Exploring Advanced Hall Effect Sensor Applications in Transportation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Evolution and Transportation Applications

Hall Effect sensors have undergone significant evolution since their discovery by Edwin Hall in 1879. Initially limited to laboratory applications, these sensors have transformed into sophisticated devices capable of precise magnetic field detection across diverse environments. The technological progression can be traced through several distinct phases, beginning with basic magnetic field detection and advancing to today's integrated smart sensing solutions.

The transportation sector has emerged as a primary beneficiary of Hall Effect sensor technology. Early automotive applications in the 1970s focused primarily on ignition timing systems, where these sensors provided non-contact measurement capabilities that significantly improved reliability over mechanical counterparts. By the 1990s, Hall Effect sensors had become standard components in anti-lock braking systems (ABS) and electronic stability control, fundamentally enhancing vehicle safety.

Modern transportation systems leverage Hall Effect sensors across numerous critical applications. In electric vehicles, these sensors enable precise motor control and battery management, directly impacting vehicle efficiency and range. For autonomous vehicles, Hall Effect technology provides essential position and speed data for navigation systems, while in railway applications, they monitor wheel rotation and track occupancy with exceptional reliability in harsh operating conditions.

The miniaturization trend has been particularly impactful, with sensor dimensions decreasing by approximately 70% over the past decade while simultaneously improving sensitivity and response times. This size reduction has enabled integration into increasingly compact transportation components without compromising performance. Concurrently, power efficiency improvements have reduced consumption by nearly 85% compared to early models, making these sensors ideal for battery-powered transportation applications.

Recent technological breakthroughs include the development of 3D Hall Effect sensors capable of measuring magnetic fields across multiple axes simultaneously. This innovation has revolutionized steering angle detection and transmission systems by providing comprehensive spatial awareness with a single component. Additionally, temperature-compensated variants now maintain accuracy across the extreme temperature ranges encountered in transportation environments (-40°C to +150°C).

The integration of Hall Effect sensors with IoT capabilities represents the latest evolutionary step, enabling real-time monitoring and predictive maintenance in transportation systems. These connected sensors transmit operational data to centralized management systems, allowing for condition-based maintenance that significantly reduces vehicle downtime and enhances overall fleet efficiency.

As transportation continues its shift toward electrification and autonomy, Hall Effect sensor technology is positioned to play an increasingly vital role in enabling these transformative changes through reliable, precise, and increasingly intelligent sensing capabilities.

The transportation sector has emerged as a primary beneficiary of Hall Effect sensor technology. Early automotive applications in the 1970s focused primarily on ignition timing systems, where these sensors provided non-contact measurement capabilities that significantly improved reliability over mechanical counterparts. By the 1990s, Hall Effect sensors had become standard components in anti-lock braking systems (ABS) and electronic stability control, fundamentally enhancing vehicle safety.

Modern transportation systems leverage Hall Effect sensors across numerous critical applications. In electric vehicles, these sensors enable precise motor control and battery management, directly impacting vehicle efficiency and range. For autonomous vehicles, Hall Effect technology provides essential position and speed data for navigation systems, while in railway applications, they monitor wheel rotation and track occupancy with exceptional reliability in harsh operating conditions.

The miniaturization trend has been particularly impactful, with sensor dimensions decreasing by approximately 70% over the past decade while simultaneously improving sensitivity and response times. This size reduction has enabled integration into increasingly compact transportation components without compromising performance. Concurrently, power efficiency improvements have reduced consumption by nearly 85% compared to early models, making these sensors ideal for battery-powered transportation applications.

Recent technological breakthroughs include the development of 3D Hall Effect sensors capable of measuring magnetic fields across multiple axes simultaneously. This innovation has revolutionized steering angle detection and transmission systems by providing comprehensive spatial awareness with a single component. Additionally, temperature-compensated variants now maintain accuracy across the extreme temperature ranges encountered in transportation environments (-40°C to +150°C).

The integration of Hall Effect sensors with IoT capabilities represents the latest evolutionary step, enabling real-time monitoring and predictive maintenance in transportation systems. These connected sensors transmit operational data to centralized management systems, allowing for condition-based maintenance that significantly reduces vehicle downtime and enhances overall fleet efficiency.

As transportation continues its shift toward electrification and autonomy, Hall Effect sensor technology is positioned to play an increasingly vital role in enabling these transformative changes through reliable, precise, and increasingly intelligent sensing capabilities.

Market Demand Analysis for Hall Sensors in Mobility Solutions

The global market for Hall Effect sensors in transportation applications is experiencing robust growth, driven by increasing vehicle electrification and the rapid advancement of autonomous driving technologies. Current market valuations place the automotive Hall sensor segment at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate of 6.8% through 2030. This growth trajectory is particularly pronounced in electric vehicles, where Hall sensors are essential components in battery management systems, motor control units, and power electronics.

Consumer demand for enhanced safety features represents a significant market driver, with advanced driver assistance systems (ADAS) increasingly incorporating Hall Effect sensors for precise position detection and speed monitoring. The market penetration of these sensors in mid-range vehicles has increased by 32% over the past five years, indicating broader adoption beyond premium vehicle segments.

Commercial transportation presents another substantial growth vector, with fleet operators seeking improved efficiency through accurate load monitoring and predictive maintenance systems. Hall sensors enable real-time monitoring of critical components, reducing downtime and maintenance costs. Industry surveys indicate that fleet managers can achieve operational cost reductions of 15-20% through implementation of comprehensive sensor-based monitoring systems.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 42% share, followed by Europe (28%) and North America (22%). China's aggressive electrification policies and Japan's advanced automotive manufacturing capabilities contribute significantly to Asia's market leadership. However, European markets are showing accelerated growth rates due to stringent emissions regulations driving electrification and safety technology adoption.

The railway sector represents an emerging application area with substantial growth potential. Modern rail systems increasingly rely on Hall sensors for speed monitoring, door operation systems, and traction control. Market research indicates that this segment is growing at 8.3% annually, outpacing the broader transportation sensor market.

Price sensitivity varies significantly across application segments. While consumer automotive applications remain highly price-competitive with strong pressure on margins, specialized applications in commercial transportation, aerospace, and high-speed rail command premium pricing due to higher reliability requirements and lower production volumes.

Supply chain analysis reveals potential constraints in rare earth materials required for high-performance Hall sensors, with 78% of global production concentrated in China. This geographic concentration presents strategic risks for manufacturers and may influence future pricing and availability dynamics in the transportation Hall sensor market.

Consumer demand for enhanced safety features represents a significant market driver, with advanced driver assistance systems (ADAS) increasingly incorporating Hall Effect sensors for precise position detection and speed monitoring. The market penetration of these sensors in mid-range vehicles has increased by 32% over the past five years, indicating broader adoption beyond premium vehicle segments.

Commercial transportation presents another substantial growth vector, with fleet operators seeking improved efficiency through accurate load monitoring and predictive maintenance systems. Hall sensors enable real-time monitoring of critical components, reducing downtime and maintenance costs. Industry surveys indicate that fleet managers can achieve operational cost reductions of 15-20% through implementation of comprehensive sensor-based monitoring systems.

Regional analysis reveals that Asia-Pacific currently dominates the market with approximately 42% share, followed by Europe (28%) and North America (22%). China's aggressive electrification policies and Japan's advanced automotive manufacturing capabilities contribute significantly to Asia's market leadership. However, European markets are showing accelerated growth rates due to stringent emissions regulations driving electrification and safety technology adoption.

The railway sector represents an emerging application area with substantial growth potential. Modern rail systems increasingly rely on Hall sensors for speed monitoring, door operation systems, and traction control. Market research indicates that this segment is growing at 8.3% annually, outpacing the broader transportation sensor market.

Price sensitivity varies significantly across application segments. While consumer automotive applications remain highly price-competitive with strong pressure on margins, specialized applications in commercial transportation, aerospace, and high-speed rail command premium pricing due to higher reliability requirements and lower production volumes.

Supply chain analysis reveals potential constraints in rare earth materials required for high-performance Hall sensors, with 78% of global production concentrated in China. This geographic concentration presents strategic risks for manufacturers and may influence future pricing and availability dynamics in the transportation Hall sensor market.

Current Challenges in Hall Effect Sensing Technology

Despite significant advancements in Hall effect sensing technology, several critical challenges persist that limit its optimal application in transportation systems. Temperature sensitivity remains one of the most significant obstacles, as Hall sensors experience drift in their output characteristics across the wide temperature ranges encountered in automotive environments (-40°C to 125°C). This thermal drift necessitates complex compensation algorithms and additional circuitry, increasing both cost and design complexity.

Signal-to-noise ratio (SNR) presents another substantial challenge, particularly in transportation applications where sensors must operate in electromagnetically noisy environments. The proximity to high-current carrying conductors, electric motors, and power electronics in modern electric and hybrid vehicles creates substantial electromagnetic interference that can compromise measurement accuracy and reliability.

Power consumption constraints pose significant limitations, especially for battery-powered applications in transportation. While Hall effect sensors are relatively energy-efficient compared to some alternatives, the continuous monitoring requirements in safety-critical systems demand further improvements in power efficiency without sacrificing performance or reliability.

Miniaturization pressures continue to intensify as vehicle designers seek to incorporate more sensors into increasingly compact spaces. Current Hall sensor packages struggle to maintain performance characteristics while reducing physical dimensions, particularly when integrated with signal conditioning circuitry and protection features necessary for harsh automotive environments.

Durability and reliability under extreme conditions represent persistent challenges. Transportation applications expose sensors to vibration, shock, humidity, and chemical contaminants that can degrade performance over time. Current encapsulation and protection methods add bulk and cost while still leaving room for improvement in long-term reliability.

Integration complexity with modern vehicle systems presents significant hurdles. As transportation systems evolve toward greater electrification and autonomy, Hall sensors must interface seamlessly with sophisticated control systems, requiring advanced digital interfaces and communication protocols that add complexity to sensor design and implementation.

Calibration and drift compensation over the lifetime of vehicles remain problematic. Current Hall sensors typically require initial calibration and may experience sensitivity drift over extended periods, necessitating either periodic recalibration or sophisticated self-calibration mechanisms that increase system complexity.

Cost pressures represent a persistent challenge, particularly for mass-market transportation applications. While Hall effect technology is mature, the additional components required for temperature compensation, signal conditioning, and protection drive up costs, limiting broader adoption in price-sensitive market segments.

Signal-to-noise ratio (SNR) presents another substantial challenge, particularly in transportation applications where sensors must operate in electromagnetically noisy environments. The proximity to high-current carrying conductors, electric motors, and power electronics in modern electric and hybrid vehicles creates substantial electromagnetic interference that can compromise measurement accuracy and reliability.

Power consumption constraints pose significant limitations, especially for battery-powered applications in transportation. While Hall effect sensors are relatively energy-efficient compared to some alternatives, the continuous monitoring requirements in safety-critical systems demand further improvements in power efficiency without sacrificing performance or reliability.

Miniaturization pressures continue to intensify as vehicle designers seek to incorporate more sensors into increasingly compact spaces. Current Hall sensor packages struggle to maintain performance characteristics while reducing physical dimensions, particularly when integrated with signal conditioning circuitry and protection features necessary for harsh automotive environments.

Durability and reliability under extreme conditions represent persistent challenges. Transportation applications expose sensors to vibration, shock, humidity, and chemical contaminants that can degrade performance over time. Current encapsulation and protection methods add bulk and cost while still leaving room for improvement in long-term reliability.

Integration complexity with modern vehicle systems presents significant hurdles. As transportation systems evolve toward greater electrification and autonomy, Hall sensors must interface seamlessly with sophisticated control systems, requiring advanced digital interfaces and communication protocols that add complexity to sensor design and implementation.

Calibration and drift compensation over the lifetime of vehicles remain problematic. Current Hall sensors typically require initial calibration and may experience sensitivity drift over extended periods, necessitating either periodic recalibration or sophisticated self-calibration mechanisms that increase system complexity.

Cost pressures represent a persistent challenge, particularly for mass-market transportation applications. While Hall effect technology is mature, the additional components required for temperature compensation, signal conditioning, and protection drive up costs, limiting broader adoption in price-sensitive market segments.

Current Hall Sensor Implementation in Transportation Systems

01 Hall Effect Sensor Design and Structure

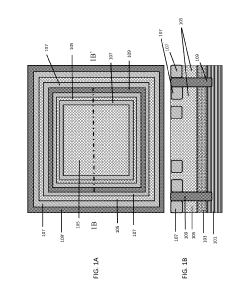

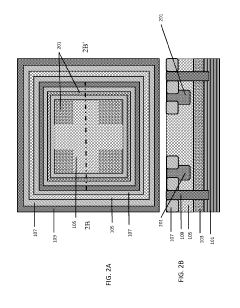

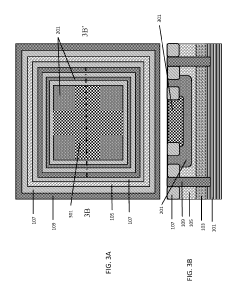

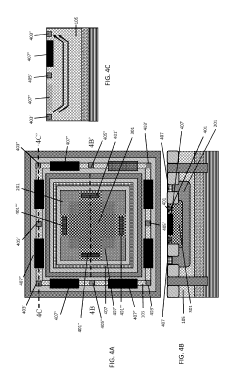

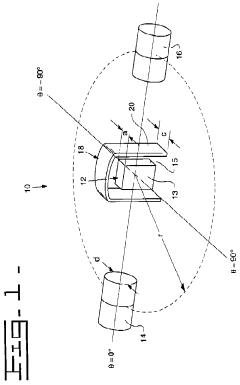

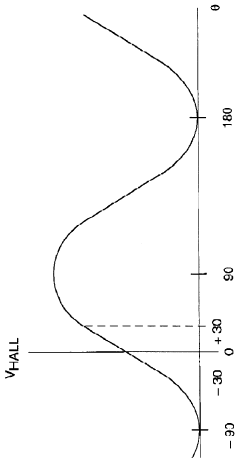

Hall effect sensors are semiconductor devices that detect magnetic fields and convert them into electrical signals. The basic structure includes a semiconductor material with current flowing through it and electrodes to measure the voltage generated perpendicular to both the current flow and magnetic field. Various designs optimize sensitivity, stability, and integration capabilities for different applications.- Hall Effect Sensor Design and Structure: Hall effect sensors are designed with specific structures to optimize their performance in detecting magnetic fields. These designs include various semiconductor materials, electrode configurations, and packaging techniques that enhance sensitivity and reliability. The structure often incorporates magnetic flux concentrators to amplify the Hall effect and improve signal-to-noise ratio. Advanced designs may include integrated temperature compensation and signal conditioning circuits to maintain accuracy across operating conditions.

- Measurement and Detection Applications: Hall effect sensors are widely used in measurement and detection applications across various industries. They can detect position, proximity, speed, and current without physical contact. These sensors are employed in automotive systems for wheel speed sensing, throttle position detection, and crankshaft positioning. In industrial applications, they monitor motor speeds, detect gear tooth movement, and measure current flow. Their non-contact operation makes them ideal for harsh environments where mechanical wear is a concern.

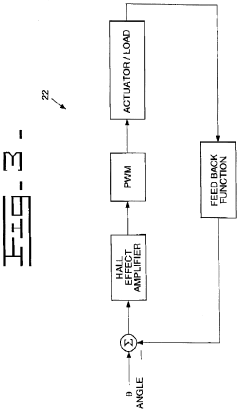

- Signal Processing and Conditioning: Signal processing and conditioning are crucial aspects of Hall effect sensor systems. Various techniques are employed to amplify the relatively weak Hall voltage, filter noise, and convert the signal to a usable output format. Advanced signal conditioning circuits may include chopper stabilization, offset cancellation, and temperature compensation. Digital signal processing methods can further enhance accuracy by applying calibration algorithms and compensating for non-linearity in the sensor response.

- Integration with Electronic Systems: Hall effect sensors are increasingly integrated with other electronic systems to create comprehensive sensing solutions. These integrated designs may combine the Hall sensor with microcontrollers, memory, communication interfaces, and power management circuits. Such integration enables smart sensing capabilities, self-diagnostics, and direct digital outputs. In automotive and industrial applications, Hall sensors are often integrated into control modules that interface directly with CAN bus or other communication networks, simplifying system design and improving reliability.

- Enhanced Sensitivity and Accuracy Techniques: Various techniques are employed to enhance the sensitivity and accuracy of Hall effect sensors. These include vertical Hall structures, spinning current methods, and dynamic offset cancellation. Advanced materials such as gallium arsenide or indium antimonide may be used instead of silicon to achieve higher sensitivity. Flux concentrators made of ferromagnetic materials can be positioned around the sensor to amplify the magnetic field. Some designs incorporate multiple Hall elements in differential configurations to reject common-mode noise and improve signal quality.

02 Measurement and Detection Applications

Hall effect sensors are widely used for precise measurement of magnetic fields, position detection, and proximity sensing. They enable non-contact measurement of current, rotation speed, and linear position. These sensors provide reliable detection capabilities in harsh environments where optical or mechanical sensors might fail, making them valuable in automotive, industrial, and consumer electronics applications.Expand Specific Solutions03 Signal Processing and Conditioning

Advanced signal processing techniques enhance Hall effect sensor performance by reducing noise, improving sensitivity, and compensating for temperature variations. Integrated circuits combine the Hall element with amplifiers, comparators, and digital processing to provide calibrated outputs. These signal conditioning methods enable higher accuracy and reliability in sensing applications.Expand Specific Solutions04 Magnetic Field Enhancement and Shielding

Various techniques are employed to enhance magnetic field sensitivity and provide shielding from external interference. Flux concentrators, specialized magnetic materials, and strategic sensor placement improve detection capabilities. Shielding designs protect sensors from stray magnetic fields and electromagnetic interference, ensuring accurate measurements in complex electromagnetic environments.Expand Specific Solutions05 Integration with Electronic Systems

Hall effect sensors are increasingly integrated into complex electronic systems for automotive, industrial automation, and consumer electronics applications. These integrated solutions combine sensing elements with power management, communication interfaces, and control logic. Modern designs focus on miniaturization, power efficiency, and compatibility with digital systems, enabling smart sensing capabilities in IoT devices and automotive systems.Expand Specific Solutions

Leading Hall Effect Sensor Manufacturers and Integrators

The Hall Effect sensor market in transportation is experiencing robust growth, currently in a mature expansion phase with an estimated market size of $1.5-2 billion and projected CAGR of 7-9% through 2028. Leading players include established semiconductor manufacturers like Honeywell International, Allegro MicroSystems, and Infineon Technologies who dominate with comprehensive product portfolios. Texas Instruments and Melexis Technologies are advancing technical innovation through high-precision sensors. The technology has reached commercial maturity in automotive applications, with companies like Lear Corp and Dongfeng Motor integrating these sensors into advanced vehicle systems. Emerging applications in transportation automation and electrification are driving continued innovation, with automotive OEMs and tier-one suppliers increasingly adopting Hall Effect technology for position sensing, speed detection, and current monitoring applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensor solutions specifically designed for transportation applications, focusing on their SmartPath technology. This platform integrates high-precision Hall effect sensors with sophisticated signal processing algorithms to provide accurate position, speed, and direction measurements in challenging automotive environments. Their sensors feature programmable sensitivity ranges (1mV/G to 15mV/G) and can operate in extreme temperature conditions (-40°C to +150°C), making them suitable for harsh transportation environments[1]. Honeywell's transportation-focused Hall sensors incorporate built-in diagnostics and self-calibration capabilities that continuously monitor sensor health and compensate for drift, ensuring reliable operation throughout the vehicle's lifecycle. Their integrated circuit designs combine the Hall sensing element with temperature compensation, amplification, and digital signal processing on a single chip, reducing size while improving noise immunity in electrically noisy vehicle environments[3].

Strengths: Superior temperature stability and drift compensation allowing for consistent performance across extreme automotive operating conditions. Integrated diagnostics provide enhanced reliability for safety-critical applications. Weaknesses: Higher cost compared to basic Hall sensors, and some implementations require more complex integration with vehicle systems, potentially increasing installation complexity.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has pioneered specialized Hall effect sensor technology for transportation applications through their APS line (Advanced Position Sensors). Their proprietary approach combines planar Hall elements with vertical Hall technology to create 3D sensing capabilities that enable precise rotational and linear position measurement in automotive systems. Allegro's sensors feature industry-leading sensitivity of up to 20mV/G with temperature drift below 50ppm/°C, ensuring stable operation across automotive temperature ranges[2]. Their transportation-focused solutions incorporate advanced signal conditioning with chopper stabilization and digital filtering that effectively eliminates the impact of mechanical vibration and electromagnetic interference common in vehicle environments. Allegro's Hall-IC technology integrates multiple sensing elements, temperature compensation circuits, and programmable output stages on a single die, enabling flexible configuration for various transportation applications including transmission position sensing, brake pedal position, and steering angle measurement[4].

Strengths: Industry-leading sensitivity and stability in high-vibration environments makes these sensors ideal for powertrain applications. Programmable output options provide flexibility for different vehicle system requirements. Weaknesses: Higher power consumption compared to some competing technologies, and more complex calibration requirements during vehicle manufacturing.

Key Patents and Innovations in Hall Effect Sensing

Hall element for 3-d sensing and method for producing the same

PatentActiveUS20190259936A1

Innovation

- The development of a 3D Hall element with separate sensing for each magnetic field component, utilizing deep trench isolation (DTI) and shallow trench isolation (STI) regions, along with p-type and n-type wells, to optimize both planar and vertical Hall elements for improved sensitivity and reduced interference, compatible with CMOS technology nodes.

Magnetic shunt device for hall effect applications

PatentInactiveUSH1990H1

Innovation

- A magnetic shunt device is positioned around the Hall effect device to null the magnetic field when it is parallel to the sensitive plane, ensuring consistent null output voltage across multiple devices by shielding the magnetic field at the zero angle position.

Safety Standards and Certification Requirements

The implementation of Hall Effect sensors in transportation systems necessitates adherence to rigorous safety standards and certification requirements across multiple jurisdictions. In the automotive sector, these sensors must comply with ISO 26262, which establishes a comprehensive framework for functional safety in road vehicles. This standard categorizes safety integrity levels (ASIL) from A to D, with Hall Effect sensors in critical applications such as steering and braking systems typically requiring ASIL C or D certification, demanding extensive validation testing and failure mode analysis.

For railway applications, EN 50155 governs electronic equipment in rolling stock, imposing stringent requirements for temperature resistance, shock, vibration, and electromagnetic compatibility. Hall Effect sensors deployed in this environment must demonstrate reliability across temperature ranges from -40°C to +85°C and withstand mechanical stresses encountered during normal railway operations.

The aerospace industry imposes even more demanding standards through DO-254 for hardware certification and DO-160 for environmental conditions. Hall Effect sensors in aircraft systems must undergo rigorous qualification testing, including altitude simulation, rapid decompression scenarios, and resistance to fluid contamination. The certification process typically requires extensive documentation of design processes, verification methods, and validation results.

Maritime applications follow IEC 60945 standards, which emphasize salt fog resistance, humidity tolerance, and protection against water ingress. Hall Effect sensors deployed in marine environments require IP67 or higher ingress protection ratings to ensure continued functionality in harsh conditions.

Beyond industry-specific standards, electromagnetic compatibility requirements outlined in IEC 61000 series apply across transportation sectors. Hall Effect sensors must demonstrate immunity to electromagnetic interference while not generating emissions that could affect other critical systems. This necessitates comprehensive EMC testing during the certification process.

Regional variations in certification requirements present additional challenges for global deployment. While European markets follow CE marking protocols under applicable directives, North American applications may require UL certification. Asian markets, particularly China and Japan, maintain their own certification systems that must be navigated for product approval.

The certification landscape continues to evolve with increasing focus on cybersecurity requirements, particularly for connected transportation systems. Standards such as ISO/SAE 21434 for automotive cybersecurity are beginning to influence sensor certification processes, requiring manufacturers to demonstrate security by design principles in their Hall Effect sensor implementations.

For railway applications, EN 50155 governs electronic equipment in rolling stock, imposing stringent requirements for temperature resistance, shock, vibration, and electromagnetic compatibility. Hall Effect sensors deployed in this environment must demonstrate reliability across temperature ranges from -40°C to +85°C and withstand mechanical stresses encountered during normal railway operations.

The aerospace industry imposes even more demanding standards through DO-254 for hardware certification and DO-160 for environmental conditions. Hall Effect sensors in aircraft systems must undergo rigorous qualification testing, including altitude simulation, rapid decompression scenarios, and resistance to fluid contamination. The certification process typically requires extensive documentation of design processes, verification methods, and validation results.

Maritime applications follow IEC 60945 standards, which emphasize salt fog resistance, humidity tolerance, and protection against water ingress. Hall Effect sensors deployed in marine environments require IP67 or higher ingress protection ratings to ensure continued functionality in harsh conditions.

Beyond industry-specific standards, electromagnetic compatibility requirements outlined in IEC 61000 series apply across transportation sectors. Hall Effect sensors must demonstrate immunity to electromagnetic interference while not generating emissions that could affect other critical systems. This necessitates comprehensive EMC testing during the certification process.

Regional variations in certification requirements present additional challenges for global deployment. While European markets follow CE marking protocols under applicable directives, North American applications may require UL certification. Asian markets, particularly China and Japan, maintain their own certification systems that must be navigated for product approval.

The certification landscape continues to evolve with increasing focus on cybersecurity requirements, particularly for connected transportation systems. Standards such as ISO/SAE 21434 for automotive cybersecurity are beginning to influence sensor certification processes, requiring manufacturers to demonstrate security by design principles in their Hall Effect sensor implementations.

Energy Efficiency Impact of Advanced Hall Sensors

Advanced Hall Effect sensors are making significant contributions to energy efficiency in transportation systems through multiple pathways. The implementation of these sensors enables precise control of electric motors in hybrid and electric vehicles, optimizing power consumption during acceleration, cruising, and regenerative braking phases. Studies indicate that advanced Hall sensor-based motor control systems can improve energy efficiency by 8-12% compared to conventional sensor technologies, directly translating to extended range capabilities for electric vehicles.

In commercial transportation, Hall Effect sensors integrated with intelligent power management systems help reduce fuel consumption in conventional combustion engines. These sensors provide accurate timing for fuel injection systems and enable cylinder deactivation technologies, allowing engines to operate at optimal efficiency points based on real-time load requirements. Fleet operators implementing these advanced sensor systems report fuel savings of 5-7% across their operations.

The energy efficiency benefits extend beyond propulsion systems. Advanced Hall sensors enable smart energy management in vehicle auxiliary systems, including climate control, lighting, and entertainment systems. By precisely monitoring current flow and enabling demand-based power distribution, these sensors help reduce parasitic energy losses that traditionally account for up to 15% of a vehicle's total energy consumption.

From a manufacturing perspective, the integration of Hall Effect sensors contributes to weight reduction in transportation systems. Modern Hall sensors are significantly smaller and lighter than previous generations while offering enhanced functionality. This miniaturization supports the broader trend toward vehicle lightweighting, with each 10% reduction in vehicle weight corresponding to approximately 6-8% improvement in energy efficiency.

The lifecycle energy impact of Hall sensor technology is also noteworthy. These sensors require minimal maintenance and demonstrate exceptional longevity, reducing the embodied energy costs associated with component replacement and service. Their solid-state design eliminates moving parts that would otherwise contribute to energy losses through friction and mechanical wear.

Looking at infrastructure applications, Hall Effect sensors are enabling more efficient traffic management systems that reduce congestion and idle time. Smart traffic signals utilizing these sensors can adapt to real-time traffic conditions, potentially reducing urban fuel consumption by up to 10% through improved traffic flow. This system-level efficiency gain represents a significant energy saving when scaled across metropolitan transportation networks.

In commercial transportation, Hall Effect sensors integrated with intelligent power management systems help reduce fuel consumption in conventional combustion engines. These sensors provide accurate timing for fuel injection systems and enable cylinder deactivation technologies, allowing engines to operate at optimal efficiency points based on real-time load requirements. Fleet operators implementing these advanced sensor systems report fuel savings of 5-7% across their operations.

The energy efficiency benefits extend beyond propulsion systems. Advanced Hall sensors enable smart energy management in vehicle auxiliary systems, including climate control, lighting, and entertainment systems. By precisely monitoring current flow and enabling demand-based power distribution, these sensors help reduce parasitic energy losses that traditionally account for up to 15% of a vehicle's total energy consumption.

From a manufacturing perspective, the integration of Hall Effect sensors contributes to weight reduction in transportation systems. Modern Hall sensors are significantly smaller and lighter than previous generations while offering enhanced functionality. This miniaturization supports the broader trend toward vehicle lightweighting, with each 10% reduction in vehicle weight corresponding to approximately 6-8% improvement in energy efficiency.

The lifecycle energy impact of Hall sensor technology is also noteworthy. These sensors require minimal maintenance and demonstrate exceptional longevity, reducing the embodied energy costs associated with component replacement and service. Their solid-state design eliminates moving parts that would otherwise contribute to energy losses through friction and mechanical wear.

Looking at infrastructure applications, Hall Effect sensors are enabling more efficient traffic management systems that reduce congestion and idle time. Smart traffic signals utilizing these sensors can adapt to real-time traffic conditions, potentially reducing urban fuel consumption by up to 10% through improved traffic flow. This system-level efficiency gain represents a significant energy saving when scaled across metropolitan transportation networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!