Efficient Noise Reduction Approaches through Vacuum Forming

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Noise Reduction Background and Objectives

Vacuum forming, a widely used manufacturing process in various industries, has long been associated with significant noise pollution. The background of noise reduction in vacuum forming can be traced back to the early days of its industrial application, where the loud, disruptive sounds produced during the process became a growing concern for worker safety and environmental impact.

The evolution of vacuum forming technology has seen a parallel development in noise reduction techniques. Initially, efforts were focused on basic sound insulation and dampening methods. However, as environmental regulations became more stringent and workplace safety standards improved, the need for more sophisticated noise reduction approaches became apparent.

The primary sources of noise in vacuum forming include the vacuum pump operation, the rapid air displacement during the forming process, and the mechanical movements of the forming machine. These sources combine to create a complex noise profile that can exceed safe decibel levels for prolonged exposure.

The objectives of efficient noise reduction in vacuum forming are multifaceted. Firstly, there is a critical need to protect worker health and safety by reducing noise levels to within acceptable limits as defined by occupational health standards. This not only improves the working environment but also helps companies comply with regulatory requirements.

Secondly, noise reduction aims to minimize the environmental impact of vacuum forming operations. This is particularly important for facilities located near residential areas or other noise-sensitive locations. By reducing noise pollution, companies can maintain better relationships with local communities and avoid potential legal issues related to noise ordinances.

Another key objective is to improve the overall efficiency and quality of the vacuum forming process. Excessive noise can be an indicator of inefficiencies in the system, such as air leaks or suboptimal machine performance. By addressing these noise sources, manufacturers can often simultaneously enhance the energy efficiency and output quality of their operations.

Furthermore, the development of efficient noise reduction techniques seeks to achieve these goals without significantly compromising the speed, cost-effectiveness, or versatility of the vacuum forming process. This balance is crucial for maintaining the competitiveness of vacuum forming as a manufacturing method in various industries.

As technology advances, the objectives have expanded to include the integration of smart, adaptive noise reduction systems that can respond dynamically to changing process conditions. This aligns with broader industry trends towards automation and Industry 4.0 principles, aiming to create more intelligent and responsive manufacturing environments.

The evolution of vacuum forming technology has seen a parallel development in noise reduction techniques. Initially, efforts were focused on basic sound insulation and dampening methods. However, as environmental regulations became more stringent and workplace safety standards improved, the need for more sophisticated noise reduction approaches became apparent.

The primary sources of noise in vacuum forming include the vacuum pump operation, the rapid air displacement during the forming process, and the mechanical movements of the forming machine. These sources combine to create a complex noise profile that can exceed safe decibel levels for prolonged exposure.

The objectives of efficient noise reduction in vacuum forming are multifaceted. Firstly, there is a critical need to protect worker health and safety by reducing noise levels to within acceptable limits as defined by occupational health standards. This not only improves the working environment but also helps companies comply with regulatory requirements.

Secondly, noise reduction aims to minimize the environmental impact of vacuum forming operations. This is particularly important for facilities located near residential areas or other noise-sensitive locations. By reducing noise pollution, companies can maintain better relationships with local communities and avoid potential legal issues related to noise ordinances.

Another key objective is to improve the overall efficiency and quality of the vacuum forming process. Excessive noise can be an indicator of inefficiencies in the system, such as air leaks or suboptimal machine performance. By addressing these noise sources, manufacturers can often simultaneously enhance the energy efficiency and output quality of their operations.

Furthermore, the development of efficient noise reduction techniques seeks to achieve these goals without significantly compromising the speed, cost-effectiveness, or versatility of the vacuum forming process. This balance is crucial for maintaining the competitiveness of vacuum forming as a manufacturing method in various industries.

As technology advances, the objectives have expanded to include the integration of smart, adaptive noise reduction systems that can respond dynamically to changing process conditions. This aligns with broader industry trends towards automation and Industry 4.0 principles, aiming to create more intelligent and responsive manufacturing environments.

Market Analysis for Quiet Vacuum Forming Solutions

The market for quiet vacuum forming solutions has been experiencing significant growth in recent years, driven by increasing demand for noise reduction in manufacturing processes. This trend is particularly evident in industries such as automotive, aerospace, and consumer goods production, where noise pollution has become a critical concern for both worker safety and environmental compliance.

The global vacuum forming market, which encompasses both traditional and noise-reduced solutions, was valued at approximately $22 billion in 2020 and is projected to reach $31 billion by 2026, growing at a CAGR of 6.2% during the forecast period. Within this broader market, the segment for quiet vacuum forming solutions is expected to grow at an even faster rate, driven by stricter noise regulations and a growing awareness of the importance of workplace noise reduction.

Key factors contributing to the market growth include the implementation of more stringent occupational health and safety regulations across various countries, particularly in Europe and North America. These regulations often mandate maximum noise levels in industrial settings, compelling manufacturers to adopt quieter production methods. Additionally, there is an increasing recognition of the long-term health benefits associated with reduced noise exposure, which is driving voluntary adoption of noise reduction technologies even in regions with less stringent regulations.

The automotive industry represents one of the largest end-users of quiet vacuum forming solutions, accounting for approximately 30% of the market share. This is primarily due to the extensive use of vacuum-formed components in vehicle interiors and the industry's focus on improving working conditions in assembly plants. The aerospace industry is another significant consumer, with a growing emphasis on lightweight, noise-reduced components for aircraft interiors.

Geographically, North America and Europe currently dominate the market for quiet vacuum forming solutions, collectively accounting for over 60% of the global market share. This is largely due to the presence of stringent noise regulations and a high concentration of industries that prioritize worker safety and environmental considerations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China and India.

Despite the positive growth outlook, the market faces certain challenges. The higher initial cost of quiet vacuum forming equipment compared to traditional systems can be a barrier to adoption, particularly for small and medium-sized enterprises. Additionally, the complexity of integrating noise reduction technologies into existing production lines without compromising efficiency presents technical challenges that manufacturers must overcome.

The global vacuum forming market, which encompasses both traditional and noise-reduced solutions, was valued at approximately $22 billion in 2020 and is projected to reach $31 billion by 2026, growing at a CAGR of 6.2% during the forecast period. Within this broader market, the segment for quiet vacuum forming solutions is expected to grow at an even faster rate, driven by stricter noise regulations and a growing awareness of the importance of workplace noise reduction.

Key factors contributing to the market growth include the implementation of more stringent occupational health and safety regulations across various countries, particularly in Europe and North America. These regulations often mandate maximum noise levels in industrial settings, compelling manufacturers to adopt quieter production methods. Additionally, there is an increasing recognition of the long-term health benefits associated with reduced noise exposure, which is driving voluntary adoption of noise reduction technologies even in regions with less stringent regulations.

The automotive industry represents one of the largest end-users of quiet vacuum forming solutions, accounting for approximately 30% of the market share. This is primarily due to the extensive use of vacuum-formed components in vehicle interiors and the industry's focus on improving working conditions in assembly plants. The aerospace industry is another significant consumer, with a growing emphasis on lightweight, noise-reduced components for aircraft interiors.

Geographically, North America and Europe currently dominate the market for quiet vacuum forming solutions, collectively accounting for over 60% of the global market share. This is largely due to the presence of stringent noise regulations and a high concentration of industries that prioritize worker safety and environmental considerations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing adoption of advanced manufacturing technologies in countries like China and India.

Despite the positive growth outlook, the market faces certain challenges. The higher initial cost of quiet vacuum forming equipment compared to traditional systems can be a barrier to adoption, particularly for small and medium-sized enterprises. Additionally, the complexity of integrating noise reduction technologies into existing production lines without compromising efficiency presents technical challenges that manufacturers must overcome.

Current Challenges in Vacuum Forming Noise Control

Vacuum forming noise control presents several significant challenges in the current manufacturing landscape. One of the primary issues is the high-frequency noise generated during the forming process, which can reach levels exceeding occupational safety limits. This noise is primarily caused by the rapid movement of air and the sudden pressure changes within the forming chamber.

Another major challenge is the variability of noise levels across different materials and product designs. Thicker plastics or more complex shapes often require higher vacuum pressures, resulting in increased noise output. This variability makes it difficult to implement a one-size-fits-all noise reduction solution, necessitating adaptable approaches for different production scenarios.

The integration of noise control measures without compromising the efficiency of the vacuum forming process poses a significant challenge. Traditional noise reduction methods, such as enclosures or barriers, can interfere with the accessibility and operational speed of the machinery, potentially reducing productivity and increasing cycle times.

Heat management is another critical issue in vacuum forming noise control. The process generates substantial heat, which can affect the properties of noise-absorbing materials and the performance of acoustic treatments. Developing heat-resistant noise control solutions that maintain their effectiveness over time is a key challenge for manufacturers.

The cost-effectiveness of noise reduction solutions remains a significant hurdle. Many advanced noise control technologies come with high implementation costs, making it difficult for smaller manufacturers to adopt them. Balancing the need for effective noise reduction with economic feasibility is an ongoing challenge in the industry.

Environmental considerations also play a role in the challenges faced by vacuum forming noise control. As sustainability becomes increasingly important, there is a growing need for noise reduction solutions that are not only effective but also environmentally friendly. This includes using recyclable materials for acoustic treatments and minimizing the carbon footprint of noise control implementations.

Lastly, the lack of standardized testing and measurement protocols for vacuum forming noise presents a challenge in assessing the effectiveness of various noise reduction approaches. Without consistent benchmarks, it becomes difficult to compare different solutions and determine the most efficient methods for specific applications.

Another major challenge is the variability of noise levels across different materials and product designs. Thicker plastics or more complex shapes often require higher vacuum pressures, resulting in increased noise output. This variability makes it difficult to implement a one-size-fits-all noise reduction solution, necessitating adaptable approaches for different production scenarios.

The integration of noise control measures without compromising the efficiency of the vacuum forming process poses a significant challenge. Traditional noise reduction methods, such as enclosures or barriers, can interfere with the accessibility and operational speed of the machinery, potentially reducing productivity and increasing cycle times.

Heat management is another critical issue in vacuum forming noise control. The process generates substantial heat, which can affect the properties of noise-absorbing materials and the performance of acoustic treatments. Developing heat-resistant noise control solutions that maintain their effectiveness over time is a key challenge for manufacturers.

The cost-effectiveness of noise reduction solutions remains a significant hurdle. Many advanced noise control technologies come with high implementation costs, making it difficult for smaller manufacturers to adopt them. Balancing the need for effective noise reduction with economic feasibility is an ongoing challenge in the industry.

Environmental considerations also play a role in the challenges faced by vacuum forming noise control. As sustainability becomes increasingly important, there is a growing need for noise reduction solutions that are not only effective but also environmentally friendly. This includes using recyclable materials for acoustic treatments and minimizing the carbon footprint of noise control implementations.

Lastly, the lack of standardized testing and measurement protocols for vacuum forming noise presents a challenge in assessing the effectiveness of various noise reduction approaches. Without consistent benchmarks, it becomes difficult to compare different solutions and determine the most efficient methods for specific applications.

Existing Noise Reduction Methods for Vacuum Forming

01 Noise reduction in vacuum forming machines

Various techniques are employed to reduce noise in vacuum forming machines. These may include using sound-absorbing materials, redesigning components to minimize vibration, and implementing noise dampening systems. Such improvements can significantly reduce the overall noise level during the vacuum forming process, creating a better working environment.- Noise reduction in vacuum forming machines: Various techniques are employed to reduce noise in vacuum forming machines. These may include sound-absorbing materials, vibration dampening systems, and improved sealing mechanisms to minimize air leakage. Such methods help create a quieter working environment without compromising the efficiency of the vacuum forming process.

- Design improvements for quieter operation: Manufacturers are focusing on redesigning vacuum forming equipment to achieve quieter operation. This includes optimizing the shape and structure of machine components, using advanced materials, and implementing innovative airflow management systems. These design improvements aim to reduce noise generation at the source.

- Acoustic enclosures and barriers: The use of acoustic enclosures and barriers is an effective method to contain and reduce noise from vacuum forming processes. These enclosures are designed to surround the machine, absorbing and deflecting sound waves. They can be customized to fit specific machine dimensions and operational requirements.

- Active noise control systems: Advanced active noise control systems are being developed for vacuum forming machines. These systems use electronic sensors and actuators to detect and counteract noise in real-time. By generating anti-noise waves, they can significantly reduce the overall noise levels in the working environment.

- Maintenance and optimization for noise reduction: Regular maintenance and optimization of vacuum forming machines play a crucial role in noise reduction. This includes proper lubrication, timely replacement of worn parts, and fine-tuning of machine settings. Implementing preventive maintenance schedules and optimizing operational parameters can help minimize noise generation during the vacuum forming process.

02 Vacuum pump noise reduction

Specific measures are taken to reduce noise generated by vacuum pumps in forming machines. This can involve using advanced pump designs, incorporating sound insulation around the pump, or implementing vibration isolation systems. These techniques help to minimize the noise produced by the vacuum pump, which is often a major source of noise in vacuum forming processes.Expand Specific Solutions03 Acoustic enclosures for vacuum forming equipment

Acoustic enclosures are designed to contain and reduce noise from vacuum forming equipment. These enclosures can be made from sound-absorbing materials and may include features such as double-walled construction or sound-dampening panels. By enclosing the noisy components of the vacuum forming process, overall noise levels in the surrounding area can be significantly reduced.Expand Specific Solutions04 Vibration isolation in vacuum forming systems

Vibration isolation techniques are implemented to reduce noise transmission in vacuum forming systems. This can involve using specialized mounts, dampers, or isolation pads to separate vibrating components from the rest of the machine or surrounding structures. By minimizing vibration transfer, these methods help to reduce noise generated during the vacuum forming process.Expand Specific Solutions05 Active noise control in vacuum forming

Active noise control systems are employed to counteract noise in vacuum forming processes. These systems use advanced sensors and algorithms to generate anti-noise signals that cancel out unwanted sound waves. By actively neutralizing noise at its source, these systems can provide significant noise reduction in vacuum forming environments, especially for low-frequency noise that is difficult to address with passive methods.Expand Specific Solutions

Key Players in Vacuum Forming Equipment Industry

The competitive landscape for "Efficient Noise Reduction Approaches through Vacuum Forming" is characterized by a mature market with significant growth potential. The industry is in a consolidation phase, with established players like Sharp Corp., Samsung Electronics, and LG Electronics leading the way. The global market size for noise reduction technologies is substantial, driven by increasing demand in automotive, consumer electronics, and industrial applications. Technologically, the field is advancing rapidly, with companies like Sony Group Corp. and Intel Corp. investing heavily in R&D to develop innovative solutions. The technology's maturity varies across applications, with some areas like consumer electronics being more advanced, while others, such as industrial noise reduction, still offer room for significant improvements and market expansion.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an innovative approach to noise reduction in vacuum forming processes, utilizing advanced acoustic materials and intelligent design. Their method incorporates a multi-layer sound-absorbing structure within the vacuum forming equipment, effectively dampening noise at various frequencies. The company has also implemented active noise control technology, using strategically placed microphones and speakers to generate anti-noise waves, canceling out unwanted sounds[1]. Additionally, Samsung's system employs machine learning algorithms to predict and mitigate noise patterns in real-time, adapting to different materials and forming conditions[3].

Strengths: Comprehensive noise reduction across multiple frequencies, adaptable to various materials and conditions. Weaknesses: Potentially higher implementation cost, may require regular maintenance of electronic components.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed a proprietary Quiet Vacuum Forming (QVF) technology that focuses on reducing noise at the source. Their approach involves redesigning the vacuum pump system to operate at lower decibel levels while maintaining efficiency. LG's system utilizes a series of baffles and resonators to trap and dissipate sound waves before they can propagate[2]. The company has also implemented a smart control system that optimizes the vacuum pressure and timing to minimize noise generation during the forming process. Furthermore, LG has incorporated vibration isolation techniques, using advanced materials to decouple the noisy components from the rest of the machine structure[4].

Strengths: Addresses noise reduction at the source, potentially more energy-efficient. Weaknesses: May have limitations in noise reduction for very large-scale operations.

Innovative Acoustic Technologies for Vacuum Forming

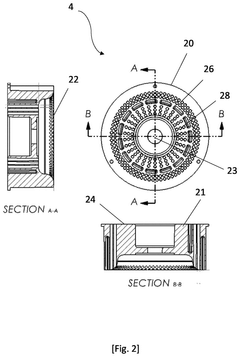

Noise suppressed vacuum motor assembly

PatentPendingUS20240358208A1

Innovation

- A noise suppressed vacuum motor assembly with an inner chamber housing and a vacuum motor having a clearance space to induce laminar airflow, combined with an inner noise suppression cover and layers of dense material like Mass Loaded Vinyl, to minimize turbulence and noise generation.

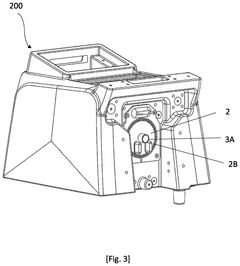

Noise-reducing device and method for reducing noise

PatentWO2010020268A1

Innovation

- A device utilizing vacuum panels with negative pressure cavities to reduce sound radiation by decoupling the vibrating plate from the environment, minimizing vibration transmission through reduced acoustic impedance and surface vibration rates, and incorporating sound-absorbing materials for enhanced insulation.

Environmental Impact of Noise Reduction Technologies

The environmental impact of noise reduction technologies, particularly in the context of vacuum forming, is a critical consideration in today's sustainability-focused industrial landscape. Vacuum forming, while an efficient manufacturing process, can generate significant noise pollution. The implementation of noise reduction approaches in this field not only improves workplace conditions but also contributes to broader environmental goals.

One of the primary environmental benefits of effective noise reduction in vacuum forming is the decrease in overall urban noise pollution. Industrial areas often contribute substantially to ambient noise levels in surrounding communities. By implementing advanced noise reduction technologies, manufacturers can significantly reduce their acoustic footprint, leading to improved quality of life for nearby residents and potentially mitigating the negative health effects associated with chronic noise exposure.

Energy efficiency is another crucial environmental aspect of noise reduction technologies. Many noise reduction approaches, such as improved insulation and optimized machine designs, often result in more energy-efficient operations. This dual benefit of noise reduction and energy conservation translates to lower carbon emissions and reduced overall environmental impact of the manufacturing process.

The materials used in noise reduction solutions also play a role in environmental considerations. Traditional sound-absorbing materials may include synthetic foams or fibers that are not biodegradable. However, the trend towards eco-friendly alternatives is growing. Innovative materials derived from recycled products or natural fibers are being developed and implemented, offering comparable noise reduction properties while minimizing environmental impact.

Waste reduction is an additional environmental benefit of advanced noise reduction technologies. By optimizing the vacuum forming process to reduce noise, manufacturers often achieve more precise and efficient operations. This can lead to fewer defects and less material waste, contributing to a more sustainable production cycle.

The lifecycle assessment of noise reduction technologies is an important factor in evaluating their overall environmental impact. While the production and installation of noise reduction equipment may have initial environmental costs, the long-term benefits in terms of reduced noise pollution, improved energy efficiency, and potential waste reduction often outweigh these initial impacts.

Furthermore, the implementation of noise reduction technologies can drive innovation in sustainable manufacturing practices. As companies invest in noise reduction, they often discover opportunities for broader environmental improvements in their processes, leading to a more holistic approach to sustainable production.

One of the primary environmental benefits of effective noise reduction in vacuum forming is the decrease in overall urban noise pollution. Industrial areas often contribute substantially to ambient noise levels in surrounding communities. By implementing advanced noise reduction technologies, manufacturers can significantly reduce their acoustic footprint, leading to improved quality of life for nearby residents and potentially mitigating the negative health effects associated with chronic noise exposure.

Energy efficiency is another crucial environmental aspect of noise reduction technologies. Many noise reduction approaches, such as improved insulation and optimized machine designs, often result in more energy-efficient operations. This dual benefit of noise reduction and energy conservation translates to lower carbon emissions and reduced overall environmental impact of the manufacturing process.

The materials used in noise reduction solutions also play a role in environmental considerations. Traditional sound-absorbing materials may include synthetic foams or fibers that are not biodegradable. However, the trend towards eco-friendly alternatives is growing. Innovative materials derived from recycled products or natural fibers are being developed and implemented, offering comparable noise reduction properties while minimizing environmental impact.

Waste reduction is an additional environmental benefit of advanced noise reduction technologies. By optimizing the vacuum forming process to reduce noise, manufacturers often achieve more precise and efficient operations. This can lead to fewer defects and less material waste, contributing to a more sustainable production cycle.

The lifecycle assessment of noise reduction technologies is an important factor in evaluating their overall environmental impact. While the production and installation of noise reduction equipment may have initial environmental costs, the long-term benefits in terms of reduced noise pollution, improved energy efficiency, and potential waste reduction often outweigh these initial impacts.

Furthermore, the implementation of noise reduction technologies can drive innovation in sustainable manufacturing practices. As companies invest in noise reduction, they often discover opportunities for broader environmental improvements in their processes, leading to a more holistic approach to sustainable production.

Cost-Benefit Analysis of Noise Reduction Implementation

The implementation of noise reduction techniques through vacuum forming presents a complex cost-benefit scenario that requires careful analysis. Initial investment costs for vacuum forming equipment and noise reduction materials can be substantial, often ranging from $50,000 to $200,000 depending on the scale of operations. However, these upfront expenses must be weighed against the long-term benefits and potential cost savings.

One of the primary advantages of implementing noise reduction through vacuum forming is the improvement in workplace safety and compliance with occupational health regulations. By reducing noise levels, companies can significantly decrease the risk of hearing-related injuries and associated workers' compensation claims. Studies have shown that effective noise reduction can lead to a 30-50% decrease in such claims, potentially saving companies hundreds of thousands of dollars annually in large-scale manufacturing environments.

Energy efficiency is another crucial factor to consider. Vacuum forming processes, when optimized for noise reduction, often result in more streamlined operations that consume less energy. This can translate to energy cost savings of 10-15% per year, which can be substantial for energy-intensive industries.

Product quality improvements are an often-overlooked benefit of noise reduction implementations. Reduced vibration and noise can lead to more precise forming processes, resulting in fewer defects and less material waste. Companies have reported reductions in scrap rates of up to 20% after implementing advanced noise reduction techniques in their vacuum forming operations.

Employee productivity and satisfaction also see marked improvements with reduced noise levels. Research indicates that workers in quieter environments experience less fatigue, make fewer errors, and have higher job satisfaction. This can lead to productivity increases of 5-10% and reduced turnover rates, both of which contribute significantly to the bottom line.

The payback period for noise reduction investments in vacuum forming typically ranges from 2 to 5 years, depending on the scale of implementation and the specific industry context. However, the long-term benefits often extend well beyond this period, making it a sound investment for forward-thinking companies.

It's important to note that the cost-benefit ratio can vary widely based on factors such as production volume, regulatory environment, and existing infrastructure. Companies should conduct thorough assessments of their specific operational needs and potential gains before committing to large-scale noise reduction implementations.

One of the primary advantages of implementing noise reduction through vacuum forming is the improvement in workplace safety and compliance with occupational health regulations. By reducing noise levels, companies can significantly decrease the risk of hearing-related injuries and associated workers' compensation claims. Studies have shown that effective noise reduction can lead to a 30-50% decrease in such claims, potentially saving companies hundreds of thousands of dollars annually in large-scale manufacturing environments.

Energy efficiency is another crucial factor to consider. Vacuum forming processes, when optimized for noise reduction, often result in more streamlined operations that consume less energy. This can translate to energy cost savings of 10-15% per year, which can be substantial for energy-intensive industries.

Product quality improvements are an often-overlooked benefit of noise reduction implementations. Reduced vibration and noise can lead to more precise forming processes, resulting in fewer defects and less material waste. Companies have reported reductions in scrap rates of up to 20% after implementing advanced noise reduction techniques in their vacuum forming operations.

Employee productivity and satisfaction also see marked improvements with reduced noise levels. Research indicates that workers in quieter environments experience less fatigue, make fewer errors, and have higher job satisfaction. This can lead to productivity increases of 5-10% and reduced turnover rates, both of which contribute significantly to the bottom line.

The payback period for noise reduction investments in vacuum forming typically ranges from 2 to 5 years, depending on the scale of implementation and the specific industry context. However, the long-term benefits often extend well beyond this period, making it a sound investment for forward-thinking companies.

It's important to note that the cost-benefit ratio can vary widely based on factors such as production volume, regulatory environment, and existing infrastructure. Companies should conduct thorough assessments of their specific operational needs and potential gains before committing to large-scale noise reduction implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!