How to Scale Up Hall Effect Sensor Solutions in Smart Factories

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern industrial automation systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when placed in a magnetic field. This fundamental principle has remained unchanged, but the application scope and technological sophistication have expanded dramatically over the decades.

The evolution of Hall Effect sensors has been marked by significant improvements in sensitivity, miniaturization, and integration capabilities. Early industrial applications were limited to basic position sensing, but today's sensors incorporate advanced signal processing, temperature compensation, and digital interfaces, enabling their deployment in complex smart factory environments.

In the context of Industry 4.0 and smart manufacturing, Hall Effect sensors serve as critical data acquisition points for monitoring machine operations, ensuring precision in automated processes, and facilitating predictive maintenance systems. Their non-contact nature makes them particularly valuable in harsh industrial environments where mechanical wear is a concern.

The primary objective of scaling up Hall Effect sensor solutions in smart factories is to create comprehensive sensing networks that can provide real-time, accurate data across manufacturing operations. This involves not only increasing the number of deployed sensors but also enhancing their connectivity, data processing capabilities, and integration with factory-wide systems.

Technical goals include developing more robust sensor architectures capable of withstanding industrial conditions while maintaining high accuracy, implementing efficient power management for wireless sensor deployments, and creating standardized communication protocols to facilitate seamless integration with existing industrial control systems.

Another critical objective is to leverage Hall Effect sensors as enablers for advanced analytics and machine learning applications in manufacturing. By providing reliable, continuous data streams about equipment operation, these sensors can support algorithms that optimize production processes, predict equipment failures, and reduce downtime.

The trajectory of Hall Effect sensor technology is moving toward greater intelligence at the edge, with sensors increasingly incorporating local processing capabilities to filter and pre-analyze data before transmission. This trend aligns with the broader movement toward distributed intelligence in industrial IoT architectures.

As manufacturing facilities worldwide seek to enhance their competitiveness through digitalization, the strategic implementation of Hall Effect sensor networks represents a foundational element in achieving the vision of fully connected, adaptive, and self-optimizing production environments.

The evolution of Hall Effect sensors has been marked by significant improvements in sensitivity, miniaturization, and integration capabilities. Early industrial applications were limited to basic position sensing, but today's sensors incorporate advanced signal processing, temperature compensation, and digital interfaces, enabling their deployment in complex smart factory environments.

In the context of Industry 4.0 and smart manufacturing, Hall Effect sensors serve as critical data acquisition points for monitoring machine operations, ensuring precision in automated processes, and facilitating predictive maintenance systems. Their non-contact nature makes them particularly valuable in harsh industrial environments where mechanical wear is a concern.

The primary objective of scaling up Hall Effect sensor solutions in smart factories is to create comprehensive sensing networks that can provide real-time, accurate data across manufacturing operations. This involves not only increasing the number of deployed sensors but also enhancing their connectivity, data processing capabilities, and integration with factory-wide systems.

Technical goals include developing more robust sensor architectures capable of withstanding industrial conditions while maintaining high accuracy, implementing efficient power management for wireless sensor deployments, and creating standardized communication protocols to facilitate seamless integration with existing industrial control systems.

Another critical objective is to leverage Hall Effect sensors as enablers for advanced analytics and machine learning applications in manufacturing. By providing reliable, continuous data streams about equipment operation, these sensors can support algorithms that optimize production processes, predict equipment failures, and reduce downtime.

The trajectory of Hall Effect sensor technology is moving toward greater intelligence at the edge, with sensors increasingly incorporating local processing capabilities to filter and pre-analyze data before transmission. This trend aligns with the broader movement toward distributed intelligence in industrial IoT architectures.

As manufacturing facilities worldwide seek to enhance their competitiveness through digitalization, the strategic implementation of Hall Effect sensor networks represents a foundational element in achieving the vision of fully connected, adaptive, and self-optimizing production environments.

Industrial IoT Market Demand Analysis

The Industrial IoT (IIoT) market is experiencing unprecedented growth, driven by the increasing adoption of smart manufacturing technologies and Industry 4.0 initiatives. The global IIoT market was valued at approximately $77.3 billion in 2020 and is projected to reach $110.6 billion by 2025, growing at a CAGR of 7.4%. Within this expanding ecosystem, sensor technologies—particularly Hall Effect sensors—are emerging as critical components for automation, monitoring, and control systems in smart factories.

Market research indicates that manufacturing enterprises are increasingly seeking comprehensive sensor solutions that can provide real-time data on machine operations, environmental conditions, and production processes. Hall Effect sensors, which detect magnetic fields and convert them into measurable electrical signals, are particularly valuable for position sensing, speed detection, and current measurement applications in industrial environments.

The demand for Hall Effect sensor solutions in smart factories is being fueled by several key factors. First, there is a growing emphasis on predictive maintenance strategies, with 60% of manufacturers reporting implementation or plans to implement such systems. These strategies rely heavily on sensor data to detect equipment anomalies before failures occur, reducing downtime by up to 50% and maintenance costs by 10-40%.

Second, the push toward energy efficiency and sustainability has created demand for precise current and power monitoring solutions. Hall Effect sensors enable non-intrusive current measurement, allowing factories to optimize energy consumption across production lines and meet increasingly stringent environmental regulations.

Third, the automotive and electronics manufacturing sectors—which together account for approximately 45% of Hall Effect sensor applications—are experiencing rapid growth in production automation. These industries require high-precision positioning and speed detection capabilities that Hall Effect sensors can reliably provide in harsh industrial environments.

Regional analysis reveals varying adoption rates, with North America and Europe leading implementation due to their established manufacturing bases and higher technology investment rates. However, the Asia-Pacific region is showing the fastest growth rate at 9.2% annually, driven by China's massive manufacturing sector modernization and Japan's advanced robotics integration.

Customer requirements are evolving toward more integrated sensor solutions that combine Hall Effect technology with wireless connectivity, edge computing capabilities, and compatibility with major industrial automation platforms. Survey data indicates that 73% of manufacturing decision-makers prioritize sensors that can seamlessly integrate with existing systems while providing a clear path for scalability.

The market is also witnessing increased demand for miniaturized Hall Effect sensors with enhanced sensitivity and lower power consumption, particularly for applications in confined spaces and battery-powered industrial IoT devices. This trend aligns with the broader movement toward more distributed sensing architectures in smart factory environments.

Market research indicates that manufacturing enterprises are increasingly seeking comprehensive sensor solutions that can provide real-time data on machine operations, environmental conditions, and production processes. Hall Effect sensors, which detect magnetic fields and convert them into measurable electrical signals, are particularly valuable for position sensing, speed detection, and current measurement applications in industrial environments.

The demand for Hall Effect sensor solutions in smart factories is being fueled by several key factors. First, there is a growing emphasis on predictive maintenance strategies, with 60% of manufacturers reporting implementation or plans to implement such systems. These strategies rely heavily on sensor data to detect equipment anomalies before failures occur, reducing downtime by up to 50% and maintenance costs by 10-40%.

Second, the push toward energy efficiency and sustainability has created demand for precise current and power monitoring solutions. Hall Effect sensors enable non-intrusive current measurement, allowing factories to optimize energy consumption across production lines and meet increasingly stringent environmental regulations.

Third, the automotive and electronics manufacturing sectors—which together account for approximately 45% of Hall Effect sensor applications—are experiencing rapid growth in production automation. These industries require high-precision positioning and speed detection capabilities that Hall Effect sensors can reliably provide in harsh industrial environments.

Regional analysis reveals varying adoption rates, with North America and Europe leading implementation due to their established manufacturing bases and higher technology investment rates. However, the Asia-Pacific region is showing the fastest growth rate at 9.2% annually, driven by China's massive manufacturing sector modernization and Japan's advanced robotics integration.

Customer requirements are evolving toward more integrated sensor solutions that combine Hall Effect technology with wireless connectivity, edge computing capabilities, and compatibility with major industrial automation platforms. Survey data indicates that 73% of manufacturing decision-makers prioritize sensors that can seamlessly integrate with existing systems while providing a clear path for scalability.

The market is also witnessing increased demand for miniaturized Hall Effect sensors with enhanced sensitivity and lower power consumption, particularly for applications in confined spaces and battery-powered industrial IoT devices. This trend aligns with the broader movement toward more distributed sensing architectures in smart factory environments.

Current Challenges in Hall Effect Sensor Deployment

Despite the proven benefits of Hall effect sensors in industrial automation, several significant challenges impede their widespread deployment in smart factory environments. The primary obstacle remains the integration complexity with existing industrial systems. Many factories operate legacy equipment that lacks standardized interfaces for modern sensor technologies, creating compatibility issues that require custom engineering solutions and increase implementation costs substantially.

Scalability presents another major hurdle, as expanding sensor networks across large manufacturing facilities demands robust infrastructure. The exponential growth in data volume from numerous sensors distributed throughout production lines necessitates sophisticated data management systems that many manufacturers have not yet developed. This challenge is compounded by bandwidth limitations in factory networks originally designed for less data-intensive operations.

Environmental factors within manufacturing settings pose significant technical challenges for Hall effect sensor deployment. Industrial environments frequently contain electromagnetic interference from heavy machinery, high temperatures, vibrations, and exposure to chemicals or particulates. These conditions can compromise sensor accuracy and reliability, requiring additional protective measures and regular recalibration protocols that increase maintenance overhead.

Power management emerges as a critical concern, particularly for wireless sensor implementations. While wireless sensors offer flexibility in placement and reduce installation complexity, they introduce power supply challenges. Battery-powered sensors require periodic replacement or recharging, creating maintenance requirements that can disrupt production schedules. Energy harvesting alternatives remain insufficient for continuous high-frequency sensing applications typical in advanced manufacturing.

Data security and privacy considerations present growing challenges as sensor networks become more interconnected. Hall effect sensors collecting operational data may inadvertently capture proprietary manufacturing processes or production metrics. Securing this sensitive information against unauthorized access while maintaining system interoperability with various factory systems requires sophisticated cybersecurity measures that many manufacturers struggle to implement effectively.

Calibration and measurement accuracy pose persistent technical challenges, particularly in applications requiring precise detection of magnetic field variations. Environmental drift, component aging, and temperature fluctuations can affect sensor performance over time. Maintaining measurement consistency across large sensor networks demands automated calibration systems and compensation algorithms that add complexity to deployment architectures.

Cost justification remains a significant barrier, especially for small and medium-sized manufacturers. While sensor costs have decreased, the total implementation expense—including installation, integration, maintenance, and training—can be substantial. Many organizations struggle to quantify the return on investment for comprehensive sensor deployments, particularly when benefits like predictive maintenance capabilities may take years to fully materialize financially.

Scalability presents another major hurdle, as expanding sensor networks across large manufacturing facilities demands robust infrastructure. The exponential growth in data volume from numerous sensors distributed throughout production lines necessitates sophisticated data management systems that many manufacturers have not yet developed. This challenge is compounded by bandwidth limitations in factory networks originally designed for less data-intensive operations.

Environmental factors within manufacturing settings pose significant technical challenges for Hall effect sensor deployment. Industrial environments frequently contain electromagnetic interference from heavy machinery, high temperatures, vibrations, and exposure to chemicals or particulates. These conditions can compromise sensor accuracy and reliability, requiring additional protective measures and regular recalibration protocols that increase maintenance overhead.

Power management emerges as a critical concern, particularly for wireless sensor implementations. While wireless sensors offer flexibility in placement and reduce installation complexity, they introduce power supply challenges. Battery-powered sensors require periodic replacement or recharging, creating maintenance requirements that can disrupt production schedules. Energy harvesting alternatives remain insufficient for continuous high-frequency sensing applications typical in advanced manufacturing.

Data security and privacy considerations present growing challenges as sensor networks become more interconnected. Hall effect sensors collecting operational data may inadvertently capture proprietary manufacturing processes or production metrics. Securing this sensitive information against unauthorized access while maintaining system interoperability with various factory systems requires sophisticated cybersecurity measures that many manufacturers struggle to implement effectively.

Calibration and measurement accuracy pose persistent technical challenges, particularly in applications requiring precise detection of magnetic field variations. Environmental drift, component aging, and temperature fluctuations can affect sensor performance over time. Maintaining measurement consistency across large sensor networks demands automated calibration systems and compensation algorithms that add complexity to deployment architectures.

Cost justification remains a significant barrier, especially for small and medium-sized manufacturers. While sensor costs have decreased, the total implementation expense—including installation, integration, maintenance, and training—can be substantial. Many organizations struggle to quantify the return on investment for comprehensive sensor deployments, particularly when benefits like predictive maintenance capabilities may take years to fully materialize financially.

Existing Hall Effect Sensor Scaling Solutions

01 Hall Effect Sensor Array Configurations

Various configurations of Hall effect sensor arrays can be implemented to scale up sensing capabilities. These include linear arrays, matrix arrangements, and distributed sensor networks that enable wider coverage areas and multi-dimensional field measurements. Advanced array designs incorporate multiple sensors working in coordination to provide enhanced spatial resolution and measurement accuracy across larger areas or volumes.- Hall Effect Sensor Array Configurations: Various configurations of Hall effect sensor arrays can be implemented to scale up sensing capabilities. These include linear arrays, matrix arrangements, and distributed sensor networks that enable wider coverage and higher resolution measurements. Such configurations allow for more comprehensive magnetic field mapping and improved spatial resolution in applications requiring large-scale sensing areas.

- Integration with Power Systems and Industrial Applications: Hall effect sensors can be scaled up for industrial and power system applications by integrating them with power electronics, motor control systems, and industrial automation equipment. These sensors provide reliable current measurement, position detection, and speed monitoring in high-power environments, enabling efficient control and protection of large-scale electrical systems.

- Miniaturization and Semiconductor Manufacturing Techniques: Advanced semiconductor manufacturing techniques enable the scaling up of Hall effect sensor production while simultaneously reducing their physical size. These techniques include integrated circuit fabrication methods, MEMS technology, and specialized packaging approaches that allow for mass production of miniaturized sensors with consistent performance characteristics.

- Enhanced Sensitivity and Measurement Range: Techniques for enhancing the sensitivity and measurement range of Hall effect sensors enable their application in large-scale sensing systems. These include signal amplification circuits, noise reduction techniques, and specialized magnetic concentrators that improve the detection of weak magnetic fields while maintaining accuracy across wider measurement ranges.

- Multi-Axis and 3D Sensing Capabilities: Advanced Hall effect sensor systems incorporate multi-axis and three-dimensional sensing capabilities to scale up their functionality. These systems use multiple sensor elements oriented in different directions to measure magnetic fields in all spatial dimensions, enabling comprehensive field mapping and more sophisticated position and orientation detection in large-scale applications.

02 Manufacturing Techniques for Large-Scale Hall Sensors

Specialized manufacturing techniques enable the production of Hall effect sensors at scale. These include semiconductor fabrication processes optimized for large sensor arrays, integration of sensors with supporting circuitry on single substrates, and batch production methods. Advanced packaging technologies protect the sensors while maintaining their sensitivity and enable deployment in various environmental conditions.Expand Specific Solutions03 Signal Processing for Multiple Hall Sensors

Signal processing architectures designed for handling data from multiple Hall effect sensors simultaneously allow for effective scaling. These include multiplexing systems, parallel processing circuits, and specialized algorithms for sensor fusion. Advanced signal conditioning techniques compensate for variations between individual sensors and environmental factors, ensuring consistent performance across large sensor networks.Expand Specific Solutions04 Power Management for Scaled Hall Sensor Systems

Power management solutions enable the operation of large-scale Hall effect sensor networks. These include low-power operation modes, energy harvesting techniques, and optimized power distribution architectures. Advanced systems implement selective activation of sensor elements and dynamic power scaling based on measurement requirements, extending battery life in portable applications and reducing energy consumption in fixed installations.Expand Specific Solutions05 Applications of Large-Scale Hall Sensor Networks

Large-scale Hall effect sensor networks find applications in various fields requiring distributed magnetic field measurements. These include industrial automation systems, automotive safety and navigation, medical imaging equipment, and scientific research instruments. Advanced implementations provide comprehensive monitoring capabilities for complex systems, enabling precise control and measurement across extended physical spaces.Expand Specific Solutions

Key Industrial Automation and Sensor Manufacturers

The Hall Effect sensor market for smart factories is experiencing rapid growth in the early maturity phase, with an estimated market size exceeding $1.5 billion and projected CAGR of 8-10% through 2028. Leading players like Honeywell, Texas Instruments, Infineon, and STMicroelectronics have established strong technological foundations with advanced sensor solutions featuring enhanced precision, miniaturization, and IoT integration capabilities. Allegro MicroSystems and ams-OSRAM are gaining market share through specialized industrial applications, while traditional industrial giants like Bosch and Siemens leverage their factory automation expertise to offer integrated solutions. The technology is evolving from basic position sensing to comprehensive systems incorporating AI-driven predictive maintenance and real-time monitoring capabilities, with increasing focus on energy efficiency and wireless connectivity.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated Hall Effect sensor platform specifically designed for smart factory environments. Their solution combines high-precision Hall Effect sensors with advanced signal processing capabilities and IoT connectivity. The system features self-calibrating sensors that maintain accuracy despite temperature fluctuations and electromagnetic interference common in factory settings. Honeywell's architecture incorporates distributed sensor networks with edge computing capabilities, allowing for real-time data processing and reduced latency. Their sensors achieve measurement accuracy within ±0.1% across a wide operating temperature range (-40°C to +150°C), making them suitable for harsh industrial environments. The platform includes proprietary algorithms for predictive maintenance that analyze sensor performance degradation patterns to forecast potential failures before they occur.

Strengths: Exceptional reliability with MTBF exceeding 100,000 hours; comprehensive integration with existing industrial control systems; advanced self-diagnostic capabilities. Weaknesses: Higher initial implementation cost compared to simpler solutions; requires specialized knowledge for optimal configuration; proprietary communication protocols may limit interoperability with some third-party systems.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered a scalable Hall Effect sensor ecosystem for smart factories centered around their DRV5000 series. Their approach focuses on power efficiency and integration density, with sensors consuming as little as 1.6mA in active mode and 5μA in low-power mode. TI's solution incorporates programmable threshold detection with automatic calibration features that compensate for manufacturing variations and temperature drift. Their architecture employs a modular design that allows factories to scale from dozens to thousands of sensing points without redesigning the underlying infrastructure. The system includes specialized interface ICs that enable direct connection to industrial networks using standard protocols like IO-Link and EtherCAT. TI has also developed reference designs for common smart factory applications such as motor control, position sensing, and current monitoring, significantly reducing implementation time.

Strengths: Exceptional power efficiency enabling battery-powered wireless implementations; high integration density; comprehensive development ecosystem with ready-to-use reference designs. Weaknesses: Less ruggedized than some competitors for extreme industrial environments; requires additional components for complete solutions; limited built-in analytics capabilities compared to more specialized offerings.

Core Patents and Innovations in Hall Effect Sensing

Wide bandwidth hall sensing circuitry with offset compensation and gain calibration

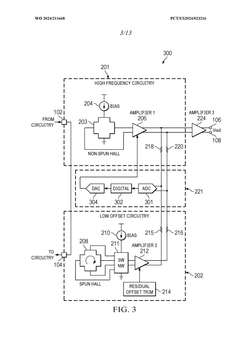

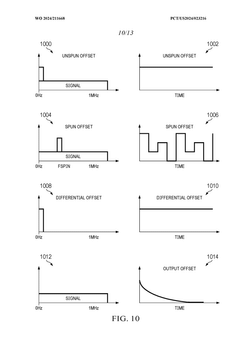

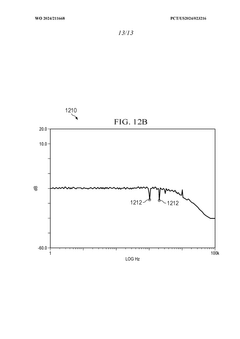

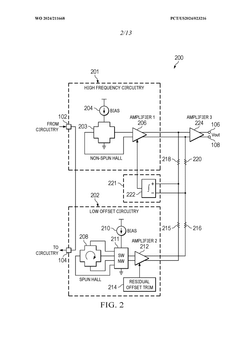

PatentWO2024211668A1

Innovation

- The implementation of a circuitry that includes a spinning technique to toggle the bias current between terminals, eliminating offset voltage by adding signals from different phases and using offset reduction circuitry to adjust the amplifier output, along with gain calibration to compensate for changes in sensor gain, thereby maintaining accurate current measurements across a wide bandwidth.

Method and system for generating reference data for a machine with a plurality of motion axis

PatentInactiveEP1288756A2

Innovation

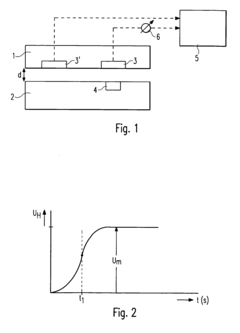

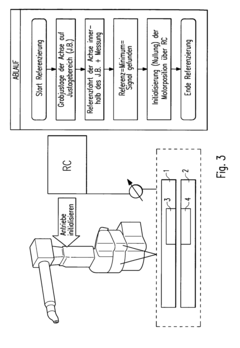

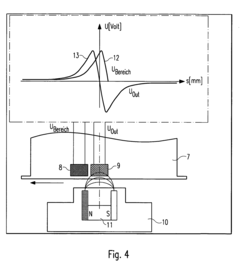

- A non-contact, robust, and reliable referencing system using Hall effect sensors with permanently attached reference elements, allowing for redundancy and compensation measurements to ensure accurate positioning without tool setup or dismantling, and utilizing phase-shifted output signals for precise position determination.

Implementation Costs and ROI Analysis

The implementation of Hall Effect sensor solutions in smart factories requires significant initial investment, but offers substantial long-term returns. Initial hardware costs typically range from $50-200 per sensor node, depending on precision requirements, environmental specifications, and integration capabilities. Enterprise-grade Hall Effect sensor systems with advanced features command premium pricing, while basic models offer more affordable entry points. Beyond hardware, installation costs average $75-150 per sensor point, varying with factory layout complexity and existing infrastructure compatibility.

Software integration represents another substantial cost component, typically ranging from $50,000-250,000 for factory-wide implementations. This includes middleware development, dashboard creation, and integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. Annual maintenance costs generally account for 15-20% of the initial implementation budget, covering calibration, replacement of damaged sensors, and software updates.

Return on investment analysis reveals compelling economics for most implementations. Payback periods typically range from 8-24 months, with larger installations achieving economies of scale that accelerate ROI timelines. Primary value drivers include production downtime reduction (typically 15-30%), predictive maintenance improvements (reducing unplanned maintenance by 25-45%), and quality control enhancements (defect reduction of 10-25%). These operational improvements translate directly to bottom-line benefits.

Energy efficiency gains from optimized machine operation typically yield 5-15% reduction in power consumption. Labor productivity improvements of 10-20% are common as workers shift from manual inspection to higher-value activities. Additionally, Hall Effect sensor implementations enable data-driven decision making that improves overall equipment effectiveness (OEE) by 5-15% in most deployments.

Phased implementation approaches can optimize ROI by targeting high-value production areas first. Critical production bottlenecks, quality-sensitive processes, and energy-intensive operations typically deliver the fastest returns. Manufacturers should develop comprehensive TCO (Total Cost of Ownership) models that account for both direct implementation costs and indirect benefits like extended equipment lifespan, reduced warranty claims, and improved regulatory compliance. Sensitivity analysis incorporating various production volumes and failure rates can help refine ROI projections and build more robust business cases for Hall Effect sensor scaling initiatives.

Software integration represents another substantial cost component, typically ranging from $50,000-250,000 for factory-wide implementations. This includes middleware development, dashboard creation, and integration with existing manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. Annual maintenance costs generally account for 15-20% of the initial implementation budget, covering calibration, replacement of damaged sensors, and software updates.

Return on investment analysis reveals compelling economics for most implementations. Payback periods typically range from 8-24 months, with larger installations achieving economies of scale that accelerate ROI timelines. Primary value drivers include production downtime reduction (typically 15-30%), predictive maintenance improvements (reducing unplanned maintenance by 25-45%), and quality control enhancements (defect reduction of 10-25%). These operational improvements translate directly to bottom-line benefits.

Energy efficiency gains from optimized machine operation typically yield 5-15% reduction in power consumption. Labor productivity improvements of 10-20% are common as workers shift from manual inspection to higher-value activities. Additionally, Hall Effect sensor implementations enable data-driven decision making that improves overall equipment effectiveness (OEE) by 5-15% in most deployments.

Phased implementation approaches can optimize ROI by targeting high-value production areas first. Critical production bottlenecks, quality-sensitive processes, and energy-intensive operations typically deliver the fastest returns. Manufacturers should develop comprehensive TCO (Total Cost of Ownership) models that account for both direct implementation costs and indirect benefits like extended equipment lifespan, reduced warranty claims, and improved regulatory compliance. Sensitivity analysis incorporating various production volumes and failure rates can help refine ROI projections and build more robust business cases for Hall Effect sensor scaling initiatives.

Cybersecurity Considerations for Scaled Sensor Networks

As the scale of Hall Effect sensor networks expands across smart factory environments, cybersecurity becomes a critical consideration that cannot be overlooked. These sensor networks generate, process, and transmit vast amounts of sensitive operational data that could become targets for malicious actors. The interconnected nature of these systems creates multiple potential attack vectors that must be systematically addressed.

Primary security vulnerabilities in scaled sensor networks include unauthorized access points, data interception during transmission, and sensor tampering. Each additional sensor introduces a new potential entry point for attackers, exponentially increasing the attack surface. Furthermore, many Hall Effect sensors operate on legacy protocols that were not designed with robust security features, creating inherent vulnerabilities when deployed at scale.

Data encryption represents a fundamental security measure for protecting sensor communications. Implementing end-to-end encryption ensures that even if data is intercepted during transmission between sensors and central systems, it remains unintelligible to unauthorized parties. For resource-constrained sensors, lightweight encryption algorithms such as PRESENT or SIMON offer viable security solutions without significant processing overhead.

Network segmentation strategies should be employed to isolate sensor networks from other factory systems. By implementing VLANs and firewalls between sensor networks and enterprise systems, potential breaches can be contained rather than compromising the entire factory infrastructure. This approach follows the principle of least privilege, ensuring sensors only have access to resources necessary for their specific functions.

Authentication mechanisms must be robust yet practical for large-scale deployments. Certificate-based authentication provides strong security but requires careful management when implemented across thousands of sensors. Mutual authentication protocols ensure both the sensor and the receiving system verify each other's identity before establishing communication channels.

Regular security audits and vulnerability assessments should be conducted across the sensor network. Automated scanning tools can help identify potential weaknesses in large-scale deployments where manual inspection would be impractical. Additionally, implementing intrusion detection systems specifically calibrated for sensor network traffic patterns can provide early warning of potential security breaches.

Secure update mechanisms are essential for maintaining security over time. As vulnerabilities are discovered, sensors must be patchable without creating new security risks during the update process. Over-the-air update capabilities with cryptographic verification of firmware integrity ensures that only authorized code executes on sensor devices, preventing malicious code injection.

Human Engineering

Primary security vulnerabilities in scaled sensor networks include unauthorized access points, data interception during transmission, and sensor tampering. Each additional sensor introduces a new potential entry point for attackers, exponentially increasing the attack surface. Furthermore, many Hall Effect sensors operate on legacy protocols that were not designed with robust security features, creating inherent vulnerabilities when deployed at scale.

Data encryption represents a fundamental security measure for protecting sensor communications. Implementing end-to-end encryption ensures that even if data is intercepted during transmission between sensors and central systems, it remains unintelligible to unauthorized parties. For resource-constrained sensors, lightweight encryption algorithms such as PRESENT or SIMON offer viable security solutions without significant processing overhead.

Network segmentation strategies should be employed to isolate sensor networks from other factory systems. By implementing VLANs and firewalls between sensor networks and enterprise systems, potential breaches can be contained rather than compromising the entire factory infrastructure. This approach follows the principle of least privilege, ensuring sensors only have access to resources necessary for their specific functions.

Authentication mechanisms must be robust yet practical for large-scale deployments. Certificate-based authentication provides strong security but requires careful management when implemented across thousands of sensors. Mutual authentication protocols ensure both the sensor and the receiving system verify each other's identity before establishing communication channels.

Regular security audits and vulnerability assessments should be conducted across the sensor network. Automated scanning tools can help identify potential weaknesses in large-scale deployments where manual inspection would be impractical. Additionally, implementing intrusion detection systems specifically calibrated for sensor network traffic patterns can provide early warning of potential security breaches.

Secure update mechanisms are essential for maintaining security over time. As vulnerabilities are discovered, sensors must be patchable without creating new security risks during the update process. Over-the-air update capabilities with cryptographic verification of firmware integrity ensures that only authorized code executes on sensor devices, preventing malicious code injection.

Human Engineering

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!