How to Design Energy-Efficient Hall Effect Sensor Systems

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Efficiency Goals

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly from their initial application in measuring magnetic fields to becoming integral components in modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has enabled the development of robust, non-contact sensing solutions across various industries.

The evolution of Hall Effect sensor technology has been marked by several key advancements. Early implementations were primarily focused on simple magnetic field detection, but technological progress has led to the integration of signal conditioning circuits, temperature compensation mechanisms, and digital interfaces. Modern Hall Effect sensors now incorporate sophisticated features such as programmable sensitivity, diagnostic capabilities, and enhanced signal processing algorithms, significantly expanding their application scope.

Energy efficiency has emerged as a critical consideration in Hall Effect sensor design due to the proliferation of battery-powered and energy-harvesting applications. Traditional Hall Effect sensors consume relatively high power compared to other sensing technologies, primarily due to the continuous current required to generate a measurable Hall voltage. This power consumption challenge becomes particularly significant in IoT devices, wearable technology, and automotive systems where energy conservation directly impacts operational longevity and maintenance requirements.

The current technological landscape presents several efficiency challenges. The inherent physics of the Hall Effect necessitates a continuous current flow, creating a fundamental power consumption floor. Additionally, signal conditioning circuits, which are essential for processing the relatively weak Hall voltage signals, contribute significantly to the overall power budget. Temperature compensation mechanisms, while necessary for measurement accuracy, further add to energy demands.

Industry goals for Hall Effect sensor efficiency improvements are multifaceted. Primary objectives include reducing quiescent current consumption to sub-microamp levels, implementing intelligent power management schemes that allow for duty-cycling without compromising response time, and developing novel materials with enhanced Hall coefficients that can generate stronger signals with lower drive currents. There is also significant interest in hybrid sensing approaches that combine Hall Effect technology with complementary sensing modalities to optimize power consumption across different operating conditions.

The efficiency targets are being driven by emerging applications in autonomous vehicles, industrial IoT, and medical devices, where extended battery life and reduced maintenance are paramount. Achieving these goals requires a holistic approach that addresses both the fundamental physics of the Hall Effect and the supporting electronic infrastructure, potentially revolutionizing how these ubiquitous sensors are deployed in energy-constrained environments.

The evolution of Hall Effect sensor technology has been marked by several key advancements. Early implementations were primarily focused on simple magnetic field detection, but technological progress has led to the integration of signal conditioning circuits, temperature compensation mechanisms, and digital interfaces. Modern Hall Effect sensors now incorporate sophisticated features such as programmable sensitivity, diagnostic capabilities, and enhanced signal processing algorithms, significantly expanding their application scope.

Energy efficiency has emerged as a critical consideration in Hall Effect sensor design due to the proliferation of battery-powered and energy-harvesting applications. Traditional Hall Effect sensors consume relatively high power compared to other sensing technologies, primarily due to the continuous current required to generate a measurable Hall voltage. This power consumption challenge becomes particularly significant in IoT devices, wearable technology, and automotive systems where energy conservation directly impacts operational longevity and maintenance requirements.

The current technological landscape presents several efficiency challenges. The inherent physics of the Hall Effect necessitates a continuous current flow, creating a fundamental power consumption floor. Additionally, signal conditioning circuits, which are essential for processing the relatively weak Hall voltage signals, contribute significantly to the overall power budget. Temperature compensation mechanisms, while necessary for measurement accuracy, further add to energy demands.

Industry goals for Hall Effect sensor efficiency improvements are multifaceted. Primary objectives include reducing quiescent current consumption to sub-microamp levels, implementing intelligent power management schemes that allow for duty-cycling without compromising response time, and developing novel materials with enhanced Hall coefficients that can generate stronger signals with lower drive currents. There is also significant interest in hybrid sensing approaches that combine Hall Effect technology with complementary sensing modalities to optimize power consumption across different operating conditions.

The efficiency targets are being driven by emerging applications in autonomous vehicles, industrial IoT, and medical devices, where extended battery life and reduced maintenance are paramount. Achieving these goals requires a holistic approach that addresses both the fundamental physics of the Hall Effect and the supporting electronic infrastructure, potentially revolutionizing how these ubiquitous sensors are deployed in energy-constrained environments.

Market Demand Analysis for Energy-Efficient Magnetic Sensing

The global market for energy-efficient magnetic sensing technologies has experienced significant growth in recent years, driven by increasing demand across multiple industries. The Hall Effect sensor market specifically is projected to reach $2.3 billion by 2026, with a compound annual growth rate of 8.7% from 2021. This growth is primarily fueled by the automotive sector, which accounts for approximately 35% of the total market share, followed by industrial automation at 28% and consumer electronics at 22%.

Energy efficiency has become a critical factor in magnetic sensing applications, particularly in battery-powered and IoT devices where power consumption directly impacts operational lifespan. Market research indicates that devices with 30-50% lower power consumption can command premium pricing, with customers willing to pay 15-20% more for sensors that significantly extend battery life. This trend is especially pronounced in wearable technology and portable medical devices, where energy efficiency is often ranked as the second most important feature after accuracy.

The automotive industry represents the largest market segment for energy-efficient Hall Effect sensors, with applications ranging from position sensing in electric power steering to current sensing in battery management systems. The transition to electric vehicles has intensified demand, as these vehicles require 2-3 times more magnetic sensors than traditional combustion engine vehicles. Market forecasts suggest that by 2025, over 70% of new vehicles will incorporate at least 15 magnetic sensors per vehicle.

Industrial IoT applications constitute another rapidly growing segment, with an estimated market value of $780 million for energy-efficient magnetic sensing solutions. The need for long-lasting battery-powered sensors in remote monitoring systems has created substantial demand for ultra-low-power Hall Effect sensors that can operate for 5+ years without battery replacement.

Consumer electronics manufacturers are increasingly adopting energy-efficient magnetic sensors for smartphones, tablets, and wearable devices. Market studies show that extending battery life ranks among the top three priorities for consumers when purchasing new devices, creating strong pull for components that minimize power consumption.

Geographically, Asia-Pacific leads the market with 42% share, followed by North America (27%) and Europe (23%). China and South Korea show the fastest growth rates at 12.3% and 10.8% respectively, driven by their robust electronics manufacturing sectors and automotive industries.

Market analysis reveals a clear correlation between energy efficiency improvements and market adoption rates. Sensors achieving power consumption reductions of 40% or more typically see adoption rates increase by 25-30% compared to conventional alternatives, highlighting the significant commercial value of energy efficiency innovations in this space.

Energy efficiency has become a critical factor in magnetic sensing applications, particularly in battery-powered and IoT devices where power consumption directly impacts operational lifespan. Market research indicates that devices with 30-50% lower power consumption can command premium pricing, with customers willing to pay 15-20% more for sensors that significantly extend battery life. This trend is especially pronounced in wearable technology and portable medical devices, where energy efficiency is often ranked as the second most important feature after accuracy.

The automotive industry represents the largest market segment for energy-efficient Hall Effect sensors, with applications ranging from position sensing in electric power steering to current sensing in battery management systems. The transition to electric vehicles has intensified demand, as these vehicles require 2-3 times more magnetic sensors than traditional combustion engine vehicles. Market forecasts suggest that by 2025, over 70% of new vehicles will incorporate at least 15 magnetic sensors per vehicle.

Industrial IoT applications constitute another rapidly growing segment, with an estimated market value of $780 million for energy-efficient magnetic sensing solutions. The need for long-lasting battery-powered sensors in remote monitoring systems has created substantial demand for ultra-low-power Hall Effect sensors that can operate for 5+ years without battery replacement.

Consumer electronics manufacturers are increasingly adopting energy-efficient magnetic sensors for smartphones, tablets, and wearable devices. Market studies show that extending battery life ranks among the top three priorities for consumers when purchasing new devices, creating strong pull for components that minimize power consumption.

Geographically, Asia-Pacific leads the market with 42% share, followed by North America (27%) and Europe (23%). China and South Korea show the fastest growth rates at 12.3% and 10.8% respectively, driven by their robust electronics manufacturing sectors and automotive industries.

Market analysis reveals a clear correlation between energy efficiency improvements and market adoption rates. Sensors achieving power consumption reductions of 40% or more typically see adoption rates increase by 25-30% compared to conventional alternatives, highlighting the significant commercial value of energy efficiency innovations in this space.

Current Challenges in Hall Effect Sensor Power Consumption

Despite significant advancements in Hall effect sensor technology, power consumption remains a critical challenge for system designers. Current Hall effect sensor systems face several power-related obstacles that limit their deployment in energy-constrained applications. The primary challenge stems from the continuous operation mode traditionally required by these sensors, which constantly draws current even when measurements are not actively needed. This always-on functionality significantly impacts battery life in portable and IoT devices.

The quiescent current consumption of commercial Hall effect sensors typically ranges from 1mA to 5mA, which becomes problematic for battery-powered applications expecting years of operation. Even modern low-power variants still consume hundreds of microamperes, creating a substantial energy burden over extended periods.

Temperature compensation circuits, essential for maintaining measurement accuracy across varying environmental conditions, introduce additional power requirements. These compensation mechanisms often involve active components that continuously consume energy to adjust for thermal drift, further exacerbating the power consumption issue.

Signal conditioning and amplification stages present another significant power challenge. The Hall voltage generated is inherently small (typically in the microvolt to millivolt range), necessitating substantial amplification. These analog front-end circuits require considerable power to maintain adequate signal-to-noise ratios while amplifying these minute signals.

Digital processing requirements compound the energy challenge. Modern Hall effect sensor systems increasingly incorporate ADCs, microcontrollers, and communication interfaces that add to the overall power budget. The trend toward more intelligent sensors with onboard processing capabilities has improved functionality but at the cost of increased energy consumption.

Wireless connectivity features, now common in IoT-oriented Hall effect sensor nodes, introduce periodic high-current transmission events that can drain batteries rapidly if not carefully managed. The power profiles of these transmission events often show current spikes orders of magnitude higher than the sensing operation itself.

Existing power management approaches like duty cycling (periodically activating the sensor) help reduce average consumption but introduce latency and may miss transient events. More sophisticated wake-on-change architectures require additional always-on detection circuitry, creating a power consumption paradox where the energy saved must be balanced against the power needed for the detection system.

Miniaturization trends further complicate power management, as smaller form factors limit battery capacity while thermal management becomes more challenging. Heat dissipation issues in compact designs can affect both measurement accuracy and long-term reliability of the sensor system.

The quiescent current consumption of commercial Hall effect sensors typically ranges from 1mA to 5mA, which becomes problematic for battery-powered applications expecting years of operation. Even modern low-power variants still consume hundreds of microamperes, creating a substantial energy burden over extended periods.

Temperature compensation circuits, essential for maintaining measurement accuracy across varying environmental conditions, introduce additional power requirements. These compensation mechanisms often involve active components that continuously consume energy to adjust for thermal drift, further exacerbating the power consumption issue.

Signal conditioning and amplification stages present another significant power challenge. The Hall voltage generated is inherently small (typically in the microvolt to millivolt range), necessitating substantial amplification. These analog front-end circuits require considerable power to maintain adequate signal-to-noise ratios while amplifying these minute signals.

Digital processing requirements compound the energy challenge. Modern Hall effect sensor systems increasingly incorporate ADCs, microcontrollers, and communication interfaces that add to the overall power budget. The trend toward more intelligent sensors with onboard processing capabilities has improved functionality but at the cost of increased energy consumption.

Wireless connectivity features, now common in IoT-oriented Hall effect sensor nodes, introduce periodic high-current transmission events that can drain batteries rapidly if not carefully managed. The power profiles of these transmission events often show current spikes orders of magnitude higher than the sensing operation itself.

Existing power management approaches like duty cycling (periodically activating the sensor) help reduce average consumption but introduce latency and may miss transient events. More sophisticated wake-on-change architectures require additional always-on detection circuitry, creating a power consumption paradox where the energy saved must be balanced against the power needed for the detection system.

Miniaturization trends further complicate power management, as smaller form factors limit battery capacity while thermal management becomes more challenging. Heat dissipation issues in compact designs can affect both measurement accuracy and long-term reliability of the sensor system.

Current Energy Optimization Techniques for Hall Effect Systems

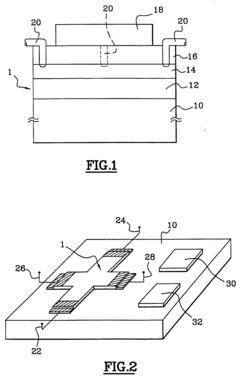

01 Low-power Hall effect sensor designs

Various designs and configurations of Hall effect sensors focus on reducing power consumption while maintaining performance. These include optimized semiconductor materials, improved circuit designs, and power management techniques that allow sensors to operate efficiently with minimal energy input. Such designs are particularly important for battery-powered applications and systems where energy efficiency is critical.- Low-power Hall effect sensor designs: Various designs and configurations of Hall effect sensors focus on reducing power consumption while maintaining performance. These include optimized semiconductor materials, improved circuit designs, and power management techniques that allow sensors to operate efficiently with minimal energy input. These innovations enable longer battery life in portable devices and reduced energy consumption in stationary applications.

- Power management techniques for Hall sensors: Advanced power management strategies specifically designed for Hall effect sensor systems help minimize energy consumption. These include sleep modes, duty cycling, adaptive sampling rates, and intelligent power control algorithms that activate sensors only when needed. Such techniques significantly reduce the overall energy footprint while ensuring reliable sensor operation and response times.

- Integration with energy-efficient systems: Hall effect sensors can be integrated into larger systems with energy efficiency considerations. This includes combining sensors with energy harvesting technologies, optimizing sensor placement and signal processing to reduce power requirements, and designing complementary circuits that work together to minimize overall system power consumption while maintaining sensing accuracy.

- Novel materials and fabrication techniques: Innovative materials and manufacturing processes can significantly improve the energy efficiency of Hall effect sensors. These include thin-film technologies, nanomaterials, and specialized semiconductor compounds that exhibit enhanced Hall effect properties at lower power levels. Advanced fabrication techniques also allow for miniaturization and integration that further reduces power requirements.

- Signal processing and amplification efficiency: Efficient signal processing and amplification techniques specifically designed for Hall effect sensors can significantly reduce power consumption. These include low-power amplifier designs, digital signal processing algorithms optimized for energy efficiency, and innovative approaches to noise reduction that allow for lower operating currents while maintaining signal integrity and measurement accuracy.

02 Power management techniques for Hall sensors

Advanced power management techniques help reduce the energy consumption of Hall effect sensor systems. These include sleep modes, duty cycling, adaptive sampling rates, and intelligent power control algorithms that activate sensors only when needed. Such techniques significantly extend battery life in portable devices and reduce overall energy consumption in various applications.Expand Specific Solutions03 Integration with energy-efficient microcontrollers

Hall effect sensors integrated with energy-efficient microcontrollers or processing units optimize overall system power consumption. These integrated solutions feature optimized signal processing, reduced communication overhead, and efficient data handling. The tight integration between sensing and processing components minimizes energy losses and enables more efficient operation in various applications.Expand Specific Solutions04 Energy harvesting for Hall sensor systems

Energy harvesting technologies paired with Hall effect sensors create self-powered or energy-neutral sensing systems. These systems capture energy from the environment (vibration, temperature differentials, light, or electromagnetic fields) to power the Hall sensor operation. This approach reduces or eliminates the need for battery replacement and enables deployment in remote or inaccessible locations.Expand Specific Solutions05 Optimized magnetic circuit designs

Improved magnetic circuit designs enhance the energy efficiency of Hall effect sensor systems. These designs include optimized magnetic flux paths, reduced air gaps, and advanced magnetic materials that increase sensitivity while reducing power requirements. Such optimizations allow sensors to operate with lower magnetic field strengths and reduced power consumption while maintaining or improving measurement accuracy.Expand Specific Solutions

Leading Manufacturers and Competitors in Hall Sensor Market

The energy-efficient Hall Effect sensor systems market is in a growth phase, with increasing demand driven by automotive, industrial, and consumer electronics applications. The market size is expanding rapidly due to the push for energy efficiency in IoT devices and smart systems. Technologically, the field shows varying maturity levels, with established players like Honeywell, Infineon, and Texas Instruments leading with advanced solutions featuring low power consumption and high sensitivity. Allegro MicroSystems and ams-OSRAM are developing specialized applications, while Asian manufacturers like Ningbo CSR Times Sensor and Beijing Smartchip are emerging as competitive forces. Research institutions such as CNRS and Hefei Institutes of Physical Science are contributing to innovation through fundamental research in materials and sensing technologies, pushing the boundaries of energy efficiency in Hall Effect sensing.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced energy-efficient Hall effect sensor systems that integrate their proprietary SmartPower technology. This approach dynamically adjusts power consumption based on operational requirements, allowing sensors to operate in ultra-low power modes when full performance isn't needed. Their design incorporates chopper-stabilized amplifiers and advanced signal conditioning circuits that minimize offset drift while maintaining high sensitivity at lower supply currents. Honeywell's Hall effect sensors feature programmable power management with sleep/wake capabilities that can reduce average current consumption by up to 90% compared to conventional always-on designs. The company has also pioneered integrated temperature compensation techniques that maintain accuracy across wide temperature ranges without requiring additional power-consuming correction circuits. Their latest generation sensors incorporate specialized magnetic concentrators that improve sensitivity-to-power ratios, enabling operation at supply currents as low as 1.5mA while maintaining robust performance characteristics.

Strengths: Industry-leading power management capabilities with proven reliability in harsh environments. Extensive experience in aerospace and industrial applications provides robust design methodologies. Weaknesses: Higher initial cost compared to simpler solutions, and some implementations may require more complex integration with microcontrollers for full power-saving benefits.

Infineon Technologies AG

Technical Solution: Infineon has pioneered energy-efficient Hall effect sensor systems through their TLE49xx series, which incorporates advanced BiCMOS and CMOS manufacturing processes specifically optimized for low power consumption. Their approach focuses on reducing both static and dynamic power requirements through innovative circuit design and semiconductor technology. Infineon's Hall sensors feature active power management that can reduce consumption to under 1.5mA in normal operation and below 2μA in standby modes. The company has developed proprietary chopper stabilization techniques that minimize offset errors while maintaining ultra-low power operation. Their integrated stray field compensation technology reduces the need for external shielding components, further decreasing system-level power requirements. Infineon's latest generation sensors incorporate embedded digital signal processing capabilities that optimize power consumption based on application requirements, with programmable sampling rates and filtering options that can be dynamically adjusted to balance performance and energy efficiency. The company has also pioneered 3D Hall effect sensors that provide multi-axis measurements with minimal additional power overhead compared to single-axis solutions.

Strengths: Industry-leading semiconductor process technology optimized specifically for magnetic sensors, extensive automotive qualification, and comprehensive development ecosystem. Weaknesses: Higher complexity in implementation for maximum power savings, and some advanced features require additional software development to fully utilize power management capabilities.

Key Innovations in Low-Power Hall Sensor Design

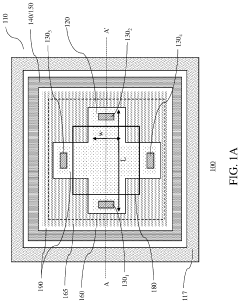

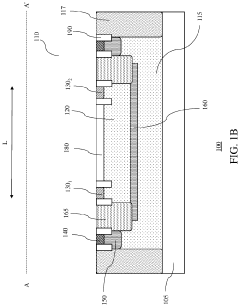

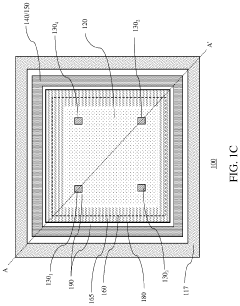

Hall-effect sensor and integrated circuit comprising such a sensor

PatentInactiveEP1091425A2

Innovation

- A Hall effect sensor structure with a thin active Si layer (less than 100 nm) and a SiO2 insulation layer, along with an insulating dielectric layer, which reduces temperature dependence and enhances magnetic field sensitivity, utilizing a quasi-two-dimensional electron gas and a guard electrode to minimize thermal effects.

Hall effect sensors with tunable sensitivity and/or resistance

PatentActiveUS11047930B2

Innovation

- A Hall effect sensor design with a tunable Hall plate thickness, achieved through adjustable implants in the separation layer and bias voltage applied to the separation layer, allowing for customizable current sensitivity and resistance, enabling high voltage and current sensitivity in the same device.

Materials Science Advancements for Hall Sensor Efficiency

Recent advancements in materials science have significantly contributed to enhancing the efficiency of Hall effect sensors. Traditional Hall sensors primarily utilized silicon as the semiconductor material, but newer compounds have emerged with superior properties. Gallium arsenide (GaAs) and indium antimonide (InSb) demonstrate higher electron mobility compared to silicon, resulting in increased sensitivity and reduced power requirements. These materials enable sensors to operate effectively at lower current levels, directly addressing energy efficiency concerns.

Graphene has emerged as a revolutionary material for Hall sensor applications due to its exceptional electron mobility and two-dimensional structure. Research indicates that graphene-based Hall sensors can achieve sensitivity levels up to 100 times greater than conventional silicon sensors while consuming significantly less power. This breakthrough allows for the development of ultra-low-power sensor systems suitable for battery-operated and energy-harvesting applications.

Magnetic material innovations have also played a crucial role in improving Hall sensor efficiency. The development of high-permeability flux concentrators using advanced soft magnetic materials like permalloy and amorphous magnetic alloys has enhanced magnetic field detection capabilities. These concentrators effectively amplify weak magnetic fields, enabling sensors to operate at lower power levels while maintaining detection accuracy.

Thin-film deposition techniques have revolutionized Hall sensor manufacturing, allowing for precise control over material properties and dimensions. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable the creation of ultra-thin sensing elements with optimized carrier concentration and mobility characteristics. These manufacturing advances have resulted in sensors with improved signal-to-noise ratios that require less amplification and consequently less power.

Heterostructure engineering represents another significant advancement, where multiple semiconductor materials are combined in layered structures to optimize carrier transport properties. Quantum well structures and modulation-doped field-effect transistors (MODFETs) incorporating these principles have demonstrated exceptional sensitivity at extremely low power levels. These sophisticated material combinations allow for fine-tuning of sensor characteristics to match specific application requirements while minimizing energy consumption.

Nanomaterials and nanocomposites are increasingly being incorporated into Hall sensor designs. Carbon nanotubes, semiconductor nanowires, and magnetic nanoparticles offer unique properties that can be leveraged for enhanced sensing performance. These materials provide advantages in terms of size reduction, increased sensitivity, and improved thermal stability, all contributing to more energy-efficient sensor operation across wider temperature ranges.

Graphene has emerged as a revolutionary material for Hall sensor applications due to its exceptional electron mobility and two-dimensional structure. Research indicates that graphene-based Hall sensors can achieve sensitivity levels up to 100 times greater than conventional silicon sensors while consuming significantly less power. This breakthrough allows for the development of ultra-low-power sensor systems suitable for battery-operated and energy-harvesting applications.

Magnetic material innovations have also played a crucial role in improving Hall sensor efficiency. The development of high-permeability flux concentrators using advanced soft magnetic materials like permalloy and amorphous magnetic alloys has enhanced magnetic field detection capabilities. These concentrators effectively amplify weak magnetic fields, enabling sensors to operate at lower power levels while maintaining detection accuracy.

Thin-film deposition techniques have revolutionized Hall sensor manufacturing, allowing for precise control over material properties and dimensions. Atomic layer deposition (ALD) and molecular beam epitaxy (MBE) enable the creation of ultra-thin sensing elements with optimized carrier concentration and mobility characteristics. These manufacturing advances have resulted in sensors with improved signal-to-noise ratios that require less amplification and consequently less power.

Heterostructure engineering represents another significant advancement, where multiple semiconductor materials are combined in layered structures to optimize carrier transport properties. Quantum well structures and modulation-doped field-effect transistors (MODFETs) incorporating these principles have demonstrated exceptional sensitivity at extremely low power levels. These sophisticated material combinations allow for fine-tuning of sensor characteristics to match specific application requirements while minimizing energy consumption.

Nanomaterials and nanocomposites are increasingly being incorporated into Hall sensor designs. Carbon nanotubes, semiconductor nanowires, and magnetic nanoparticles offer unique properties that can be leveraged for enhanced sensing performance. These materials provide advantages in terms of size reduction, increased sensitivity, and improved thermal stability, all contributing to more energy-efficient sensor operation across wider temperature ranges.

Integration Strategies with Energy Harvesting Technologies

The integration of energy harvesting technologies with Hall effect sensor systems represents a significant advancement in achieving truly sustainable and autonomous sensing solutions. By combining these technologies, it becomes possible to create self-powered sensor networks that can operate indefinitely without battery replacement, dramatically reducing maintenance costs and environmental impact. Various energy harvesting methods can be effectively paired with Hall effect sensors, including photovoltaic cells that convert ambient light, thermoelectric generators that utilize temperature differentials, piezoelectric elements that harvest mechanical vibrations, and electromagnetic harvesters that capture energy from magnetic field variations.

When designing integrated systems, power management circuits play a crucial role in matching the harvested energy profile with the sensor's consumption patterns. These circuits typically incorporate ultra-low-power voltage regulators, efficient energy storage elements such as supercapacitors or thin-film batteries, and intelligent power distribution systems. The implementation of adaptive duty cycling techniques further optimizes energy usage by adjusting the sensor's active periods based on available harvested energy and application requirements.

For industrial applications, vibration-based energy harvesting has proven particularly effective when paired with Hall effect sensors monitoring rotating machinery. The same mechanical energy that generates the magnetic fields being measured can simultaneously power the sensing system. In automotive environments, thermoelectric generators can harvest waste heat from engine components while Hall effect sensors monitor position and speed parameters, creating a symbiotic relationship between the sensing function and power generation.

Recent advancements in MEMS-based energy harvesters have enabled miniaturized integration solutions suitable for IoT applications. These micro-scale harvesters can be co-packaged with Hall effect sensors and their associated electronics, resulting in compact, fully autonomous sensing nodes. The development of hybrid harvesting approaches—combining multiple energy sources—has further enhanced system reliability by ensuring continuous operation across varying environmental conditions.

Looking toward future developments, the integration of machine learning algorithms with energy harvesting systems shows promise for optimizing power management. These algorithms can predict energy availability patterns and adjust sensor parameters accordingly, maximizing system efficiency. Additionally, emerging materials such as flexible organic photovoltaics and high-efficiency thermoelectric compounds are expanding the application range of integrated Hall effect sensor systems to previously challenging environments.

Standardization efforts are currently underway to establish protocols for energy harvesting interfaces with sensor systems, which will facilitate wider adoption and interoperability between components from different manufacturers. As these integrated solutions mature, they are expected to become the standard approach for implementing Hall effect sensors in remote monitoring, industrial automation, and smart infrastructure applications.

When designing integrated systems, power management circuits play a crucial role in matching the harvested energy profile with the sensor's consumption patterns. These circuits typically incorporate ultra-low-power voltage regulators, efficient energy storage elements such as supercapacitors or thin-film batteries, and intelligent power distribution systems. The implementation of adaptive duty cycling techniques further optimizes energy usage by adjusting the sensor's active periods based on available harvested energy and application requirements.

For industrial applications, vibration-based energy harvesting has proven particularly effective when paired with Hall effect sensors monitoring rotating machinery. The same mechanical energy that generates the magnetic fields being measured can simultaneously power the sensing system. In automotive environments, thermoelectric generators can harvest waste heat from engine components while Hall effect sensors monitor position and speed parameters, creating a symbiotic relationship between the sensing function and power generation.

Recent advancements in MEMS-based energy harvesters have enabled miniaturized integration solutions suitable for IoT applications. These micro-scale harvesters can be co-packaged with Hall effect sensors and their associated electronics, resulting in compact, fully autonomous sensing nodes. The development of hybrid harvesting approaches—combining multiple energy sources—has further enhanced system reliability by ensuring continuous operation across varying environmental conditions.

Looking toward future developments, the integration of machine learning algorithms with energy harvesting systems shows promise for optimizing power management. These algorithms can predict energy availability patterns and adjust sensor parameters accordingly, maximizing system efficiency. Additionally, emerging materials such as flexible organic photovoltaics and high-efficiency thermoelectric compounds are expanding the application range of integrated Hall effect sensor systems to previously challenging environments.

Standardization efforts are currently underway to establish protocols for energy harvesting interfaces with sensor systems, which will facilitate wider adoption and interoperability between components from different manufacturers. As these integrated solutions mature, they are expected to become the standard approach for implementing Hall effect sensors in remote monitoring, industrial automation, and smart infrastructure applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!