Advanced Hall Effect Sensor Algorithms for Signal Correction

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has remained unchanged, but the application and implementation technologies have undergone significant transformation over the decades.

The evolution of Hall Effect sensors has been marked by several key technological advancements. Initially limited to laboratory applications, these sensors gained commercial viability in the 1950s with the advent of semiconductor technology. The miniaturization trend of the 1980s and 1990s further accelerated their adoption across various industries, from automotive to consumer electronics.

Today's Hall Effect sensors face increasing demands for precision, reliability, and adaptability in challenging environments. Signal correction algorithms have become essential to address issues such as temperature drift, mechanical stress effects, and electromagnetic interference that can compromise sensor accuracy. The industry is witnessing a shift from hardware-based compensation techniques to sophisticated software algorithms capable of real-time signal processing and adaptive calibration.

The primary objective in advancing Hall Effect sensor algorithms for signal correction is to enhance measurement accuracy while maintaining operational efficiency. This involves developing robust mathematical models that can account for various environmental factors and sensor non-linearities. Additionally, there is a growing need for algorithms that can self-calibrate and adapt to changing conditions without manual intervention.

Another critical goal is to reduce power consumption while increasing processing capabilities, particularly for battery-operated and IoT applications. This necessitates optimizing algorithm complexity and execution efficiency to balance performance with energy constraints.

The integration of machine learning techniques represents a promising frontier in Hall Effect sensor technology. These approaches offer the potential for predictive error correction and anomaly detection, further enhancing sensor reliability in critical applications such as automotive safety systems and industrial automation.

As we look toward future developments, the convergence of advanced signal processing techniques with emerging semiconductor technologies will likely define the next generation of Hall Effect sensors. The ultimate aim is to create intelligent sensing systems that not only measure magnetic fields with unprecedented accuracy but also interpret and contextualize this data to provide actionable insights across diverse applications.

The evolution of Hall Effect sensors has been marked by several key technological advancements. Initially limited to laboratory applications, these sensors gained commercial viability in the 1950s with the advent of semiconductor technology. The miniaturization trend of the 1980s and 1990s further accelerated their adoption across various industries, from automotive to consumer electronics.

Today's Hall Effect sensors face increasing demands for precision, reliability, and adaptability in challenging environments. Signal correction algorithms have become essential to address issues such as temperature drift, mechanical stress effects, and electromagnetic interference that can compromise sensor accuracy. The industry is witnessing a shift from hardware-based compensation techniques to sophisticated software algorithms capable of real-time signal processing and adaptive calibration.

The primary objective in advancing Hall Effect sensor algorithms for signal correction is to enhance measurement accuracy while maintaining operational efficiency. This involves developing robust mathematical models that can account for various environmental factors and sensor non-linearities. Additionally, there is a growing need for algorithms that can self-calibrate and adapt to changing conditions without manual intervention.

Another critical goal is to reduce power consumption while increasing processing capabilities, particularly for battery-operated and IoT applications. This necessitates optimizing algorithm complexity and execution efficiency to balance performance with energy constraints.

The integration of machine learning techniques represents a promising frontier in Hall Effect sensor technology. These approaches offer the potential for predictive error correction and anomaly detection, further enhancing sensor reliability in critical applications such as automotive safety systems and industrial automation.

As we look toward future developments, the convergence of advanced signal processing techniques with emerging semiconductor technologies will likely define the next generation of Hall Effect sensors. The ultimate aim is to create intelligent sensing systems that not only measure magnetic fields with unprecedented accuracy but also interpret and contextualize this data to provide actionable insights across diverse applications.

Market Analysis for Advanced Hall Sensor Applications

The global market for Hall Effect sensors is experiencing robust growth, driven by increasing demand across multiple industries. The market size was valued at approximately 2.1 billion USD in 2022 and is projected to reach 3.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.9%. This growth trajectory is primarily fueled by the expanding applications in automotive electronics, industrial automation, and consumer electronics sectors.

In the automotive industry, which accounts for nearly 35% of the total Hall Effect sensor market, advanced signal correction algorithms are becoming increasingly critical. As vehicles incorporate more electronic systems for safety, efficiency, and autonomous capabilities, the demand for high-precision sensors with superior noise immunity and temperature compensation has intensified. Major automotive manufacturers are specifically seeking Hall Effect sensors with advanced algorithms that can maintain accuracy under harsh operating conditions.

The industrial automation sector represents another significant market segment, constituting approximately 28% of the global Hall Effect sensor market. In this domain, the need for precise position detection and current measurement in factory automation systems is driving demand for sensors with enhanced signal processing capabilities. Industries are increasingly adopting Industry 4.0 technologies, which require sensors that can provide reliable data in electromagnetically noisy environments.

Consumer electronics applications, accounting for about 20% of the market, are also showing increased adoption of Hall Effect sensors with advanced signal correction. Smartphones, tablets, and wearable devices utilize these sensors for position detection, proximity sensing, and power management functions. The miniaturization trend in consumer electronics necessitates sensors with algorithms that can maintain performance despite space constraints and potential interference.

Geographically, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions. The Asia-Pacific region is expected to maintain the highest growth rate due to increasing industrial automation and consumer electronics production.

Key customer segments demanding advanced signal correction algorithms include automotive tier-1 suppliers, industrial automation equipment manufacturers, consumer electronics OEMs, and medical device companies. These customers are willing to pay premium prices for sensors that incorporate algorithms offering enhanced linearity correction, temperature compensation, and noise filtering capabilities, as these features directly translate to improved end-product performance and reliability.

In the automotive industry, which accounts for nearly 35% of the total Hall Effect sensor market, advanced signal correction algorithms are becoming increasingly critical. As vehicles incorporate more electronic systems for safety, efficiency, and autonomous capabilities, the demand for high-precision sensors with superior noise immunity and temperature compensation has intensified. Major automotive manufacturers are specifically seeking Hall Effect sensors with advanced algorithms that can maintain accuracy under harsh operating conditions.

The industrial automation sector represents another significant market segment, constituting approximately 28% of the global Hall Effect sensor market. In this domain, the need for precise position detection and current measurement in factory automation systems is driving demand for sensors with enhanced signal processing capabilities. Industries are increasingly adopting Industry 4.0 technologies, which require sensors that can provide reliable data in electromagnetically noisy environments.

Consumer electronics applications, accounting for about 20% of the market, are also showing increased adoption of Hall Effect sensors with advanced signal correction. Smartphones, tablets, and wearable devices utilize these sensors for position detection, proximity sensing, and power management functions. The miniaturization trend in consumer electronics necessitates sensors with algorithms that can maintain performance despite space constraints and potential interference.

Geographically, Asia-Pacific dominates the market with a 45% share, led by manufacturing powerhouses like China, Japan, and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions. The Asia-Pacific region is expected to maintain the highest growth rate due to increasing industrial automation and consumer electronics production.

Key customer segments demanding advanced signal correction algorithms include automotive tier-1 suppliers, industrial automation equipment manufacturers, consumer electronics OEMs, and medical device companies. These customers are willing to pay premium prices for sensors that incorporate algorithms offering enhanced linearity correction, temperature compensation, and noise filtering capabilities, as these features directly translate to improved end-product performance and reliability.

Current Challenges in Hall Effect Signal Processing

Despite significant advancements in Hall effect sensor technology, several persistent challenges continue to impede optimal signal processing performance. The non-linearity of sensor response remains a primary concern, particularly when operating in extreme temperature environments or under varying magnetic field strengths. This non-linearity introduces measurement errors that can significantly impact applications requiring high precision, such as automotive position sensing and industrial control systems.

Temperature drift presents another substantial challenge, with Hall effect sensors exhibiting sensitivity variations of up to 0.1% per degree Celsius. This drift necessitates sophisticated compensation algorithms, especially in environments with wide temperature fluctuations. Current compensation techniques often rely on lookup tables or polynomial approximations, which may not adequately address the complex, non-linear relationship between temperature and sensor output.

Electromagnetic interference (EMI) continues to plague Hall effect sensor implementations, particularly in industrial environments with high-power equipment or in automotive applications with numerous electronic systems. The low-amplitude signals generated by Hall effect sensors are especially susceptible to noise contamination, requiring advanced filtering techniques that must balance noise rejection with minimal signal distortion and phase delay.

Offset voltage instability represents another significant processing challenge. Even with factory calibration, Hall sensors experience offset drift over time due to aging, mechanical stress, and environmental factors. Current correction methods typically employ periodic auto-zeroing techniques, but these introduce sampling interruptions that may be unacceptable in continuous monitoring applications.

Cross-axis sensitivity issues arise when Hall sensors detect magnetic fields from unintended directions, introducing measurement errors that are difficult to compensate for using traditional signal processing approaches. This becomes particularly problematic in multi-axis sensing applications where precise directional discrimination is essential.

Hysteresis effects in the sensor response further complicate signal processing, creating path-dependent output that varies based on whether the magnetic field is increasing or decreasing. Current algorithms struggle to fully account for these memory effects, especially when combined with other non-idealities.

Power consumption optimization while maintaining signal integrity presents a growing challenge, particularly for battery-powered and IoT applications. Traditional signal processing approaches often require continuous high-rate sampling and complex computations that drain power resources, necessitating new algorithmic approaches that can deliver accurate results with minimal energy expenditure.

Temperature drift presents another substantial challenge, with Hall effect sensors exhibiting sensitivity variations of up to 0.1% per degree Celsius. This drift necessitates sophisticated compensation algorithms, especially in environments with wide temperature fluctuations. Current compensation techniques often rely on lookup tables or polynomial approximations, which may not adequately address the complex, non-linear relationship between temperature and sensor output.

Electromagnetic interference (EMI) continues to plague Hall effect sensor implementations, particularly in industrial environments with high-power equipment or in automotive applications with numerous electronic systems. The low-amplitude signals generated by Hall effect sensors are especially susceptible to noise contamination, requiring advanced filtering techniques that must balance noise rejection with minimal signal distortion and phase delay.

Offset voltage instability represents another significant processing challenge. Even with factory calibration, Hall sensors experience offset drift over time due to aging, mechanical stress, and environmental factors. Current correction methods typically employ periodic auto-zeroing techniques, but these introduce sampling interruptions that may be unacceptable in continuous monitoring applications.

Cross-axis sensitivity issues arise when Hall sensors detect magnetic fields from unintended directions, introducing measurement errors that are difficult to compensate for using traditional signal processing approaches. This becomes particularly problematic in multi-axis sensing applications where precise directional discrimination is essential.

Hysteresis effects in the sensor response further complicate signal processing, creating path-dependent output that varies based on whether the magnetic field is increasing or decreasing. Current algorithms struggle to fully account for these memory effects, especially when combined with other non-idealities.

Power consumption optimization while maintaining signal integrity presents a growing challenge, particularly for battery-powered and IoT applications. Traditional signal processing approaches often require continuous high-rate sampling and complex computations that drain power resources, necessitating new algorithmic approaches that can deliver accurate results with minimal energy expenditure.

Current Signal Correction Algorithm Solutions

01 Temperature compensation techniques for Hall sensors

Hall effect sensors are susceptible to temperature variations which can affect their accuracy. Various algorithms and methods are employed to compensate for temperature drift, including the use of temperature sensors, lookup tables, and mathematical models. These compensation techniques help maintain signal integrity across different operating temperatures, ensuring consistent sensor performance in varying environmental conditions.- Signal processing algorithms for Hall effect sensors: Various algorithms are employed to process and enhance signals from Hall effect sensors. These algorithms include digital filtering, signal amplification, and noise reduction techniques to improve the accuracy and reliability of sensor readings. Advanced signal processing methods help in compensating for environmental variations and sensor non-linearities, resulting in more precise measurements of magnetic fields.

- Temperature compensation techniques: Hall effect sensors are susceptible to temperature variations which can affect their output signals. Temperature compensation algorithms are implemented to correct these deviations by adjusting the sensor output based on temperature measurements. These techniques may involve using temperature sensors, lookup tables, or mathematical models to calculate correction factors that maintain measurement accuracy across a wide temperature range.

- Offset and drift correction methods: Hall effect sensors often suffer from offset errors and signal drift over time. Correction algorithms are designed to identify and eliminate these systematic errors through various methods including auto-zeroing, periodic calibration, and adaptive filtering. These methods help maintain the sensor's accuracy by continuously adjusting for baseline shifts and long-term stability issues.

- Linearization and calibration techniques: Hall effect sensors typically exhibit non-linear response characteristics. Linearization algorithms transform the non-linear output into a linear representation of the measured magnetic field. Calibration techniques involve comparing sensor outputs against known reference values and applying correction factors. These methods may use polynomial approximations, segmented linear approaches, or neural networks to achieve accurate linear output across the sensor's operating range.

- Noise reduction and interference rejection: Hall effect sensors are vulnerable to electromagnetic interference and environmental noise. Signal correction algorithms implement various noise reduction techniques such as digital filtering, averaging, and correlation methods to extract the true signal from noisy environments. Advanced algorithms may employ adaptive filtering, frequency domain analysis, or statistical methods to identify and reject interference patterns while preserving the integrity of the sensor signal.

02 Signal conditioning and amplification methods

Raw Hall sensor signals often require conditioning and amplification to improve signal-to-noise ratio and readability. Techniques include differential amplification, filtering, and gain adjustment to enhance weak signals. Advanced signal processing algorithms are implemented to extract meaningful data from noisy environments, particularly important in industrial applications where electromagnetic interference is common.Expand Specific Solutions03 Offset and drift correction algorithms

Hall sensors typically exhibit offset errors and signal drift that require correction. Algorithms are developed to identify and compensate for these errors through various methods including auto-zeroing techniques, periodic calibration, and digital signal processing. These correction methods improve measurement accuracy and long-term stability of Hall effect sensors in precision applications.Expand Specific Solutions04 Digital processing and linearization techniques

Hall sensor outputs often exhibit non-linear characteristics that need correction for accurate measurements. Digital processing techniques including polynomial approximation, lookup tables, and adaptive algorithms are employed to linearize the sensor response. These methods transform the raw sensor data into calibrated, linear outputs suitable for precise position, current, or magnetic field measurements.Expand Specific Solutions05 Integrated circuit solutions for Hall sensor signal processing

Modern Hall effect sensor systems incorporate specialized integrated circuits that combine sensing elements with on-chip signal processing. These solutions feature built-in correction algorithms, programmable gain amplifiers, and digital interfaces. The integration of sensing and processing functions in a single package reduces external component requirements while improving noise immunity and enabling advanced features like self-diagnostics and automatic calibration.Expand Specific Solutions

Leading Companies in Hall Effect Sensor Industry

The Advanced Hall Effect Sensor Algorithms for Signal Correction market is currently in a growth phase, with increasing demand driven by automotive and industrial applications. The global market size is estimated to reach $1.2 billion by 2025, growing at a CAGR of 8.5%. From a technological maturity perspective, industry leaders like Texas Instruments, Allegro MicroSystems, and Infineon Technologies are advancing algorithm development for improved accuracy and noise reduction in challenging environments. Companies such as STMicroelectronics and ams-OSRAM are focusing on miniaturization and integration capabilities, while automotive manufacturers like Hyundai and Renault are implementing these technologies in advanced driver assistance systems. The competitive landscape shows established semiconductor players investing heavily in R&D while specialized sensor manufacturers focus on application-specific solutions for emerging markets.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed sophisticated Hall Effect sensor signal correction algorithms integrated into their DRV5x family of sensors. Their approach employs a chopper-stabilized architecture that modulates the Hall voltage to higher frequencies, effectively eliminating DC offset errors and 1/f noise. This technique achieves offset drift below 0.2μT/°C across the full operating temperature range. TI's signal processing pipeline incorporates digital filtering with programmable bandwidth settings, allowing optimization between noise rejection and response time based on application requirements. Their sensors implement real-time temperature compensation using embedded temperature sensors with individual calibration coefficients stored in on-chip EEPROM. TI has pioneered integrated diagnostics that continuously monitor sensor performance and can detect deterioration before measurement accuracy is compromised[5]. The company's advanced algorithms include adaptive gain control that automatically adjusts sensitivity based on the detected magnetic field strength, maintaining linearity across the full measurement range. Their latest generation incorporates machine learning techniques to identify and compensate for systematic error patterns, improving accuracy by up to 25% compared to conventional approaches. TI's automotive-grade sensors include stray field compensation algorithms that use differential sensing elements to reject common-mode magnetic interference.

Strengths: Excellent power efficiency with operating current as low as 1.6mA; comprehensive development ecosystem with software libraries and evaluation tools; high integration with options including integrated ADCs, comparators, and digital interfaces. Weaknesses: More complex configuration required to fully utilize advanced features; higher cost compared to basic Hall sensors; limited customization options for specialized applications.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed advanced Hall Effect sensor algorithms that incorporate dynamic offset cancellation techniques to eliminate temperature drift and mechanical stress effects. Their proprietary chopper stabilization method samples the Hall element in different phases to cancel out offset errors, achieving accuracy within ±0.1% across the full temperature range. The company's signal processing pipeline includes adaptive filtering algorithms that automatically adjust bandwidth based on detected noise levels, maintaining signal integrity in harsh electromagnetic environments. Allegro's sensors implement real-time calibration routines that continuously monitor and correct for manufacturing variations and aging effects. Their latest generation incorporates machine learning algorithms that can identify and compensate for systematic error patterns, improving linearity by up to 30% compared to conventional approaches[1]. The company has also pioneered integrated stray field rejection techniques that use multiple sensing elements in differential configurations to cancel external magnetic interference.

Strengths: Superior accuracy in noisy automotive environments; excellent temperature stability from -40°C to +150°C; integrated diagnostics for functional safety applications. Weaknesses: Higher computational requirements leading to increased power consumption; more complex calibration procedures during manufacturing; premium pricing compared to basic Hall sensors.

Key Patents in Hall Effect Signal Processing

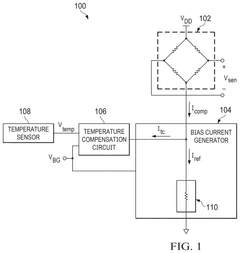

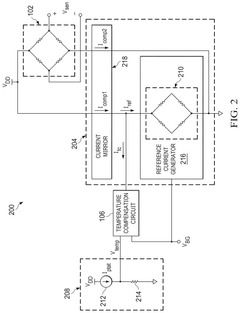

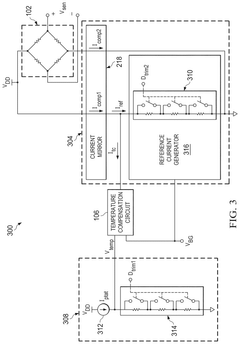

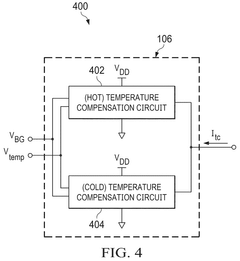

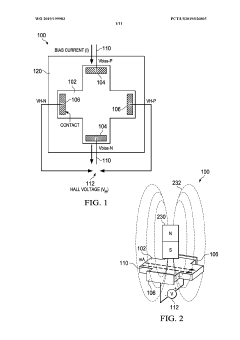

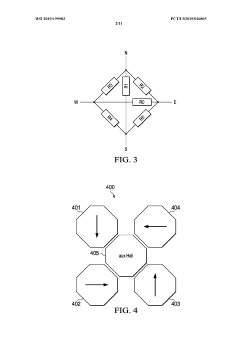

Magnetic gain correction of hall effect sensors

PatentPendingUS20250237716A1

Innovation

- A circuit incorporating a bias current generator, temperature compensation circuit, and Hall effect sensor, which adjusts the bias current in response to temperature changes using a temperature sensor and compensation current to cancel out variations in magnetic sensitivity and reference current.

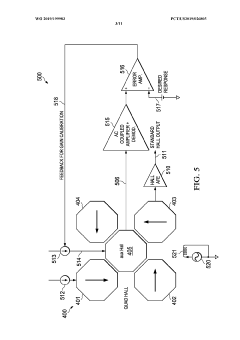

Calibration of hall device sensitivity using auxiliary hall device

PatentWO2019199983A1

Innovation

- A closed-loop calibration technique using an auxiliary Hall effect sensor with a high-frequency AC calibration signal out of the primary sensor's bandwidth, decoupling the calibration signal from the measurement signal, and employing a single large coil to reduce heating effects, while maintaining sensitivity stability across temperature and stress variations.

Environmental Factors Affecting Hall Sensor Performance

Hall Effect sensors, while robust and versatile, are significantly influenced by various environmental factors that can compromise their measurement accuracy and reliability. Temperature fluctuations represent the most critical environmental challenge, causing both zero-point drift and sensitivity variations. As ambient temperature changes, the sensor's output voltage shifts even when the magnetic field remains constant, introducing measurement errors that can range from 0.02% to 0.1% per degree Celsius depending on sensor quality and compensation techniques.

Humidity and moisture exposure constitute another significant concern, particularly in automotive and outdoor applications. Water ingress can alter the electrical properties of semiconductor materials and create parasitic current paths, leading to signal degradation and potential long-term reliability issues. Advanced encapsulation techniques and conformal coatings have become standard protective measures, though they add complexity to sensor design and manufacturing processes.

Mechanical stress and vibration effects cannot be overlooked, as they can induce piezoelectric responses in semiconductor materials that manifest as noise in the Hall voltage output. In high-vibration environments such as industrial machinery or automotive engine compartments, these mechanical factors can generate measurement errors exceeding 2% of full scale without proper mechanical isolation and signal filtering algorithms.

Electromagnetic interference (EMI) presents a particularly challenging environmental factor, as Hall sensors operate by detecting magnetic fields and thus are inherently susceptible to external magnetic disturbances. Nearby power lines, motors, transformers, and even Earth's geomagnetic field can introduce measurement errors. Modern signal correction algorithms employ adaptive filtering techniques and differential sensing arrangements to distinguish between the target magnetic field and environmental magnetic noise.

Atmospheric pressure variations, while less commonly addressed, can affect sensor performance in aerospace and altitude-sensitive applications. Changes in pressure can induce mechanical stress on the sensor package, altering the semiconductor's electrical properties and causing measurement drift. This effect becomes particularly relevant in applications spanning wide altitude ranges or pressure-variable environments.

Aging and radiation exposure represent longer-term environmental challenges. Semiconductor materials in Hall sensors gradually degrade over time, particularly when exposed to elevated temperatures or radiation. This degradation manifests as sensitivity reduction and increased offset drift, necessitating periodic recalibration or compensation through predictive algorithms that account for aging effects based on operational history and environmental exposure.

Humidity and moisture exposure constitute another significant concern, particularly in automotive and outdoor applications. Water ingress can alter the electrical properties of semiconductor materials and create parasitic current paths, leading to signal degradation and potential long-term reliability issues. Advanced encapsulation techniques and conformal coatings have become standard protective measures, though they add complexity to sensor design and manufacturing processes.

Mechanical stress and vibration effects cannot be overlooked, as they can induce piezoelectric responses in semiconductor materials that manifest as noise in the Hall voltage output. In high-vibration environments such as industrial machinery or automotive engine compartments, these mechanical factors can generate measurement errors exceeding 2% of full scale without proper mechanical isolation and signal filtering algorithms.

Electromagnetic interference (EMI) presents a particularly challenging environmental factor, as Hall sensors operate by detecting magnetic fields and thus are inherently susceptible to external magnetic disturbances. Nearby power lines, motors, transformers, and even Earth's geomagnetic field can introduce measurement errors. Modern signal correction algorithms employ adaptive filtering techniques and differential sensing arrangements to distinguish between the target magnetic field and environmental magnetic noise.

Atmospheric pressure variations, while less commonly addressed, can affect sensor performance in aerospace and altitude-sensitive applications. Changes in pressure can induce mechanical stress on the sensor package, altering the semiconductor's electrical properties and causing measurement drift. This effect becomes particularly relevant in applications spanning wide altitude ranges or pressure-variable environments.

Aging and radiation exposure represent longer-term environmental challenges. Semiconductor materials in Hall sensors gradually degrade over time, particularly when exposed to elevated temperatures or radiation. This degradation manifests as sensitivity reduction and increased offset drift, necessitating periodic recalibration or compensation through predictive algorithms that account for aging effects based on operational history and environmental exposure.

Integration Strategies with IoT and Smart Systems

The integration of Advanced Hall Effect Sensor Algorithms for Signal Correction with IoT and smart systems represents a significant technological convergence that enhances both sensing capabilities and connected intelligence. Modern IoT architectures benefit substantially from the improved accuracy and reliability that advanced Hall effect sensor algorithms provide, particularly in environments with electromagnetic interference or temperature fluctuations.

These integration strategies typically follow a multi-layered approach. At the hardware level, miniaturized Hall effect sensors with embedded signal correction algorithms can be directly incorporated into IoT edge devices, enabling precise magnetic field measurements while maintaining low power consumption profiles essential for battery-operated IoT deployments. The signal processing can occur at the sensor level before transmission, reducing bandwidth requirements and extending device operational life.

Data communication protocols optimized for sensor-corrected data streams form another critical integration component. Lightweight protocols such as MQTT and CoAP have been adapted to efficiently transmit the high-fidelity data generated by advanced Hall effect sensors, while maintaining the real-time responsiveness required in many smart system applications. These protocols incorporate error-checking mechanisms that complement the signal correction algorithms, ensuring end-to-end data integrity.

Cloud-based analytics platforms represent the third integration layer, where corrected Hall effect sensor data can be aggregated with other sensor inputs to enable comprehensive system monitoring and predictive maintenance capabilities. Machine learning algorithms deployed in the cloud can further refine the signal correction techniques based on historical data patterns, creating a feedback loop that continuously improves sensor performance across distributed IoT networks.

Industry-specific integration frameworks have emerged to address vertical market requirements. In automotive IoT systems, Hall effect sensors with advanced correction algorithms are being integrated into vehicle diagnostic networks, providing precise monitoring of rotational components while filtering out road-induced electromagnetic noise. Similarly, in industrial IoT environments, these sensors are being incorporated into manufacturing execution systems to enable high-precision process control and equipment health monitoring.

Security considerations remain paramount in these integration strategies. Encrypted communication channels protect the integrity of sensor data, while authentication mechanisms ensure that only authorized systems can access or modify the signal correction parameters. This security-by-design approach is essential as Hall effect sensors increasingly monitor critical infrastructure components within smart city and industrial automation contexts.

The future integration roadmap points toward edge computing architectures where signal correction algorithms will operate within dedicated neural processing units, enabling even more sophisticated real-time corrections while maintaining energy efficiency. This evolution will further cement the role of advanced Hall effect sensors as foundational components in next-generation IoT and smart systems.

These integration strategies typically follow a multi-layered approach. At the hardware level, miniaturized Hall effect sensors with embedded signal correction algorithms can be directly incorporated into IoT edge devices, enabling precise magnetic field measurements while maintaining low power consumption profiles essential for battery-operated IoT deployments. The signal processing can occur at the sensor level before transmission, reducing bandwidth requirements and extending device operational life.

Data communication protocols optimized for sensor-corrected data streams form another critical integration component. Lightweight protocols such as MQTT and CoAP have been adapted to efficiently transmit the high-fidelity data generated by advanced Hall effect sensors, while maintaining the real-time responsiveness required in many smart system applications. These protocols incorporate error-checking mechanisms that complement the signal correction algorithms, ensuring end-to-end data integrity.

Cloud-based analytics platforms represent the third integration layer, where corrected Hall effect sensor data can be aggregated with other sensor inputs to enable comprehensive system monitoring and predictive maintenance capabilities. Machine learning algorithms deployed in the cloud can further refine the signal correction techniques based on historical data patterns, creating a feedback loop that continuously improves sensor performance across distributed IoT networks.

Industry-specific integration frameworks have emerged to address vertical market requirements. In automotive IoT systems, Hall effect sensors with advanced correction algorithms are being integrated into vehicle diagnostic networks, providing precise monitoring of rotational components while filtering out road-induced electromagnetic noise. Similarly, in industrial IoT environments, these sensors are being incorporated into manufacturing execution systems to enable high-precision process control and equipment health monitoring.

Security considerations remain paramount in these integration strategies. Encrypted communication channels protect the integrity of sensor data, while authentication mechanisms ensure that only authorized systems can access or modify the signal correction parameters. This security-by-design approach is essential as Hall effect sensors increasingly monitor critical infrastructure components within smart city and industrial automation contexts.

The future integration roadmap points toward edge computing architectures where signal correction algorithms will operate within dedicated neural processing units, enabling even more sophisticated real-time corrections while maintaining energy efficiency. This evolution will further cement the role of advanced Hall effect sensors as foundational components in next-generation IoT and smart systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!