regular training sessions and workshops can help staff understand the digital twin concept and its applications in vacuum forming.

Integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) systems is another critical aspect of implementation. This integration enables a holistic view of the production process and facilitates data-driven decision-making across the organization. Cloud-based solutions can offer scalability and flexibility, allowing for easier updates and maintenance of the digital twin model.

Continuous validation and calibration of the digital twin model are necessary to maintain its accuracy and relevance. This involves comparing simulation results with real-world data and making adjustments as needed. Implementing a feedback loop that incorporates machine learning algorithms can enable the digital twin to improve its predictive capabilities over time.

Finally, establishing key performance indicators (KPIs) to measure the impact of the digital twin on vacuum forming optimization is crucial. These KPIs may include reduced material waste, improved product quality, increased energy efficiency, and shortened production cycles. Regular assessment of these metrics will help justify the investment in digital twin technology and guide future optimization efforts.

Sustainability Impact

The integration of digital twins in vacuum forming optimization presents significant opportunities for enhancing sustainability across the manufacturing process. By creating virtual replicas of physical systems, digital twins enable manufacturers to simulate and analyze various scenarios, leading to more efficient resource utilization and reduced environmental impact.

One of the primary sustainability benefits of digital twins in vacuum forming is the reduction of material waste. Through accurate simulations, manufacturers can optimize material usage, minimizing excess trimming and scrap generation. This not only conserves raw materials but also reduces the energy required for production and waste disposal. Additionally, digital twins facilitate the development of more precise molds and tooling, further reducing material waste and improving overall product quality.

Energy efficiency is another crucial aspect of sustainability that digital twins can address in vacuum forming. By simulating different process parameters and equipment configurations, manufacturers can identify optimal operating conditions that minimize energy consumption without compromising product quality. This may include optimizing heating cycles, vacuum pressure, and cooling times, resulting in significant energy savings over time.

Digital twins also contribute to extending the lifespan of vacuum forming equipment through predictive maintenance. By continuously monitoring and analyzing equipment performance, potential issues can be identified and addressed proactively, reducing unexpected downtime and the need for premature equipment replacement. This not only improves operational efficiency but also reduces the environmental impact associated with manufacturing and disposing of new machinery.

Furthermore, digital twins enable more sustainable product design by allowing manufacturers to virtually test and iterate designs before physical prototyping. This approach reduces the number of physical prototypes required, conserving materials and energy typically expended during the prototyping phase. It also facilitates the exploration of eco-friendly materials and design alternatives that may have been challenging to test in traditional manufacturing environments.

The implementation of digital twins in vacuum forming can also lead to more sustainable supply chain practices. By providing accurate production forecasts and inventory management, digital twins help minimize overproduction and reduce the need for excessive storage, thereby decreasing the overall carbon footprint of the manufacturing process. Additionally, this technology can optimize transportation routes and logistics, further reducing emissions associated with product distribution.

In conclusion, the role of digital twins in vacuum forming optimization offers substantial potential for improving sustainability across various aspects of the manufacturing process. From material and energy conservation to equipment longevity and sustainable design practices, digital twins provide a powerful tool for manufacturers to reduce their environmental impact while maintaining or even improving product quality and operational efficiency.

One of the primary sustainability benefits of digital twins in vacuum forming is the reduction of material waste. Through accurate simulations, manufacturers can optimize material usage, minimizing excess trimming and scrap generation. This not only conserves raw materials but also reduces the energy required for production and waste disposal. Additionally, digital twins facilitate the development of more precise molds and tooling, further reducing material waste and improving overall product quality.

Energy efficiency is another crucial aspect of sustainability that digital twins can address in vacuum forming. By simulating different process parameters and equipment configurations, manufacturers can identify optimal operating conditions that minimize energy consumption without compromising product quality. This may include optimizing heating cycles, vacuum pressure, and cooling times, resulting in significant energy savings over time.

Digital twins also contribute to extending the lifespan of vacuum forming equipment through predictive maintenance. By continuously monitoring and analyzing equipment performance, potential issues can be identified and addressed proactively, reducing unexpected downtime and the need for premature equipment replacement. This not only improves operational efficiency but also reduces the environmental impact associated with manufacturing and disposing of new machinery.

Furthermore, digital twins enable more sustainable product design by allowing manufacturers to virtually test and iterate designs before physical prototyping. This approach reduces the number of physical prototypes required, conserving materials and energy typically expended during the prototyping phase. It also facilitates the exploration of eco-friendly materials and design alternatives that may have been challenging to test in traditional manufacturing environments.

The implementation of digital twins in vacuum forming can also lead to more sustainable supply chain practices. By providing accurate production forecasts and inventory management, digital twins help minimize overproduction and reduce the need for excessive storage, thereby decreasing the overall carbon footprint of the manufacturing process. Additionally, this technology can optimize transportation routes and logistics, further reducing emissions associated with product distribution.

In conclusion, the role of digital twins in vacuum forming optimization offers substantial potential for improving sustainability across various aspects of the manufacturing process. From material and energy conservation to equipment longevity and sustainable design practices, digital twins provide a powerful tool for manufacturers to reduce their environmental impact while maintaining or even improving product quality and operational efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!