Vacuum Forming's Role in Next-Gen Helmet Protection Systems

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Helmet Protection Evolution

The evolution of helmet protection systems has been a continuous journey of innovation and technological advancement, driven by the need for enhanced safety in various fields, including sports, military, and industrial applications. The history of helmet protection can be traced back to ancient times, but significant developments have occurred in the past century.

In the early 20th century, helmets were primarily designed for basic impact protection, often using materials like leather and metal. The introduction of plastics in the mid-20th century marked a significant turning point, allowing for lighter and more versatile designs. This period saw the emergence of polycarbonate and ABS (Acrylonitrile Butadiene Styrene) as popular materials for helmet shells.

The 1970s and 1980s witnessed a surge in research on head injuries and biomechanics, leading to more sophisticated helmet designs. Energy-absorbing liners, such as expanded polystyrene (EPS) foam, became standard in many helmet types. This era also saw the introduction of multi-impact protection systems, particularly important in sports like American football.

The late 20th and early 21st centuries brought about a focus on specialized helmet designs for different activities. For instance, bicycle helmets evolved from simple hard shells to aerodynamic designs with improved ventilation. Military helmets incorporated advanced materials like aramid fibers for ballistic protection.

Recent years have seen a shift towards smart helmet technologies. Sensors and electronic systems are being integrated into helmets to monitor impact forces, detect concussions, and even provide communication capabilities. This trend represents a convergence of traditional protection methods with cutting-edge digital technologies.

The role of vacuum forming in helmet protection systems has become increasingly significant in recent years. This manufacturing process allows for the creation of complex shapes and contours that can enhance the helmet's protective capabilities while maintaining lightweight properties. Vacuum forming enables the production of custom-fit helmets, which provide better protection by ensuring a snug fit to the wearer's head.

Looking towards the future, the evolution of helmet protection is likely to focus on several key areas. Advanced materials research is exploring the use of novel composites and nanostructured materials that can offer superior impact absorption and energy dissipation. Biomimetic designs, inspired by natural structures like honeycombs or animal skulls, are being investigated for their potential to improve protection.

Furthermore, the integration of active protection systems is an emerging trend. These systems could potentially use smart materials or rapid inflation mechanisms to provide additional protection upon impact detection. The combination of passive and active protection elements represents a new frontier in helmet safety technology.

In the early 20th century, helmets were primarily designed for basic impact protection, often using materials like leather and metal. The introduction of plastics in the mid-20th century marked a significant turning point, allowing for lighter and more versatile designs. This period saw the emergence of polycarbonate and ABS (Acrylonitrile Butadiene Styrene) as popular materials for helmet shells.

The 1970s and 1980s witnessed a surge in research on head injuries and biomechanics, leading to more sophisticated helmet designs. Energy-absorbing liners, such as expanded polystyrene (EPS) foam, became standard in many helmet types. This era also saw the introduction of multi-impact protection systems, particularly important in sports like American football.

The late 20th and early 21st centuries brought about a focus on specialized helmet designs for different activities. For instance, bicycle helmets evolved from simple hard shells to aerodynamic designs with improved ventilation. Military helmets incorporated advanced materials like aramid fibers for ballistic protection.

Recent years have seen a shift towards smart helmet technologies. Sensors and electronic systems are being integrated into helmets to monitor impact forces, detect concussions, and even provide communication capabilities. This trend represents a convergence of traditional protection methods with cutting-edge digital technologies.

The role of vacuum forming in helmet protection systems has become increasingly significant in recent years. This manufacturing process allows for the creation of complex shapes and contours that can enhance the helmet's protective capabilities while maintaining lightweight properties. Vacuum forming enables the production of custom-fit helmets, which provide better protection by ensuring a snug fit to the wearer's head.

Looking towards the future, the evolution of helmet protection is likely to focus on several key areas. Advanced materials research is exploring the use of novel composites and nanostructured materials that can offer superior impact absorption and energy dissipation. Biomimetic designs, inspired by natural structures like honeycombs or animal skulls, are being investigated for their potential to improve protection.

Furthermore, the integration of active protection systems is an emerging trend. These systems could potentially use smart materials or rapid inflation mechanisms to provide additional protection upon impact detection. The combination of passive and active protection elements represents a new frontier in helmet safety technology.

Market Demand Analysis

The market demand for advanced helmet protection systems utilizing vacuum forming technology is experiencing significant growth, driven by increasing awareness of safety concerns across various sectors. In the sports industry, particularly in high-impact sports like football, hockey, and cycling, there is a growing emphasis on preventing traumatic brain injuries. This has led to a surge in demand for helmets that offer superior protection without compromising comfort or performance.

The military and law enforcement sectors are also key drivers of market demand for next-generation helmet protection systems. With the evolving nature of modern warfare and security threats, there is a pressing need for lightweight, durable, and highly protective helmets that can withstand diverse combat scenarios. Vacuum forming technology offers the potential to create helmets with complex geometries and integrated features that enhance both protection and functionality.

In the automotive industry, the rising focus on occupant safety has created a new market segment for advanced helmet-like protection systems in vehicles. This includes the development of integrated headrests and roof structures that utilize vacuum forming techniques to create energy-absorbing components, potentially revolutionizing passenger safety in automobiles.

The construction and industrial sectors represent another significant market for advanced helmet protection. As workplace safety regulations become more stringent, there is an increasing demand for helmets that offer improved impact resistance and ergonomics. Vacuum forming's ability to create custom-fit helmets with enhanced protective properties aligns well with these industry requirements.

The global personal protective equipment (PPE) market, which includes advanced helmet systems, is projected to grow substantially in the coming years. This growth is fueled by stringent safety regulations, increasing awareness of workplace hazards, and the need for more comfortable and effective protective gear. The versatility of vacuum forming in creating complex shapes and incorporating multiple materials makes it particularly attractive for manufacturers looking to innovate in this space.

Furthermore, the ongoing COVID-19 pandemic has heightened awareness of personal protection, potentially expanding the market for advanced helmet systems with integrated respiratory protection features. This presents an opportunity for vacuum forming technology to contribute to the development of multi-functional protective headgear that addresses both impact protection and airborne hazards.

As consumers become more safety-conscious and willing to invest in premium protective gear, there is a growing market for customized and technologically advanced helmet solutions. Vacuum forming's ability to facilitate rapid prototyping and cost-effective production of complex designs positions it well to meet this demand for personalized and high-performance helmet protection systems across various industries.

The military and law enforcement sectors are also key drivers of market demand for next-generation helmet protection systems. With the evolving nature of modern warfare and security threats, there is a pressing need for lightweight, durable, and highly protective helmets that can withstand diverse combat scenarios. Vacuum forming technology offers the potential to create helmets with complex geometries and integrated features that enhance both protection and functionality.

In the automotive industry, the rising focus on occupant safety has created a new market segment for advanced helmet-like protection systems in vehicles. This includes the development of integrated headrests and roof structures that utilize vacuum forming techniques to create energy-absorbing components, potentially revolutionizing passenger safety in automobiles.

The construction and industrial sectors represent another significant market for advanced helmet protection. As workplace safety regulations become more stringent, there is an increasing demand for helmets that offer improved impact resistance and ergonomics. Vacuum forming's ability to create custom-fit helmets with enhanced protective properties aligns well with these industry requirements.

The global personal protective equipment (PPE) market, which includes advanced helmet systems, is projected to grow substantially in the coming years. This growth is fueled by stringent safety regulations, increasing awareness of workplace hazards, and the need for more comfortable and effective protective gear. The versatility of vacuum forming in creating complex shapes and incorporating multiple materials makes it particularly attractive for manufacturers looking to innovate in this space.

Furthermore, the ongoing COVID-19 pandemic has heightened awareness of personal protection, potentially expanding the market for advanced helmet systems with integrated respiratory protection features. This presents an opportunity for vacuum forming technology to contribute to the development of multi-functional protective headgear that addresses both impact protection and airborne hazards.

As consumers become more safety-conscious and willing to invest in premium protective gear, there is a growing market for customized and technologically advanced helmet solutions. Vacuum forming's ability to facilitate rapid prototyping and cost-effective production of complex designs positions it well to meet this demand for personalized and high-performance helmet protection systems across various industries.

Vacuum Forming Challenges

Vacuum forming, while a versatile and cost-effective manufacturing process, faces several challenges when applied to next-generation helmet protection systems. One of the primary obstacles is achieving consistent material thickness across complex helmet geometries. The uneven distribution of material can lead to weak points in the helmet structure, compromising its protective capabilities.

Another significant challenge lies in the limited material options suitable for vacuum forming in high-performance helmet applications. While thermoplastics are commonly used, they may not always meet the stringent requirements for impact resistance, heat dissipation, and durability needed in advanced helmet designs. This constraint often necessitates additional reinforcement or composite layering, adding complexity to the manufacturing process.

The precision of mold design and fabrication also presents a considerable hurdle. Intricate helmet shapes with varying contours require highly accurate molds to ensure proper fit and functionality. Any imperfections in the mold can result in defects in the final product, potentially affecting the helmet's protective properties and comfort.

Temperature control during the vacuum forming process is crucial yet challenging, particularly for large-scale production. Maintaining uniform heating across the entire sheet of plastic material is essential to prevent warping or uneven stretching. Inconsistencies in temperature can lead to structural weaknesses or dimensional inaccuracies in the finished helmet.

The cooling phase of vacuum-formed helmets also poses difficulties. Rapid and uniform cooling is necessary to prevent internal stresses and maintain the desired shape. However, achieving this consistently across various helmet sizes and designs can be problematic, potentially leading to quality issues or increased production times.

Vacuum forming's limitations in creating sharp edges and fine details can be a significant drawback in helmet design. This constraint may necessitate additional post-forming processes or compromise certain design elements, potentially affecting both aesthetics and functionality.

Lastly, the integration of advanced features such as ventilation systems, electronic components, or multi-layered protection within the vacuum forming process presents complex engineering challenges. These elements often require innovative approaches to mold design and material selection, pushing the boundaries of traditional vacuum forming techniques.

Another significant challenge lies in the limited material options suitable for vacuum forming in high-performance helmet applications. While thermoplastics are commonly used, they may not always meet the stringent requirements for impact resistance, heat dissipation, and durability needed in advanced helmet designs. This constraint often necessitates additional reinforcement or composite layering, adding complexity to the manufacturing process.

The precision of mold design and fabrication also presents a considerable hurdle. Intricate helmet shapes with varying contours require highly accurate molds to ensure proper fit and functionality. Any imperfections in the mold can result in defects in the final product, potentially affecting the helmet's protective properties and comfort.

Temperature control during the vacuum forming process is crucial yet challenging, particularly for large-scale production. Maintaining uniform heating across the entire sheet of plastic material is essential to prevent warping or uneven stretching. Inconsistencies in temperature can lead to structural weaknesses or dimensional inaccuracies in the finished helmet.

The cooling phase of vacuum-formed helmets also poses difficulties. Rapid and uniform cooling is necessary to prevent internal stresses and maintain the desired shape. However, achieving this consistently across various helmet sizes and designs can be problematic, potentially leading to quality issues or increased production times.

Vacuum forming's limitations in creating sharp edges and fine details can be a significant drawback in helmet design. This constraint may necessitate additional post-forming processes or compromise certain design elements, potentially affecting both aesthetics and functionality.

Lastly, the integration of advanced features such as ventilation systems, electronic components, or multi-layered protection within the vacuum forming process presents complex engineering challenges. These elements often require innovative approaches to mold design and material selection, pushing the boundaries of traditional vacuum forming techniques.

Current Vacuum Solutions

01 Protective covers for vacuum forming machines

Specialized protective covers are designed for vacuum forming machines to enhance safety during operation. These covers shield operators from potential hazards and help maintain a clean working environment. They are typically made from durable materials that can withstand the heat and pressure involved in the vacuum forming process.- Protective covers for vacuum forming machines: Specialized protective covers are designed for vacuum forming machines to enhance safety during operation. These covers shield operators from potential hazards such as heat, moving parts, and debris. They can be made from durable materials and may include features like transparent viewing windows for monitoring the forming process.

- Vacuum-formed protective equipment: Various protective equipment can be manufactured using vacuum forming techniques. This includes items such as helmets, face shields, and body armor. The vacuum forming process allows for the creation of lightweight yet durable protective gear that can be customized for specific applications.

- Vacuum-formed packaging for protection: Vacuum forming is utilized to create protective packaging solutions. This includes custom-fit trays, blister packs, and clamshell containers that securely hold and protect products during storage and transportation. The formed packaging can be designed with specific contours and cushioning features to prevent damage to sensitive items.

- Vacuum-formed protective coatings: Protective coatings can be applied to surfaces using vacuum forming techniques. This process involves applying a thin layer of material that conforms to the shape of the object, providing a protective barrier against environmental factors, corrosion, or wear. These coatings can be used on various substrates to enhance durability and longevity.

- Vacuum-formed protective structures: Large-scale protective structures can be created using vacuum forming methods. This includes items such as vehicle components, architectural elements, and industrial enclosures. The vacuum forming process allows for the production of complex shapes with integrated protective features, such as reinforced areas or impact-resistant designs.

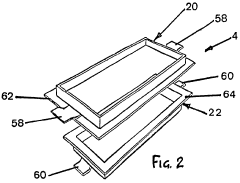

02 Vacuum-formed protective components

Various protective components can be manufactured using vacuum forming techniques. This includes items such as protective casings, shields, and enclosures for electronic devices, automotive parts, and industrial equipment. The vacuum forming process allows for the creation of complex shapes with good structural integrity and lightweight properties.Expand Specific Solutions03 Thermal protection in vacuum forming

Thermal protection is crucial in vacuum forming processes to prevent overheating and ensure product quality. This involves the use of heat-resistant materials, cooling systems, and temperature control mechanisms. Proper thermal management helps maintain the integrity of the formed products and protects the equipment from heat-related damage.Expand Specific Solutions04 Vacuum-formed protective packaging

Vacuum forming is widely used in the production of protective packaging for various industries. This includes custom-fit trays, blister packs, and clamshell containers that provide protection during transportation and storage. The process allows for the creation of packaging that conforms closely to the shape of the product, offering enhanced protection against impacts and environmental factors.Expand Specific Solutions05 Safety features for vacuum forming equipment

Modern vacuum forming equipment incorporates various safety features to protect operators and ensure smooth operation. These may include emergency stop buttons, interlocking guards, pressure relief valves, and sensors that monitor critical parameters. Such features help prevent accidents, minimize downtime, and comply with industry safety standards.Expand Specific Solutions

Key Industry Players

The vacuum forming technology in next-generation helmet protection systems is in a growth phase, with increasing market size and evolving technical maturity. The industry is experiencing rapid innovation as companies like HJC Corp., Bell Sports, Inc., and Schuberth GmbH invest in advanced manufacturing processes. The market is expanding due to rising demand for lightweight, high-performance helmets across various sectors, including sports, automotive, and military applications. While established players dominate, emerging companies like Park & Diamond, Inc. are introducing novel designs, pushing the boundaries of helmet technology. The competitive landscape is characterized by a mix of traditional manufacturers adapting to new technologies and innovative startups disrupting the market with cutting-edge solutions.

HJC Corp.

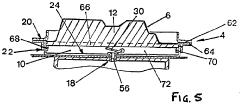

Technical Solution: HJC Corp. has advanced the use of vacuum forming in their helmet protection systems through their Advanced Channeling Ventilation System (ACS). This system utilizes vacuum forming to create precise air channels within the helmet structure, enhancing both cooling and aerodynamics[7]. HJC's process also incorporates their Advanced Composite Shell technology, which uses vacuum forming to combine multiple materials, including carbon fiber, fiberglass, and organic fibers, creating a shell that is both strong and lightweight[8]. The company has further innovated by integrating their Emergency Quick Release System (EQRS) into the vacuum-formed design, allowing for safer helmet removal in emergency situations.

Strengths: Enhanced ventilation and aerodynamics, multi-material integration, emergency safety features. Weaknesses: Complex manufacturing process, potential for higher production costs.

Bell Sports, Inc.

Technical Solution: Bell Sports has innovated in vacuum forming technology for helmet protection systems by developing a proprietary process called Variable Density Technology (VDT). This technique allows for the creation of helmet liners with varying densities in different areas, optimizing impact protection where it's needed most[3]. The company uses advanced computer simulations to determine the ideal density distribution based on impact data from real-world scenarios. Bell's vacuum forming process also incorporates their Flex Impact Liner, which uses a segmented design to allow for better energy dissipation and comfort[4]. Additionally, they have integrated their MIPS (Multi-directional Impact Protection System) technology into the vacuum-formed shell, enhancing rotational impact protection.

Strengths: Optimized impact protection through variable density, integration of multiple protective technologies. Weaknesses: Potential for increased production time due to complex manufacturing process.

Innovative Forming Tech

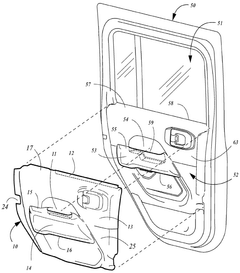

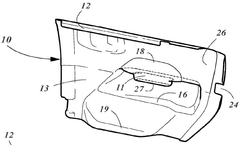

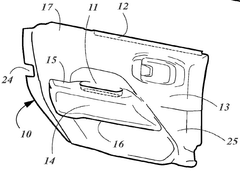

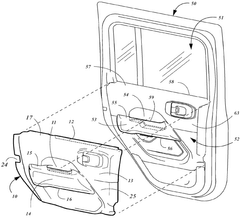

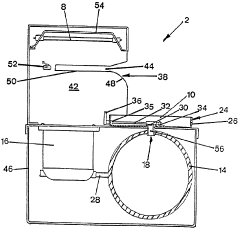

Protective shell for passenger vehicle door

PatentPendingCA3183751A1

Innovation

- A thin, hard plastic protective shell designed to fit over the vehicle's door panel, securely attachable without fasteners or adhesives, using a deformable sheet with a protrusion to enclose the door pull and a locking well that fits into the door well, allowing easy installation and removal while maintaining the panel's functionality.

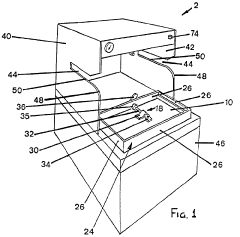

A vacuum forming machine in which vacuum is automatically initiated upon delivery of the sheet to the machine

PatentInactiveGB2248579A

Innovation

- A simplified vacuum forming machine design featuring a holder that moves from a heating position to a forming position automatically operates the valve, creating a vacuum to shape the plastic sheet, with a spring-biased valve plate and guide means for easy operation and reduced manual intervention.

Material Science Impact

The impact of material science on vacuum forming in next-generation helmet protection systems is profound and multifaceted. Advanced materials have revolutionized the capabilities of vacuum-formed helmets, enhancing their protective properties while maintaining or even reducing weight.

Polymer science has played a crucial role in developing high-performance thermoplastics that are ideal for vacuum forming processes. These materials, such as advanced polycarbonates and high-density polyethylene (HDPE), offer superior impact resistance and energy absorption capabilities. The molecular structure of these polymers allows for excellent formability under vacuum conditions while retaining strength and durability in the final product.

Nanocomposites have emerged as a game-changing material in helmet design. By incorporating nanoparticles into the polymer matrix, researchers have created materials with enhanced mechanical properties, including improved tensile strength and impact resistance. These nanocomposites can be effectively vacuum formed, resulting in helmets that offer superior protection without compromising on weight or comfort.

The development of multi-layer materials has further expanded the possibilities for vacuum-formed helmets. Engineers can now design helmets with distinct layers, each serving a specific protective function. For instance, an outer layer might be optimized for abrasion resistance, while inner layers focus on energy absorption and comfort. Vacuum forming allows these layers to be seamlessly integrated, creating a cohesive and highly effective protective structure.

Advancements in bio-inspired materials have also influenced helmet design. Materials that mimic natural structures, such as the impact-resistant properties of certain animal shells or plant structures, are being adapted for use in helmet production. These biomimetic materials can often be processed using vacuum forming techniques, leading to helmets that combine the best of nature's designs with modern manufacturing capabilities.

The integration of smart materials into vacuum-formed helmets represents another frontier in material science impact. Materials that can change properties in response to external stimuli, such as temperature or impact force, are being incorporated into helmet designs. These smart materials can enhance the adaptive protection capabilities of helmets, potentially revolutionizing safety in various applications, from sports to military use.

In conclusion, material science has significantly expanded the potential of vacuum forming in creating next-generation helmet protection systems. Through the development of advanced polymers, nanocomposites, multi-layer structures, bio-inspired materials, and smart materials, the field has enabled the production of helmets that offer unprecedented levels of protection, comfort, and functionality. As material science continues to evolve, we can expect further innovations that will push the boundaries of what is possible in helmet design and manufacturing.

Polymer science has played a crucial role in developing high-performance thermoplastics that are ideal for vacuum forming processes. These materials, such as advanced polycarbonates and high-density polyethylene (HDPE), offer superior impact resistance and energy absorption capabilities. The molecular structure of these polymers allows for excellent formability under vacuum conditions while retaining strength and durability in the final product.

Nanocomposites have emerged as a game-changing material in helmet design. By incorporating nanoparticles into the polymer matrix, researchers have created materials with enhanced mechanical properties, including improved tensile strength and impact resistance. These nanocomposites can be effectively vacuum formed, resulting in helmets that offer superior protection without compromising on weight or comfort.

The development of multi-layer materials has further expanded the possibilities for vacuum-formed helmets. Engineers can now design helmets with distinct layers, each serving a specific protective function. For instance, an outer layer might be optimized for abrasion resistance, while inner layers focus on energy absorption and comfort. Vacuum forming allows these layers to be seamlessly integrated, creating a cohesive and highly effective protective structure.

Advancements in bio-inspired materials have also influenced helmet design. Materials that mimic natural structures, such as the impact-resistant properties of certain animal shells or plant structures, are being adapted for use in helmet production. These biomimetic materials can often be processed using vacuum forming techniques, leading to helmets that combine the best of nature's designs with modern manufacturing capabilities.

The integration of smart materials into vacuum-formed helmets represents another frontier in material science impact. Materials that can change properties in response to external stimuli, such as temperature or impact force, are being incorporated into helmet designs. These smart materials can enhance the adaptive protection capabilities of helmets, potentially revolutionizing safety in various applications, from sports to military use.

In conclusion, material science has significantly expanded the potential of vacuum forming in creating next-generation helmet protection systems. Through the development of advanced polymers, nanocomposites, multi-layer structures, bio-inspired materials, and smart materials, the field has enabled the production of helmets that offer unprecedented levels of protection, comfort, and functionality. As material science continues to evolve, we can expect further innovations that will push the boundaries of what is possible in helmet design and manufacturing.

Safety Standards Compliance

Vacuum forming technology in next-generation helmet protection systems must adhere to rigorous safety standards to ensure optimal user protection. These standards are established by various regulatory bodies and industry organizations to guarantee the quality, reliability, and effectiveness of helmet designs. The International Organization for Standardization (ISO) provides global benchmarks for helmet safety, while regional entities such as the European Committee for Standardization (CEN) and the U.S. Consumer Product Safety Commission (CPSC) set specific requirements for their respective markets.

For vacuum-formed helmets, compliance with impact resistance standards is crucial. These standards typically involve tests simulating various collision scenarios, measuring the helmet's ability to absorb and distribute impact forces. The EN 1078 standard in Europe and the CPSC 16 CFR Part 1203 in the United States are examples of such regulations for bicycle helmets. These standards specify minimum performance criteria for impact attenuation, retention system strength, and coverage area.

Additionally, vacuum-formed helmets must meet standards related to material properties and durability. This includes resistance to environmental factors such as temperature extremes, UV radiation, and moisture. The ASTM F1447 standard, for instance, outlines specific requirements for helmet materials and their performance under different conditions. Compliance with these standards ensures that vacuum-formed helmets maintain their protective properties throughout their intended lifespan.

Ventilation and ergonomic standards also play a significant role in helmet design. Vacuum forming techniques must be optimized to create helmets that provide adequate airflow while maintaining structural integrity. Standards such as EN 960 address head form specifications, ensuring that helmets fit a wide range of head sizes and shapes comfortably and securely.

As technology advances, safety standards are continually evolving to address new challenges and incorporate emerging protective technologies. Vacuum forming processes must adapt to meet these changing requirements, potentially incorporating advanced materials or composite structures to enhance protection. For instance, the integration of energy-absorbing foams or impact-dispersing layers within the vacuum-formed shell may become necessary to comply with future standards.

Manufacturers employing vacuum forming for helmet production must implement rigorous quality control measures to ensure consistent compliance with safety standards. This involves regular testing and certification processes, often conducted by independent laboratories. Documentation of compliance and traceability of materials and manufacturing processes are essential components of meeting regulatory requirements.

In conclusion, the role of vacuum forming in next-generation helmet protection systems is intrinsically linked to safety standards compliance. As the technology evolves, manufacturers must remain vigilant in adapting their processes and designs to meet and exceed these standards, ensuring the highest level of protection for helmet users across various applications.

For vacuum-formed helmets, compliance with impact resistance standards is crucial. These standards typically involve tests simulating various collision scenarios, measuring the helmet's ability to absorb and distribute impact forces. The EN 1078 standard in Europe and the CPSC 16 CFR Part 1203 in the United States are examples of such regulations for bicycle helmets. These standards specify minimum performance criteria for impact attenuation, retention system strength, and coverage area.

Additionally, vacuum-formed helmets must meet standards related to material properties and durability. This includes resistance to environmental factors such as temperature extremes, UV radiation, and moisture. The ASTM F1447 standard, for instance, outlines specific requirements for helmet materials and their performance under different conditions. Compliance with these standards ensures that vacuum-formed helmets maintain their protective properties throughout their intended lifespan.

Ventilation and ergonomic standards also play a significant role in helmet design. Vacuum forming techniques must be optimized to create helmets that provide adequate airflow while maintaining structural integrity. Standards such as EN 960 address head form specifications, ensuring that helmets fit a wide range of head sizes and shapes comfortably and securely.

As technology advances, safety standards are continually evolving to address new challenges and incorporate emerging protective technologies. Vacuum forming processes must adapt to meet these changing requirements, potentially incorporating advanced materials or composite structures to enhance protection. For instance, the integration of energy-absorbing foams or impact-dispersing layers within the vacuum-formed shell may become necessary to comply with future standards.

Manufacturers employing vacuum forming for helmet production must implement rigorous quality control measures to ensure consistent compliance with safety standards. This involves regular testing and certification processes, often conducted by independent laboratories. Documentation of compliance and traceability of materials and manufacturing processes are essential components of meeting regulatory requirements.

In conclusion, the role of vacuum forming in next-generation helmet protection systems is intrinsically linked to safety standards compliance. As the technology evolves, manufacturers must remain vigilant in adapting their processes and designs to meet and exceed these standards, ensuring the highest level of protection for helmet users across various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!