How to Implement Hall Effect Sensors in High-Impact Environments

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, represent a cornerstone technology in modern sensing applications. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a perpendicular magnetic field. This fundamental principle has evolved from theoretical physics to practical applications across numerous industries over the past century.

The evolution of Hall Effect sensor technology has been marked by significant advancements in materials science, semiconductor manufacturing, and integrated circuit design. Early implementations utilized simple semiconductor materials, while modern sensors incorporate sophisticated integrated circuits with signal conditioning, temperature compensation, and digital interfaces. This progression has dramatically improved sensitivity, reliability, and functionality while reducing size and power consumption.

In high-impact environments, Hall Effect sensors face unique challenges that have driven specialized development paths. These environments, characterized by extreme temperatures, mechanical shock, vibration, electromagnetic interference, and exposure to corrosive substances, demand robust sensing solutions that maintain accuracy and reliability under adverse conditions. The technology has responded through innovations in packaging, shielding, and circuit design to address these demanding requirements.

The global market for Hall Effect sensors has experienced consistent growth, driven by automotive applications, industrial automation, consumer electronics, and emerging IoT implementations. This growth trajectory is expected to continue as industries increasingly rely on precise, non-contact position and current sensing in challenging operational environments.

The primary technical objectives for implementing Hall Effect sensors in high-impact environments include enhancing mechanical robustness without compromising sensitivity, developing advanced temperature compensation techniques for extreme thermal conditions, improving electromagnetic compatibility for noisy industrial settings, and creating innovative encapsulation methods to protect against moisture, chemicals, and particulates.

Research and development efforts are currently focused on several promising directions: the integration of Hall Effect sensors with MEMS technology for improved shock resistance, the development of new semiconductor materials with superior thermal stability, the implementation of advanced signal processing algorithms for noise rejection, and the creation of self-diagnostic capabilities to ensure operational reliability in critical applications.

The convergence of Hall Effect sensing with emerging technologies such as edge computing and artificial intelligence presents opportunities for predictive maintenance and adaptive calibration, potentially revolutionizing how these sensors perform in the most demanding industrial and automotive applications. These technological objectives align with broader industry trends toward increased reliability, miniaturization, and intelligence in sensing systems.

The evolution of Hall Effect sensor technology has been marked by significant advancements in materials science, semiconductor manufacturing, and integrated circuit design. Early implementations utilized simple semiconductor materials, while modern sensors incorporate sophisticated integrated circuits with signal conditioning, temperature compensation, and digital interfaces. This progression has dramatically improved sensitivity, reliability, and functionality while reducing size and power consumption.

In high-impact environments, Hall Effect sensors face unique challenges that have driven specialized development paths. These environments, characterized by extreme temperatures, mechanical shock, vibration, electromagnetic interference, and exposure to corrosive substances, demand robust sensing solutions that maintain accuracy and reliability under adverse conditions. The technology has responded through innovations in packaging, shielding, and circuit design to address these demanding requirements.

The global market for Hall Effect sensors has experienced consistent growth, driven by automotive applications, industrial automation, consumer electronics, and emerging IoT implementations. This growth trajectory is expected to continue as industries increasingly rely on precise, non-contact position and current sensing in challenging operational environments.

The primary technical objectives for implementing Hall Effect sensors in high-impact environments include enhancing mechanical robustness without compromising sensitivity, developing advanced temperature compensation techniques for extreme thermal conditions, improving electromagnetic compatibility for noisy industrial settings, and creating innovative encapsulation methods to protect against moisture, chemicals, and particulates.

Research and development efforts are currently focused on several promising directions: the integration of Hall Effect sensors with MEMS technology for improved shock resistance, the development of new semiconductor materials with superior thermal stability, the implementation of advanced signal processing algorithms for noise rejection, and the creation of self-diagnostic capabilities to ensure operational reliability in critical applications.

The convergence of Hall Effect sensing with emerging technologies such as edge computing and artificial intelligence presents opportunities for predictive maintenance and adaptive calibration, potentially revolutionizing how these sensors perform in the most demanding industrial and automotive applications. These technological objectives align with broader industry trends toward increased reliability, miniaturization, and intelligence in sensing systems.

Market Demand Analysis for Robust Sensing Solutions

The global market for robust sensing solutions, particularly Hall Effect sensors capable of withstanding high-impact environments, has been experiencing significant growth driven by industrial automation, automotive safety systems, and aerospace applications. Current market research indicates that the industrial sensor market is projected to reach $35.2 billion by 2027, with Hall Effect sensors representing a rapidly expanding segment due to their reliability in extreme conditions.

The automotive industry constitutes the largest demand sector, requiring sensors that can maintain functionality during collision events, vibration, and temperature fluctuations. With the rise of electric vehicles and advanced driver assistance systems (ADAS), the need for impact-resistant position and proximity sensors has increased by approximately 22% annually since 2020. Manufacturers are specifically seeking sensors that can maintain calibration accuracy after repeated mechanical shocks.

Heavy machinery and construction equipment represent another substantial market segment, where sensors must withstand continuous vibration, debris impact, and exposure to harsh environmental elements. Market analysis reveals that equipment downtime due to sensor failure costs this industry over $4.3 billion annually, creating strong demand for more resilient sensing technologies.

The aerospace and defense sectors demonstrate growing requirements for sensors capable of functioning under extreme g-forces, radiation exposure, and rapid temperature variations. These applications typically demand the highest performance specifications and are willing to pay premium prices for guaranteed reliability, with contracts often valued 40-60% higher than comparable industrial applications.

Consumer electronics manufacturers are increasingly incorporating impact-resistant sensors in portable devices, wearables, and IoT applications. This market segment values miniaturization alongside durability, with an estimated 18% compound annual growth rate for ruggedized sensors in consumer applications through 2026.

Regional analysis shows North America and Europe leading in adoption of high-performance sensing solutions, while Asia-Pacific markets demonstrate the fastest growth rate at 25% annually, primarily driven by manufacturing automation in China, South Korea, and India. Emerging economies are showing accelerated adoption as industrial modernization initiatives prioritize equipment reliability and reduced maintenance costs.

Customer requirements analysis reveals five critical factors driving purchasing decisions: impact resistance (rated by g-force tolerance), temperature operating range, moisture/contaminant protection, long-term calibration stability, and mean time between failures (MTBF). Sensors offering documented performance across these metrics command price premiums of 30-45% compared to standard alternatives.

The automotive industry constitutes the largest demand sector, requiring sensors that can maintain functionality during collision events, vibration, and temperature fluctuations. With the rise of electric vehicles and advanced driver assistance systems (ADAS), the need for impact-resistant position and proximity sensors has increased by approximately 22% annually since 2020. Manufacturers are specifically seeking sensors that can maintain calibration accuracy after repeated mechanical shocks.

Heavy machinery and construction equipment represent another substantial market segment, where sensors must withstand continuous vibration, debris impact, and exposure to harsh environmental elements. Market analysis reveals that equipment downtime due to sensor failure costs this industry over $4.3 billion annually, creating strong demand for more resilient sensing technologies.

The aerospace and defense sectors demonstrate growing requirements for sensors capable of functioning under extreme g-forces, radiation exposure, and rapid temperature variations. These applications typically demand the highest performance specifications and are willing to pay premium prices for guaranteed reliability, with contracts often valued 40-60% higher than comparable industrial applications.

Consumer electronics manufacturers are increasingly incorporating impact-resistant sensors in portable devices, wearables, and IoT applications. This market segment values miniaturization alongside durability, with an estimated 18% compound annual growth rate for ruggedized sensors in consumer applications through 2026.

Regional analysis shows North America and Europe leading in adoption of high-performance sensing solutions, while Asia-Pacific markets demonstrate the fastest growth rate at 25% annually, primarily driven by manufacturing automation in China, South Korea, and India. Emerging economies are showing accelerated adoption as industrial modernization initiatives prioritize equipment reliability and reduced maintenance costs.

Customer requirements analysis reveals five critical factors driving purchasing decisions: impact resistance (rated by g-force tolerance), temperature operating range, moisture/contaminant protection, long-term calibration stability, and mean time between failures (MTBF). Sensors offering documented performance across these metrics command price premiums of 30-45% compared to standard alternatives.

Current Challenges in High-Impact Environments

High-impact environments present significant challenges for Hall Effect sensor implementation due to extreme conditions that can compromise sensor functionality and reliability. These environments typically include industrial machinery, automotive applications, aerospace systems, and outdoor equipment where sensors face severe mechanical stress, temperature fluctuations, and electromagnetic interference.

Mechanical durability represents a primary concern as Hall Effect sensors in high-impact settings must withstand repeated shock loads, vibration, and physical impacts. Traditional sensor packaging often fails under these conditions, with connection points and internal components susceptible to fatigue failure. Industry data indicates that approximately 35% of sensor failures in industrial applications stem from mechanical damage, highlighting the critical need for robust encapsulation technologies.

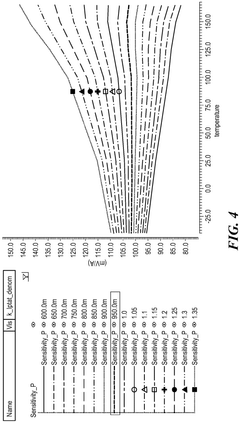

Temperature variation poses another substantial challenge. High-impact environments frequently experience extreme temperature ranges, from sub-zero conditions in outdoor applications to elevated temperatures exceeding 150°C in automotive engine compartments. Standard Hall Effect sensors typically operate reliably between -40°C and 85°C, with performance degradation occurring outside this range. Temperature fluctuations affect magnetic field sensitivity and can lead to signal drift, compromising measurement accuracy.

Electromagnetic interference (EMI) presents a significant obstacle in industrial settings where high-power equipment generates substantial electromagnetic noise. Hall Effect sensors, being inherently sensitive to magnetic fields, can produce false readings when exposed to unintended electromagnetic sources. Current shielding techniques add bulk and cost to sensor implementations, creating design constraints for compact applications.

Power management challenges are particularly acute in battery-operated or energy-efficient systems. While Hall Effect sensors are relatively low-power components, the supporting circuitry required for signal conditioning and processing in noisy environments can significantly increase power consumption. This creates a technical dilemma between implementing robust signal processing and maintaining energy efficiency.

Moisture and chemical exposure represent additional environmental stressors. In automotive and outdoor applications, sensors must resist corrosion from road salt, industrial chemicals, and atmospheric moisture. Current encapsulation methods often trade waterproofing capability for thermal performance, creating vulnerability in applications requiring both attributes.

Integration complexity increases in high-impact environments, as designers must balance protective measures with size constraints and accessibility requirements. The additional components required for protection—such as shock absorbers, thermal management systems, and EMI shields—can significantly increase the overall footprint and installation complexity of sensor systems, limiting their application in space-constrained designs.

Mechanical durability represents a primary concern as Hall Effect sensors in high-impact settings must withstand repeated shock loads, vibration, and physical impacts. Traditional sensor packaging often fails under these conditions, with connection points and internal components susceptible to fatigue failure. Industry data indicates that approximately 35% of sensor failures in industrial applications stem from mechanical damage, highlighting the critical need for robust encapsulation technologies.

Temperature variation poses another substantial challenge. High-impact environments frequently experience extreme temperature ranges, from sub-zero conditions in outdoor applications to elevated temperatures exceeding 150°C in automotive engine compartments. Standard Hall Effect sensors typically operate reliably between -40°C and 85°C, with performance degradation occurring outside this range. Temperature fluctuations affect magnetic field sensitivity and can lead to signal drift, compromising measurement accuracy.

Electromagnetic interference (EMI) presents a significant obstacle in industrial settings where high-power equipment generates substantial electromagnetic noise. Hall Effect sensors, being inherently sensitive to magnetic fields, can produce false readings when exposed to unintended electromagnetic sources. Current shielding techniques add bulk and cost to sensor implementations, creating design constraints for compact applications.

Power management challenges are particularly acute in battery-operated or energy-efficient systems. While Hall Effect sensors are relatively low-power components, the supporting circuitry required for signal conditioning and processing in noisy environments can significantly increase power consumption. This creates a technical dilemma between implementing robust signal processing and maintaining energy efficiency.

Moisture and chemical exposure represent additional environmental stressors. In automotive and outdoor applications, sensors must resist corrosion from road salt, industrial chemicals, and atmospheric moisture. Current encapsulation methods often trade waterproofing capability for thermal performance, creating vulnerability in applications requiring both attributes.

Integration complexity increases in high-impact environments, as designers must balance protective measures with size constraints and accessibility requirements. The additional components required for protection—such as shock absorbers, thermal management systems, and EMI shields—can significantly increase the overall footprint and installation complexity of sensor systems, limiting their application in space-constrained designs.

Current Implementation Approaches and Methodologies

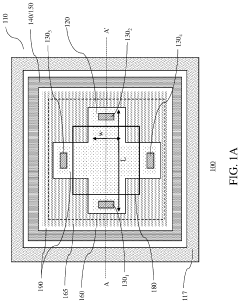

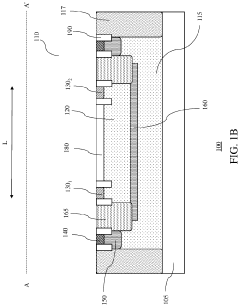

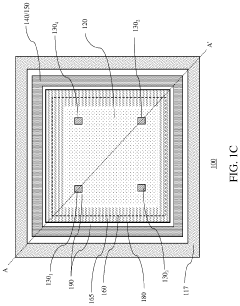

01 Hall Effect Sensor Design and Structure

Hall effect sensors are designed with specific structures to optimize their performance. These designs include various semiconductor materials, packaging configurations, and integration with other components. The structure of the sensor affects its sensitivity, stability, and reliability in detecting magnetic fields. Advanced designs may incorporate features to minimize temperature drift and improve signal-to-noise ratio.- Hall Effect Sensor Design and Structure: Hall effect sensors are designed with specific structures to detect magnetic fields. These designs include various semiconductor materials and configurations to optimize sensitivity and performance. The structure typically includes a thin semiconductor layer with electrical contacts for current input and voltage measurement. Advanced designs may incorporate multiple sensing elements or specialized geometries to enhance detection capabilities.

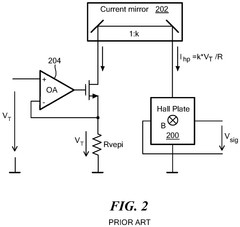

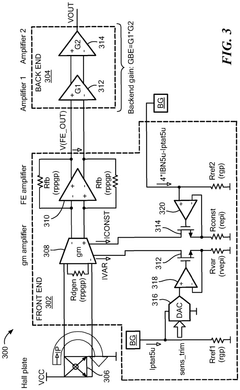

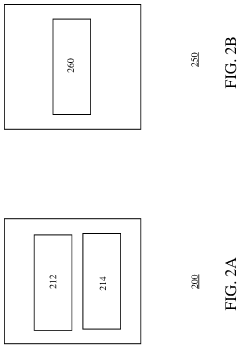

- Magnetic Field Detection and Measurement Techniques: Various techniques are employed in Hall effect sensors to detect and measure magnetic fields accurately. These include signal amplification, noise reduction methods, and calibration techniques to improve sensitivity and reliability. Some sensors use differential measurement approaches to eliminate temperature effects and other environmental variables. Advanced signal processing algorithms may be integrated to enhance measurement precision.

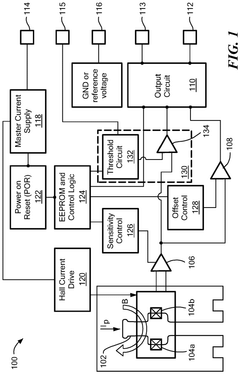

- Integration with Electronic Systems and Applications: Hall effect sensors are integrated into various electronic systems for applications such as position sensing, current measurement, and proximity detection. Integration techniques include embedding sensors in integrated circuits, combining with signal conditioning electronics, and interfacing with microcontrollers. These sensors find applications in automotive systems, industrial equipment, consumer electronics, and medical devices.

- Enhanced Sensitivity and Performance Improvements: Innovations in Hall effect sensors focus on enhancing sensitivity and overall performance. These improvements include developing new semiconductor materials, optimizing geometry, and implementing advanced biasing techniques. Some designs incorporate flux concentrators or magnetic shields to enhance field detection. Temperature compensation methods and specialized packaging are also used to improve stability and reliability across varying environmental conditions.

- Specialized Hall Effect Sensor Configurations: Specialized configurations of Hall effect sensors are designed for specific applications or environments. These include vertical Hall sensors for detecting magnetic fields parallel to the chip surface, multi-axis sensors for measuring fields in multiple directions, and array configurations for spatial field mapping. Some designs incorporate protective features for harsh environments or high-reliability applications such as automotive safety systems or industrial controls.

02 Magnetic Field Detection and Measurement

Hall effect sensors are primarily used for detecting and measuring magnetic fields. They operate based on the Hall effect principle, where a voltage is generated perpendicular to the current flow when a magnetic field is applied. These sensors can measure both static and dynamic magnetic fields with high precision. Applications include position sensing, current measurement, and proximity detection in various industrial and consumer electronics.Expand Specific Solutions03 Integration with Electronic Circuits

Hall effect sensors are often integrated with electronic circuits to enhance their functionality. This integration may include amplifiers, comparators, and digital signal processing components. Integrated circuits can provide temperature compensation, calibration capabilities, and digital output formats. The combination of Hall effect sensors with specialized electronic circuits enables more sophisticated sensing applications and improves overall system performance.Expand Specific Solutions04 Automotive and Industrial Applications

Hall effect sensors are widely used in automotive and industrial applications for position sensing, speed detection, and current monitoring. In automotive systems, they are employed in throttle position sensors, crankshaft position sensors, and ABS systems. Industrial applications include motor control, robotics, and safety systems. These sensors provide reliable non-contact measurement in harsh environments with high temperature variations and vibration.Expand Specific Solutions05 Advanced Sensing Technologies

Recent developments in Hall effect sensor technology include enhanced sensitivity, miniaturization, and integration with other sensing technologies. Advanced sensing technologies may combine Hall effect principles with magnetoresistive effects or incorporate novel materials to improve performance. These innovations enable new applications in consumer electronics, medical devices, and IoT systems. Some advanced sensors also feature programmable sensitivity and built-in diagnostics for improved reliability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Hall Effect sensor market for high-impact environments is currently in a growth phase, with increasing demand across automotive, industrial, and aerospace sectors. The market size is projected to expand significantly due to rising applications in harsh operating conditions. Technologically, established players like Honeywell International, Texas Instruments, and Infineon Technologies lead with mature solutions offering high reliability and precision. Allegro MicroSystems and STMicroelectronics have developed specialized robust sensors with enhanced durability. Emerging companies like Melexis and Senis AG are focusing on innovative designs specifically for extreme environments. The competitive landscape shows a mix of large diversified corporations and specialized sensor manufacturers, with differentiation occurring through temperature range capabilities, shock resistance, and signal processing advancements.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed ruggedized Hall effect sensors specifically designed for high-impact environments, featuring multi-layer protection systems that include specialized packaging with reinforced housings and shock-absorbing materials. Their sensors incorporate advanced temperature compensation circuits that maintain accuracy across extreme temperature ranges (-40°C to +150°C), making them suitable for aerospace and industrial applications. Honeywell's proprietary SMART (Self-Monitoring And Reporting Technology) system continuously monitors sensor health, providing real-time diagnostics and predictive maintenance capabilities. Their sensors utilize specialized signal conditioning circuitry that filters out electromagnetic interference and vibration-induced noise, ensuring reliable operation in electrically noisy environments. Additionally, Honeywell implements redundant sensing elements in critical applications to provide fail-safe operation and enhanced reliability in high-impact scenarios.

Strengths: Superior environmental protection with military-grade durability standards; advanced self-diagnostic capabilities; excellent temperature stability across extreme conditions. Weaknesses: Higher cost compared to standard Hall sensors; larger form factor due to protective elements; higher power consumption requirements for advanced features.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a comprehensive Hall effect sensor solution for high-impact environments through their DRV5x series. These sensors feature integrated circuit designs that combine the Hall sensing element with signal processing on a single chip, reducing vulnerability to mechanical stress. TI's approach includes specialized silicon-on-insulator (SOI) technology that provides inherent isolation from substrate noise and improved immunity to latch-up in high-impact situations. Their sensors incorporate chopper stabilization techniques to minimize offset drift caused by mechanical stress and temperature variations. For high-impact industrial applications, TI implements programmable thresholds and hysteresis settings that can be adjusted in-field to optimize performance under varying environmental conditions. Additionally, their sensors feature built-in diagnostics that can detect anomalies caused by physical impacts and provide appropriate fault signals to the host system.

Strengths: Excellent integration of sensing and processing elements; programmable sensitivity and threshold settings; good noise immunity through advanced signal processing. Weaknesses: Less specialized in extreme ruggedness compared to military-focused competitors; limited redundancy features in standard product offerings.

Critical Patents and Technical Innovations

Hall plate current sensor having stress compensation

PatentPendingEP4571325A1

Innovation

- The implementation of a voltage-driven Hall plate sensor with stress compensation using vertical and lateral 'epi' resistors, along with current ratios and trimming for temperature compensation, to stabilize sensitivity across temperature and stress variations.

Hall effect sensors with tunable sensitivity and/or resistance

PatentActiveUS11047930B2

Innovation

- A Hall effect sensor design with a tunable Hall plate thickness, achieved through adjustable implants in the separation layer and bias voltage applied to the separation layer, allowing for customizable current sensitivity and resistance, enabling high voltage and current sensitivity in the same device.

Material Science Advancements for Sensor Durability

Recent advancements in material science have significantly contributed to enhancing the durability of Hall effect sensors in high-impact environments. Traditional sensor housings made from standard polymers often fail under extreme conditions, leading researchers to develop composite materials that combine the electrical insulation properties of polymers with the mechanical strength of reinforcing agents.

Carbon fiber reinforced polymers (CFRPs) have emerged as a leading solution, offering exceptional strength-to-weight ratios while maintaining the necessary electrical characteristics for sensor operation. These materials can withstand impact forces up to 50% greater than conventional housings while adding minimal bulk to the sensor package.

Ceramic-polymer hybrids represent another breakthrough, utilizing aluminum oxide or silicon nitride matrices with specialized polymer fillers. These materials provide superior thermal stability in environments ranging from -65°C to +200°C, addressing a critical weakness in earlier sensor designs. The ceramic components offer excellent wear resistance while the polymer elements absorb vibration and impact energy.

Nano-engineered coatings have revolutionized surface protection for Hall effect sensors. These ultra-thin layers, often just 10-100 nanometers thick, can be applied to sensor components to provide chemical resistance against corrosive substances commonly found in industrial environments. Particularly promising are diamond-like carbon (DLC) coatings, which combine hardness approaching that of diamond with excellent tribological properties.

Self-healing materials represent the cutting edge of sensor durability research. These innovative compounds contain microcapsules filled with repair agents that are released when the material experiences damage. Early field tests show these materials can extend sensor life by up to 40% in high-vibration applications such as mining equipment and heavy machinery.

Metamaterials engineered at the microscopic level offer customized mechanical properties that can be tailored to specific impact profiles. By creating precisely designed internal structures, these materials can redirect impact forces away from sensitive sensor components. This approach has shown particular promise in automotive applications where sensors must survive both continuous vibration and occasional severe impacts.

The integration of these advanced materials has enabled a new generation of Hall effect sensors capable of operating reliably in environments previously considered too harsh for precision electronic components. As material science continues to evolve, we can expect further improvements in sensor durability, expanding their application potential in extreme industrial settings.

Carbon fiber reinforced polymers (CFRPs) have emerged as a leading solution, offering exceptional strength-to-weight ratios while maintaining the necessary electrical characteristics for sensor operation. These materials can withstand impact forces up to 50% greater than conventional housings while adding minimal bulk to the sensor package.

Ceramic-polymer hybrids represent another breakthrough, utilizing aluminum oxide or silicon nitride matrices with specialized polymer fillers. These materials provide superior thermal stability in environments ranging from -65°C to +200°C, addressing a critical weakness in earlier sensor designs. The ceramic components offer excellent wear resistance while the polymer elements absorb vibration and impact energy.

Nano-engineered coatings have revolutionized surface protection for Hall effect sensors. These ultra-thin layers, often just 10-100 nanometers thick, can be applied to sensor components to provide chemical resistance against corrosive substances commonly found in industrial environments. Particularly promising are diamond-like carbon (DLC) coatings, which combine hardness approaching that of diamond with excellent tribological properties.

Self-healing materials represent the cutting edge of sensor durability research. These innovative compounds contain microcapsules filled with repair agents that are released when the material experiences damage. Early field tests show these materials can extend sensor life by up to 40% in high-vibration applications such as mining equipment and heavy machinery.

Metamaterials engineered at the microscopic level offer customized mechanical properties that can be tailored to specific impact profiles. By creating precisely designed internal structures, these materials can redirect impact forces away from sensitive sensor components. This approach has shown particular promise in automotive applications where sensors must survive both continuous vibration and occasional severe impacts.

The integration of these advanced materials has enabled a new generation of Hall effect sensors capable of operating reliably in environments previously considered too harsh for precision electronic components. As material science continues to evolve, we can expect further improvements in sensor durability, expanding their application potential in extreme industrial settings.

Environmental Testing Standards and Certification Requirements

The implementation of Hall Effect sensors in high-impact environments necessitates adherence to rigorous environmental testing standards and certification requirements. These standards ensure that sensors can withstand extreme conditions while maintaining operational integrity. The International Electrotechnical Commission (IEC) provides several relevant standards, including IEC 60068 for environmental testing of electronic components and IEC 61000 for electromagnetic compatibility. Additionally, MIL-STD-810 offers comprehensive guidelines for military and aerospace applications, covering shock, vibration, temperature extremes, and humidity testing protocols.

For automotive applications, the AEC-Q100 qualification is essential, defining stress test qualifications for integrated circuits in harsh automotive environments. This standard categorizes components into different grades based on operating temperature ranges, with Grade 0 (-40°C to +150°C) being the most stringent for engine compartment applications where Hall Effect sensors are commonly deployed.

The IP (Ingress Protection) rating system, defined by IEC 60529, is crucial for evaluating sensor enclosures. High-impact environments typically require ratings of IP67 or higher, indicating complete dust protection and water immersion resistance. For sensors exposed to corrosive substances, additional certifications like NEMA 4X may be necessary to ensure chemical resistance properties.

Vibration and shock testing standards vary by industry. ISO 16750-3 applies to road vehicles, while RTCA DO-160 governs avionics equipment. These standards specify test procedures including random vibration profiles, mechanical shock parameters, and operational/survival thresholds that Hall Effect sensors must meet to receive certification.

Electromagnetic compatibility (EMC) testing is particularly important for Hall Effect sensors due to their magnetic field sensitivity. Standards like IEC 61000-4-3 for radiated RF immunity and IEC 61000-4-8 for power frequency magnetic field immunity establish minimum performance criteria during exposure to electromagnetic disturbances.

For hazardous environments, additional certifications such as ATEX (Europe) or UL (North America) may be required. These certifications ensure that sensors will not become ignition sources in potentially explosive atmospheres. The specific zone classification (0, 1, or 2) determines the level of protection required.

Reliability testing standards, including JEDEC JESD22 for semiconductor devices, define accelerated life testing methodologies to predict long-term performance. For Hall Effect sensors in high-impact environments, highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) are recommended to identify potential failure modes before field deployment.

Compliance with these standards not only ensures operational reliability but often serves as a prerequisite for market access in regulated industries. Manufacturers must carefully document test results and maintain certification records throughout the product lifecycle to demonstrate ongoing compliance.

For automotive applications, the AEC-Q100 qualification is essential, defining stress test qualifications for integrated circuits in harsh automotive environments. This standard categorizes components into different grades based on operating temperature ranges, with Grade 0 (-40°C to +150°C) being the most stringent for engine compartment applications where Hall Effect sensors are commonly deployed.

The IP (Ingress Protection) rating system, defined by IEC 60529, is crucial for evaluating sensor enclosures. High-impact environments typically require ratings of IP67 or higher, indicating complete dust protection and water immersion resistance. For sensors exposed to corrosive substances, additional certifications like NEMA 4X may be necessary to ensure chemical resistance properties.

Vibration and shock testing standards vary by industry. ISO 16750-3 applies to road vehicles, while RTCA DO-160 governs avionics equipment. These standards specify test procedures including random vibration profiles, mechanical shock parameters, and operational/survival thresholds that Hall Effect sensors must meet to receive certification.

Electromagnetic compatibility (EMC) testing is particularly important for Hall Effect sensors due to their magnetic field sensitivity. Standards like IEC 61000-4-3 for radiated RF immunity and IEC 61000-4-8 for power frequency magnetic field immunity establish minimum performance criteria during exposure to electromagnetic disturbances.

For hazardous environments, additional certifications such as ATEX (Europe) or UL (North America) may be required. These certifications ensure that sensors will not become ignition sources in potentially explosive atmospheres. The specific zone classification (0, 1, or 2) determines the level of protection required.

Reliability testing standards, including JEDEC JESD22 for semiconductor devices, define accelerated life testing methodologies to predict long-term performance. For Hall Effect sensors in high-impact environments, highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) are recommended to identify potential failure modes before field deployment.

Compliance with these standards not only ensures operational reliability but often serves as a prerequisite for market access in regulated industries. Manufacturers must carefully document test results and maintain certification records throughout the product lifecycle to demonstrate ongoing compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!