Optimized Heating Profiles for Consistent Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Heating Optimization Background

Vacuum forming is a widely used manufacturing process in various industries, including packaging, automotive, and consumer goods. The technique involves heating a thermoplastic sheet until it becomes pliable, then using vacuum pressure to form it over a mold. The heating phase is crucial for achieving consistent and high-quality results, making the optimization of heating profiles a critical area of research and development.

The history of vacuum forming dates back to the 1940s, with significant advancements occurring in the 1960s and 1970s. As the process gained popularity, manufacturers recognized the need for more precise control over the heating phase to improve product quality and reduce waste. Early heating methods relied on simple radiant heaters with limited control, often resulting in inconsistent results and material waste.

Over time, the industry has seen a shift towards more sophisticated heating systems, including zoned heating elements, infrared technology, and computer-controlled heating profiles. These advancements have allowed for better temperature distribution across the thermoplastic sheet, reducing the occurrence of thin spots, webbing, and other defects associated with uneven heating.

Despite these improvements, achieving consistent results in vacuum forming remains a challenge, particularly when dealing with complex geometries or large-scale production. Variations in ambient temperature, material properties, and equipment performance can all impact the heating process, leading to inconsistencies in the final product. This has driven the need for ongoing research into optimized heating profiles that can adapt to these variables and deliver reliable results.

The goal of research in this area is to develop heating profiles that can consistently produce high-quality vacuum-formed parts while minimizing energy consumption and cycle times. This involves a multidisciplinary approach, combining materials science, heat transfer principles, and process control engineering. Researchers are exploring various aspects, including the relationship between heating patterns and material behavior, the impact of different heat sources on temperature distribution, and the potential for real-time adjustments based on sensor feedback.

Recent technological advancements have opened up new possibilities for heating optimization. Machine learning algorithms are being applied to analyze vast amounts of process data and identify optimal heating patterns for different materials and mold designs. Additionally, the integration of Internet of Things (IoT) devices and advanced sensors is enabling more precise monitoring and control of the heating process, paving the way for adaptive heating profiles that can respond to real-time conditions.

As industries continue to demand higher quality standards and increased efficiency, the importance of optimized heating profiles in vacuum forming cannot be overstated. This research area not only promises to improve product quality and consistency but also has the potential to significantly reduce energy consumption and material waste, aligning with broader sustainability goals in manufacturing.

The history of vacuum forming dates back to the 1940s, with significant advancements occurring in the 1960s and 1970s. As the process gained popularity, manufacturers recognized the need for more precise control over the heating phase to improve product quality and reduce waste. Early heating methods relied on simple radiant heaters with limited control, often resulting in inconsistent results and material waste.

Over time, the industry has seen a shift towards more sophisticated heating systems, including zoned heating elements, infrared technology, and computer-controlled heating profiles. These advancements have allowed for better temperature distribution across the thermoplastic sheet, reducing the occurrence of thin spots, webbing, and other defects associated with uneven heating.

Despite these improvements, achieving consistent results in vacuum forming remains a challenge, particularly when dealing with complex geometries or large-scale production. Variations in ambient temperature, material properties, and equipment performance can all impact the heating process, leading to inconsistencies in the final product. This has driven the need for ongoing research into optimized heating profiles that can adapt to these variables and deliver reliable results.

The goal of research in this area is to develop heating profiles that can consistently produce high-quality vacuum-formed parts while minimizing energy consumption and cycle times. This involves a multidisciplinary approach, combining materials science, heat transfer principles, and process control engineering. Researchers are exploring various aspects, including the relationship between heating patterns and material behavior, the impact of different heat sources on temperature distribution, and the potential for real-time adjustments based on sensor feedback.

Recent technological advancements have opened up new possibilities for heating optimization. Machine learning algorithms are being applied to analyze vast amounts of process data and identify optimal heating patterns for different materials and mold designs. Additionally, the integration of Internet of Things (IoT) devices and advanced sensors is enabling more precise monitoring and control of the heating process, paving the way for adaptive heating profiles that can respond to real-time conditions.

As industries continue to demand higher quality standards and increased efficiency, the importance of optimized heating profiles in vacuum forming cannot be overstated. This research area not only promises to improve product quality and consistency but also has the potential to significantly reduce energy consumption and material waste, aligning with broader sustainability goals in manufacturing.

Market Demand Analysis

The vacuum forming industry has experienced significant growth in recent years, driven by increasing demand across various sectors such as packaging, automotive, aerospace, and consumer goods. The global vacuum forming market is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2021 to 2028, reaching a market value of $22.3 billion by the end of the forecast period.

One of the key factors contributing to this market growth is the rising demand for lightweight and cost-effective packaging solutions in the food and beverage industry. Vacuum-formed packaging offers excellent protection, extended shelf life, and attractive presentation for products, making it a preferred choice for manufacturers. Additionally, the automotive sector's shift towards lightweight components to improve fuel efficiency has further boosted the demand for vacuum-formed parts.

The healthcare and medical device industry has also emerged as a significant consumer of vacuum-formed products. The need for sterile, disposable medical equipment and packaging has increased substantially, especially in light of recent global health crises. This trend is expected to continue, driving further growth in the vacuum forming market.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for vacuum forming, with China and India leading the charge. The rapid industrialization, expanding manufacturing sector, and increasing consumer goods production in these countries are the primary drivers of this growth. North America and Europe, while mature markets, continue to show steady demand, particularly in high-tech industries and specialized applications.

The optimization of heating profiles for consistent vacuum forming is becoming increasingly crucial as manufacturers strive to improve product quality, reduce waste, and enhance energy efficiency. Inconsistent heating can lead to defects such as webbing, thinning, or incomplete forming, resulting in increased production costs and decreased customer satisfaction. As a result, there is a growing market demand for advanced heating control systems and optimized heating profiles that can ensure uniform material distribution and consistent product quality.

Furthermore, the push towards sustainability and eco-friendly manufacturing processes has created a new dimension of market demand. Manufacturers are seeking ways to reduce energy consumption in the vacuum forming process, and optimized heating profiles can play a significant role in achieving this goal. This aligns with the broader industry trend of adopting more environmentally responsible practices and meeting increasingly stringent regulatory requirements.

In conclusion, the market demand for research on optimized heating profiles for consistent vacuum forming is driven by the overall growth of the vacuum forming industry, the need for improved product quality and efficiency, and the push towards more sustainable manufacturing processes. As competition intensifies and customer expectations rise, manufacturers who can leverage advanced heating profile optimization techniques will likely gain a significant competitive advantage in the market.

One of the key factors contributing to this market growth is the rising demand for lightweight and cost-effective packaging solutions in the food and beverage industry. Vacuum-formed packaging offers excellent protection, extended shelf life, and attractive presentation for products, making it a preferred choice for manufacturers. Additionally, the automotive sector's shift towards lightweight components to improve fuel efficiency has further boosted the demand for vacuum-formed parts.

The healthcare and medical device industry has also emerged as a significant consumer of vacuum-formed products. The need for sterile, disposable medical equipment and packaging has increased substantially, especially in light of recent global health crises. This trend is expected to continue, driving further growth in the vacuum forming market.

In terms of regional demand, Asia-Pacific is anticipated to be the fastest-growing market for vacuum forming, with China and India leading the charge. The rapid industrialization, expanding manufacturing sector, and increasing consumer goods production in these countries are the primary drivers of this growth. North America and Europe, while mature markets, continue to show steady demand, particularly in high-tech industries and specialized applications.

The optimization of heating profiles for consistent vacuum forming is becoming increasingly crucial as manufacturers strive to improve product quality, reduce waste, and enhance energy efficiency. Inconsistent heating can lead to defects such as webbing, thinning, or incomplete forming, resulting in increased production costs and decreased customer satisfaction. As a result, there is a growing market demand for advanced heating control systems and optimized heating profiles that can ensure uniform material distribution and consistent product quality.

Furthermore, the push towards sustainability and eco-friendly manufacturing processes has created a new dimension of market demand. Manufacturers are seeking ways to reduce energy consumption in the vacuum forming process, and optimized heating profiles can play a significant role in achieving this goal. This aligns with the broader industry trend of adopting more environmentally responsible practices and meeting increasingly stringent regulatory requirements.

In conclusion, the market demand for research on optimized heating profiles for consistent vacuum forming is driven by the overall growth of the vacuum forming industry, the need for improved product quality and efficiency, and the push towards more sustainable manufacturing processes. As competition intensifies and customer expectations rise, manufacturers who can leverage advanced heating profile optimization techniques will likely gain a significant competitive advantage in the market.

Current Challenges in Heating Profiles

Vacuum forming is a widely used manufacturing process in various industries, but achieving consistent and high-quality results remains a challenge. One of the most critical factors in this process is the heating profile, which directly impacts the material's formability and the final product's quality. Despite advancements in technology, several challenges persist in optimizing heating profiles for consistent vacuum forming.

Temperature uniformity across the sheet material is a significant hurdle. Uneven heating can lead to areas of over-softening or under-softening, resulting in inconsistent material thickness and poor product quality. This issue is particularly pronounced when dealing with large or complex-shaped parts, where maintaining uniform heat distribution becomes increasingly difficult.

Another challenge is the variability in material properties. Different plastics and composites respond differently to heat, and even within the same material type, batch-to-batch variations can occur. This variability necessitates constant adjustments to heating profiles, making it challenging to establish a standardized process for consistent results across different production runs.

The time-temperature relationship in heating profiles presents another complexity. Determining the optimal heating time and temperature for each specific material and product design requires extensive experimentation and fine-tuning. Overheating can lead to material degradation or sagging, while underheating results in poor formability and surface defects.

Energy efficiency is an ongoing concern in the industry. Current heating methods, such as infrared or convection heating, can be energy-intensive. Balancing the need for rapid and uniform heating with energy conservation goals poses a significant challenge in optimizing heating profiles.

The integration of real-time monitoring and control systems for heating profiles is still evolving. While some advanced systems exist, many manufacturers struggle with implementing precise, adaptive control mechanisms that can respond to variations in material properties or environmental conditions during the forming process.

Lastly, the challenge of scalability and flexibility in heating profiles is becoming more prominent. As manufacturers seek to increase production efficiency and accommodate a wider range of products, developing heating profiles that can be quickly adapted to different materials, thicknesses, and product geometries without compromising quality or consistency remains a significant hurdle.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, sophisticated control systems, and innovative heating technologies. The pursuit of optimized heating profiles for consistent vacuum forming continues to drive research and development in this field, promising improved product quality, increased efficiency, and enhanced manufacturing capabilities in the future.

Temperature uniformity across the sheet material is a significant hurdle. Uneven heating can lead to areas of over-softening or under-softening, resulting in inconsistent material thickness and poor product quality. This issue is particularly pronounced when dealing with large or complex-shaped parts, where maintaining uniform heat distribution becomes increasingly difficult.

Another challenge is the variability in material properties. Different plastics and composites respond differently to heat, and even within the same material type, batch-to-batch variations can occur. This variability necessitates constant adjustments to heating profiles, making it challenging to establish a standardized process for consistent results across different production runs.

The time-temperature relationship in heating profiles presents another complexity. Determining the optimal heating time and temperature for each specific material and product design requires extensive experimentation and fine-tuning. Overheating can lead to material degradation or sagging, while underheating results in poor formability and surface defects.

Energy efficiency is an ongoing concern in the industry. Current heating methods, such as infrared or convection heating, can be energy-intensive. Balancing the need for rapid and uniform heating with energy conservation goals poses a significant challenge in optimizing heating profiles.

The integration of real-time monitoring and control systems for heating profiles is still evolving. While some advanced systems exist, many manufacturers struggle with implementing precise, adaptive control mechanisms that can respond to variations in material properties or environmental conditions during the forming process.

Lastly, the challenge of scalability and flexibility in heating profiles is becoming more prominent. As manufacturers seek to increase production efficiency and accommodate a wider range of products, developing heating profiles that can be quickly adapted to different materials, thicknesses, and product geometries without compromising quality or consistency remains a significant hurdle.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, sophisticated control systems, and innovative heating technologies. The pursuit of optimized heating profiles for consistent vacuum forming continues to drive research and development in this field, promising improved product quality, increased efficiency, and enhanced manufacturing capabilities in the future.

Existing Heating Profile Solutions

01 Temperature control systems for consistent heating profiles

Advanced temperature control systems are employed to maintain consistent heating profiles across various industrial processes. These systems utilize precise sensors, feedback mechanisms, and algorithms to ensure uniform heat distribution and temperature stability, which is crucial for product quality and process efficiency.- Temperature control systems for consistent heating profiles: Advanced temperature control systems are employed to maintain consistent heating profiles across various processes. These systems utilize precise sensors, feedback mechanisms, and algorithms to ensure uniform heat distribution and temperature stability. This technology is crucial in industries where precise temperature control is essential for product quality and process efficiency.

- Adaptive heating algorithms for profile consistency: Innovative adaptive heating algorithms are developed to maintain consistent heating profiles under varying conditions. These algorithms dynamically adjust heating parameters based on real-time data, environmental factors, and material properties. This approach ensures optimal heating consistency across different batches or production runs, improving overall product quality and energy efficiency.

- Multi-zone heating systems for uniform temperature distribution: Multi-zone heating systems are designed to achieve uniform temperature distribution across large or complex objects. These systems utilize multiple independently controlled heating elements or zones, allowing for precise temperature management in different areas. This technology is particularly useful in applications where consistent heating is required across non-uniform shapes or materials.

- Thermal modeling and simulation for heating profile optimization: Advanced thermal modeling and simulation techniques are employed to optimize heating profiles before implementation. These computational methods allow engineers to predict heat distribution, identify potential inconsistencies, and refine heating strategies. By simulating various scenarios, manufacturers can achieve more consistent and efficient heating profiles in real-world applications.

- Sensor integration for real-time heating profile monitoring: Sophisticated sensor integration systems are developed for real-time monitoring and adjustment of heating profiles. These systems employ a network of temperature sensors, often combined with other types of sensors, to provide comprehensive data on the heating process. The continuous monitoring allows for immediate corrections to maintain consistency, ensuring that the desired heating profile is maintained throughout the entire process.

02 Heating profile optimization for material processing

Optimizing heating profiles is essential in material processing applications such as heat treatment, curing, and drying. This involves developing specific temperature-time curves tailored to the material properties and desired outcomes, often utilizing computer-aided simulations and real-time adjustments to achieve consistency.Expand Specific Solutions03 Data-driven approaches for heating profile consistency

Implementing data-driven approaches, including machine learning and artificial intelligence, to analyze and predict optimal heating profiles. These methods use historical data and real-time process information to continuously improve heating consistency and adapt to varying conditions or materials.Expand Specific Solutions04 Multi-zone heating systems for improved consistency

Developing multi-zone heating systems that allow for independent temperature control in different areas of the heating process. This approach enables finer adjustments to compensate for variations in heat distribution, resulting in more consistent heating profiles across the entire product or process.Expand Specific Solutions05 Adaptive control strategies for maintaining heating profile consistency

Implementing adaptive control strategies that can automatically adjust heating parameters based on real-time feedback and changing process conditions. These systems use advanced algorithms to maintain consistent heating profiles despite variations in input materials, environmental factors, or equipment performance.Expand Specific Solutions

Key Industry Players

The research on optimized heating profiles for consistent vacuum forming is in a mature stage of industry development, with a significant market size driven by diverse applications across automotive, packaging, and consumer goods sectors. The technology's maturity is evident from the involvement of established players like BSH Hausgeräte GmbH and Siemens AG, who bring extensive experience in manufacturing and process optimization. Companies such as Asano Laboratories Co., Ltd. and Kiefel Packaging BV specialize in thermoforming equipment, indicating a well-developed ecosystem of suppliers and manufacturers. The competitive landscape is characterized by a mix of large conglomerates and specialized firms, suggesting ongoing innovation and refinement in heating profile optimization techniques for vacuum forming processes.

Siemens AG

Technical Solution: Siemens AG has developed an advanced heating profile optimization system for vacuum forming processes. Their solution utilizes machine learning algorithms to analyze historical data and predict optimal heating patterns. The system employs a network of distributed temperature sensors to provide real-time feedback, allowing for dynamic adjustments during the forming process[1]. Siemens' approach incorporates digital twin technology, creating a virtual model of the vacuum forming setup to simulate and refine heating profiles before implementation[2]. This enables manufacturers to achieve consistent results across various materials and complex geometries while minimizing energy consumption[3].

Strengths: Comprehensive data-driven approach, real-time adaptability, and energy efficiency. Weaknesses: High initial implementation cost and potential complexity for smaller operations.

Molecor Tecnologia SL

Technical Solution: Molecor Tecnologia SL has focused on optimizing heating profiles specifically for PVC pipe production using vacuum forming techniques. Their approach involves a segmented heating chamber with individually controlled heating elements, allowing for precise temperature gradients along the pipe length[10]. Molecor's system employs a combination of contact and radiant heating methods, optimized through extensive computational fluid dynamics simulations. The company has developed a proprietary algorithm that adjusts heating profiles based on pipe diameter, wall thickness, and desired mechanical properties[11]. This technology enables the production of PVC pipes with enhanced structural integrity and uniform wall thickness distribution[12].

Strengths: Specialized for PVC pipe production, precise control of temperature gradients, and improved product quality. Weaknesses: Limited versatility for non-pipe applications and potential scalability issues for very large diameter pipes.

Core Innovations in Heating Control

Heat insulation structure

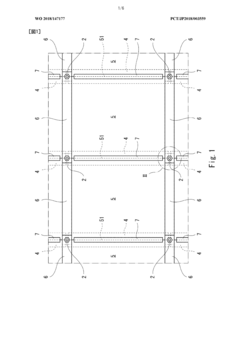

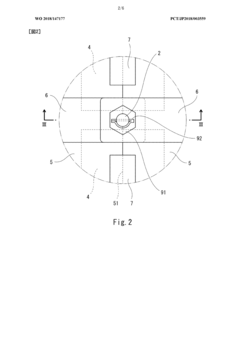

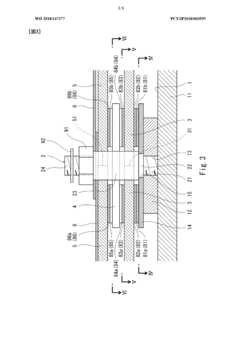

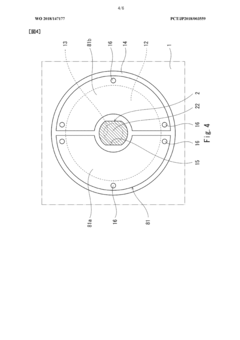

PatentWO2018147177A1

Innovation

- The proposed heat insulation structure reduces the number of through holes by using a configuration of fasteners, multiple laminated vacuum insulation sheets, and presser plates, where the sheets are arranged with hook-and-loop fasteners and presser plates to ensure secure attachment and minimize gaps, thereby enhancing heat insulation performance.

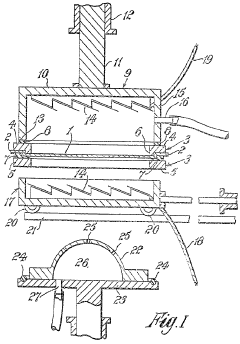

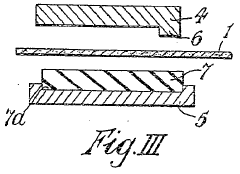

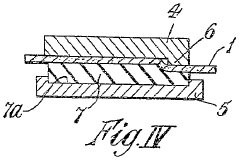

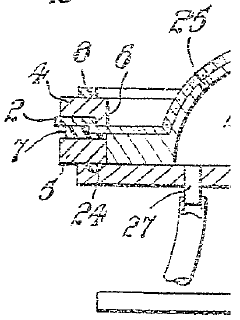

Improvements in vacuum forming of shaped articles

PatentInactiveGB1003031A

Innovation

- The method involves heating the sheet while reducing pressure on the upper surface to maintain a substantially planar configuration, using peripheral clamping means and heating units, and an open-sided box-like member for air evacuation, ensuring uniform heating and minimizing sagging. The clamping system includes a composite framework with a resilient rubber strip and abutment to secure the sheet.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in optimizing heating profiles for consistent vacuum forming. The process of vacuum forming inherently requires significant energy input to heat thermoplastic sheets to their forming temperature. However, inefficient heating can lead to excessive energy consumption, increased production costs, and potential quality issues in the final product.

One of the primary focuses in energy-efficient vacuum forming is the development of precise heating control systems. These systems aim to deliver the exact amount of heat required to achieve the optimal forming temperature, without overheating or wasting energy. Advanced temperature sensors and feedback mechanisms play a crucial role in maintaining accurate temperature profiles throughout the heating process.

The use of zoned heating elements has shown promising results in improving energy efficiency. By dividing the heating area into multiple zones, each controlled independently, manufacturers can tailor the heat distribution to match the specific requirements of different parts of the plastic sheet. This targeted approach reduces overall energy consumption by avoiding unnecessary heating of areas that require less thermal input.

Infrared heating technology has gained traction in recent years due to its energy-efficient properties. Compared to traditional convection heating methods, infrared heaters can transfer heat more directly to the plastic material, resulting in faster heating times and reduced energy loss to the surrounding environment. The ability to quickly adjust infrared heating intensity also contributes to more precise temperature control and energy savings.

Insulation improvements in vacuum forming machines have demonstrated significant impact on energy efficiency. Enhanced insulation materials and designs help retain heat within the forming area, reducing heat loss to the environment and consequently lowering the energy required to maintain the desired temperature. This is particularly important in maintaining consistent heating profiles across multiple production cycles.

The integration of heat recovery systems presents another avenue for energy optimization. By capturing and reusing waste heat generated during the cooling phase of the vacuum forming process, manufacturers can reduce the overall energy demand for subsequent heating cycles. This circular approach to energy management can lead to substantial savings in long-term operations.

Advancements in materials science also contribute to energy efficiency in vacuum forming. The development of thermoplastic materials with lower forming temperatures or narrower processing windows allows for reduced energy input while still achieving desired product properties. This synergy between material innovation and process optimization holds promise for further energy savings in the industry.

One of the primary focuses in energy-efficient vacuum forming is the development of precise heating control systems. These systems aim to deliver the exact amount of heat required to achieve the optimal forming temperature, without overheating or wasting energy. Advanced temperature sensors and feedback mechanisms play a crucial role in maintaining accurate temperature profiles throughout the heating process.

The use of zoned heating elements has shown promising results in improving energy efficiency. By dividing the heating area into multiple zones, each controlled independently, manufacturers can tailor the heat distribution to match the specific requirements of different parts of the plastic sheet. This targeted approach reduces overall energy consumption by avoiding unnecessary heating of areas that require less thermal input.

Infrared heating technology has gained traction in recent years due to its energy-efficient properties. Compared to traditional convection heating methods, infrared heaters can transfer heat more directly to the plastic material, resulting in faster heating times and reduced energy loss to the surrounding environment. The ability to quickly adjust infrared heating intensity also contributes to more precise temperature control and energy savings.

Insulation improvements in vacuum forming machines have demonstrated significant impact on energy efficiency. Enhanced insulation materials and designs help retain heat within the forming area, reducing heat loss to the environment and consequently lowering the energy required to maintain the desired temperature. This is particularly important in maintaining consistent heating profiles across multiple production cycles.

The integration of heat recovery systems presents another avenue for energy optimization. By capturing and reusing waste heat generated during the cooling phase of the vacuum forming process, manufacturers can reduce the overall energy demand for subsequent heating cycles. This circular approach to energy management can lead to substantial savings in long-term operations.

Advancements in materials science also contribute to energy efficiency in vacuum forming. The development of thermoplastic materials with lower forming temperatures or narrower processing windows allows for reduced energy input while still achieving desired product properties. This synergy between material innovation and process optimization holds promise for further energy savings in the industry.

Material-Specific Heating Strategies

Material-specific heating strategies play a crucial role in optimizing vacuum forming processes for consistent results. Different materials exhibit unique thermal properties, requiring tailored heating profiles to achieve optimal formability and final product quality. Thermoplastics, the primary materials used in vacuum forming, encompass a wide range of polymers with varying glass transition temperatures and melting points.

For amorphous polymers like polystyrene (PS) and acrylonitrile butadiene styrene (ABS), a gradual heating approach is often preferred. This involves slowly raising the temperature to just above the glass transition point, allowing for uniform heat distribution throughout the sheet. The heating profile typically includes a pre-heating phase, followed by a controlled ramp-up to the forming temperature, and a brief holding period to ensure consistent heat penetration.

Semi-crystalline polymers such as polyethylene (PE) and polypropylene (PP) require more precise temperature control due to their distinct melting behavior. The heating strategy for these materials often involves a two-stage process. The first stage heats the material to just below its melting point, allowing for initial softening. The second stage rapidly increases the temperature to slightly above the melting point, ensuring complete melting of the crystalline regions without degrading the polymer structure.

High-performance thermoplastics like polyetheretherketone (PEEK) and polyetherimide (PEI) demand more sophisticated heating strategies. These materials often require higher processing temperatures and longer heating cycles. A multi-zone heating approach is commonly employed, where different sections of the sheet are heated at varying rates to account for thickness variations and to prevent overheating of thinner areas.

The development of material-specific heating profiles also considers the impact of additives and fillers on thermal behavior. For example, glass-fiber reinforced polymers may require higher temperatures and longer heating times to ensure proper softening of the matrix material without compromising the reinforcing fibers.

Advanced heating technologies, such as zoned ceramic heaters and infrared heating systems, enable precise control over temperature distribution across the sheet. These systems can be programmed to deliver customized heating profiles tailored to specific material characteristics, sheet thickness, and part geometry. Integrating real-time temperature monitoring and feedback control further enhances the consistency and repeatability of the heating process.

For amorphous polymers like polystyrene (PS) and acrylonitrile butadiene styrene (ABS), a gradual heating approach is often preferred. This involves slowly raising the temperature to just above the glass transition point, allowing for uniform heat distribution throughout the sheet. The heating profile typically includes a pre-heating phase, followed by a controlled ramp-up to the forming temperature, and a brief holding period to ensure consistent heat penetration.

Semi-crystalline polymers such as polyethylene (PE) and polypropylene (PP) require more precise temperature control due to their distinct melting behavior. The heating strategy for these materials often involves a two-stage process. The first stage heats the material to just below its melting point, allowing for initial softening. The second stage rapidly increases the temperature to slightly above the melting point, ensuring complete melting of the crystalline regions without degrading the polymer structure.

High-performance thermoplastics like polyetheretherketone (PEEK) and polyetherimide (PEI) demand more sophisticated heating strategies. These materials often require higher processing temperatures and longer heating cycles. A multi-zone heating approach is commonly employed, where different sections of the sheet are heated at varying rates to account for thickness variations and to prevent overheating of thinner areas.

The development of material-specific heating profiles also considers the impact of additives and fillers on thermal behavior. For example, glass-fiber reinforced polymers may require higher temperatures and longer heating times to ensure proper softening of the matrix material without compromising the reinforcing fibers.

Advanced heating technologies, such as zoned ceramic heaters and infrared heating systems, enable precise control over temperature distribution across the sheet. These systems can be programmed to deliver customized heating profiles tailored to specific material characteristics, sheet thickness, and part geometry. Integrating real-time temperature monitoring and feedback control further enhances the consistency and repeatability of the heating process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!