Improving Hall Effect Sensor Responsiveness in Automated Control

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly from their initial application in measuring magnetic fields to becoming integral components in modern automated control systems. The technology leverages the Hall Effect principle, wherein a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has enabled the development of sensors capable of non-contact detection and measurement of magnetic fields, position, displacement, and current.

The evolution of Hall Effect sensors has been marked by several significant advancements. Early implementations in the mid-20th century were primarily limited to laboratory applications due to their low sensitivity and high susceptibility to temperature variations. The 1970s witnessed a breakthrough with the integration of Hall Effect elements into silicon-based integrated circuits, dramatically improving reliability and reducing manufacturing costs. By the 1990s, the introduction of BiCMOS and CMOS technologies further enhanced sensor performance, enabling higher sensitivity and better temperature stability.

In recent years, the miniaturization trend has led to the development of micro-Hall sensors with dimensions in the micrometer range, significantly expanding their application scope. Concurrently, advancements in signal processing techniques have improved sensor accuracy and responsiveness, making them suitable for high-precision automated control systems.

The current technological landscape presents both opportunities and challenges. While Hall Effect sensors offer advantages such as contactless operation, durability, and compatibility with harsh environments, they still face limitations in terms of response time, particularly in high-speed automated control applications. The typical response time of conventional Hall Effect sensors ranges from 1 to 10 milliseconds, which becomes a bottleneck in systems requiring real-time feedback with sub-millisecond precision.

The primary objective of improving Hall Effect sensor responsiveness is to achieve response times below 0.5 milliseconds while maintaining high accuracy and reliability. This enhancement would enable their application in next-generation automated control systems, including high-frequency power electronics, ultra-precise robotics, and advanced automotive safety systems.

Secondary objectives include enhancing signal-to-noise ratio to improve measurement accuracy in electromagnetically noisy environments, reducing temperature drift to ensure consistent performance across wide operating temperature ranges, and developing more energy-efficient designs to support battery-powered and energy-harvesting applications. Additionally, there is a growing need for sensors capable of measuring multi-dimensional magnetic fields simultaneously, which would enable more sophisticated control algorithms and system designs.

The evolution of Hall Effect sensors has been marked by several significant advancements. Early implementations in the mid-20th century were primarily limited to laboratory applications due to their low sensitivity and high susceptibility to temperature variations. The 1970s witnessed a breakthrough with the integration of Hall Effect elements into silicon-based integrated circuits, dramatically improving reliability and reducing manufacturing costs. By the 1990s, the introduction of BiCMOS and CMOS technologies further enhanced sensor performance, enabling higher sensitivity and better temperature stability.

In recent years, the miniaturization trend has led to the development of micro-Hall sensors with dimensions in the micrometer range, significantly expanding their application scope. Concurrently, advancements in signal processing techniques have improved sensor accuracy and responsiveness, making them suitable for high-precision automated control systems.

The current technological landscape presents both opportunities and challenges. While Hall Effect sensors offer advantages such as contactless operation, durability, and compatibility with harsh environments, they still face limitations in terms of response time, particularly in high-speed automated control applications. The typical response time of conventional Hall Effect sensors ranges from 1 to 10 milliseconds, which becomes a bottleneck in systems requiring real-time feedback with sub-millisecond precision.

The primary objective of improving Hall Effect sensor responsiveness is to achieve response times below 0.5 milliseconds while maintaining high accuracy and reliability. This enhancement would enable their application in next-generation automated control systems, including high-frequency power electronics, ultra-precise robotics, and advanced automotive safety systems.

Secondary objectives include enhancing signal-to-noise ratio to improve measurement accuracy in electromagnetically noisy environments, reducing temperature drift to ensure consistent performance across wide operating temperature ranges, and developing more energy-efficient designs to support battery-powered and energy-harvesting applications. Additionally, there is a growing need for sensors capable of measuring multi-dimensional magnetic fields simultaneously, which would enable more sophisticated control algorithms and system designs.

Market Demand Analysis for Responsive Control Systems

The global market for responsive control systems has witnessed substantial growth in recent years, driven primarily by the increasing automation across various industries. The demand for Hall Effect sensors with enhanced responsiveness is particularly pronounced in automotive, industrial automation, consumer electronics, and aerospace sectors. These industries require precise, reliable, and fast-responding sensors to enable advanced control systems that can operate in real-time environments.

In the automotive industry, the transition toward electric and autonomous vehicles has created a significant demand surge for responsive Hall Effect sensors. These sensors are critical components in electric motor control systems, battery management systems, and various driver assistance features. Market research indicates that the automotive sensor market is expected to grow at a compound annual growth rate of 8.3% through 2028, with Hall Effect sensors representing a substantial portion of this growth.

Industrial automation represents another major market driver, as manufacturers increasingly implement Industry 4.0 technologies. The need for precise position sensing, current monitoring, and speed detection in automated manufacturing environments has elevated the importance of responsive Hall Effect sensors. Factory automation systems require sensors that can provide accurate feedback with minimal latency to ensure production efficiency and safety.

Consumer electronics manufacturers are also significant consumers of Hall Effect sensors, particularly for applications requiring position detection and proximity sensing. The growing complexity of smartphones, tablets, and wearable devices demands sensors with higher responsiveness and lower power consumption. This segment shows particular sensitivity to size constraints and cost considerations while maintaining performance requirements.

The aerospace and defense sectors present a specialized market for high-performance Hall Effect sensors that can operate reliably in extreme conditions. These applications typically demand sensors with exceptional responsiveness, accuracy, and durability, often justifying premium pricing for superior technical specifications.

Market analysis reveals that end-users across industries are increasingly prioritizing three key performance metrics in Hall Effect sensors: response time, sensitivity, and signal-to-noise ratio. The demand for sensors with response times below 1 microsecond has grown substantially, particularly in applications involving high-speed motion control and safety-critical systems.

Regional market assessment shows that Asia-Pacific currently leads in terms of volume consumption, driven by the region's manufacturing strength in electronics and automotive components. However, North America and Europe maintain leadership in high-performance applications requiring advanced sensor technologies, particularly in aerospace, medical devices, and specialized industrial equipment.

In the automotive industry, the transition toward electric and autonomous vehicles has created a significant demand surge for responsive Hall Effect sensors. These sensors are critical components in electric motor control systems, battery management systems, and various driver assistance features. Market research indicates that the automotive sensor market is expected to grow at a compound annual growth rate of 8.3% through 2028, with Hall Effect sensors representing a substantial portion of this growth.

Industrial automation represents another major market driver, as manufacturers increasingly implement Industry 4.0 technologies. The need for precise position sensing, current monitoring, and speed detection in automated manufacturing environments has elevated the importance of responsive Hall Effect sensors. Factory automation systems require sensors that can provide accurate feedback with minimal latency to ensure production efficiency and safety.

Consumer electronics manufacturers are also significant consumers of Hall Effect sensors, particularly for applications requiring position detection and proximity sensing. The growing complexity of smartphones, tablets, and wearable devices demands sensors with higher responsiveness and lower power consumption. This segment shows particular sensitivity to size constraints and cost considerations while maintaining performance requirements.

The aerospace and defense sectors present a specialized market for high-performance Hall Effect sensors that can operate reliably in extreme conditions. These applications typically demand sensors with exceptional responsiveness, accuracy, and durability, often justifying premium pricing for superior technical specifications.

Market analysis reveals that end-users across industries are increasingly prioritizing three key performance metrics in Hall Effect sensors: response time, sensitivity, and signal-to-noise ratio. The demand for sensors with response times below 1 microsecond has grown substantially, particularly in applications involving high-speed motion control and safety-critical systems.

Regional market assessment shows that Asia-Pacific currently leads in terms of volume consumption, driven by the region's manufacturing strength in electronics and automotive components. However, North America and Europe maintain leadership in high-performance applications requiring advanced sensor technologies, particularly in aerospace, medical devices, and specialized industrial equipment.

Current Limitations and Technical Challenges in Hall Sensors

Hall Effect sensors, while widely deployed in automated control systems, face several significant limitations that impede their optimal performance in high-precision applications. The primary challenge lies in their response time, which typically ranges from 1-10 microseconds. This latency becomes problematic in ultra-high-speed control systems where nanosecond-level responsiveness is increasingly required, particularly in advanced manufacturing robotics and aerospace applications.

Temperature sensitivity represents another critical limitation, as Hall sensors exhibit drift characteristics that can reach up to ±0.1% per degree Celsius. This temperature dependence necessitates complex compensation algorithms that add computational overhead and can still leave residual errors in environments with rapid temperature fluctuations, such as in automotive engine compartments or industrial processing equipment.

Signal-to-noise ratio (SNR) degradation occurs particularly in low magnetic field detection scenarios, where electrical noise can overwhelm the small Hall voltage. Current sensor designs struggle to maintain acceptable SNR below 50 gauss without significant signal conditioning, limiting their application in subtle magnetic field detection required for certain medical devices and precision instruments.

Power consumption remains a constraint for battery-operated and IoT applications. Standard Hall Effect sensors typically draw 2-5 mA during continuous operation, which becomes prohibitive for long-term deployment in remote sensing applications. While power-saving modes exist, they inevitably compromise sampling rates and response times.

Miniaturization efforts face fundamental physical barriers as reducing the sensing element size decreases the effective Hall voltage, requiring more sensitive amplification stages that introduce additional noise. The current minimum practical size of approximately 1mm² for the complete sensing package limits integration into microelectromechanical systems (MEMS) and nanoscale applications.

Cross-axis sensitivity presents accuracy challenges, with typical sensors exhibiting 1-3% error from orthogonal magnetic fields. This becomes particularly problematic in multi-axis motion control systems where precise directional discrimination is essential.

Manufacturing variability introduces calibration requirements, as Hall coefficient variations between production batches can reach ±5%. This necessitates individual calibration procedures that increase production costs and complexity, especially for high-precision applications requiring better than 0.1% accuracy.

Integration with digital systems presents interface challenges, as the analog output of Hall sensors requires conversion and processing that can introduce additional latency and quantization errors, particularly problematic in real-time control systems operating at high frequencies.

Temperature sensitivity represents another critical limitation, as Hall sensors exhibit drift characteristics that can reach up to ±0.1% per degree Celsius. This temperature dependence necessitates complex compensation algorithms that add computational overhead and can still leave residual errors in environments with rapid temperature fluctuations, such as in automotive engine compartments or industrial processing equipment.

Signal-to-noise ratio (SNR) degradation occurs particularly in low magnetic field detection scenarios, where electrical noise can overwhelm the small Hall voltage. Current sensor designs struggle to maintain acceptable SNR below 50 gauss without significant signal conditioning, limiting their application in subtle magnetic field detection required for certain medical devices and precision instruments.

Power consumption remains a constraint for battery-operated and IoT applications. Standard Hall Effect sensors typically draw 2-5 mA during continuous operation, which becomes prohibitive for long-term deployment in remote sensing applications. While power-saving modes exist, they inevitably compromise sampling rates and response times.

Miniaturization efforts face fundamental physical barriers as reducing the sensing element size decreases the effective Hall voltage, requiring more sensitive amplification stages that introduce additional noise. The current minimum practical size of approximately 1mm² for the complete sensing package limits integration into microelectromechanical systems (MEMS) and nanoscale applications.

Cross-axis sensitivity presents accuracy challenges, with typical sensors exhibiting 1-3% error from orthogonal magnetic fields. This becomes particularly problematic in multi-axis motion control systems where precise directional discrimination is essential.

Manufacturing variability introduces calibration requirements, as Hall coefficient variations between production batches can reach ±5%. This necessitates individual calibration procedures that increase production costs and complexity, especially for high-precision applications requiring better than 0.1% accuracy.

Integration with digital systems presents interface challenges, as the analog output of Hall sensors requires conversion and processing that can introduce additional latency and quantization errors, particularly problematic in real-time control systems operating at high frequencies.

Current Solutions for Hall Sensor Responsiveness Enhancement

01 Magnetic field sensitivity enhancement techniques

Various techniques can be employed to enhance the sensitivity of Hall effect sensors to magnetic fields. These include optimizing the semiconductor material properties, implementing flux concentrators, and utilizing specialized geometries. Enhanced sensitivity allows for detection of weaker magnetic fields and improves the overall responsiveness of the sensor to magnetic field changes, making them more suitable for precision applications.- Enhancing Hall sensor sensitivity and response time: Various techniques can be employed to enhance the sensitivity and response time of Hall effect sensors. These include optimizing the semiconductor material properties, reducing the sensor's thickness, and implementing specialized circuit designs. Enhanced sensitivity allows for detection of weaker magnetic fields, while improved response time enables faster measurement of changing magnetic fields, making these sensors suitable for high-speed applications.

- Hall sensor design configurations for improved responsiveness: Specific design configurations can significantly improve Hall effect sensor responsiveness. These include vertical Hall sensors, integrated flux concentrators, and optimized geometry of sensing elements. Such designs can enhance the magnetic field concentration at the sensing element, resulting in better signal-to-noise ratios and more responsive detection of magnetic field changes across various operating conditions.

- Signal processing techniques for Hall sensors: Advanced signal processing techniques can significantly improve Hall effect sensor responsiveness. These include chopper stabilization, dynamic offset cancellation, and specialized amplification circuits. Such techniques help reduce noise, eliminate drift, and enhance the sensor's ability to detect small magnetic field changes, resulting in more accurate and responsive measurements even in challenging environments.

- Temperature compensation for Hall sensors: Temperature variations can significantly affect Hall sensor responsiveness. Implementing temperature compensation techniques, such as integrated temperature sensors, calibration algorithms, and specialized biasing circuits, helps maintain consistent sensor performance across a wide temperature range. This ensures reliable operation and consistent responsiveness regardless of environmental temperature fluctuations.

- Packaging and integration solutions for Hall sensors: Advanced packaging and integration solutions can enhance Hall sensor responsiveness by optimizing the positioning of sensing elements relative to magnetic sources. These include flip-chip packaging, system-in-package solutions, and specialized mounting techniques. Such approaches minimize interference, reduce parasitic effects, and improve magnetic coupling, resulting in more responsive and accurate sensor performance in practical applications.

02 Response time improvement methods

Methods to improve the response time of Hall effect sensors focus on reducing parasitic capacitances, optimizing circuit design, and implementing advanced signal processing techniques. Faster response times enable real-time monitoring of rapidly changing magnetic fields, which is crucial for applications requiring immediate feedback such as automotive safety systems and high-speed industrial controls.Expand Specific Solutions03 Temperature compensation for stable responsiveness

Temperature compensation techniques are implemented to maintain consistent Hall effect sensor responsiveness across varying environmental conditions. These include integrated temperature sensors, specialized biasing circuits, and materials with low temperature coefficients. Such compensation ensures reliable sensor performance in automotive, industrial, and outdoor applications where temperature fluctuations are common.Expand Specific Solutions04 Integrated circuit design for improved Hall sensor performance

Advanced integrated circuit designs incorporate specialized amplification stages, noise reduction techniques, and signal conditioning to enhance Hall effect sensor responsiveness. These designs often include chopper stabilization, differential sensing architectures, and custom CMOS processes optimized for magnetic sensing applications. The integration of processing capabilities directly with the sensing element reduces signal degradation and improves overall sensor performance.Expand Specific Solutions05 Novel materials and structures for enhanced responsiveness

Research into novel materials and structural designs has led to significant improvements in Hall effect sensor responsiveness. These innovations include thin-film semiconductor materials, quantum well structures, and nanoscale sensing elements. By leveraging these advanced materials and structures, sensors can achieve higher sensitivity, better signal-to-noise ratios, and improved magnetic field resolution, enabling applications in increasingly demanding environments.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Hall Effect Sensor responsiveness market is currently in a growth phase, with increasing demand driven by automation and IoT applications. The market is projected to expand significantly as industries adopt more sophisticated control systems. Technologically, the field shows varying maturity levels, with established players like Honeywell International, Texas Instruments, and Allegro MicroSystems leading innovation through advanced semiconductor processes and integrated solutions. Companies such as Bosch, STMicroelectronics, and TDK Electronics are advancing miniaturization and sensitivity improvements, while automotive specialists like Valeo and Brose are focusing on application-specific optimizations. Asian manufacturers including Asahi Kasei Microdevices and Hangzhou Sitai are rapidly closing technological gaps, creating a competitive global landscape with differentiation occurring through response time, temperature stability, and integration capabilities.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensor solutions with integrated signal conditioning circuits that significantly improve responsiveness in automated control systems. Their SmartSense technology incorporates temperature compensation algorithms and digital filtering to enhance signal stability and reduce noise interference[1]. The company's latest generation of Hall sensors features programmable sensitivity ranges and response times as low as 1.5 microseconds, enabling real-time feedback in high-speed control applications[3]. Honeywell's integrated approach combines the Hall sensing element with advanced ASIC processing on a single chip, allowing for customizable threshold detection and hysteresis settings that optimize performance for specific industrial environments[5]. Their sensors also incorporate fault detection capabilities and diagnostics that ensure system reliability in critical applications.

Strengths: Superior temperature stability across wide operating ranges (-40°C to 150°C); excellent immunity to electromagnetic interference; highly customizable response characteristics. Weaknesses: Higher cost compared to basic Hall sensors; requires more complex integration; power consumption may be higher than simpler alternatives in battery-operated systems.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has pioneered chopper-stabilized Hall effect sensors that dramatically improve responsiveness in automated control systems. Their patented technology employs dynamic offset cancellation techniques that reduce the effects of stress, temperature drift, and aging on sensor performance[2]. Allegro's A1369 series incorporates proprietary BiCMOS wafer fabrication process that integrates both the Hall element and signal processing circuitry, achieving response times under 3 microseconds with high accuracy[4]. The company's sensors feature programmable bandwidth settings (20-20kHz) allowing system designers to optimize between speed and noise immunity based on application requirements[6]. Allegro has also developed advanced packaging solutions that improve thermal performance and mechanical stress resistance, critical factors in maintaining consistent sensor response in harsh industrial environments.

Strengths: Industry-leading sensitivity stability over temperature and lifetime; excellent signal-to-noise ratio; robust protection against mechanical stress effects. Weaknesses: More complex calibration requirements; higher initial implementation cost; limited flexibility for extremely specialized applications requiring custom sensing characteristics.

Core Technical Innovations in Hall Effect Sensing

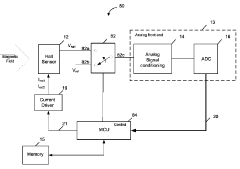

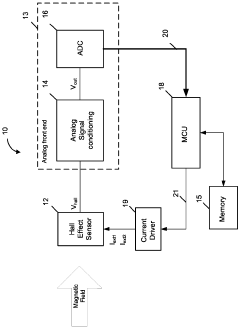

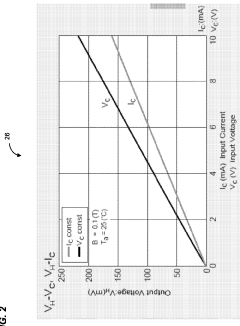

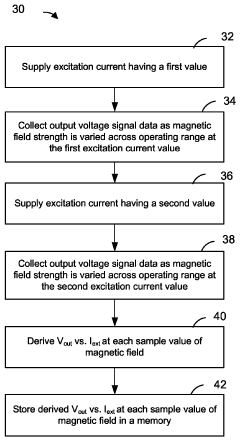

Hall effect sensor system with diagnostic capabilities

PatentActiveCA2921687C

Innovation

- A method and system that utilize a microcontroller to supply excitation current at different values to the hall effect sensor, obtain corresponding voltage measurements, and verify the sensor's operation based on calibration data, detecting faults in the analog front end and automatically setting the system to a safe mode if measurements are invalid.

Method for generating control signals for managing the operation of a synchronous motor, control device and actuator

PatentActiveEP3167543A2

Innovation

- A method that acquires status information from Hall effect sensors, estimates complementary information to characterize virtual sensor evolution, and generates control signals based on the motor's operating stage, optimizing torque, thermal performance, and efficiency, even with fewer sensors than motor phases, by adjusting electrical phase shifts and time intervals between sensor state changes.

Integration Challenges in Automated Control Systems

The integration of Hall Effect sensors into automated control systems presents several significant challenges that require careful consideration during system design and implementation. The primary obstacle lies in achieving seamless communication between these magnetic field sensors and the broader control architecture. Interface compatibility issues frequently emerge when Hall Effect sensors, which typically output analog signals, must interact with digital control systems. This signal conversion process introduces latency and potential data loss, compromising the responsiveness that is critical for real-time control applications.

Environmental factors pose another substantial integration challenge. Hall Effect sensors exhibit sensitivity to temperature fluctuations, electromagnetic interference (EMI), and mechanical stress, all of which are commonly present in industrial automation environments. These external factors can significantly degrade sensor performance and reliability, necessitating robust shielding solutions and compensation algorithms to maintain accuracy under varying conditions.

Power management represents a critical consideration, particularly in wireless or battery-operated automated control systems. Hall Effect sensors require consistent power supply to maintain optimal responsiveness, yet must operate within the energy constraints of the overall system. Balancing power consumption with performance requirements often necessitates sophisticated power management strategies and circuit design optimizations.

Calibration and drift compensation present ongoing integration challenges throughout the system lifecycle. Hall Effect sensors typically require initial calibration during installation and periodic recalibration to account for drift over time. Implementing effective auto-calibration routines within the control system architecture adds complexity but remains essential for maintaining long-term measurement accuracy and system reliability.

Spatial constraints within automated control systems often limit sensor placement options, potentially forcing compromises in positioning that affect measurement accuracy. The physical integration must account for magnetic field orientation requirements while ensuring the sensor remains protected from mechanical damage and environmental exposure. These physical integration challenges frequently necessitate custom mounting solutions and housing designs.

Software integration challenges include developing efficient algorithms for signal processing, implementing appropriate filtering techniques to reduce noise, and creating robust error detection mechanisms. The control system must be capable of interpreting sensor data correctly and responding appropriately to both normal operation signals and fault conditions, requiring sophisticated software architecture and thorough testing protocols.

Addressing these integration challenges requires a multidisciplinary approach combining expertise in electronics, mechanical engineering, software development, and systems integration. Successful implementation demands careful consideration of the specific application requirements and environmental conditions to select appropriate sensor variants and integration strategies.

Environmental factors pose another substantial integration challenge. Hall Effect sensors exhibit sensitivity to temperature fluctuations, electromagnetic interference (EMI), and mechanical stress, all of which are commonly present in industrial automation environments. These external factors can significantly degrade sensor performance and reliability, necessitating robust shielding solutions and compensation algorithms to maintain accuracy under varying conditions.

Power management represents a critical consideration, particularly in wireless or battery-operated automated control systems. Hall Effect sensors require consistent power supply to maintain optimal responsiveness, yet must operate within the energy constraints of the overall system. Balancing power consumption with performance requirements often necessitates sophisticated power management strategies and circuit design optimizations.

Calibration and drift compensation present ongoing integration challenges throughout the system lifecycle. Hall Effect sensors typically require initial calibration during installation and periodic recalibration to account for drift over time. Implementing effective auto-calibration routines within the control system architecture adds complexity but remains essential for maintaining long-term measurement accuracy and system reliability.

Spatial constraints within automated control systems often limit sensor placement options, potentially forcing compromises in positioning that affect measurement accuracy. The physical integration must account for magnetic field orientation requirements while ensuring the sensor remains protected from mechanical damage and environmental exposure. These physical integration challenges frequently necessitate custom mounting solutions and housing designs.

Software integration challenges include developing efficient algorithms for signal processing, implementing appropriate filtering techniques to reduce noise, and creating robust error detection mechanisms. The control system must be capable of interpreting sensor data correctly and responding appropriately to both normal operation signals and fault conditions, requiring sophisticated software architecture and thorough testing protocols.

Addressing these integration challenges requires a multidisciplinary approach combining expertise in electronics, mechanical engineering, software development, and systems integration. Successful implementation demands careful consideration of the specific application requirements and environmental conditions to select appropriate sensor variants and integration strategies.

Environmental Factors Affecting Hall Sensor Performance

Hall Effect sensors, while robust and reliable in many applications, are significantly influenced by various environmental factors that can alter their performance characteristics. Temperature variations represent one of the most critical environmental challenges, as they directly affect the sensor's magnetic sensitivity and offset voltage. In extreme temperature conditions, both high and low, Hall sensors may exhibit drift in their output signals, leading to measurement inaccuracies in automated control systems. Research indicates that for every 10°C change in temperature, sensitivity can vary by up to 0.1%, which becomes particularly problematic in precision applications.

Humidity and moisture exposure constitute another significant environmental concern. When moisture penetrates the sensor housing, it can cause corrosion of internal components and create parasitic current paths that distort the Hall voltage. In industrial environments where condensation is common, protective enclosures with appropriate IP ratings become essential to maintain sensor integrity and measurement reliability.

Electromagnetic interference (EMI) from nearby power lines, motors, or other electronic equipment can severely compromise Hall sensor performance. The interference manifests as noise in the output signal, potentially masking the actual magnetic field measurements. Studies have shown that unshielded Hall sensors operating near high-current conductors can experience signal-to-noise ratio degradation of up to 20dB, necessitating proper shielding techniques and signal filtering algorithms.

Mechanical stress and vibration represent additional environmental challenges that affect sensor stability. When Hall Effect sensors are subjected to mechanical deformation due to mounting pressure or operational vibration, the semiconductor material's properties can change, altering the Hall coefficient. This phenomenon, known as the piezoresistive effect, can introduce measurement errors of up to 2% under severe mechanical stress conditions.

Atmospheric pressure variations, while less commonly considered, can impact hermetically sealed sensors by creating pressure differentials that physically stress the sensor package. In aerospace applications where rapid pressure changes occur, this can lead to temporary or permanent shifts in calibration parameters.

Exposure to radiation in specialized environments such as nuclear facilities or space applications degrades semiconductor performance over time. Radiation-induced lattice defects in the Hall element can permanently alter its electrical characteristics, with research indicating sensitivity reductions of up to 15% after exposure to 100 kGy of gamma radiation.

Dust and particulate contamination present challenges particularly in industrial environments, where accumulation on sensor surfaces can affect thermal dissipation properties and, in extreme cases, interfere with moving parts in sensor assemblies that incorporate Hall elements for position detection.

Humidity and moisture exposure constitute another significant environmental concern. When moisture penetrates the sensor housing, it can cause corrosion of internal components and create parasitic current paths that distort the Hall voltage. In industrial environments where condensation is common, protective enclosures with appropriate IP ratings become essential to maintain sensor integrity and measurement reliability.

Electromagnetic interference (EMI) from nearby power lines, motors, or other electronic equipment can severely compromise Hall sensor performance. The interference manifests as noise in the output signal, potentially masking the actual magnetic field measurements. Studies have shown that unshielded Hall sensors operating near high-current conductors can experience signal-to-noise ratio degradation of up to 20dB, necessitating proper shielding techniques and signal filtering algorithms.

Mechanical stress and vibration represent additional environmental challenges that affect sensor stability. When Hall Effect sensors are subjected to mechanical deformation due to mounting pressure or operational vibration, the semiconductor material's properties can change, altering the Hall coefficient. This phenomenon, known as the piezoresistive effect, can introduce measurement errors of up to 2% under severe mechanical stress conditions.

Atmospheric pressure variations, while less commonly considered, can impact hermetically sealed sensors by creating pressure differentials that physically stress the sensor package. In aerospace applications where rapid pressure changes occur, this can lead to temporary or permanent shifts in calibration parameters.

Exposure to radiation in specialized environments such as nuclear facilities or space applications degrades semiconductor performance over time. Radiation-induced lattice defects in the Hall element can permanently alter its electrical characteristics, with research indicating sensitivity reductions of up to 15% after exposure to 100 kGy of gamma radiation.

Dust and particulate contamination present challenges particularly in industrial environments, where accumulation on sensor surfaces can affect thermal dissipation properties and, in extreme cases, interfere with moving parts in sensor assemblies that incorporate Hall elements for position detection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!