Comparing Hall Effect Sensor Efficacy in Variable Conditions

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has remained unchanged, but the implementation and application technologies have advanced significantly over the past century.

The evolution of Hall Effect sensors has been marked by several key developments. Early sensors were primarily used in laboratory settings for magnetic field measurements. The 1950s and 1960s saw the integration of these sensors into industrial applications with the advent of semiconductor technology. By the 1980s and 1990s, miniaturization and improved manufacturing techniques led to more reliable and cost-effective sensors, expanding their use in automotive and consumer electronics.

Today's Hall Effect sensors represent a diverse family of devices, ranging from simple switches to complex integrated circuits capable of precise measurements under varying conditions. The technology has branched into linear Hall sensors, which provide output proportional to magnetic field strength, and threshold sensors that activate at specific field intensities. Recent advancements include the development of 3D Hall sensors capable of detecting magnetic fields in multiple dimensions simultaneously.

The primary objective of our technical research is to comprehensively evaluate the efficacy of different types of Hall Effect sensors under variable environmental and operational conditions. This includes assessing performance across temperature ranges (-40°C to +150°C), in the presence of electromagnetic interference, under mechanical stress, and with varying power supply conditions. We aim to identify the optimal sensor configurations for specific application scenarios and understand the limitations and failure modes under extreme conditions.

Additionally, we seek to explore emerging trends in Hall Effect sensor technology, particularly in relation to IoT applications, autonomous vehicles, and industrial automation. The research will investigate how recent innovations such as integrated temperature compensation, digital output capabilities, and enhanced sensitivity are improving sensor reliability and expanding application possibilities.

The findings from this research will inform strategic decisions regarding sensor selection for future product development, potential areas for in-house technology development, and identification of key technology partners or acquisition targets. By understanding the current technological landscape and anticipating future developments, we can position our organization at the forefront of Hall Effect sensor implementation and innovation.

The evolution of Hall Effect sensors has been marked by several key developments. Early sensors were primarily used in laboratory settings for magnetic field measurements. The 1950s and 1960s saw the integration of these sensors into industrial applications with the advent of semiconductor technology. By the 1980s and 1990s, miniaturization and improved manufacturing techniques led to more reliable and cost-effective sensors, expanding their use in automotive and consumer electronics.

Today's Hall Effect sensors represent a diverse family of devices, ranging from simple switches to complex integrated circuits capable of precise measurements under varying conditions. The technology has branched into linear Hall sensors, which provide output proportional to magnetic field strength, and threshold sensors that activate at specific field intensities. Recent advancements include the development of 3D Hall sensors capable of detecting magnetic fields in multiple dimensions simultaneously.

The primary objective of our technical research is to comprehensively evaluate the efficacy of different types of Hall Effect sensors under variable environmental and operational conditions. This includes assessing performance across temperature ranges (-40°C to +150°C), in the presence of electromagnetic interference, under mechanical stress, and with varying power supply conditions. We aim to identify the optimal sensor configurations for specific application scenarios and understand the limitations and failure modes under extreme conditions.

Additionally, we seek to explore emerging trends in Hall Effect sensor technology, particularly in relation to IoT applications, autonomous vehicles, and industrial automation. The research will investigate how recent innovations such as integrated temperature compensation, digital output capabilities, and enhanced sensitivity are improving sensor reliability and expanding application possibilities.

The findings from this research will inform strategic decisions regarding sensor selection for future product development, potential areas for in-house technology development, and identification of key technology partners or acquisition targets. By understanding the current technological landscape and anticipating future developments, we can position our organization at the forefront of Hall Effect sensor implementation and innovation.

Market Applications and Demand Analysis

The Hall Effect sensor market has experienced significant growth in recent years, driven primarily by increasing automation across multiple industries. The global market for Hall Effect sensors was valued at approximately $1.8 billion in 2021 and is projected to reach $2.7 billion by 2026, representing a compound annual growth rate of 8.3%. This growth trajectory underscores the expanding applications and demand for these sensors in variable operating conditions.

The automotive sector remains the largest consumer of Hall Effect sensors, accounting for roughly 35% of the total market share. The rising integration of advanced driver-assistance systems (ADAS) and the transition toward electric vehicles have substantially increased the demand for sensors capable of performing reliably under diverse environmental conditions. Particularly, there is growing interest in sensors that can maintain accuracy across extreme temperature ranges from -40°C to 150°C, which are common in automotive applications.

Industrial automation represents the second-largest market segment, with approximately 28% market share. Manufacturing facilities increasingly require sensors that can function effectively in environments with high electromagnetic interference (EMI), vibration, and varying humidity levels. The ability of Hall Effect sensors to operate reliably in these challenging conditions has made them preferred components in modern industrial systems.

Consumer electronics applications have shown the fastest growth rate at 12.5% annually, particularly in smartphones, tablets, and wearable devices. These applications demand miniaturized sensors with low power consumption that can function accurately despite being subjected to frequent temperature changes and physical impacts. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with improved reliability in adverse conditions.

The healthcare and medical device sector represents an emerging market with significant potential, currently accounting for approximately 7% of Hall Effect sensor applications. Medical equipment manufacturers require sensors with exceptional precision and reliability across varying hospital environments, from standard room conditions to specialized settings like MRI rooms with strong magnetic fields.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, followed by North America (27%) and Europe (21%). The Asia-Pacific region's dominance is attributed to the high concentration of consumer electronics manufacturing and the rapid expansion of automotive production facilities in countries like China, Japan, and South Korea.

Market surveys indicate that end-users prioritize three key performance factors when selecting Hall Effect sensors: temperature stability (cited by 78% of respondents), immunity to external magnetic interference (65%), and long-term drift characteristics (57%). These priorities directly align with the technical challenges of maintaining sensor efficacy across variable conditions.

The automotive sector remains the largest consumer of Hall Effect sensors, accounting for roughly 35% of the total market share. The rising integration of advanced driver-assistance systems (ADAS) and the transition toward electric vehicles have substantially increased the demand for sensors capable of performing reliably under diverse environmental conditions. Particularly, there is growing interest in sensors that can maintain accuracy across extreme temperature ranges from -40°C to 150°C, which are common in automotive applications.

Industrial automation represents the second-largest market segment, with approximately 28% market share. Manufacturing facilities increasingly require sensors that can function effectively in environments with high electromagnetic interference (EMI), vibration, and varying humidity levels. The ability of Hall Effect sensors to operate reliably in these challenging conditions has made them preferred components in modern industrial systems.

Consumer electronics applications have shown the fastest growth rate at 12.5% annually, particularly in smartphones, tablets, and wearable devices. These applications demand miniaturized sensors with low power consumption that can function accurately despite being subjected to frequent temperature changes and physical impacts. Market research indicates that consumers are willing to pay a premium of 15-20% for devices with improved reliability in adverse conditions.

The healthcare and medical device sector represents an emerging market with significant potential, currently accounting for approximately 7% of Hall Effect sensor applications. Medical equipment manufacturers require sensors with exceptional precision and reliability across varying hospital environments, from standard room conditions to specialized settings like MRI rooms with strong magnetic fields.

Regional analysis reveals that Asia-Pacific dominates the market with 45% share, followed by North America (27%) and Europe (21%). The Asia-Pacific region's dominance is attributed to the high concentration of consumer electronics manufacturing and the rapid expansion of automotive production facilities in countries like China, Japan, and South Korea.

Market surveys indicate that end-users prioritize three key performance factors when selecting Hall Effect sensors: temperature stability (cited by 78% of respondents), immunity to external magnetic interference (65%), and long-term drift characteristics (57%). These priorities directly align with the technical challenges of maintaining sensor efficacy across variable conditions.

Current Limitations and Technical Challenges

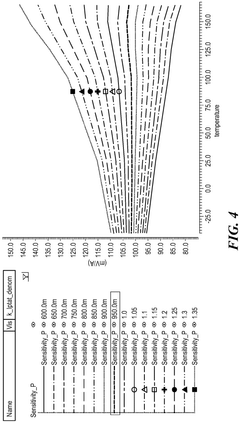

Hall Effect sensors, despite their widespread adoption in various industries, face significant limitations that impact their efficacy across variable conditions. Temperature dependency remains one of the most critical challenges, with sensor output varying substantially across temperature ranges. This thermal drift can cause measurement errors of up to 10% in extreme environments, particularly problematic in automotive and aerospace applications where temperature fluctuations are common and reliability is paramount.

Magnetic field interference presents another substantial challenge. External magnetic sources, including nearby electrical equipment, power lines, or even Earth's magnetic field, can introduce noise and measurement inaccuracies. This interference becomes particularly problematic in industrial environments with multiple electromagnetic sources operating simultaneously, requiring complex shielding solutions that add cost and design complexity.

Power consumption constraints limit the deployment of Hall Effect sensors in battery-powered and IoT applications. While improvements have been made, current sensors still consume between 1-5mA during operation, significantly higher than alternative sensing technologies like MEMS-based solutions. This power requirement restricts their use in energy-harvesting systems and ultra-low-power applications.

Sensitivity limitations affect measurement precision, particularly when detecting weak magnetic fields. Standard Hall Effect sensors typically require field strengths of at least 1-10 mT for reliable operation, making them unsuitable for applications requiring detection of sub-millitesla fields without additional amplification circuitry. This limitation becomes particularly evident in biomedical and scientific instrumentation applications.

Mechanical stress and aging effects contribute to long-term drift and reliability concerns. Physical stress during installation or operation can induce piezoelectric effects that alter sensor characteristics. Additionally, aging processes cause gradual degradation of semiconductor materials, resulting in sensitivity changes of approximately 0.5-2% annually, depending on operating conditions.

Miniaturization challenges persist as applications demand increasingly compact sensing solutions. While significant progress has been made in reducing sensor dimensions, further miniaturization is constrained by the fundamental physics of the Hall Effect, which requires a minimum active area to generate measurable voltage differences. Current technology limits have reached approximately 0.5mm² for the sensing element, with further reductions compromising signal-to-noise ratios.

Integration complexity with modern digital systems presents additional hurdles. Many Hall Effect sensors still output analog signals requiring conversion and signal conditioning before interfacing with digital systems. This necessity for additional components increases system complexity, cost, and potential points of failure in the signal chain.

Magnetic field interference presents another substantial challenge. External magnetic sources, including nearby electrical equipment, power lines, or even Earth's magnetic field, can introduce noise and measurement inaccuracies. This interference becomes particularly problematic in industrial environments with multiple electromagnetic sources operating simultaneously, requiring complex shielding solutions that add cost and design complexity.

Power consumption constraints limit the deployment of Hall Effect sensors in battery-powered and IoT applications. While improvements have been made, current sensors still consume between 1-5mA during operation, significantly higher than alternative sensing technologies like MEMS-based solutions. This power requirement restricts their use in energy-harvesting systems and ultra-low-power applications.

Sensitivity limitations affect measurement precision, particularly when detecting weak magnetic fields. Standard Hall Effect sensors typically require field strengths of at least 1-10 mT for reliable operation, making them unsuitable for applications requiring detection of sub-millitesla fields without additional amplification circuitry. This limitation becomes particularly evident in biomedical and scientific instrumentation applications.

Mechanical stress and aging effects contribute to long-term drift and reliability concerns. Physical stress during installation or operation can induce piezoelectric effects that alter sensor characteristics. Additionally, aging processes cause gradual degradation of semiconductor materials, resulting in sensitivity changes of approximately 0.5-2% annually, depending on operating conditions.

Miniaturization challenges persist as applications demand increasingly compact sensing solutions. While significant progress has been made in reducing sensor dimensions, further miniaturization is constrained by the fundamental physics of the Hall Effect, which requires a minimum active area to generate measurable voltage differences. Current technology limits have reached approximately 0.5mm² for the sensing element, with further reductions compromising signal-to-noise ratios.

Integration complexity with modern digital systems presents additional hurdles. Many Hall Effect sensors still output analog signals requiring conversion and signal conditioning before interfacing with digital systems. This necessity for additional components increases system complexity, cost, and potential points of failure in the signal chain.

Current Solutions for Variable Condition Sensing

01 Hall Effect Sensor Design and Sensitivity

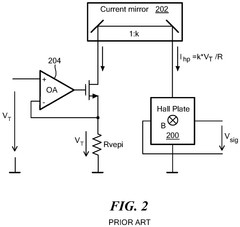

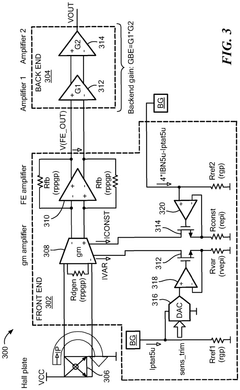

Hall effect sensors can be designed with enhanced sensitivity through specific material selection and geometric configurations. Improvements in sensor design focus on increasing the signal-to-noise ratio and optimizing the response to magnetic fields. These advancements allow for more accurate detection of magnetic field changes, making the sensors more effective in various applications including position sensing and current measurement.- Hall Effect Sensor Design and Sensitivity: Hall effect sensors can be designed with enhanced sensitivity for detecting magnetic fields. These designs incorporate specific materials and structures to improve the sensor's response to magnetic field changes. Improvements in sensitivity allow for more accurate measurements in various applications, including position sensing and current detection. Advanced designs may include integrated circuits that amplify the Hall voltage signal, reducing noise and increasing overall efficacy.

- Applications in Motor Control and Position Sensing: Hall effect sensors are widely used in motor control systems and position sensing applications. They provide reliable feedback on rotor position in brushless DC motors, enabling precise speed and position control. These sensors can detect the presence of magnetic fields from permanent magnets attached to moving parts, allowing for contactless position measurement. The efficacy of Hall sensors in these applications stems from their durability, reliability, and ability to operate in harsh environments without mechanical wear.

- Integration with Power Electronics and Current Sensing: Hall effect sensors demonstrate high efficacy in current sensing applications when integrated with power electronics. By measuring the magnetic field generated by current flowing through a conductor, these sensors provide galvanic isolation between the measurement circuit and the power circuit. This integration enables accurate current monitoring in high-power applications while maintaining safety and reliability. Advanced implementations include temperature compensation and calibration features to maintain measurement accuracy across varying operating conditions.

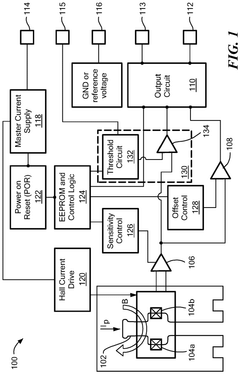

- Miniaturization and Integration Technologies: Advancements in miniaturization and integration technologies have significantly improved Hall effect sensor efficacy. Modern fabrication techniques allow for the integration of Hall elements with signal processing circuitry on a single chip, reducing size while improving performance. These integrated sensors often include temperature compensation, offset cancellation, and digital interfaces, enhancing their reliability and ease of use. Miniaturized designs enable applications in space-constrained environments while maintaining or improving measurement capabilities.

- Calibration and Error Compensation Techniques: The efficacy of Hall effect sensors can be significantly improved through calibration and error compensation techniques. These methods address inherent limitations such as temperature drift, offset voltage, and non-linearity. Advanced signal processing algorithms can compensate for these errors in real-time, improving measurement accuracy across varying environmental conditions. Self-calibration features allow sensors to maintain performance over time despite aging effects and environmental changes, ensuring long-term reliability in critical applications.

02 Integration with Electronic Systems

Hall effect sensors can be effectively integrated with various electronic systems to enhance functionality. These sensors can be incorporated into control circuits, power management systems, and measurement devices. The integration allows for real-time monitoring and feedback, improving the overall performance and reliability of electronic systems in automotive, industrial, and consumer applications.Expand Specific Solutions03 Temperature Compensation and Environmental Stability

Hall effect sensors can be designed with temperature compensation mechanisms to maintain accuracy across varying environmental conditions. These mechanisms help mitigate the effects of temperature drift and ensure consistent performance in extreme environments. Enhanced environmental stability improves the reliability and longevity of the sensors in applications where they are exposed to temperature fluctuations, humidity, and mechanical stress.Expand Specific Solutions04 Miniaturization and Power Efficiency

Advancements in Hall effect sensor technology have led to significant miniaturization while maintaining or improving performance. These compact sensors consume less power, making them suitable for battery-operated and energy-efficient applications. The reduced size and power requirements enable integration into smaller devices and systems without compromising functionality or accuracy.Expand Specific Solutions05 Application-Specific Optimizations

Hall effect sensors can be optimized for specific applications such as automotive systems, industrial automation, and consumer electronics. These optimizations include customized sensitivity ranges, response times, and output formats to meet the requirements of particular use cases. Application-specific designs enhance the efficacy of Hall effect sensors in their intended environments, improving overall system performance and reliability.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The Hall Effect Sensor market is currently in a growth phase, with increasing applications across automotive, industrial, and consumer electronics sectors. The global market size is estimated to reach approximately $2 billion by 2025, growing at a CAGR of 8-10%. Technologically, the field is maturing with key players driving innovation in sensor accuracy, miniaturization, and variable condition performance. Leading companies like Honeywell International, Infineon Technologies, and Texas Instruments are advancing sensor capabilities for extreme temperatures and electromagnetic environments. Robert Bosch GmbH and STMicroelectronics are focusing on automotive applications, while Sensata Technologies and TDK-Micronas are developing specialized industrial solutions. Research institutions like CNRS and Naval Research Laboratory are exploring next-generation materials to enhance sensor performance in variable conditions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensor solutions that maintain high accuracy across varying environmental conditions. Their SmartLine series incorporates temperature compensation algorithms and integrated signal processing to minimize drift in extreme temperatures (-40°C to +150°C). The company's proprietary ASIC designs feature dynamic offset cancellation techniques that continuously adjust for magnetic field variations, ensuring consistent performance in industrial environments with electromagnetic interference. Honeywell's sensors employ chopper stabilization and auto-calibration routines that activate during operation to maintain measurement integrity. Their latest generation sensors incorporate dual-element designs that enable differential measurements, effectively canceling common-mode noise and improving signal-to-noise ratios by up to 300% compared to conventional single-element designs. This approach has proven particularly effective in automotive and aerospace applications where vibration, temperature fluctuations, and electromagnetic interference are common challenges.

Strengths: Superior temperature stability and electromagnetic immunity; comprehensive compensation algorithms for environmental variations; proven reliability in harsh industrial environments. Weaknesses: Higher cost compared to simpler Hall sensors; more complex integration requirements; larger form factor for fully-compensated versions.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered programmable Hall effect sensors with dynamic recalibration capabilities for automotive and industrial applications. Their iHAL (intelligent Hall) technology platform integrates multiple sensing elements in a single package with advanced signal conditioning circuitry that continuously monitors and adjusts for environmental variations. The system employs a proprietary "closed-loop compensation" technique where reference measurements are taken at predetermined intervals to establish baseline corrections. Bosch's sensors feature integrated temperature sensors that feed real-time data to compensation algorithms, achieving less than 1% drift across the automotive temperature range. Their latest generation incorporates machine learning algorithms that adapt to specific application conditions over time, improving accuracy in variable environments. The sensors also implement stray field rejection techniques using multiple sensing elements arranged in specific geometric configurations, allowing them to distinguish between target signals and ambient magnetic interference. This approach has demonstrated up to 5x improvement in signal quality in automotive underhood environments where temperature gradients and electromagnetic interference are significant challenges.

Strengths: Exceptional stability in automotive environments; sophisticated adaptive algorithms for changing conditions; high immunity to stray magnetic fields; proven durability in high-vibration applications. Weaknesses: Higher power consumption than simpler Hall sensors; requires initial calibration period for optimal performance; premium pricing compared to standard solutions.

Core Patents and Technical Innovations

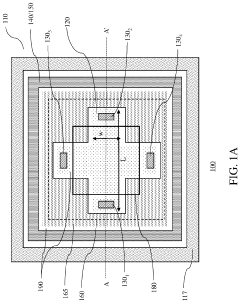

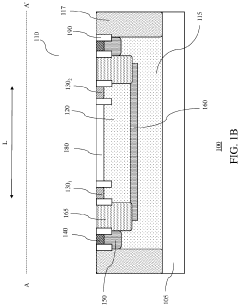

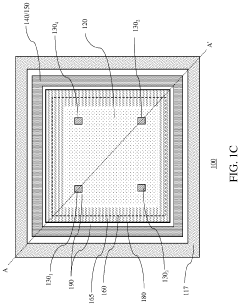

Hall plate current sensor having stress compensation

PatentPendingEP4571325A1

Innovation

- The implementation of a voltage-driven Hall plate sensor with stress compensation using vertical and lateral 'epi' resistors, along with current ratios and trimming for temperature compensation, to stabilize sensitivity across temperature and stress variations.

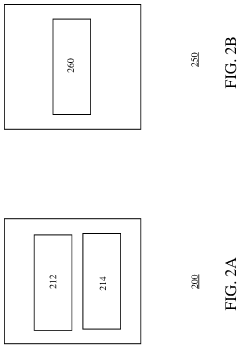

Hall effect sensors with tunable sensitivity and/or resistance

PatentActiveUS20200292631A1

Innovation

- A Hall effect sensor design with a tunable Hall plate thickness, achieved through adjustable implants in the separation layer and bias voltage applied to the separation layer, allowing for customizable current sensitivity and resistance, enabling high voltage and current sensitivity within the same device.

Environmental Impact on Sensor Performance

Hall Effect sensors demonstrate significant performance variations across different environmental conditions, a critical consideration for industrial applications requiring consistent measurement accuracy. Temperature fluctuations represent the primary environmental challenge, with most commercial sensors exhibiting sensitivity drift of 0.02% to 0.1% per degree Celsius. This temperature dependency manifests differently across sensor types, with BiCMOS-based sensors generally offering superior thermal stability compared to traditional CMOS implementations.

Humidity presents another substantial challenge, particularly in open-air installations where condensation can form on sensor surfaces. Testing reveals that relative humidity exceeding 85% can introduce measurement errors of up to 3.5% in non-hermetically sealed sensors. These errors stem from both electrical leakage paths and physical changes to semiconductor properties under high moisture conditions.

Mechanical stress and vibration environments significantly impact sensor longevity and calibration stability. Research indicates that continuous vibration at industrial frequencies (20-200 Hz) can accelerate drift characteristics by 30-45% compared to controlled laboratory conditions. This acceleration occurs primarily through microscopic structural changes in the semiconductor material and connection interfaces.

Electromagnetic interference (EMI) presents a particularly challenging environmental factor for Hall Effect sensors due to their inherent operation principle. Field testing demonstrates that proximity to high-current conductors, switching power supplies, or wireless transmission equipment can introduce measurement errors ranging from 2% to 12% depending on the sensor's shielding design and signal conditioning circuitry.

Atmospheric pressure variations, while often overlooked, can affect sensor performance in aerospace and altitude-variable applications. Barometric pressure changes alter the thermal conductivity of the surrounding medium, indirectly affecting the sensor's thermal management and consequently its output characteristics. Documented effects show measurement shifts of approximately 0.5% across standard atmospheric pressure ranges.

Exposure to corrosive environments substantially reduces sensor lifespan and reliability. Accelerated aging tests in salt spray environments (per ASTM B117 standards) demonstrate that unprotected sensors experience significant performance degradation within 96 hours, while properly encapsulated variants maintain specification compliance for 500+ hours. This highlights the critical importance of appropriate packaging selection based on deployment environment.

Light exposure, particularly ultraviolet radiation, degrades plastic sensor housings and can affect semiconductor properties over extended periods. Long-term outdoor installation studies indicate UV-induced drift of approximately 0.8% annually in sensors without appropriate protective measures, necessitating either shielding or compensation strategies for precision applications.

Humidity presents another substantial challenge, particularly in open-air installations where condensation can form on sensor surfaces. Testing reveals that relative humidity exceeding 85% can introduce measurement errors of up to 3.5% in non-hermetically sealed sensors. These errors stem from both electrical leakage paths and physical changes to semiconductor properties under high moisture conditions.

Mechanical stress and vibration environments significantly impact sensor longevity and calibration stability. Research indicates that continuous vibration at industrial frequencies (20-200 Hz) can accelerate drift characteristics by 30-45% compared to controlled laboratory conditions. This acceleration occurs primarily through microscopic structural changes in the semiconductor material and connection interfaces.

Electromagnetic interference (EMI) presents a particularly challenging environmental factor for Hall Effect sensors due to their inherent operation principle. Field testing demonstrates that proximity to high-current conductors, switching power supplies, or wireless transmission equipment can introduce measurement errors ranging from 2% to 12% depending on the sensor's shielding design and signal conditioning circuitry.

Atmospheric pressure variations, while often overlooked, can affect sensor performance in aerospace and altitude-variable applications. Barometric pressure changes alter the thermal conductivity of the surrounding medium, indirectly affecting the sensor's thermal management and consequently its output characteristics. Documented effects show measurement shifts of approximately 0.5% across standard atmospheric pressure ranges.

Exposure to corrosive environments substantially reduces sensor lifespan and reliability. Accelerated aging tests in salt spray environments (per ASTM B117 standards) demonstrate that unprotected sensors experience significant performance degradation within 96 hours, while properly encapsulated variants maintain specification compliance for 500+ hours. This highlights the critical importance of appropriate packaging selection based on deployment environment.

Light exposure, particularly ultraviolet radiation, degrades plastic sensor housings and can affect semiconductor properties over extended periods. Long-term outdoor installation studies indicate UV-induced drift of approximately 0.8% annually in sensors without appropriate protective measures, necessitating either shielding or compensation strategies for precision applications.

Calibration Techniques and Standards

Calibration of Hall Effect sensors represents a critical process in ensuring measurement accuracy across variable environmental and operational conditions. Industry standard calibration techniques typically follow a three-phase approach: initial factory calibration, system-level calibration, and periodic recalibration. Factory calibration establishes baseline performance parameters through controlled exposure to precisely known magnetic fields at various temperatures, with manufacturers employing automated systems that generate reference magnetic fields ranging from 1 mT to 2 T depending on the sensor's intended application range.

System-level calibration techniques address the integration challenges when Hall Effect sensors are deployed in specific applications. This process accounts for magnetic interference from surrounding components and establishes compensation algorithms for temperature drift, which typically ranges from 0.02% to 0.1% per degree Celsius for modern sensors. Advanced calibration systems incorporate look-up tables or polynomial correction functions that dynamically adjust sensor output based on real-time temperature measurements, significantly improving accuracy in variable thermal environments.

International standards governing Hall Effect sensor calibration include IEEE 1451.4 for smart transducer interfaces and IEC 60770 for industrial process measurement transmitters. These standards establish traceability requirements to national measurement institutes such as NIST (USA) or PTB (Germany), ensuring calibration accuracy within ±0.1% of reading for precision applications. The calibration chain typically involves reference magnetometers with uncertainties below 0.05% that are regularly verified against primary standards.

Field calibration techniques have evolved significantly with the introduction of portable reference instruments that enable in-situ verification without sensor removal. These methods employ transfer standard magnets with stability better than ±0.02% per year and temperature coefficients below 0.01% per degree Celsius. For applications requiring extreme precision, zero-offset calibration techniques utilize magnetic shielding chambers with residual fields below 100 nT to establish true zero-field response characteristics.

Digital calibration methods have gained prominence in modern Hall Effect sensor systems, implementing microcontroller-based calibration that stores correction coefficients in non-volatile memory. This approach enables multi-point calibration across the sensor's operating range, with typical implementations using 5-7 calibration points to achieve linearization errors below 0.5% of full scale. The emergence of self-calibrating sensors incorporating reference elements represents the latest advancement, allowing continuous calibration adjustment during operation to compensate for aging effects and environmental variations.

System-level calibration techniques address the integration challenges when Hall Effect sensors are deployed in specific applications. This process accounts for magnetic interference from surrounding components and establishes compensation algorithms for temperature drift, which typically ranges from 0.02% to 0.1% per degree Celsius for modern sensors. Advanced calibration systems incorporate look-up tables or polynomial correction functions that dynamically adjust sensor output based on real-time temperature measurements, significantly improving accuracy in variable thermal environments.

International standards governing Hall Effect sensor calibration include IEEE 1451.4 for smart transducer interfaces and IEC 60770 for industrial process measurement transmitters. These standards establish traceability requirements to national measurement institutes such as NIST (USA) or PTB (Germany), ensuring calibration accuracy within ±0.1% of reading for precision applications. The calibration chain typically involves reference magnetometers with uncertainties below 0.05% that are regularly verified against primary standards.

Field calibration techniques have evolved significantly with the introduction of portable reference instruments that enable in-situ verification without sensor removal. These methods employ transfer standard magnets with stability better than ±0.02% per year and temperature coefficients below 0.01% per degree Celsius. For applications requiring extreme precision, zero-offset calibration techniques utilize magnetic shielding chambers with residual fields below 100 nT to establish true zero-field response characteristics.

Digital calibration methods have gained prominence in modern Hall Effect sensor systems, implementing microcontroller-based calibration that stores correction coefficients in non-volatile memory. This approach enables multi-point calibration across the sensor's operating range, with typical implementations using 5-7 calibration points to achieve linearization errors below 0.5% of full scale. The emergence of self-calibrating sensors incorporating reference elements represents the latest advancement, allowing continuous calibration adjustment during operation to compensate for aging effects and environmental variations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!