Enhanced Connectivity Solutions Enabled by Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Connectivity Background and Objectives

Vacuum forming has been a cornerstone in manufacturing for decades, primarily used in packaging and product design. However, recent advancements have opened new possibilities for enhancing connectivity solutions through this versatile process. The evolution of vacuum forming technology has been driven by the increasing demand for more efficient, cost-effective, and environmentally friendly production methods in the electronics and telecommunications industries.

The primary objective of exploring enhanced connectivity solutions enabled by vacuum forming is to revolutionize the way we design and manufacture components for communication devices, network infrastructure, and smart home systems. By leveraging the unique capabilities of vacuum forming, we aim to create more integrated, lightweight, and durable connectivity solutions that can meet the growing demands of the digital age.

One of the key trends driving this technological evolution is the miniaturization of electronic components. As devices become smaller and more powerful, there is a growing need for manufacturing processes that can produce intricate, precise shapes while maintaining structural integrity. Vacuum forming offers a promising avenue for creating complex geometries that can house and protect sensitive electronic components, while also providing excellent electromagnetic shielding properties.

Another significant factor propelling the development of vacuum-formed connectivity solutions is the push towards sustainability in manufacturing. Traditional methods of producing connectivity components often involve multiple materials and complex assembly processes, leading to increased waste and energy consumption. Vacuum forming presents an opportunity to streamline production, reduce material usage, and create more recyclable products, aligning with global efforts to minimize environmental impact.

The convergence of 5G technology and the Internet of Things (IoT) has also played a crucial role in shaping the objectives of this technological pursuit. As we move towards a more connected world, there is an unprecedented demand for reliable, high-performance connectivity solutions that can be deployed rapidly and at scale. Vacuum forming's ability to produce lightweight, yet robust components makes it an ideal candidate for creating next-generation antennas, signal boosters, and other critical infrastructure elements.

Furthermore, the adaptability of vacuum forming to various materials, including advanced composites and smart polymers, opens up new possibilities for creating multifunctional connectivity solutions. This versatility allows for the integration of features such as self-healing capabilities, adaptive signal routing, and even energy harvesting, potentially leading to a new class of intelligent, self-sustaining connectivity devices.

As we delve deeper into the potential of vacuum forming for enhanced connectivity solutions, our goal is not only to improve existing technologies but also to pave the way for entirely new applications and innovations in the field of telecommunications and beyond. By pushing the boundaries of what is possible with vacuum forming, we aim to create a foundation for more resilient, efficient, and interconnected communication systems that can support the digital infrastructure of the future.

The primary objective of exploring enhanced connectivity solutions enabled by vacuum forming is to revolutionize the way we design and manufacture components for communication devices, network infrastructure, and smart home systems. By leveraging the unique capabilities of vacuum forming, we aim to create more integrated, lightweight, and durable connectivity solutions that can meet the growing demands of the digital age.

One of the key trends driving this technological evolution is the miniaturization of electronic components. As devices become smaller and more powerful, there is a growing need for manufacturing processes that can produce intricate, precise shapes while maintaining structural integrity. Vacuum forming offers a promising avenue for creating complex geometries that can house and protect sensitive electronic components, while also providing excellent electromagnetic shielding properties.

Another significant factor propelling the development of vacuum-formed connectivity solutions is the push towards sustainability in manufacturing. Traditional methods of producing connectivity components often involve multiple materials and complex assembly processes, leading to increased waste and energy consumption. Vacuum forming presents an opportunity to streamline production, reduce material usage, and create more recyclable products, aligning with global efforts to minimize environmental impact.

The convergence of 5G technology and the Internet of Things (IoT) has also played a crucial role in shaping the objectives of this technological pursuit. As we move towards a more connected world, there is an unprecedented demand for reliable, high-performance connectivity solutions that can be deployed rapidly and at scale. Vacuum forming's ability to produce lightweight, yet robust components makes it an ideal candidate for creating next-generation antennas, signal boosters, and other critical infrastructure elements.

Furthermore, the adaptability of vacuum forming to various materials, including advanced composites and smart polymers, opens up new possibilities for creating multifunctional connectivity solutions. This versatility allows for the integration of features such as self-healing capabilities, adaptive signal routing, and even energy harvesting, potentially leading to a new class of intelligent, self-sustaining connectivity devices.

As we delve deeper into the potential of vacuum forming for enhanced connectivity solutions, our goal is not only to improve existing technologies but also to pave the way for entirely new applications and innovations in the field of telecommunications and beyond. By pushing the boundaries of what is possible with vacuum forming, we aim to create a foundation for more resilient, efficient, and interconnected communication systems that can support the digital infrastructure of the future.

Market Demand for Enhanced Connectivity Solutions

The market demand for enhanced connectivity solutions enabled by vacuum forming has been steadily increasing in recent years, driven by the growing need for more efficient and reliable communication systems across various industries. This technology offers significant advantages in terms of cost-effectiveness, durability, and design flexibility, making it particularly attractive for applications in telecommunications, automotive, aerospace, and consumer electronics sectors.

In the telecommunications industry, the demand for vacuum-formed connectivity solutions has been fueled by the rapid expansion of 5G networks and the Internet of Things (IoT). These technologies require a vast number of small cell antennas and signal boosters, which can be efficiently produced using vacuum forming techniques. The ability to create lightweight, weather-resistant housings for these devices has made vacuum forming a preferred manufacturing method for many telecom equipment manufacturers.

The automotive sector has also shown a strong interest in enhanced connectivity solutions utilizing vacuum forming. As vehicles become increasingly connected and autonomous, there is a growing need for integrated antennas, sensors, and communication modules. Vacuum forming allows for the production of complex, aerodynamic shapes that can house these components while maintaining the vehicle's aesthetic appeal and fuel efficiency.

In the aerospace industry, the demand for lightweight, high-performance connectivity solutions has led to increased adoption of vacuum-formed components. These are used in satellite communications, in-flight entertainment systems, and aircraft navigation equipment. The ability to create precise, custom-shaped parts that meet stringent industry standards has made vacuum forming an essential technology in this sector.

Consumer electronics manufacturers have also recognized the benefits of vacuum-formed connectivity solutions. The technology enables the production of sleek, ergonomic designs for devices such as smartphones, tablets, and wearables. Additionally, vacuum forming allows for the integration of antennas and other connectivity components directly into the device's housing, improving signal quality and reducing overall device size.

The market for enhanced connectivity solutions enabled by vacuum forming is expected to continue its growth trajectory in the coming years. This is largely due to the ongoing digital transformation across industries and the increasing demand for connected devices in both consumer and industrial applications. The technology's ability to produce complex shapes with high precision, while maintaining cost-effectiveness and scalability, positions it as a key enabler for the next generation of connectivity solutions.

Furthermore, the push towards more sustainable manufacturing processes has also contributed to the rising demand for vacuum-formed connectivity solutions. The technology allows for the use of recyclable materials and produces less waste compared to traditional manufacturing methods, aligning with the growing emphasis on environmental responsibility in product design and manufacturing.

In the telecommunications industry, the demand for vacuum-formed connectivity solutions has been fueled by the rapid expansion of 5G networks and the Internet of Things (IoT). These technologies require a vast number of small cell antennas and signal boosters, which can be efficiently produced using vacuum forming techniques. The ability to create lightweight, weather-resistant housings for these devices has made vacuum forming a preferred manufacturing method for many telecom equipment manufacturers.

The automotive sector has also shown a strong interest in enhanced connectivity solutions utilizing vacuum forming. As vehicles become increasingly connected and autonomous, there is a growing need for integrated antennas, sensors, and communication modules. Vacuum forming allows for the production of complex, aerodynamic shapes that can house these components while maintaining the vehicle's aesthetic appeal and fuel efficiency.

In the aerospace industry, the demand for lightweight, high-performance connectivity solutions has led to increased adoption of vacuum-formed components. These are used in satellite communications, in-flight entertainment systems, and aircraft navigation equipment. The ability to create precise, custom-shaped parts that meet stringent industry standards has made vacuum forming an essential technology in this sector.

Consumer electronics manufacturers have also recognized the benefits of vacuum-formed connectivity solutions. The technology enables the production of sleek, ergonomic designs for devices such as smartphones, tablets, and wearables. Additionally, vacuum forming allows for the integration of antennas and other connectivity components directly into the device's housing, improving signal quality and reducing overall device size.

The market for enhanced connectivity solutions enabled by vacuum forming is expected to continue its growth trajectory in the coming years. This is largely due to the ongoing digital transformation across industries and the increasing demand for connected devices in both consumer and industrial applications. The technology's ability to produce complex shapes with high precision, while maintaining cost-effectiveness and scalability, positions it as a key enabler for the next generation of connectivity solutions.

Furthermore, the push towards more sustainable manufacturing processes has also contributed to the rising demand for vacuum-formed connectivity solutions. The technology allows for the use of recyclable materials and produces less waste compared to traditional manufacturing methods, aligning with the growing emphasis on environmental responsibility in product design and manufacturing.

Current State and Challenges in Vacuum Forming Connectivity

Vacuum forming technology has made significant strides in enhancing connectivity solutions across various industries. Currently, this process is widely utilized in the production of electronic enclosures, automotive components, and consumer electronics, offering a cost-effective method for creating complex shapes with embedded connectivity features.

The state-of-the-art in vacuum forming connectivity involves the integration of conductive materials and circuits directly into the formed plastic components. This approach has led to the development of smart packaging, interactive displays, and seamless user interfaces. Advanced techniques now allow for the incorporation of flexible printed circuits and antennas within the vacuum-formed structures, enabling improved wireless connectivity and reducing the need for separate electronic assemblies.

Despite these advancements, several challenges persist in the field of vacuum forming connectivity. One of the primary obstacles is the limited temperature resistance of many conductive materials, which can be compromised during the heating phase of the vacuum forming process. This constraint often necessitates the use of specialized heat-resistant conductive compounds or post-forming application methods, potentially increasing production costs and complexity.

Another significant challenge lies in achieving consistent electrical performance across curved and stretched surfaces. As the plastic sheet is formed over a mold, conductive pathways may experience varying degrees of deformation, potentially leading to inconsistencies in signal transmission or degradation of electrical properties. Addressing this issue requires careful material selection and innovative design strategies to maintain connectivity integrity throughout the forming process.

The integration of multiple connectivity technologies within a single vacuum-formed component presents additional hurdles. Combining different types of sensors, antennas, and conductive pathways while ensuring electromagnetic compatibility and minimal signal interference remains a complex task. Engineers must navigate these challenges to create cohesive, multi-functional connectivity solutions that meet the demands of modern applications.

Scalability and mass production considerations also pose challenges in vacuum forming connectivity. While the process is well-suited for medium to large production runs, achieving consistent results across high-volume manufacturing can be difficult, particularly when incorporating advanced connectivity features. Ensuring uniform distribution of conductive materials and maintaining precise tolerances for electrical components throughout the production cycle requires sophisticated quality control measures and potentially specialized equipment.

As the demand for more integrated and seamless connectivity solutions continues to grow, the vacuum forming industry faces the ongoing challenge of balancing cost-effectiveness with technological advancement. Overcoming these hurdles will be crucial in unlocking the full potential of vacuum forming in creating next-generation connected devices and components.

The state-of-the-art in vacuum forming connectivity involves the integration of conductive materials and circuits directly into the formed plastic components. This approach has led to the development of smart packaging, interactive displays, and seamless user interfaces. Advanced techniques now allow for the incorporation of flexible printed circuits and antennas within the vacuum-formed structures, enabling improved wireless connectivity and reducing the need for separate electronic assemblies.

Despite these advancements, several challenges persist in the field of vacuum forming connectivity. One of the primary obstacles is the limited temperature resistance of many conductive materials, which can be compromised during the heating phase of the vacuum forming process. This constraint often necessitates the use of specialized heat-resistant conductive compounds or post-forming application methods, potentially increasing production costs and complexity.

Another significant challenge lies in achieving consistent electrical performance across curved and stretched surfaces. As the plastic sheet is formed over a mold, conductive pathways may experience varying degrees of deformation, potentially leading to inconsistencies in signal transmission or degradation of electrical properties. Addressing this issue requires careful material selection and innovative design strategies to maintain connectivity integrity throughout the forming process.

The integration of multiple connectivity technologies within a single vacuum-formed component presents additional hurdles. Combining different types of sensors, antennas, and conductive pathways while ensuring electromagnetic compatibility and minimal signal interference remains a complex task. Engineers must navigate these challenges to create cohesive, multi-functional connectivity solutions that meet the demands of modern applications.

Scalability and mass production considerations also pose challenges in vacuum forming connectivity. While the process is well-suited for medium to large production runs, achieving consistent results across high-volume manufacturing can be difficult, particularly when incorporating advanced connectivity features. Ensuring uniform distribution of conductive materials and maintaining precise tolerances for electrical components throughout the production cycle requires sophisticated quality control measures and potentially specialized equipment.

As the demand for more integrated and seamless connectivity solutions continues to grow, the vacuum forming industry faces the ongoing challenge of balancing cost-effectiveness with technological advancement. Overcoming these hurdles will be crucial in unlocking the full potential of vacuum forming in creating next-generation connected devices and components.

Existing Vacuum Forming Connectivity Solutions

01 Wireless connectivity in vacuum forming systems

Integration of wireless communication technologies in vacuum forming processes to enable remote monitoring, control, and data exchange. This allows for improved connectivity between various components of the vacuum forming system, enhancing overall efficiency and automation.- Wireless connectivity in vacuum forming systems: Integration of wireless communication technologies in vacuum forming processes to enable remote monitoring, control, and data exchange. This allows for improved connectivity between various components of the vacuum forming system, enhancing overall efficiency and automation.

- Network protocols for vacuum forming equipment: Implementation of specialized network protocols designed for vacuum forming equipment to ensure seamless communication and data transfer. These protocols optimize connectivity between different machines and control systems in the vacuum forming process.

- IoT integration in vacuum forming: Incorporation of Internet of Things (IoT) technologies in vacuum forming processes, enabling real-time data collection, analysis, and connectivity. This integration allows for improved monitoring, predictive maintenance, and overall process optimization.

- Cloud-based connectivity solutions for vacuum forming: Utilization of cloud computing platforms to enhance connectivity in vacuum forming operations. This approach enables centralized data storage, remote access, and improved collaboration across multiple vacuum forming sites or production lines.

- Connectivity interfaces for vacuum forming machines: Development of specialized connectivity interfaces and protocols for vacuum forming machines, allowing for seamless integration with various control systems and manufacturing execution systems (MES). These interfaces enhance interoperability and data exchange capabilities in vacuum forming processes.

02 Network protocols for vacuum forming equipment

Implementation of specialized network protocols tailored for vacuum forming equipment to ensure reliable and secure communication. These protocols facilitate seamless data transfer between different machines and control systems in the vacuum forming process.Expand Specific Solutions03 IoT integration in vacuum forming

Incorporation of Internet of Things (IoT) technologies in vacuum forming processes, enabling real-time data collection, analysis, and decision-making. This integration allows for predictive maintenance, quality control, and optimization of the vacuum forming operations.Expand Specific Solutions04 Cloud-based connectivity solutions for vacuum forming

Utilization of cloud computing platforms to enhance connectivity in vacuum forming systems. This approach enables centralized data storage, remote access to production information, and improved collaboration across multiple vacuum forming facilities.Expand Specific Solutions05 Connectivity interfaces for vacuum forming machines

Development of specialized connectivity interfaces and protocols for vacuum forming machines, allowing seamless integration with existing manufacturing systems and networks. These interfaces facilitate data exchange, machine-to-machine communication, and integration with enterprise resource planning (ERP) systems.Expand Specific Solutions

Key Players in Vacuum Forming and Connectivity Industries

The competitive landscape for "Enhanced Connectivity Solutions Enabled by Vacuum Forming" is in an early growth stage, with increasing market potential as industries seek innovative connectivity solutions. The market size is expanding, driven by demand in automotive, aerospace, and electronics sectors. Technologically, the field is evolving rapidly, with companies like Mercedes-Benz Group AG, Airbus Operations GmbH, and AVIC Shenyang Aircraft Corp. leading research and development efforts. These firms are leveraging vacuum forming techniques to create advanced, lightweight connectivity solutions, potentially revolutionizing product design and manufacturing processes across various industries.

HARTING Electronics GmbH & Co. KG

Technical Solution: HARTING Electronics has pioneered vacuum forming techniques for creating advanced connector housings and interface solutions. Their process utilizes specialized thermoplastic materials that can withstand high temperatures and provide excellent electromagnetic shielding[2]. The company has developed a proprietary vacuum forming method that allows for the creation of intricate connector shapes with built-in shielding and grounding features[4]. This technology enables the production of lightweight, yet robust connectors that can be seamlessly integrated into various electronic devices and systems, enhancing overall connectivity performance[6]. HARTING's vacuum-formed connectors also incorporate innovative sealing technologies to ensure protection against environmental factors in harsh industrial environments[8].

Strengths: High-performance shielding, lightweight design, and environmental protection. Weaknesses: Limited to specific materials compatible with the vacuum forming process.

Airbus Operations GmbH

Technical Solution: Airbus Operations GmbH has developed advanced vacuum forming techniques for enhanced connectivity solutions in aircraft manufacturing. Their approach involves using high-performance thermoplastics and precise temperature control to create complex, lightweight structures with integrated connectivity features[1]. The company has implemented a multi-layer vacuum forming process that allows for the embedding of conductive materials and antenna elements directly into aircraft panels, reducing weight and improving signal transmission[3]. This technology enables seamless integration of communication systems, sensors, and other electronic components into the aircraft structure, enhancing overall connectivity while maintaining aerodynamic efficiency[5].

Strengths: Lightweight integration of connectivity features, improved signal transmission, and aerodynamic efficiency. Weaknesses: Potential complexity in manufacturing process and higher initial costs compared to traditional methods.

Core Innovations in Vacuum Forming for Connectivity

Thermally insulating wall

PatentInactiveEP1238237A1

Innovation

- Forming lead-throughs by material deformation of the cover layers to create vacuum-tight connections without additional components, allowing for cost-effective production and improved material homogeneity, with deformations such as cup-like designs for enhanced support and reliability.

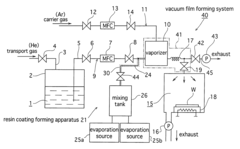

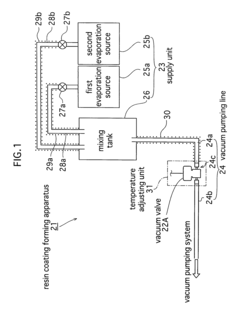

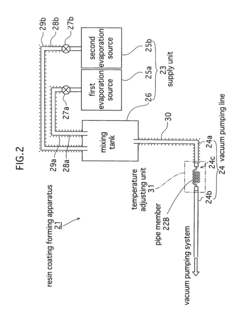

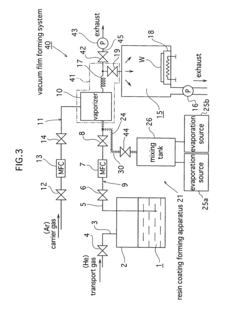

Method for producing component for vacuum apparatus, resin coating forming apparatus and vacuum film forming system

PatentInactiveUS8252113B2

Innovation

- A method involving connecting the internal flow path of vacuum components to a vacuum pumping line, supplying monomer vapor to form a resin coating uniformly on the internal surfaces, allowing for precise control of coating thickness and uniformity, using a resin coating forming apparatus that includes a supply unit, vacuum pumping line, and temperature adjusting unit to deposit monomer vapor onto the internal flow path.

Material Advancements for Vacuum Forming Connectivity

Vacuum forming technology has witnessed significant advancements in material science, leading to enhanced connectivity solutions. The development of innovative materials has been crucial in improving the performance, durability, and functionality of vacuum-formed components used in various connectivity applications.

One of the key material advancements in vacuum forming for connectivity solutions is the introduction of high-performance thermoplastics. These materials offer superior mechanical properties, thermal stability, and chemical resistance, making them ideal for use in demanding environments. Polymers such as polyetherimide (PEI), polyetheretherketone (PEEK), and polyphenylsulfone (PPSU) have gained prominence due to their ability to withstand high temperatures and maintain dimensional stability during the vacuum forming process.

Conductive polymers have emerged as a game-changer in vacuum-formed connectivity solutions. These materials combine the electrical properties of metals with the processability of plastics, enabling the creation of intricate conductive patterns and structures through vacuum forming. This advancement has paved the way for the integration of electrical circuits directly into vacuum-formed components, reducing the need for separate conductive elements and simplifying assembly processes.

Nanocomposite materials have also made significant contributions to vacuum forming connectivity. By incorporating nanoscale fillers such as carbon nanotubes, graphene, or metal nanoparticles into polymer matrices, researchers have developed materials with enhanced electrical conductivity, thermal management properties, and mechanical strength. These nanocomposites allow for the creation of lightweight yet robust vacuum-formed components with improved signal transmission capabilities.

The development of shape memory polymers (SMPs) has opened up new possibilities in vacuum-formed connectivity solutions. These materials can be programmed to change shape or physical properties in response to external stimuli such as temperature or electrical current. This property enables the creation of adaptive connectivity components that can self-adjust or self-heal, enhancing the reliability and longevity of vacuum-formed products.

Biodegradable and sustainable materials have gained traction in vacuum forming applications, addressing environmental concerns associated with traditional plastics. Materials derived from renewable sources, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), are being explored for their potential in creating eco-friendly connectivity solutions through vacuum forming.

The integration of smart materials into vacuum forming processes has led to the development of intelligent connectivity solutions. Materials with embedded sensors or actuators can provide real-time feedback on environmental conditions, structural integrity, or electrical performance, enabling predictive maintenance and enhanced functionality in connectivity applications.

One of the key material advancements in vacuum forming for connectivity solutions is the introduction of high-performance thermoplastics. These materials offer superior mechanical properties, thermal stability, and chemical resistance, making them ideal for use in demanding environments. Polymers such as polyetherimide (PEI), polyetheretherketone (PEEK), and polyphenylsulfone (PPSU) have gained prominence due to their ability to withstand high temperatures and maintain dimensional stability during the vacuum forming process.

Conductive polymers have emerged as a game-changer in vacuum-formed connectivity solutions. These materials combine the electrical properties of metals with the processability of plastics, enabling the creation of intricate conductive patterns and structures through vacuum forming. This advancement has paved the way for the integration of electrical circuits directly into vacuum-formed components, reducing the need for separate conductive elements and simplifying assembly processes.

Nanocomposite materials have also made significant contributions to vacuum forming connectivity. By incorporating nanoscale fillers such as carbon nanotubes, graphene, or metal nanoparticles into polymer matrices, researchers have developed materials with enhanced electrical conductivity, thermal management properties, and mechanical strength. These nanocomposites allow for the creation of lightweight yet robust vacuum-formed components with improved signal transmission capabilities.

The development of shape memory polymers (SMPs) has opened up new possibilities in vacuum-formed connectivity solutions. These materials can be programmed to change shape or physical properties in response to external stimuli such as temperature or electrical current. This property enables the creation of adaptive connectivity components that can self-adjust or self-heal, enhancing the reliability and longevity of vacuum-formed products.

Biodegradable and sustainable materials have gained traction in vacuum forming applications, addressing environmental concerns associated with traditional plastics. Materials derived from renewable sources, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), are being explored for their potential in creating eco-friendly connectivity solutions through vacuum forming.

The integration of smart materials into vacuum forming processes has led to the development of intelligent connectivity solutions. Materials with embedded sensors or actuators can provide real-time feedback on environmental conditions, structural integrity, or electrical performance, enabling predictive maintenance and enhanced functionality in connectivity applications.

Environmental Impact of Vacuum Forming Processes

Vacuum forming processes, while offering significant advantages in manufacturing, also pose environmental challenges that require careful consideration. The primary environmental impacts stem from energy consumption, material waste, and emissions. Energy usage is a major concern, as vacuum forming machines typically require substantial power to operate, contributing to increased carbon footprints. The heating process, essential for softening thermoplastic sheets, is particularly energy-intensive and often relies on fossil fuel-based electricity sources.

Material waste is another significant environmental issue associated with vacuum forming. The process inherently generates offcuts and excess material that cannot be easily reused in the same production cycle. While some thermoplastics are recyclable, the recycling process itself consumes energy and resources. Additionally, not all materials used in vacuum forming are readily recyclable, leading to increased landfill waste.

Emissions from vacuum forming processes, though generally lower than some other manufacturing methods, still contribute to air pollution. The heating of certain plastics can release volatile organic compounds (VOCs) and other potentially harmful substances into the atmosphere. These emissions not only affect local air quality but also contribute to broader environmental issues such as smog formation and climate change.

Water usage in vacuum forming is relatively low compared to other manufacturing processes. However, the cooling systems used in some vacuum forming operations can consume significant amounts of water, potentially straining local water resources. Moreover, any contaminated water from the process requires proper treatment before disposal to prevent water pollution.

The choice of materials in vacuum forming also has environmental implications. Many commonly used thermoplastics are derived from non-renewable petroleum sources, contributing to resource depletion. The production of these raw materials often involves energy-intensive processes and can result in pollution at various stages of the supply chain.

To mitigate these environmental impacts, the industry is exploring several strategies. These include the development of more energy-efficient vacuum forming machines, the use of renewable energy sources for power, and the implementation of closed-loop recycling systems to minimize waste. Additionally, research into bio-based and biodegradable plastics offers potential alternatives to traditional petroleum-based materials, potentially reducing the overall environmental footprint of vacuum forming processes.

Material waste is another significant environmental issue associated with vacuum forming. The process inherently generates offcuts and excess material that cannot be easily reused in the same production cycle. While some thermoplastics are recyclable, the recycling process itself consumes energy and resources. Additionally, not all materials used in vacuum forming are readily recyclable, leading to increased landfill waste.

Emissions from vacuum forming processes, though generally lower than some other manufacturing methods, still contribute to air pollution. The heating of certain plastics can release volatile organic compounds (VOCs) and other potentially harmful substances into the atmosphere. These emissions not only affect local air quality but also contribute to broader environmental issues such as smog formation and climate change.

Water usage in vacuum forming is relatively low compared to other manufacturing processes. However, the cooling systems used in some vacuum forming operations can consume significant amounts of water, potentially straining local water resources. Moreover, any contaminated water from the process requires proper treatment before disposal to prevent water pollution.

The choice of materials in vacuum forming also has environmental implications. Many commonly used thermoplastics are derived from non-renewable petroleum sources, contributing to resource depletion. The production of these raw materials often involves energy-intensive processes and can result in pollution at various stages of the supply chain.

To mitigate these environmental impacts, the industry is exploring several strategies. These include the development of more energy-efficient vacuum forming machines, the use of renewable energy sources for power, and the implementation of closed-loop recycling systems to minimize waste. Additionally, research into bio-based and biodegradable plastics offers potential alternatives to traditional petroleum-based materials, potentially reducing the overall environmental footprint of vacuum forming processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!