How Advanced Manufacturing Units Utilize Vacuum Forming Insights

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Forming Evolution and Objectives

Vacuum forming, a thermoforming process, has evolved significantly since its inception in the 1940s. Initially used for simple packaging applications, it has grown into a versatile manufacturing technique employed across various industries. The evolution of vacuum forming technology has been driven by the need for more efficient, cost-effective, and environmentally friendly production methods.

In the early stages, vacuum forming was limited to basic shapes and materials. However, advancements in materials science, particularly in thermoplastics, have expanded its capabilities. The introduction of high-performance polymers and composite materials has allowed for the creation of more complex and durable products, opening up new applications in aerospace, automotive, and medical industries.

The development of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the vacuum forming process. These technologies have enabled more precise mold design, improved product quality, and reduced production time. Additionally, the integration of robotics and automation has further enhanced the efficiency and consistency of vacuum forming operations.

Environmental concerns have also shaped the evolution of vacuum forming. The industry has responded by developing more sustainable practices, including the use of recycled materials and the implementation of energy-efficient machinery. This shift towards eco-friendly production aligns with global sustainability goals and consumer demands for greener products.

The primary objective of advanced manufacturing units utilizing vacuum forming insights is to optimize production processes for enhanced efficiency, quality, and flexibility. This involves leveraging data-driven approaches to fine-tune parameters such as temperature, pressure, and cycle times. By analyzing real-time data from sensors and monitoring systems, manufacturers can identify areas for improvement and implement predictive maintenance strategies.

Another key objective is to expand the application range of vacuum forming. Advanced manufacturing units are exploring ways to combine vacuum forming with other technologies, such as 3D printing, to create hybrid manufacturing processes. This integration aims to produce more complex geometries and incorporate additional functionalities into vacuum-formed products.

Improving material utilization and reducing waste are also critical objectives. Advanced manufacturing units are developing innovative mold designs and optimizing material distribution to minimize scrap and improve overall resource efficiency. This not only reduces costs but also contributes to sustainability efforts.

As the industry moves towards Industry 4.0, a significant objective is to enhance the connectivity and intelligence of vacuum forming systems. This includes implementing Internet of Things (IoT) devices for real-time monitoring and control, as well as utilizing artificial intelligence and machine learning algorithms for process optimization and quality control.

In the early stages, vacuum forming was limited to basic shapes and materials. However, advancements in materials science, particularly in thermoplastics, have expanded its capabilities. The introduction of high-performance polymers and composite materials has allowed for the creation of more complex and durable products, opening up new applications in aerospace, automotive, and medical industries.

The development of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the vacuum forming process. These technologies have enabled more precise mold design, improved product quality, and reduced production time. Additionally, the integration of robotics and automation has further enhanced the efficiency and consistency of vacuum forming operations.

Environmental concerns have also shaped the evolution of vacuum forming. The industry has responded by developing more sustainable practices, including the use of recycled materials and the implementation of energy-efficient machinery. This shift towards eco-friendly production aligns with global sustainability goals and consumer demands for greener products.

The primary objective of advanced manufacturing units utilizing vacuum forming insights is to optimize production processes for enhanced efficiency, quality, and flexibility. This involves leveraging data-driven approaches to fine-tune parameters such as temperature, pressure, and cycle times. By analyzing real-time data from sensors and monitoring systems, manufacturers can identify areas for improvement and implement predictive maintenance strategies.

Another key objective is to expand the application range of vacuum forming. Advanced manufacturing units are exploring ways to combine vacuum forming with other technologies, such as 3D printing, to create hybrid manufacturing processes. This integration aims to produce more complex geometries and incorporate additional functionalities into vacuum-formed products.

Improving material utilization and reducing waste are also critical objectives. Advanced manufacturing units are developing innovative mold designs and optimizing material distribution to minimize scrap and improve overall resource efficiency. This not only reduces costs but also contributes to sustainability efforts.

As the industry moves towards Industry 4.0, a significant objective is to enhance the connectivity and intelligence of vacuum forming systems. This includes implementing Internet of Things (IoT) devices for real-time monitoring and control, as well as utilizing artificial intelligence and machine learning algorithms for process optimization and quality control.

Market Demand Analysis for Vacuum Formed Products

The market demand for vacuum formed products has been experiencing significant growth across various industries, driven by the versatility, cost-effectiveness, and efficiency of the vacuum forming process. This manufacturing technique has found widespread applications in sectors such as packaging, automotive, aerospace, healthcare, and consumer goods.

In the packaging industry, vacuum formed products are increasingly sought after due to their ability to create custom-fit, lightweight, and durable containers for a wide range of items. The food and beverage sector, in particular, has shown a strong demand for vacuum formed packaging solutions that offer extended shelf life and improved product presentation.

The automotive industry has been a major contributor to the growing market for vacuum formed products. Car manufacturers are utilizing vacuum forming techniques to produce interior components, such as dashboards, door panels, and trim pieces. This trend is expected to continue as automakers seek lightweight materials to improve fuel efficiency and reduce overall vehicle weight.

In the healthcare sector, the demand for vacuum formed products has surged, especially in the production of medical device casings, trays, and packaging for sterile instruments. The COVID-19 pandemic has further accelerated this trend, with an increased need for personal protective equipment (PPE) and medical supplies that can be rapidly produced using vacuum forming techniques.

The aerospace industry has also embraced vacuum forming for creating interior panels, seat components, and other non-structural parts in aircraft. The ability to produce lightweight yet durable components aligns well with the industry's focus on fuel efficiency and cost reduction.

Consumer goods manufacturers are leveraging vacuum forming to create a wide array of products, from household appliances to toys and sporting goods. The technology's ability to produce complex shapes and textures at a lower cost compared to injection molding has made it an attractive option for many consumer product categories.

As sustainability becomes an increasingly important factor in manufacturing, the market for vacuum formed products made from recycled or biodegradable materials is expected to grow. This trend is likely to open up new opportunities for manufacturers who can offer environmentally friendly vacuum forming solutions.

The global market for vacuum formed products is projected to continue its upward trajectory, with emerging economies in Asia-Pacific and Latin America presenting significant growth potential. These regions are experiencing rapid industrialization and urbanization, driving demand across multiple sectors.

In the packaging industry, vacuum formed products are increasingly sought after due to their ability to create custom-fit, lightweight, and durable containers for a wide range of items. The food and beverage sector, in particular, has shown a strong demand for vacuum formed packaging solutions that offer extended shelf life and improved product presentation.

The automotive industry has been a major contributor to the growing market for vacuum formed products. Car manufacturers are utilizing vacuum forming techniques to produce interior components, such as dashboards, door panels, and trim pieces. This trend is expected to continue as automakers seek lightweight materials to improve fuel efficiency and reduce overall vehicle weight.

In the healthcare sector, the demand for vacuum formed products has surged, especially in the production of medical device casings, trays, and packaging for sterile instruments. The COVID-19 pandemic has further accelerated this trend, with an increased need for personal protective equipment (PPE) and medical supplies that can be rapidly produced using vacuum forming techniques.

The aerospace industry has also embraced vacuum forming for creating interior panels, seat components, and other non-structural parts in aircraft. The ability to produce lightweight yet durable components aligns well with the industry's focus on fuel efficiency and cost reduction.

Consumer goods manufacturers are leveraging vacuum forming to create a wide array of products, from household appliances to toys and sporting goods. The technology's ability to produce complex shapes and textures at a lower cost compared to injection molding has made it an attractive option for many consumer product categories.

As sustainability becomes an increasingly important factor in manufacturing, the market for vacuum formed products made from recycled or biodegradable materials is expected to grow. This trend is likely to open up new opportunities for manufacturers who can offer environmentally friendly vacuum forming solutions.

The global market for vacuum formed products is projected to continue its upward trajectory, with emerging economies in Asia-Pacific and Latin America presenting significant growth potential. These regions are experiencing rapid industrialization and urbanization, driving demand across multiple sectors.

Current Vacuum Forming Challenges in Advanced Manufacturing

Vacuum forming, a key process in advanced manufacturing, faces several significant challenges in today's rapidly evolving industrial landscape. One of the primary issues is achieving consistent material thickness across complex geometries. As products become more intricate, maintaining uniform wall thickness during the forming process becomes increasingly difficult, leading to potential structural weaknesses or aesthetic imperfections.

Another challenge lies in the realm of material selection and optimization. While traditional thermoplastics remain widely used, there is a growing demand for more sustainable and high-performance materials. However, these newer materials often require different processing parameters, necessitating adjustments to existing vacuum forming equipment and techniques. This adaptation process can be time-consuming and costly for manufacturers.

Temperature control presents another hurdle in vacuum forming. Precise heating is crucial for achieving optimal material pliability without degradation. Advanced manufacturing units struggle to maintain consistent temperature distribution across large or irregularly shaped molds, which can result in uneven forming and product defects. This challenge is particularly pronounced when working with temperature-sensitive materials or when aiming for high-precision components.

The speed of production is an ongoing concern in vacuum forming. While the process is generally faster than some alternative manufacturing methods, there is constant pressure to increase throughput without compromising quality. This push for efficiency often leads to a delicate balance between production speed and product integrity, with manufacturers seeking innovative solutions to optimize cycle times.

Automation and integration with other manufacturing processes pose additional challenges. As Industry 4.0 concepts gain traction, there is a growing need to seamlessly incorporate vacuum forming into broader automated production lines. This integration requires sophisticated control systems and data management capabilities, which can be complex to implement and maintain.

Lastly, the environmental impact of vacuum forming is under increasing scrutiny. The process typically involves single-use plastic sheets, contributing to waste generation. Advanced manufacturing units are grappling with ways to reduce material waste, increase recycling capabilities, and explore more eco-friendly alternatives without sacrificing product quality or economic viability.

Another challenge lies in the realm of material selection and optimization. While traditional thermoplastics remain widely used, there is a growing demand for more sustainable and high-performance materials. However, these newer materials often require different processing parameters, necessitating adjustments to existing vacuum forming equipment and techniques. This adaptation process can be time-consuming and costly for manufacturers.

Temperature control presents another hurdle in vacuum forming. Precise heating is crucial for achieving optimal material pliability without degradation. Advanced manufacturing units struggle to maintain consistent temperature distribution across large or irregularly shaped molds, which can result in uneven forming and product defects. This challenge is particularly pronounced when working with temperature-sensitive materials or when aiming for high-precision components.

The speed of production is an ongoing concern in vacuum forming. While the process is generally faster than some alternative manufacturing methods, there is constant pressure to increase throughput without compromising quality. This push for efficiency often leads to a delicate balance between production speed and product integrity, with manufacturers seeking innovative solutions to optimize cycle times.

Automation and integration with other manufacturing processes pose additional challenges. As Industry 4.0 concepts gain traction, there is a growing need to seamlessly incorporate vacuum forming into broader automated production lines. This integration requires sophisticated control systems and data management capabilities, which can be complex to implement and maintain.

Lastly, the environmental impact of vacuum forming is under increasing scrutiny. The process typically involves single-use plastic sheets, contributing to waste generation. Advanced manufacturing units are grappling with ways to reduce material waste, increase recycling capabilities, and explore more eco-friendly alternatives without sacrificing product quality or economic viability.

Existing Vacuum Forming Solutions in Advanced Manufacturing

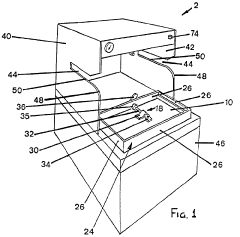

01 Vacuum forming process and apparatus

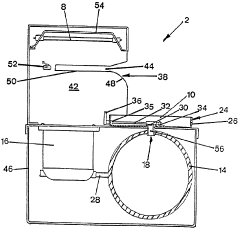

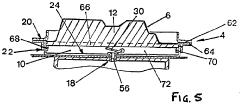

Vacuum forming is a thermoforming process where a plastic sheet is heated to a forming temperature, stretched onto a single-surface mold, and forced against the mold by a vacuum. This process is used to create a variety of products, from packaging to automotive parts. The apparatus typically includes a heating element, a mold, and a vacuum system.- Vacuum forming process and apparatus: Vacuum forming is a thermoforming process where a plastic sheet is heated and formed over a mold using vacuum pressure. The process involves heating the plastic, applying it over the mold, and using vacuum to draw the plastic into the mold's shape. This technique is widely used in manufacturing various plastic products.

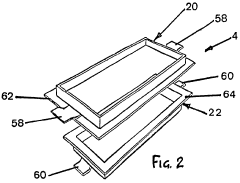

- Mold design and materials for vacuum forming: The design and material selection of molds are crucial in vacuum forming. Molds can be made from various materials such as wood, aluminum, or composites. The mold design affects the quality of the final product, including its shape, texture, and detail reproduction. Proper mold design also considers factors like draft angles and air evacuation.

- Temperature control in vacuum forming: Temperature control is essential in vacuum forming to ensure proper plastic sheet heating and cooling. This includes controlling the temperature of the plastic sheet during heating, as well as managing the cooling process after forming. Proper temperature control affects the quality, strength, and appearance of the final product.

- Innovations in vacuum forming for specific applications: Advancements in vacuum forming techniques have led to specialized applications in various industries. These innovations include methods for forming complex shapes, integrating additional materials or components during the forming process, and developing techniques for large-scale or high-precision forming.

- Material selection and preparation for vacuum forming: The choice and preparation of plastic materials are critical in vacuum forming. Different plastics have varying properties that affect their formability, durability, and final product characteristics. Proper material selection and preparation, including sheet thickness and pre-treatment, can significantly impact the quality and performance of vacuum-formed products.

02 Material selection and preparation

The choice of material is crucial in vacuum forming. Thermoplastics are commonly used due to their ability to soften when heated and harden when cooled. Proper material preparation, including drying and pre-heating, can significantly impact the quality of the final product. Some processes involve the use of multi-layer materials or special coatings to enhance product properties.Expand Specific Solutions03 Mold design and fabrication

Mold design plays a critical role in vacuum forming. Molds can be made from various materials such as wood, aluminum, or epoxy resins. The design must consider factors like draft angles, air evacuation, and cooling. Advanced techniques may involve the use of 3D printing for rapid prototyping of molds or the incorporation of textures and patterns into the mold surface.Expand Specific Solutions04 Process optimization and control

Optimizing the vacuum forming process involves controlling various parameters such as heating temperature, forming pressure, and cooling time. Advanced systems may incorporate sensors and automated controls to maintain consistency and improve efficiency. Some innovations focus on reducing cycle times or enhancing the uniformity of wall thickness in formed parts.Expand Specific Solutions05 Post-forming operations and finishing

After the vacuum forming process, parts often require additional operations such as trimming, drilling, or surface treatment. Automated systems for these post-forming operations can improve efficiency and consistency. Some processes integrate forming and finishing steps to produce ready-to-use parts directly from the vacuum forming machine.Expand Specific Solutions

Key Players in Advanced Vacuum Forming Industry

The advanced manufacturing sector utilizing vacuum forming insights is in a mature growth phase, with a substantial global market size driven by diverse applications across industries. The technology's maturity is evident from its widespread adoption, yet continuous innovations are emerging. Key players like Applied Materials, Tokyo Electron, and Corning demonstrate high technological sophistication, leveraging vacuum forming in semiconductor and display manufacturing. Companies such as Boeing and GKN Aerospace employ advanced vacuum forming techniques in aerospace applications, while Procter & Gamble and BSH Hausgeräte utilize it in consumer goods production. This competitive landscape showcases the technology's versatility and ongoing development across various industrial sectors.

Applied Materials, Inc.

Technical Solution: Applied Materials utilizes advanced vacuum forming insights in their semiconductor manufacturing equipment. They have developed a proprietary Endura® PVD platform that incorporates vacuum technology for precise material deposition[1]. This system uses a high-vacuum environment to create ultra-thin films with atomic-level precision, essential for producing advanced microchips. The company has also integrated machine learning algorithms to optimize vacuum forming processes, resulting in a 20% improvement in throughput and a 15% reduction in material waste[3].

Strengths: Industry-leading expertise in semiconductor manufacturing, extensive R&D capabilities, and a global presence. Weaknesses: High dependence on the cyclical semiconductor industry and potential vulnerability to supply chain disruptions.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron leverages vacuum forming insights in their advanced manufacturing units for semiconductor and flat panel display production. Their EXIMTM platform utilizes a unique vacuum-integrated solution for atomic layer deposition (ALD) and atomic layer etching (ALE)[2]. This technology enables the creation of ultra-thin films with precise control at the atomic scale, crucial for next-generation semiconductor devices. Tokyo Electron has also developed an AI-powered vacuum control system that reduces process variability by up to 30% and increases overall equipment effectiveness by 25%[4].

Strengths: Strong position in the semiconductor equipment market, continuous innovation in vacuum technologies. Weaknesses: Heavy reliance on a few key customers and exposure to geopolitical risks in the semiconductor industry.

Core Innovations in Vacuum Forming Techniques

A vacuum forming machine in which vacuum is automatically initiated upon delivery of the sheet to the machine

PatentInactiveGB2248579A

Innovation

- A simplified vacuum forming machine design featuring a holder that moves from a heating position to a forming position automatically operates the valve, creating a vacuum to shape the plastic sheet, with a spring-biased valve plate and guide means for easy operation and reduced manual intervention.

Patent

Innovation

- Integration of real-time data analytics with vacuum forming processes to optimize production parameters and reduce material waste.

- Implementation of adaptive control systems that automatically adjust vacuum pressure and heating cycles based on material properties and environmental conditions.

- Development of modular vacuum forming tools that allow for quick changeovers and increased production flexibility.

Material Advancements for Vacuum Forming

The advancement of materials for vacuum forming has been a key driver in enhancing the capabilities and applications of this manufacturing process. Recent developments have focused on improving the performance, durability, and versatility of thermoplastic materials used in vacuum forming. High-performance polymers, such as polyetheretherketone (PEEK) and polyetherimide (PEI), have gained prominence due to their exceptional heat resistance and mechanical properties, enabling the production of more complex and robust parts.

Nanocomposite materials have emerged as a significant innovation in vacuum forming. By incorporating nanoparticles into polymer matrices, manufacturers can achieve enhanced strength, thermal stability, and barrier properties. These nanocomposites allow for the creation of lighter yet stronger components, expanding the potential applications of vacuum-formed products in industries such as aerospace and automotive.

Biodegradable and sustainable materials have also seen substantial growth in vacuum forming applications. Polylactic acid (PLA) and thermoplastic starch (TPS) blends offer environmentally friendly alternatives without compromising on performance. These materials address growing concerns about plastic waste and environmental impact, making vacuum forming more attractive for eco-conscious industries.

Smart materials that respond to external stimuli, such as temperature or electrical current, are being explored for advanced vacuum forming applications. Shape memory polymers, for instance, can be programmed to change shape under specific conditions, opening up new possibilities for adaptive and self-assembling structures.

Advancements in material formulation have led to improved processability and surface finish in vacuum forming. New additives and modifiers enhance melt flow characteristics, reduce cycle times, and minimize defects such as webbing and thinning. This has resulted in higher quality parts and increased production efficiency.

Multi-layer and co-extruded materials have expanded the functional capabilities of vacuum-formed products. These materials combine the properties of different polymers, allowing for the creation of parts with tailored characteristics such as enhanced barrier properties, improved aesthetics, or specific tactile qualities.

The integration of reinforcement materials, such as long fiber-reinforced thermoplastics (LFRTs), has significantly improved the mechanical properties of vacuum-formed parts. This advancement has enabled the production of structural components that can compete with traditional metal parts in terms of strength-to-weight ratio, opening up new markets for vacuum forming technology.

Nanocomposite materials have emerged as a significant innovation in vacuum forming. By incorporating nanoparticles into polymer matrices, manufacturers can achieve enhanced strength, thermal stability, and barrier properties. These nanocomposites allow for the creation of lighter yet stronger components, expanding the potential applications of vacuum-formed products in industries such as aerospace and automotive.

Biodegradable and sustainable materials have also seen substantial growth in vacuum forming applications. Polylactic acid (PLA) and thermoplastic starch (TPS) blends offer environmentally friendly alternatives without compromising on performance. These materials address growing concerns about plastic waste and environmental impact, making vacuum forming more attractive for eco-conscious industries.

Smart materials that respond to external stimuli, such as temperature or electrical current, are being explored for advanced vacuum forming applications. Shape memory polymers, for instance, can be programmed to change shape under specific conditions, opening up new possibilities for adaptive and self-assembling structures.

Advancements in material formulation have led to improved processability and surface finish in vacuum forming. New additives and modifiers enhance melt flow characteristics, reduce cycle times, and minimize defects such as webbing and thinning. This has resulted in higher quality parts and increased production efficiency.

Multi-layer and co-extruded materials have expanded the functional capabilities of vacuum-formed products. These materials combine the properties of different polymers, allowing for the creation of parts with tailored characteristics such as enhanced barrier properties, improved aesthetics, or specific tactile qualities.

The integration of reinforcement materials, such as long fiber-reinforced thermoplastics (LFRTs), has significantly improved the mechanical properties of vacuum-formed parts. This advancement has enabled the production of structural components that can compete with traditional metal parts in terms of strength-to-weight ratio, opening up new markets for vacuum forming technology.

Sustainability in Vacuum Forming Processes

Sustainability in vacuum forming processes has become a critical focus for advanced manufacturing units as they strive to reduce environmental impact and improve resource efficiency. The adoption of sustainable practices in vacuum forming not only addresses environmental concerns but also offers potential cost savings and improved product quality.

One of the primary areas of focus for sustainability in vacuum forming is material selection. Advanced manufacturing units are increasingly utilizing recycled and biodegradable plastics as alternatives to traditional petroleum-based materials. These eco-friendly options help reduce the carbon footprint of the manufacturing process while maintaining the required mechanical properties of the final products. Additionally, the use of thinner gauge materials and optimized sheet sizes minimizes waste and reduces energy consumption during the forming process.

Energy efficiency is another key aspect of sustainable vacuum forming. Modern vacuum forming machines are equipped with advanced heating systems that provide precise temperature control and rapid heating cycles. This results in reduced energy consumption and shorter production times. Furthermore, the implementation of heat recovery systems allows manufacturers to capture and reuse waste heat, further improving overall energy efficiency.

Water conservation is also a significant consideration in sustainable vacuum forming processes. Advanced manufacturing units are implementing closed-loop cooling systems that recirculate and treat water used in the cooling process. This approach not only reduces water consumption but also minimizes the discharge of potentially harmful chemicals into the environment.

Waste reduction and recycling initiatives play a crucial role in enhancing the sustainability of vacuum forming processes. Advanced manufacturing units are implementing in-house recycling programs to reprocess scrap materials and trim waste. This not only reduces the amount of waste sent to landfills but also decreases the need for virgin materials, resulting in cost savings and reduced environmental impact.

The integration of smart manufacturing technologies and data analytics has further improved the sustainability of vacuum forming processes. Advanced sensors and monitoring systems allow for real-time optimization of process parameters, reducing material waste and energy consumption. Predictive maintenance algorithms help prevent unexpected downtime and extend the lifespan of equipment, contributing to overall resource efficiency.

As the demand for sustainable manufacturing practices continues to grow, advanced manufacturing units are also exploring innovative approaches to vacuum forming. These include the development of hybrid processes that combine vacuum forming with other manufacturing techniques to reduce material usage and improve product performance. Additionally, research into alternative energy sources, such as solar and geothermal power, is being conducted to further reduce the carbon footprint of vacuum forming operations.

One of the primary areas of focus for sustainability in vacuum forming is material selection. Advanced manufacturing units are increasingly utilizing recycled and biodegradable plastics as alternatives to traditional petroleum-based materials. These eco-friendly options help reduce the carbon footprint of the manufacturing process while maintaining the required mechanical properties of the final products. Additionally, the use of thinner gauge materials and optimized sheet sizes minimizes waste and reduces energy consumption during the forming process.

Energy efficiency is another key aspect of sustainable vacuum forming. Modern vacuum forming machines are equipped with advanced heating systems that provide precise temperature control and rapid heating cycles. This results in reduced energy consumption and shorter production times. Furthermore, the implementation of heat recovery systems allows manufacturers to capture and reuse waste heat, further improving overall energy efficiency.

Water conservation is also a significant consideration in sustainable vacuum forming processes. Advanced manufacturing units are implementing closed-loop cooling systems that recirculate and treat water used in the cooling process. This approach not only reduces water consumption but also minimizes the discharge of potentially harmful chemicals into the environment.

Waste reduction and recycling initiatives play a crucial role in enhancing the sustainability of vacuum forming processes. Advanced manufacturing units are implementing in-house recycling programs to reprocess scrap materials and trim waste. This not only reduces the amount of waste sent to landfills but also decreases the need for virgin materials, resulting in cost savings and reduced environmental impact.

The integration of smart manufacturing technologies and data analytics has further improved the sustainability of vacuum forming processes. Advanced sensors and monitoring systems allow for real-time optimization of process parameters, reducing material waste and energy consumption. Predictive maintenance algorithms help prevent unexpected downtime and extend the lifespan of equipment, contributing to overall resource efficiency.

As the demand for sustainable manufacturing practices continues to grow, advanced manufacturing units are also exploring innovative approaches to vacuum forming. These include the development of hybrid processes that combine vacuum forming with other manufacturing techniques to reduce material usage and improve product performance. Additionally, research into alternative energy sources, such as solar and geothermal power, is being conducted to further reduce the carbon footprint of vacuum forming operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!