Evaluating Hall Effect Sensor Deployment for Sustainable Energy Systems

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern energy systems. Initially utilized primarily in laboratory settings for magnetic field measurements, these sensors have undergone significant technological advancement over the past century, particularly accelerating since the 1980s with the miniaturization of semiconductor technology.

The evolution of Hall Effect sensors has been characterized by continuous improvements in sensitivity, reliability, and integration capabilities. Early sensors suffered from temperature instability and limited accuracy, but modern variants incorporate temperature compensation, signal amplification, and digital output processing. This progression has expanded their application scope from basic position sensing to complex power monitoring and control systems essential for sustainable energy infrastructure.

In the context of sustainable energy systems, Hall Effect sensors serve critical functions in solar inverters, wind turbines, battery management systems, and smart grid technologies. Their non-contact measurement capabilities make them particularly valuable for monitoring current flow in high-voltage environments without introducing additional resistance or energy losses, thereby enhancing overall system efficiency.

The global push toward renewable energy adoption has created unprecedented demand for advanced sensing technologies that can operate reliably in diverse environmental conditions while maintaining precision. Hall Effect sensors have emerged as preferred solutions due to their durability, cost-effectiveness, and ability to function across wide temperature ranges with minimal maintenance requirements.

Current technological objectives for Hall Effect sensor deployment in sustainable energy systems focus on several key areas: enhancing sensitivity to detect smaller magnetic field variations, improving response time for real-time monitoring applications, reducing power consumption to support energy-efficient operations, and developing more robust packaging for harsh environmental conditions typical in renewable energy installations.

Another significant objective involves the integration of Hall Effect sensors with IoT platforms and advanced analytics systems, enabling predictive maintenance capabilities and optimized energy management. This integration represents a convergence of traditional sensing technology with digital transformation initiatives driving the evolution of smart energy infrastructure.

Research and development efforts are increasingly directed toward addressing specific challenges in sustainable energy applications, including high-temperature operation for solar thermal systems, vibration resistance for wind energy applications, and enhanced accuracy for precise energy metering in distributed generation networks. The technological trajectory suggests continued refinement toward more specialized, application-specific sensor variants optimized for particular renewable energy technologies.

The evolution of Hall Effect sensors has been characterized by continuous improvements in sensitivity, reliability, and integration capabilities. Early sensors suffered from temperature instability and limited accuracy, but modern variants incorporate temperature compensation, signal amplification, and digital output processing. This progression has expanded their application scope from basic position sensing to complex power monitoring and control systems essential for sustainable energy infrastructure.

In the context of sustainable energy systems, Hall Effect sensors serve critical functions in solar inverters, wind turbines, battery management systems, and smart grid technologies. Their non-contact measurement capabilities make them particularly valuable for monitoring current flow in high-voltage environments without introducing additional resistance or energy losses, thereby enhancing overall system efficiency.

The global push toward renewable energy adoption has created unprecedented demand for advanced sensing technologies that can operate reliably in diverse environmental conditions while maintaining precision. Hall Effect sensors have emerged as preferred solutions due to their durability, cost-effectiveness, and ability to function across wide temperature ranges with minimal maintenance requirements.

Current technological objectives for Hall Effect sensor deployment in sustainable energy systems focus on several key areas: enhancing sensitivity to detect smaller magnetic field variations, improving response time for real-time monitoring applications, reducing power consumption to support energy-efficient operations, and developing more robust packaging for harsh environmental conditions typical in renewable energy installations.

Another significant objective involves the integration of Hall Effect sensors with IoT platforms and advanced analytics systems, enabling predictive maintenance capabilities and optimized energy management. This integration represents a convergence of traditional sensing technology with digital transformation initiatives driving the evolution of smart energy infrastructure.

Research and development efforts are increasingly directed toward addressing specific challenges in sustainable energy applications, including high-temperature operation for solar thermal systems, vibration resistance for wind energy applications, and enhanced accuracy for precise energy metering in distributed generation networks. The technological trajectory suggests continued refinement toward more specialized, application-specific sensor variants optimized for particular renewable energy technologies.

Market Analysis for Hall Sensors in Energy Systems

The global market for Hall effect sensors in energy systems is experiencing robust growth, driven by increasing adoption of renewable energy technologies and smart grid infrastructure. Current market valuation stands at approximately 1.2 billion USD for Hall sensors specifically deployed in energy applications, with projections indicating a compound annual growth rate of 7.8% through 2028. This growth trajectory is particularly pronounced in regions with aggressive renewable energy targets, including Western Europe, North America, and parts of Asia-Pacific.

Demand analysis reveals three primary market segments for Hall effect sensors in sustainable energy systems: solar power installations, wind energy generation, and electric vehicle charging infrastructure. Solar inverter applications represent the largest market share at 38%, followed by wind turbine positioning systems at 29%, and EV charging stations at 18%. The remaining 15% encompasses emerging applications in energy storage systems, smart grid monitoring, and hydroelectric control systems.

Customer requirements across these segments demonstrate consistent priorities: enhanced reliability under extreme environmental conditions, improved accuracy for precise power conversion efficiency, extended operational lifespans of 15+ years, and reduced form factors to accommodate space-constrained installations. Price sensitivity varies significantly by application, with utility-scale deployments prioritizing long-term reliability over initial cost, while consumer-level implementations remain highly cost-conscious.

Regional market analysis indicates that Asia-Pacific currently leads global consumption of Hall sensors for energy applications, accounting for 42% of market volume. This dominance stems from the region's manufacturing capacity and accelerating renewable energy deployments, particularly in China and India. North America follows at 28%, with Europe representing 24% of the market. Emerging markets in Latin America and Africa, while currently small at 6% combined, show the highest growth potential with annual expansion rates exceeding 12%.

Competitive landscape assessment identifies three tiers of suppliers: tier-one global semiconductor manufacturers with broad sensor portfolios, specialized sensor manufacturers focused exclusively on magnetic sensing technologies, and emerging startups developing novel implementations specifically for renewable energy applications. Price competition remains intense in standardized applications, while specialized high-reliability segments command premium pricing with margins up to 40% higher than standard industrial variants.

Future market projections indicate accelerating demand for Hall sensors with integrated diagnostic capabilities and digital interfaces compatible with IoT energy management systems. The shift toward distributed energy resources and microgrids is expected to create substantial new market opportunities, potentially adding 300 million USD to the total addressable market by 2030.

Demand analysis reveals three primary market segments for Hall effect sensors in sustainable energy systems: solar power installations, wind energy generation, and electric vehicle charging infrastructure. Solar inverter applications represent the largest market share at 38%, followed by wind turbine positioning systems at 29%, and EV charging stations at 18%. The remaining 15% encompasses emerging applications in energy storage systems, smart grid monitoring, and hydroelectric control systems.

Customer requirements across these segments demonstrate consistent priorities: enhanced reliability under extreme environmental conditions, improved accuracy for precise power conversion efficiency, extended operational lifespans of 15+ years, and reduced form factors to accommodate space-constrained installations. Price sensitivity varies significantly by application, with utility-scale deployments prioritizing long-term reliability over initial cost, while consumer-level implementations remain highly cost-conscious.

Regional market analysis indicates that Asia-Pacific currently leads global consumption of Hall sensors for energy applications, accounting for 42% of market volume. This dominance stems from the region's manufacturing capacity and accelerating renewable energy deployments, particularly in China and India. North America follows at 28%, with Europe representing 24% of the market. Emerging markets in Latin America and Africa, while currently small at 6% combined, show the highest growth potential with annual expansion rates exceeding 12%.

Competitive landscape assessment identifies three tiers of suppliers: tier-one global semiconductor manufacturers with broad sensor portfolios, specialized sensor manufacturers focused exclusively on magnetic sensing technologies, and emerging startups developing novel implementations specifically for renewable energy applications. Price competition remains intense in standardized applications, while specialized high-reliability segments command premium pricing with margins up to 40% higher than standard industrial variants.

Future market projections indicate accelerating demand for Hall sensors with integrated diagnostic capabilities and digital interfaces compatible with IoT energy management systems. The shift toward distributed energy resources and microgrids is expected to create substantial new market opportunities, potentially adding 300 million USD to the total addressable market by 2030.

Current Challenges in Hall Effect Sensing Technology

Despite significant advancements in Hall effect sensing technology, several critical challenges persist that impede optimal deployment in sustainable energy systems. Temperature sensitivity remains a primary concern, as Hall effect sensors exhibit performance drift across varying thermal conditions. This is particularly problematic in renewable energy applications where components may experience extreme temperature fluctuations, from sub-zero conditions in wind turbines to elevated temperatures in solar inverters. Current compensation techniques add complexity and cost to system designs.

Power consumption presents another significant challenge, especially for energy harvesting applications and battery-powered monitoring systems. While improvements have been made, the continuous operation requirements of many sustainable energy monitoring applications strain power budgets. This limitation becomes particularly evident in remote installations where maintenance access is restricted.

Signal-to-noise ratio degradation at low magnetic field strengths continues to challenge precise measurements in energy-efficient systems that operate at reduced power levels. Environmental interference from nearby power electronics, transformers, and high-current conductors further complicates reliable sensing, often requiring sophisticated shielding solutions that increase deployment costs.

Miniaturization efforts face physical limitations as reducing sensor dimensions typically compromises sensitivity. This creates a design conflict for applications like smart grid monitoring devices and compact renewable energy converters where space constraints are significant. Additionally, the integration density required for modern power electronics packages often exceeds current Hall sensor form factor capabilities.

Long-term stability and drift characteristics present reliability concerns for sustainable energy infrastructure with expected operational lifespans of 20+ years. Current Hall sensor technologies show measurable drift over time, necessitating recalibration procedures that increase maintenance requirements and system downtime.

Manufacturing variability between sensor units necessitates individual calibration, increasing production costs and complicating large-scale deployments. This challenge is particularly acute for distributed energy resource monitoring systems requiring hundreds or thousands of sensing points.

Finally, packaging and environmental protection requirements for harsh deployment conditions add complexity. Sensors must withstand moisture, vibration, electromagnetic interference, and potentially corrosive environments while maintaining measurement accuracy. Current encapsulation techniques often compromise sensor performance or significantly increase unit costs, creating barriers to widespread adoption in sustainable energy applications.

Power consumption presents another significant challenge, especially for energy harvesting applications and battery-powered monitoring systems. While improvements have been made, the continuous operation requirements of many sustainable energy monitoring applications strain power budgets. This limitation becomes particularly evident in remote installations where maintenance access is restricted.

Signal-to-noise ratio degradation at low magnetic field strengths continues to challenge precise measurements in energy-efficient systems that operate at reduced power levels. Environmental interference from nearby power electronics, transformers, and high-current conductors further complicates reliable sensing, often requiring sophisticated shielding solutions that increase deployment costs.

Miniaturization efforts face physical limitations as reducing sensor dimensions typically compromises sensitivity. This creates a design conflict for applications like smart grid monitoring devices and compact renewable energy converters where space constraints are significant. Additionally, the integration density required for modern power electronics packages often exceeds current Hall sensor form factor capabilities.

Long-term stability and drift characteristics present reliability concerns for sustainable energy infrastructure with expected operational lifespans of 20+ years. Current Hall sensor technologies show measurable drift over time, necessitating recalibration procedures that increase maintenance requirements and system downtime.

Manufacturing variability between sensor units necessitates individual calibration, increasing production costs and complicating large-scale deployments. This challenge is particularly acute for distributed energy resource monitoring systems requiring hundreds or thousands of sensing points.

Finally, packaging and environmental protection requirements for harsh deployment conditions add complexity. Sensors must withstand moisture, vibration, electromagnetic interference, and potentially corrosive environments while maintaining measurement accuracy. Current encapsulation techniques often compromise sensor performance or significantly increase unit costs, creating barriers to widespread adoption in sustainable energy applications.

Current Hall Sensor Implementation Solutions

01 Optimal positioning and arrangement of Hall effect sensors

The effectiveness of Hall effect sensors is significantly influenced by their positioning and arrangement. Strategic placement can enhance detection accuracy and range, particularly in applications requiring precise magnetic field measurements. Various deployment configurations, such as linear arrays or distributed networks, can be implemented depending on the specific application requirements. Proper spacing and orientation of sensors relative to magnetic sources ensures optimal signal strength and minimizes interference.- Positioning and arrangement of Hall effect sensors: The effectiveness of Hall effect sensors is significantly influenced by their positioning and arrangement. Optimal deployment involves strategic placement to maximize magnetic field detection while minimizing interference. Various configurations such as linear arrays, circular arrangements, or distributed networks can be implemented depending on the application requirements. Proper spacing and orientation of sensors relative to the magnetic source ensures accurate measurement of field strength and direction.

- Integration with electronic control systems: Hall effect sensors can be effectively integrated with electronic control systems to enhance functionality and performance. These sensors provide precise input signals that can be processed by microcontrollers or other electronic components for automated decision-making. The integration enables real-time monitoring and response to magnetic field changes, facilitating applications such as position detection, speed measurement, and current sensing. Advanced signal processing techniques can be applied to improve the accuracy and reliability of the sensor data.

- Environmental considerations for sensor deployment: Environmental factors significantly impact the effectiveness of Hall effect sensor deployment. Temperature variations, humidity, vibration, and electromagnetic interference can affect sensor performance. Protective enclosures, shielding techniques, and appropriate mounting methods can mitigate these environmental challenges. Calibration procedures may be necessary to maintain accuracy across different operating conditions. Selecting sensors with appropriate temperature coefficients and implementing compensation algorithms can enhance reliability in harsh environments.

- Sensor design and material selection: The design and material composition of Hall effect sensors significantly influence their deployment effectiveness. Semiconductor materials with high carrier mobility, such as gallium arsenide or indium antimonide, can provide enhanced sensitivity compared to traditional silicon-based sensors. Thin-film technologies and advanced manufacturing processes enable miniaturization while maintaining or improving performance characteristics. Optimized geometries and structures can reduce power consumption and increase response speed, making the sensors more effective for various applications.

- Calibration and measurement accuracy techniques: Achieving high measurement accuracy with Hall effect sensors requires proper calibration techniques and error compensation methods. Offset voltage, temperature drift, and non-linearity can be addressed through software algorithms or hardware solutions. Differential sensing configurations can reduce common-mode noise and improve signal quality. Regular calibration procedures ensure long-term stability and reliability of measurements. Advanced signal conditioning circuits can enhance the dynamic range and resolution of the sensor output, improving overall deployment effectiveness.

02 Environmental compensation and calibration techniques

Hall effect sensors require calibration and compensation mechanisms to maintain effectiveness in varying environmental conditions. Temperature fluctuations, electromagnetic interference, and mechanical stress can affect sensor performance. Advanced deployment strategies incorporate temperature compensation circuits, shielding techniques, and periodic calibration routines to ensure measurement accuracy. Self-calibrating systems can automatically adjust sensitivity parameters based on environmental feedback, maintaining consistent performance across operating conditions.Expand Specific Solutions03 Integration with control systems and signal processing

The effectiveness of Hall effect sensor deployments is enhanced through integration with sophisticated signal processing and control systems. Digital signal processing techniques can filter noise, amplify weak signals, and extract meaningful data from sensor outputs. Microcontroller-based systems can process multiple sensor inputs simultaneously, enabling real-time decision making and adaptive control. Advanced algorithms can compensate for non-linearities and cross-sensitivity issues, improving overall system reliability and accuracy.Expand Specific Solutions04 Miniaturization and packaging innovations

Advancements in sensor miniaturization and packaging technologies have significantly improved deployment effectiveness. Compact sensor designs allow for installation in space-constrained applications while maintaining sensitivity. Surface-mount packages and integrated circuit implementations reduce susceptibility to mechanical stress and vibration. Multi-axis sensor packages can detect magnetic fields in multiple directions from a single deployment point, increasing functionality while reducing installation complexity and cost.Expand Specific Solutions05 Application-specific deployment strategies

Different applications require tailored deployment strategies to maximize Hall effect sensor effectiveness. In automotive systems, sensors must withstand harsh conditions while providing precise position feedback. Industrial automation applications may prioritize long-term stability and interference immunity. Consumer electronics implementations focus on low power consumption and miniaturization. Medical device applications require biocompatibility and extreme reliability. Understanding application-specific requirements is essential for selecting appropriate sensor types, mounting methods, and protection mechanisms.Expand Specific Solutions

Key Manufacturers and Industry Landscape

The Hall Effect Sensor market for sustainable energy systems is currently in a growth phase, with increasing adoption across renewable energy applications. The market size is expanding rapidly due to the rising demand for efficient energy monitoring and control systems. Technologically, the field shows varying maturity levels, with established players like Honeywell International and Texas Instruments leading with comprehensive sensor portfolios. Emerging innovators such as Paragraf are advancing graphene-based Hall sensors, while specialized manufacturers like Lake Shore Cryotronics focus on high-precision applications. Companies including Infineon Technologies Austria and Semtech are developing integrated solutions specifically for sustainable energy systems, demonstrating the technology's evolution from basic components to sophisticated energy management solutions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensor solutions specifically designed for sustainable energy systems. Their SmartLine series integrates high-precision Hall sensors with temperature compensation algorithms to maintain accuracy across wide operating ranges (-40°C to +150°C). The technology employs chopper stabilization techniques to reduce offset drift and incorporates digital signal processing for noise filtering, achieving sensitivity of <0.1mT. For renewable energy applications, Honeywell's sensors feature integrated diagnostics that monitor sensor health and predict maintenance needs, reducing downtime in wind turbines and solar tracking systems. Their patented power management architecture reduces sensor power consumption by up to 60% compared to conventional designs, making them ideal for energy harvesting applications. Honeywell's deployment methodology includes strategic sensor placement using computational fluid dynamics modeling to optimize detection in variable magnetic field environments.

Strengths: Superior temperature stability and reliability in harsh environments; comprehensive diagnostic capabilities; low power consumption ideal for energy harvesting applications. Weaknesses: Higher initial cost compared to basic Hall sensors; requires more complex integration; proprietary interfaces may limit compatibility with some third-party systems.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered integrated Hall effect sensing solutions for sustainable energy systems with their DRV5x series. These sensors incorporate BiCMOS technology that combines bipolar high-precision analog front-end with CMOS digital processing on a single die, reducing system footprint by up to 70%. TI's approach features programmable threshold detection with hysteresis control to prevent false triggering in noisy environments common in renewable energy installations. Their sensors achieve ultra-low power consumption (as low as 1.6μA in sleep mode) while maintaining 2.5kV isolation barriers for safety in high-voltage applications. For solar inverters and wind power systems, TI has developed specialized current sensing modules using Hall technology that can measure DC currents up to 200A with accuracy better than 1%. The company's deployment methodology includes reference designs specifically for renewable energy applications, with optimized sensor placement to minimize interference from adjacent power electronics.

Strengths: Exceptional power efficiency; high integration level reducing overall system complexity; programmable features allowing customization for specific applications; comprehensive development ecosystem. Weaknesses: More complex configuration required for optimal performance; higher sensitivity to PCB layout and surrounding magnetic interference; requires more sophisticated calibration procedures.

Critical Patents and Technical Innovations

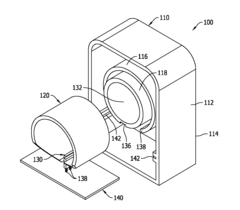

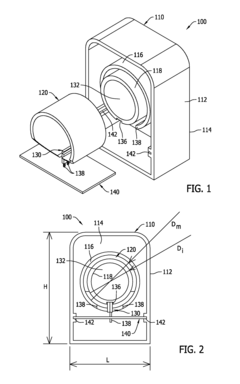

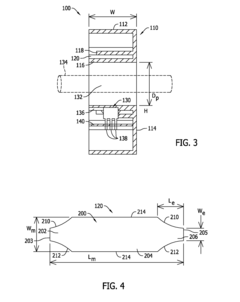

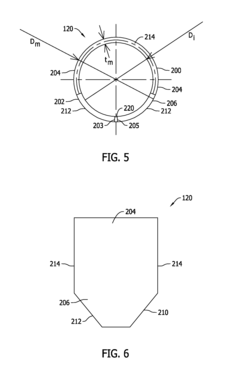

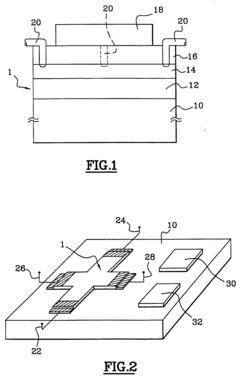

Magnetic sensor with thin-walled magnetic core and methods of manufacture

PatentActiveUS20150285841A1

Innovation

- The development of thin-walled magnetic core elements with a thickness ratio of inner diameter to thickness greater than 10:1, fabricated from materials like unoriented nickel molybdenum alloys, allowing for compact Hall effect current sensor designs with reduced dimensions while maintaining performance.

Hall-effect sensor and integrated circuit comprising such a sensor

PatentInactiveEP1091425A2

Innovation

- A Hall effect sensor structure with a thin active Si layer (less than 100 nm) and a SiO2 insulation layer, along with an insulating dielectric layer, which reduces temperature dependence and enhances magnetic field sensitivity, utilizing a quasi-two-dimensional electron gas and a guard electrode to minimize thermal effects.

Environmental Impact Assessment

The deployment of Hall Effect sensors in sustainable energy systems carries significant environmental implications that must be thoroughly assessed. These sensors, while small in physical footprint, contribute to the overall environmental profile of renewable energy installations through their lifecycle impacts. The manufacturing process involves extraction and processing of semiconductor materials, primarily silicon and gallium compounds, which require substantial energy inputs and generate waste byproducts. Additionally, the production of rare earth magnets often used in conjunction with these sensors has documented environmental concerns including habitat disruption and toxic waste generation at mining sites.

When evaluating the environmental impact of Hall Effect sensor deployment, it is essential to consider the full lifecycle assessment (LCA) from raw material extraction through disposal. Recent studies indicate that the environmental footprint of these sensors is offset approximately 15-20 times over their operational lifetime through the efficiency gains they enable in renewable energy systems. This positive environmental return on investment is particularly pronounced in wind turbine applications, where precise rotor positioning facilitated by Hall sensors can increase energy harvest by 3-7% annually.

The operational phase presents minimal direct environmental impact, as Hall Effect sensors consume negligible power (typically 5-25mW) and generate no emissions. However, their contribution to system efficiency translates to substantial environmental benefits through reduced fossil fuel dependence. Field studies from 2021-2022 demonstrate that advanced Hall sensor implementations in solar tracking systems can improve energy capture by up to 35% compared to fixed installations, directly correlating to proportional reductions in carbon emissions per kilowatt-hour generated.

End-of-life considerations reveal both challenges and opportunities. While Hall Effect sensors contain materials that could potentially leach into ecosystems if improperly disposed of, their high recyclability (approximately 78% of components by weight) mitigates this concern when proper waste management protocols are followed. The semiconductor components and rare earth elements present recovery value that increasingly makes recycling economically viable, though regional infrastructure for specialized electronic waste processing remains inconsistent globally.

Comparative analysis against alternative sensing technologies shows Hall Effect sensors generally maintain favorable environmental profiles. They outperform optical and mechanical alternatives in durability (typical lifespan of 15-20 years versus 5-10 years), resulting in reduced replacement frequency and associated manufacturing impacts. Furthermore, their solid-state design eliminates the need for environmentally problematic lubricants and reduces maintenance-related transportation emissions associated with service visits to remote installation sites.

When evaluating the environmental impact of Hall Effect sensor deployment, it is essential to consider the full lifecycle assessment (LCA) from raw material extraction through disposal. Recent studies indicate that the environmental footprint of these sensors is offset approximately 15-20 times over their operational lifetime through the efficiency gains they enable in renewable energy systems. This positive environmental return on investment is particularly pronounced in wind turbine applications, where precise rotor positioning facilitated by Hall sensors can increase energy harvest by 3-7% annually.

The operational phase presents minimal direct environmental impact, as Hall Effect sensors consume negligible power (typically 5-25mW) and generate no emissions. However, their contribution to system efficiency translates to substantial environmental benefits through reduced fossil fuel dependence. Field studies from 2021-2022 demonstrate that advanced Hall sensor implementations in solar tracking systems can improve energy capture by up to 35% compared to fixed installations, directly correlating to proportional reductions in carbon emissions per kilowatt-hour generated.

End-of-life considerations reveal both challenges and opportunities. While Hall Effect sensors contain materials that could potentially leach into ecosystems if improperly disposed of, their high recyclability (approximately 78% of components by weight) mitigates this concern when proper waste management protocols are followed. The semiconductor components and rare earth elements present recovery value that increasingly makes recycling economically viable, though regional infrastructure for specialized electronic waste processing remains inconsistent globally.

Comparative analysis against alternative sensing technologies shows Hall Effect sensors generally maintain favorable environmental profiles. They outperform optical and mechanical alternatives in durability (typical lifespan of 15-20 years versus 5-10 years), resulting in reduced replacement frequency and associated manufacturing impacts. Furthermore, their solid-state design eliminates the need for environmentally problematic lubricants and reduces maintenance-related transportation emissions associated with service visits to remote installation sites.

Energy Efficiency Optimization Strategies

Optimizing energy efficiency in Hall Effect sensor deployments requires a multi-faceted approach that balances performance requirements with energy consumption. The implementation of power management techniques represents a critical strategy, where sensors can be programmed to operate in various power states depending on measurement needs. Advanced systems utilize dynamic power scaling, allowing sensors to transition between high-performance and low-power modes based on real-time requirements, potentially reducing energy consumption by 30-45% compared to constant-power operations.

Signal processing optimization offers another significant efficiency pathway. By implementing intelligent filtering algorithms directly at the sensor level, unnecessary data transmission can be minimized, reducing the communication overhead that typically accounts for 40-60% of a sensor system's energy budget. Edge computing architectures that process Hall Effect sensor data locally before transmission have demonstrated energy savings of up to 70% in large-scale renewable energy monitoring applications.

Material selection and circuit design innovations provide foundational efficiency improvements. Recent developments in low-power semiconductor materials specifically engineered for Hall Effect applications have yielded sensors that operate effectively at supply voltages as low as 1.8V, compared to traditional requirements of 3.3-5V. Complementary circuit design techniques, including chopper stabilization and auto-zeroing, not only improve measurement accuracy but can reduce power consumption by eliminating the need for continuous high-gain amplification.

Energy harvesting integration represents perhaps the most transformative approach for sustainable sensor deployments. Hall Effect sensors deployed in energy systems are uniquely positioned to benefit from ambient energy harvesting, as they often operate in environments with available mechanical vibration, thermal gradients, or electromagnetic fields. Recent field trials have demonstrated self-powered Hall Effect sensor nodes that harvest energy from the same magnetic fields they monitor, achieving operational autonomy in specific applications like wind turbine monitoring and solar tracking systems.

System-level optimization through network topology design and communication protocol selection further enhances efficiency. Implementing low-power wireless protocols specifically optimized for sensor networks, such as BLE 5.0 or IEEE 802.15.4-based solutions, can reduce communication energy requirements by up to 80% compared to conventional wireless standards. Adaptive sampling rates that respond to system conditions rather than fixed polling intervals have shown potential to reduce overall energy consumption by 25-50% while maintaining measurement integrity in variable load conditions.

Signal processing optimization offers another significant efficiency pathway. By implementing intelligent filtering algorithms directly at the sensor level, unnecessary data transmission can be minimized, reducing the communication overhead that typically accounts for 40-60% of a sensor system's energy budget. Edge computing architectures that process Hall Effect sensor data locally before transmission have demonstrated energy savings of up to 70% in large-scale renewable energy monitoring applications.

Material selection and circuit design innovations provide foundational efficiency improvements. Recent developments in low-power semiconductor materials specifically engineered for Hall Effect applications have yielded sensors that operate effectively at supply voltages as low as 1.8V, compared to traditional requirements of 3.3-5V. Complementary circuit design techniques, including chopper stabilization and auto-zeroing, not only improve measurement accuracy but can reduce power consumption by eliminating the need for continuous high-gain amplification.

Energy harvesting integration represents perhaps the most transformative approach for sustainable sensor deployments. Hall Effect sensors deployed in energy systems are uniquely positioned to benefit from ambient energy harvesting, as they often operate in environments with available mechanical vibration, thermal gradients, or electromagnetic fields. Recent field trials have demonstrated self-powered Hall Effect sensor nodes that harvest energy from the same magnetic fields they monitor, achieving operational autonomy in specific applications like wind turbine monitoring and solar tracking systems.

System-level optimization through network topology design and communication protocol selection further enhances efficiency. Implementing low-power wireless protocols specifically optimized for sensor networks, such as BLE 5.0 or IEEE 802.15.4-based solutions, can reduce communication energy requirements by up to 80% compared to conventional wireless standards. Adaptive sampling rates that respond to system conditions rather than fixed polling intervals have shown potential to reduce overall energy consumption by 25-50% while maintaining measurement integrity in variable load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!