The Growth Potential of Energy Storage Systems via Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Storage Evolution

Energy storage systems have undergone significant evolution over the past decades, driven by the increasing demand for efficient and sustainable power solutions. The journey began with traditional batteries and has progressed to advanced technologies like lithium-ion, flow batteries, and emerging solid-state solutions. This evolution has been marked by continuous improvements in energy density, cycle life, and cost-effectiveness.

The early stages of energy storage were dominated by lead-acid batteries, which, despite their limitations, played a crucial role in various applications. As technology advanced, nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries emerged, offering higher energy densities and improved performance. However, the real breakthrough came with the introduction of lithium-ion batteries in the 1990s, revolutionizing portable electronics and later finding applications in electric vehicles and grid-scale storage.

In recent years, the focus has shifted towards developing more sustainable and efficient energy storage solutions. This has led to the exploration of novel materials and manufacturing techniques, including the potential use of vacuum forming in energy storage systems. Vacuum forming, traditionally used in packaging and product design, is now being investigated for its potential to create lightweight, cost-effective, and scalable energy storage components.

The integration of vacuum forming in energy storage represents a convergence of manufacturing innovation and energy technology. This approach could potentially address some of the key challenges in energy storage, such as weight reduction, improved thermal management, and enhanced structural integrity. By enabling the production of complex shapes and structures, vacuum forming could lead to more efficient packaging of energy storage systems, ultimately increasing their energy density and overall performance.

As the world transitions towards renewable energy sources, the importance of efficient and reliable energy storage continues to grow. This has spurred research into new chemistries and architectures for batteries and other storage technologies. Alongside chemical innovations, manufacturing processes like vacuum forming are being explored to enhance the physical characteristics and production efficiency of energy storage systems.

The evolution of energy storage is not limited to batteries alone. Other technologies such as pumped hydro storage, compressed air energy storage, and flywheel systems have also seen significant advancements. These diverse approaches to energy storage highlight the multifaceted nature of the challenge and the need for a range of solutions to meet varying energy needs across different scales and applications.

The early stages of energy storage were dominated by lead-acid batteries, which, despite their limitations, played a crucial role in various applications. As technology advanced, nickel-cadmium (NiCd) and nickel-metal hydride (NiMH) batteries emerged, offering higher energy densities and improved performance. However, the real breakthrough came with the introduction of lithium-ion batteries in the 1990s, revolutionizing portable electronics and later finding applications in electric vehicles and grid-scale storage.

In recent years, the focus has shifted towards developing more sustainable and efficient energy storage solutions. This has led to the exploration of novel materials and manufacturing techniques, including the potential use of vacuum forming in energy storage systems. Vacuum forming, traditionally used in packaging and product design, is now being investigated for its potential to create lightweight, cost-effective, and scalable energy storage components.

The integration of vacuum forming in energy storage represents a convergence of manufacturing innovation and energy technology. This approach could potentially address some of the key challenges in energy storage, such as weight reduction, improved thermal management, and enhanced structural integrity. By enabling the production of complex shapes and structures, vacuum forming could lead to more efficient packaging of energy storage systems, ultimately increasing their energy density and overall performance.

As the world transitions towards renewable energy sources, the importance of efficient and reliable energy storage continues to grow. This has spurred research into new chemistries and architectures for batteries and other storage technologies. Alongside chemical innovations, manufacturing processes like vacuum forming are being explored to enhance the physical characteristics and production efficiency of energy storage systems.

The evolution of energy storage is not limited to batteries alone. Other technologies such as pumped hydro storage, compressed air energy storage, and flywheel systems have also seen significant advancements. These diverse approaches to energy storage highlight the multifaceted nature of the challenge and the need for a range of solutions to meet varying energy needs across different scales and applications.

Market Demand Analysis

The energy storage market is experiencing significant growth, driven by the increasing demand for renewable energy integration and grid stability. Vacuum forming technology in energy storage systems presents a promising avenue for market expansion, particularly in the production of advanced battery components and structural elements for various storage solutions.

The global energy storage market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the rapid adoption of renewable energy sources, such as solar and wind power, which require efficient storage solutions to manage intermittency issues. Vacuum forming technology offers potential advantages in manufacturing lightweight, durable, and cost-effective components for these storage systems, aligning well with market demands for improved performance and reduced costs.

In the electric vehicle (EV) sector, the demand for high-performance batteries is surging. Vacuum forming techniques can contribute to the production of advanced battery casings and thermal management systems, addressing the market's need for lighter, more efficient energy storage solutions in EVs. This aligns with the projected growth of the EV market, which is expected to reach a significant market share in the automotive industry by 2030.

The stationary energy storage market, including grid-scale and residential applications, is another area where vacuum-formed components could see increased demand. As utilities and homeowners seek more reliable and efficient energy storage options, the market for advanced battery systems and structural components is expanding. Vacuum forming can offer advantages in producing custom-designed, lightweight enclosures and structural elements for these applications.

Industrial and commercial sectors are also driving demand for energy storage solutions, particularly in applications such as uninterruptible power supplies (UPS) and peak shaving systems. Vacuum-formed components can contribute to the development of more compact, efficient, and cost-effective storage solutions for these markets, addressing the growing need for reliable power management in various industries.

The renewable energy sector's growth is a key driver for energy storage demand. As countries worldwide increase their renewable energy capacity, the need for efficient and scalable storage solutions becomes more pressing. Vacuum forming technology can play a role in developing innovative storage system designs that are both economical and adaptable to various renewable energy applications.

In conclusion, the market demand for energy storage systems utilizing vacuum forming technology is poised for significant growth across multiple sectors. The technology's potential to enhance performance, reduce costs, and improve manufacturing efficiency aligns well with the evolving needs of the energy storage market. As the industry continues to expand and innovate, vacuum forming is likely to play an increasingly important role in meeting the growing demand for advanced energy storage solutions.

The global energy storage market is projected to grow substantially in the coming years, with a compound annual growth rate (CAGR) exceeding 20% through 2030. This growth is primarily fueled by the rapid adoption of renewable energy sources, such as solar and wind power, which require efficient storage solutions to manage intermittency issues. Vacuum forming technology offers potential advantages in manufacturing lightweight, durable, and cost-effective components for these storage systems, aligning well with market demands for improved performance and reduced costs.

In the electric vehicle (EV) sector, the demand for high-performance batteries is surging. Vacuum forming techniques can contribute to the production of advanced battery casings and thermal management systems, addressing the market's need for lighter, more efficient energy storage solutions in EVs. This aligns with the projected growth of the EV market, which is expected to reach a significant market share in the automotive industry by 2030.

The stationary energy storage market, including grid-scale and residential applications, is another area where vacuum-formed components could see increased demand. As utilities and homeowners seek more reliable and efficient energy storage options, the market for advanced battery systems and structural components is expanding. Vacuum forming can offer advantages in producing custom-designed, lightweight enclosures and structural elements for these applications.

Industrial and commercial sectors are also driving demand for energy storage solutions, particularly in applications such as uninterruptible power supplies (UPS) and peak shaving systems. Vacuum-formed components can contribute to the development of more compact, efficient, and cost-effective storage solutions for these markets, addressing the growing need for reliable power management in various industries.

The renewable energy sector's growth is a key driver for energy storage demand. As countries worldwide increase their renewable energy capacity, the need for efficient and scalable storage solutions becomes more pressing. Vacuum forming technology can play a role in developing innovative storage system designs that are both economical and adaptable to various renewable energy applications.

In conclusion, the market demand for energy storage systems utilizing vacuum forming technology is poised for significant growth across multiple sectors. The technology's potential to enhance performance, reduce costs, and improve manufacturing efficiency aligns well with the evolving needs of the energy storage market. As the industry continues to expand and innovate, vacuum forming is likely to play an increasingly important role in meeting the growing demand for advanced energy storage solutions.

Vacuum Forming Challenges

Vacuum forming, while a promising technique for energy storage system manufacturing, faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the limitation in material selection. The process requires thermoplastic materials that can be heated and formed, which restricts the range of materials suitable for energy storage applications. This constraint can impact the overall performance and durability of the energy storage systems produced.

Another critical challenge lies in the precision and uniformity of the formed components. Vacuum forming may struggle to maintain consistent thickness across complex geometries, potentially leading to weak points or areas of reduced efficiency in energy storage devices. This issue becomes particularly pronounced when dealing with large-scale or intricate designs, which are often necessary for high-capacity energy storage systems.

The scalability of vacuum forming for mass production of energy storage components also presents difficulties. While the process is relatively straightforward for small-scale production, scaling up to meet industrial demands can be problematic. Ensuring consistent quality and maintaining production speed across larger volumes remains a significant hurdle for manufacturers.

Temperature control during the vacuum forming process is another crucial challenge. Precise heating is essential to achieve the desired malleability of the material without compromising its structural integrity or energy storage properties. Overheating can lead to material degradation, while insufficient heating may result in incomplete forming or poor surface finish.

The environmental impact of vacuum forming in energy storage system production is also a concern. The process typically involves the use of plastics, which raises questions about sustainability and end-of-life recycling. Developing eco-friendly materials that are compatible with vacuum forming while meeting the performance requirements of energy storage systems is an ongoing challenge.

Lastly, the integration of additional components and materials post-forming can be complex. Energy storage systems often require the incorporation of conductive elements, electrodes, or other functional materials. The vacuum forming process may limit the ability to seamlessly integrate these components, necessitating additional manufacturing steps and potentially increasing production costs and complexity.

Addressing these challenges is crucial for realizing the full potential of vacuum forming in the energy storage sector. Innovations in material science, process optimization, and design engineering will be key to overcoming these obstacles and enhancing the viability of vacuum forming for advanced energy storage applications.

Another critical challenge lies in the precision and uniformity of the formed components. Vacuum forming may struggle to maintain consistent thickness across complex geometries, potentially leading to weak points or areas of reduced efficiency in energy storage devices. This issue becomes particularly pronounced when dealing with large-scale or intricate designs, which are often necessary for high-capacity energy storage systems.

The scalability of vacuum forming for mass production of energy storage components also presents difficulties. While the process is relatively straightforward for small-scale production, scaling up to meet industrial demands can be problematic. Ensuring consistent quality and maintaining production speed across larger volumes remains a significant hurdle for manufacturers.

Temperature control during the vacuum forming process is another crucial challenge. Precise heating is essential to achieve the desired malleability of the material without compromising its structural integrity or energy storage properties. Overheating can lead to material degradation, while insufficient heating may result in incomplete forming or poor surface finish.

The environmental impact of vacuum forming in energy storage system production is also a concern. The process typically involves the use of plastics, which raises questions about sustainability and end-of-life recycling. Developing eco-friendly materials that are compatible with vacuum forming while meeting the performance requirements of energy storage systems is an ongoing challenge.

Lastly, the integration of additional components and materials post-forming can be complex. Energy storage systems often require the incorporation of conductive elements, electrodes, or other functional materials. The vacuum forming process may limit the ability to seamlessly integrate these components, necessitating additional manufacturing steps and potentially increasing production costs and complexity.

Addressing these challenges is crucial for realizing the full potential of vacuum forming in the energy storage sector. Innovations in material science, process optimization, and design engineering will be key to overcoming these obstacles and enhancing the viability of vacuum forming for advanced energy storage applications.

Current Solutions

01 Advanced battery technologies for energy storage

Development of innovative battery technologies to enhance energy storage capacity, efficiency, and lifespan. This includes improvements in lithium-ion batteries, solid-state batteries, and other emerging battery chemistries. These advancements aim to increase energy density, reduce costs, and improve safety for various applications, from grid-scale storage to electric vehicles.- Advanced battery technologies: The growth potential of energy storage systems is significantly enhanced by advancements in battery technologies. These include improvements in lithium-ion batteries, development of solid-state batteries, and exploration of new materials for energy storage. Such innovations lead to increased energy density, longer lifespan, and improved safety, making energy storage systems more efficient and cost-effective for various applications.

- Grid-scale energy storage solutions: Large-scale energy storage systems for power grids show substantial growth potential. These systems help balance supply and demand, integrate renewable energy sources, and improve grid stability. Technologies such as flow batteries, compressed air energy storage, and pumped hydro storage are being developed and implemented to meet the increasing demand for grid-scale energy storage.

- Integration with renewable energy sources: The growth of energy storage systems is closely tied to the expansion of renewable energy sources. Storage solutions are essential for managing the intermittent nature of solar and wind power, enabling a more stable and reliable supply of clean energy. This integration drives the development of hybrid systems and smart grid technologies, further boosting the potential of energy storage markets.

- Electric vehicle battery innovations: The electric vehicle (EV) market is a significant driver for energy storage system growth. Advancements in EV batteries, including fast-charging technologies, increased range, and improved durability, are accelerating the adoption of electric vehicles. This growth in the EV sector is spurring innovations in energy storage that have applications beyond transportation.

- Emerging energy storage technologies: Novel energy storage technologies are emerging with significant growth potential. These include thermal energy storage, hydrogen storage systems, and advanced supercapacitors. Such innovations offer unique advantages in specific applications, complementing traditional battery technologies and expanding the overall market for energy storage systems.

02 Grid-scale energy storage solutions

Implementation of large-scale energy storage systems to support grid stability, integrate renewable energy sources, and manage peak demand. These solutions include battery arrays, pumped hydro storage, compressed air energy storage, and other technologies designed to store and release energy as needed, improving grid reliability and enabling higher penetration of intermittent renewable energy sources.Expand Specific Solutions03 Thermal energy storage systems

Development of thermal energy storage technologies to capture and store heat or cold for later use. This includes molten salt storage for concentrated solar power plants, phase change materials for building climate control, and other innovative approaches to store thermal energy efficiently. These systems can help balance energy supply and demand, reduce peak loads, and improve overall energy efficiency.Expand Specific Solutions04 Energy management and control systems

Integration of smart energy management and control systems to optimize the operation of energy storage systems. These systems utilize advanced algorithms, artificial intelligence, and real-time data analysis to predict energy demand, manage storage capacity, and coordinate with renewable energy sources. They aim to improve overall system efficiency, reduce costs, and enhance grid stability.Expand Specific Solutions05 Hybrid and integrated energy storage solutions

Development of hybrid and integrated energy storage systems that combine multiple storage technologies or integrate storage with generation sources. These solutions aim to leverage the strengths of different storage methods, such as combining batteries with flywheels or integrating storage directly with solar panels or wind turbines. The goal is to create more flexible, efficient, and cost-effective energy storage solutions for various applications.Expand Specific Solutions

Industry Leaders

The energy storage systems market via vacuum forming is in a growth phase, driven by increasing demand for renewable energy integration and grid stability. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Energy Dome SpA and Quidnet Energy developing innovative CO2-based and hydroelectric storage solutions, respectively. Established players such as Halliburton Energy Services and Schlumberger are also exploring this space, leveraging their expertise in energy technologies. Academic institutions like MIT and Xi'an Jiaotong University are contributing to research and development, pushing the boundaries of energy storage efficiency and scalability.

Energy Dome SpA

Technical Solution: Energy Dome has developed an innovative CO2 Battery technology that utilizes vacuum forming in its energy storage system. The system employs a closed-loop thermodynamic process where CO2 is compressed, stored, and then expanded to drive a turbine for electricity generation. The vacuum forming process is crucial in creating the dome-shaped structure that houses the compressed CO2, allowing for efficient storage and minimal land use. This technology can achieve round-trip efficiencies of up to 75-80%[1], with a potential lifespan of over 25 years[2]. The system can be scaled from 20 to 200 MWh, providing flexibility for various grid applications[3].

Strengths: High efficiency, long lifespan, scalability, and use of abundant, non-toxic CO2. Weaknesses: Relatively new technology with limited real-world deployment data, potential high initial costs for infrastructure.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed a novel energy storage system utilizing vacuum-forming techniques for advanced battery designs. Their approach involves creating thin, flexible battery components through vacuum forming, allowing for unique geometries and improved energy density. The process enables the production of 3D-structured battery electrodes with enhanced surface area and ion transport pathways[4]. This technology has shown potential to increase energy density by up to 30% compared to conventional lithium-ion batteries[5]. Additionally, the vacuum-forming process allows for the integration of solid-state electrolytes, potentially improving safety and cycle life[6].

Strengths: Increased energy density, improved safety with solid-state electrolytes, and potential for flexible form factors. Weaknesses: Still in research phase, may face challenges in scaling up to mass production.

Key Innovations

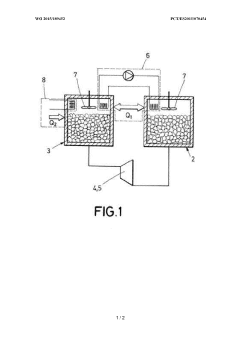

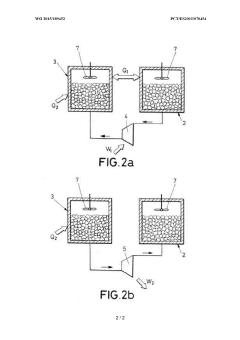

Energy storage method and system for storing energy

PatentWO2015189452A1

Innovation

- A vapor sorption/desorption energy storage system using thermally insulated tanks with sorbents and a compressor/expander device, capable of storing energy with low environmental impact, high power density, and extended duration, utilizing residual heat to increase storage capacity.

Environmental Impact

The environmental impact of energy storage systems via vacuum forming is a critical consideration in the development and deployment of this technology. As these systems gain traction in the renewable energy sector, their potential to mitigate climate change must be balanced against their own environmental footprint.

Vacuum forming processes used in energy storage systems can contribute to reduced material waste compared to traditional manufacturing methods. The precise molding of components allows for optimized designs that minimize excess material usage. This efficiency in production can lead to a lower overall environmental impact during the manufacturing phase.

However, the energy-intensive nature of vacuum forming processes cannot be overlooked. The high temperatures and pressures required for shaping materials can result in significant energy consumption. To address this concern, manufacturers are increasingly exploring ways to integrate renewable energy sources into their production facilities, thereby reducing the carbon footprint associated with the manufacturing process.

The materials used in vacuum-formed energy storage systems also play a crucial role in their environmental impact. Many of these systems utilize advanced polymers and composites, which may pose challenges for recycling and end-of-life disposal. Ongoing research is focused on developing more environmentally friendly materials that maintain the necessary performance characteristics while improving recyclability and biodegradability.

In terms of operational environmental impact, energy storage systems created through vacuum forming can contribute significantly to the integration of renewable energy sources into the grid. By enabling the storage of excess energy generated during peak production periods, these systems help to reduce reliance on fossil fuel-based power plants for load balancing. This capability is particularly valuable in mitigating the intermittency issues associated with solar and wind power.

The longevity and durability of vacuum-formed energy storage components also factor into their environmental impact. The precise shaping and controlled production environment can result in components with enhanced structural integrity and resistance to environmental stressors. This increased durability can lead to longer operational lifespans, reducing the frequency of replacements and the associated environmental costs of manufacturing and disposal.

As the technology advances, there is a growing emphasis on designing energy storage systems with a circular economy approach. This involves considering the entire lifecycle of the product, from raw material sourcing to end-of-life management. Vacuum forming techniques are being adapted to facilitate easier disassembly and material recovery, supporting more effective recycling and refurbishment processes.

Vacuum forming processes used in energy storage systems can contribute to reduced material waste compared to traditional manufacturing methods. The precise molding of components allows for optimized designs that minimize excess material usage. This efficiency in production can lead to a lower overall environmental impact during the manufacturing phase.

However, the energy-intensive nature of vacuum forming processes cannot be overlooked. The high temperatures and pressures required for shaping materials can result in significant energy consumption. To address this concern, manufacturers are increasingly exploring ways to integrate renewable energy sources into their production facilities, thereby reducing the carbon footprint associated with the manufacturing process.

The materials used in vacuum-formed energy storage systems also play a crucial role in their environmental impact. Many of these systems utilize advanced polymers and composites, which may pose challenges for recycling and end-of-life disposal. Ongoing research is focused on developing more environmentally friendly materials that maintain the necessary performance characteristics while improving recyclability and biodegradability.

In terms of operational environmental impact, energy storage systems created through vacuum forming can contribute significantly to the integration of renewable energy sources into the grid. By enabling the storage of excess energy generated during peak production periods, these systems help to reduce reliance on fossil fuel-based power plants for load balancing. This capability is particularly valuable in mitigating the intermittency issues associated with solar and wind power.

The longevity and durability of vacuum-formed energy storage components also factor into their environmental impact. The precise shaping and controlled production environment can result in components with enhanced structural integrity and resistance to environmental stressors. This increased durability can lead to longer operational lifespans, reducing the frequency of replacements and the associated environmental costs of manufacturing and disposal.

As the technology advances, there is a growing emphasis on designing energy storage systems with a circular economy approach. This involves considering the entire lifecycle of the product, from raw material sourcing to end-of-life management. Vacuum forming techniques are being adapted to facilitate easier disassembly and material recovery, supporting more effective recycling and refurbishment processes.

Cost-Benefit Analysis

The cost-benefit analysis of energy storage systems via vacuum forming reveals a complex interplay of economic factors and technological advancements. Initial investment costs for vacuum forming equipment and materials are relatively high, potentially deterring smaller-scale implementations. However, the long-term benefits of this technology are substantial, particularly in terms of energy efficiency and operational cost reduction.

Vacuum forming processes significantly enhance the energy density and overall performance of storage systems. This improvement translates to increased capacity and longer operational lifespans, effectively reducing the cost per unit of energy stored over time. The scalability of vacuum forming techniques also allows for economies of scale, potentially lowering production costs as manufacturing volumes increase.

From an operational perspective, energy storage systems produced through vacuum forming demonstrate superior durability and resistance to environmental factors. This robustness reduces maintenance requirements and extends the system's lifespan, contributing to lower total cost of ownership. Additionally, the improved energy efficiency of these systems leads to reduced energy losses during storage and discharge cycles, further enhancing their economic viability.

The environmental benefits of advanced energy storage systems also factor into the cost-benefit equation. By enabling greater integration of renewable energy sources and improving grid stability, these systems contribute to reduced carbon emissions and associated environmental costs. While challenging to quantify precisely, these positive externalities add significant value to the overall benefit calculation.

However, it is crucial to consider the potential drawbacks. The specialized nature of vacuum forming technology may require additional training for personnel, incurring short-term costs. Furthermore, the rapid pace of technological advancement in the energy storage sector could lead to faster obsolescence, potentially shortening the economic lifespan of current systems.

Market dynamics play a critical role in the cost-benefit analysis. As demand for high-performance energy storage solutions grows, particularly in renewable energy and electric vehicle sectors, economies of scale are likely to improve the economic proposition of vacuum-formed systems. Government incentives and regulatory frameworks supporting clean energy technologies could further tip the balance in favor of these advanced storage solutions.

In conclusion, while the upfront costs of implementing vacuum forming technology in energy storage systems are significant, the long-term benefits in terms of performance, efficiency, and durability present a compelling economic case. As the technology matures and production scales up, the cost-benefit ratio is expected to improve further, solidifying the growth potential of this innovative approach to energy storage.

Vacuum forming processes significantly enhance the energy density and overall performance of storage systems. This improvement translates to increased capacity and longer operational lifespans, effectively reducing the cost per unit of energy stored over time. The scalability of vacuum forming techniques also allows for economies of scale, potentially lowering production costs as manufacturing volumes increase.

From an operational perspective, energy storage systems produced through vacuum forming demonstrate superior durability and resistance to environmental factors. This robustness reduces maintenance requirements and extends the system's lifespan, contributing to lower total cost of ownership. Additionally, the improved energy efficiency of these systems leads to reduced energy losses during storage and discharge cycles, further enhancing their economic viability.

The environmental benefits of advanced energy storage systems also factor into the cost-benefit equation. By enabling greater integration of renewable energy sources and improving grid stability, these systems contribute to reduced carbon emissions and associated environmental costs. While challenging to quantify precisely, these positive externalities add significant value to the overall benefit calculation.

However, it is crucial to consider the potential drawbacks. The specialized nature of vacuum forming technology may require additional training for personnel, incurring short-term costs. Furthermore, the rapid pace of technological advancement in the energy storage sector could lead to faster obsolescence, potentially shortening the economic lifespan of current systems.

Market dynamics play a critical role in the cost-benefit analysis. As demand for high-performance energy storage solutions grows, particularly in renewable energy and electric vehicle sectors, economies of scale are likely to improve the economic proposition of vacuum-formed systems. Government incentives and regulatory frameworks supporting clean energy technologies could further tip the balance in favor of these advanced storage solutions.

In conclusion, while the upfront costs of implementing vacuum forming technology in energy storage systems are significant, the long-term benefits in terms of performance, efficiency, and durability present a compelling economic case. As the technology matures and production scales up, the cost-benefit ratio is expected to improve further, solidifying the growth potential of this innovative approach to energy storage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!