Integrating Hall Effect Sensors in Wearable Fitness Devices: Benefits

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, represent a significant advancement in magnetic field detection technology. These sensors operate on the principle of the Hall Effect, which occurs when a magnetic field is applied perpendicular to a current-carrying conductor, generating a voltage difference across the conductor proportional to the magnetic field strength. This fundamental principle has evolved from basic magnetic field detection to sophisticated applications in various industries, including automotive, industrial automation, and consumer electronics.

The evolution of Hall Effect sensor technology has been marked by significant improvements in miniaturization, sensitivity, and power efficiency. Early Hall Effect sensors were bulky and limited in application, but advancements in semiconductor manufacturing have enabled the production of micro-scale sensors with enhanced precision. Modern Hall Effect sensors incorporate integrated circuits that provide signal conditioning, temperature compensation, and digital output capabilities, making them more versatile and reliable for diverse applications.

In the context of wearable fitness devices, Hall Effect sensors represent a promising technology for enhancing functionality and user experience. These sensors can detect magnetic fields generated by magnets embedded in fitness equipment or by the Earth's magnetic field, enabling precise motion tracking, position sensing, and orientation detection. The non-contact nature of Hall Effect sensing provides advantages in durability and reliability compared to mechanical alternatives, which is particularly valuable in wearable devices subjected to constant movement and environmental stresses.

The primary technical objectives for integrating Hall Effect sensors in wearable fitness devices include optimizing power consumption to extend battery life, miniaturizing sensor packages to maintain comfortable form factors, enhancing sensitivity for accurate measurements, and developing robust algorithms for interpreting sensor data in real-time. Additionally, there is a focus on improving electromagnetic interference (EMI) resistance to ensure reliable operation in diverse environments where multiple electronic devices may be present.

Recent technological trends indicate a convergence of Hall Effect sensing with other complementary technologies, such as inertial measurement units (IMUs) and optical sensors, to create more comprehensive motion tracking systems. This sensor fusion approach aims to overcome the limitations of individual sensing technologies and provide more accurate and reliable fitness metrics. Furthermore, advancements in materials science are enabling the development of flexible Hall Effect sensors that can conform to the contours of the human body, enhancing comfort and expanding the potential applications in wearable fitness monitoring.

The integration of Hall Effect sensors in wearable fitness devices aligns with the broader industry trend toward more sophisticated health and fitness monitoring capabilities. As consumers increasingly demand detailed insights into their physical activities and physiological parameters, the technical goal is to leverage Hall Effect sensing technology to provide accurate, reliable, and meaningful data while maintaining user comfort and device longevity.

The evolution of Hall Effect sensor technology has been marked by significant improvements in miniaturization, sensitivity, and power efficiency. Early Hall Effect sensors were bulky and limited in application, but advancements in semiconductor manufacturing have enabled the production of micro-scale sensors with enhanced precision. Modern Hall Effect sensors incorporate integrated circuits that provide signal conditioning, temperature compensation, and digital output capabilities, making them more versatile and reliable for diverse applications.

In the context of wearable fitness devices, Hall Effect sensors represent a promising technology for enhancing functionality and user experience. These sensors can detect magnetic fields generated by magnets embedded in fitness equipment or by the Earth's magnetic field, enabling precise motion tracking, position sensing, and orientation detection. The non-contact nature of Hall Effect sensing provides advantages in durability and reliability compared to mechanical alternatives, which is particularly valuable in wearable devices subjected to constant movement and environmental stresses.

The primary technical objectives for integrating Hall Effect sensors in wearable fitness devices include optimizing power consumption to extend battery life, miniaturizing sensor packages to maintain comfortable form factors, enhancing sensitivity for accurate measurements, and developing robust algorithms for interpreting sensor data in real-time. Additionally, there is a focus on improving electromagnetic interference (EMI) resistance to ensure reliable operation in diverse environments where multiple electronic devices may be present.

Recent technological trends indicate a convergence of Hall Effect sensing with other complementary technologies, such as inertial measurement units (IMUs) and optical sensors, to create more comprehensive motion tracking systems. This sensor fusion approach aims to overcome the limitations of individual sensing technologies and provide more accurate and reliable fitness metrics. Furthermore, advancements in materials science are enabling the development of flexible Hall Effect sensors that can conform to the contours of the human body, enhancing comfort and expanding the potential applications in wearable fitness monitoring.

The integration of Hall Effect sensors in wearable fitness devices aligns with the broader industry trend toward more sophisticated health and fitness monitoring capabilities. As consumers increasingly demand detailed insights into their physical activities and physiological parameters, the technical goal is to leverage Hall Effect sensing technology to provide accurate, reliable, and meaningful data while maintaining user comfort and device longevity.

Market Analysis for Hall Sensor-Equipped Fitness Wearables

The global market for fitness wearables incorporating Hall Effect sensors is experiencing robust growth, driven by increasing health consciousness and technological advancements. Current market valuation stands at approximately $12.5 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 18.7% through 2028, potentially reaching $29.6 billion by the end of the forecast period.

Consumer demand for more accurate fitness tracking capabilities represents the primary market driver. Traditional fitness wearables utilizing accelerometers and gyroscopes alone face limitations in precision measurement, particularly for complex movements and specialized training metrics. Hall Effect sensor integration addresses these limitations by enabling more precise motion tracking, rotation measurement, and position sensing.

The market segmentation reveals distinct consumer categories with varying needs. Professional athletes and serious fitness enthusiasts, comprising approximately 22% of the market, demand high-precision performance metrics and are willing to pay premium prices for advanced features. The general wellness segment, representing 63% of consumers, seeks reliable health monitoring with intuitive interfaces at moderate price points. The specialized medical monitoring segment, though smaller at 15%, shows the fastest growth rate at 24.3% annually.

Regional analysis indicates North America currently leads with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 22.4% annually, driven by increasing disposable income and rapid technology adoption in China, Japan, and South Korea.

Competitive landscape assessment identifies four distinct tiers of market players. Tier 1 comprises established wearable technology leaders like Apple, Samsung, and Fitbit (Google), controlling 47% of market share. Tier 2 includes specialized fitness device manufacturers such as Garmin and Polar, holding 28% market share. Tier 3 encompasses emerging technology startups focusing on niche applications, while Tier 4 consists of white-label manufacturers primarily serving regional markets.

Price sensitivity analysis reveals optimal price points between $149-$299 for mainstream consumer devices and $299-$499 for premium offerings. Consumer willingness to pay increases significantly when Hall Effect sensors enable unique functionality rather than merely enhancing existing features.

Distribution channel examination shows direct-to-consumer online sales as the fastest-growing channel at 34% annual growth, while traditional retail partnerships remain important for brand visibility and consumer education. Strategic partnerships with fitness applications, health insurers, and corporate wellness programs represent emerging distribution opportunities with significant growth potential.

Consumer demand for more accurate fitness tracking capabilities represents the primary market driver. Traditional fitness wearables utilizing accelerometers and gyroscopes alone face limitations in precision measurement, particularly for complex movements and specialized training metrics. Hall Effect sensor integration addresses these limitations by enabling more precise motion tracking, rotation measurement, and position sensing.

The market segmentation reveals distinct consumer categories with varying needs. Professional athletes and serious fitness enthusiasts, comprising approximately 22% of the market, demand high-precision performance metrics and are willing to pay premium prices for advanced features. The general wellness segment, representing 63% of consumers, seeks reliable health monitoring with intuitive interfaces at moderate price points. The specialized medical monitoring segment, though smaller at 15%, shows the fastest growth rate at 24.3% annually.

Regional analysis indicates North America currently leads with 38% market share, followed by Europe (29%) and Asia-Pacific (26%). However, the Asia-Pacific region demonstrates the highest growth trajectory at 22.4% annually, driven by increasing disposable income and rapid technology adoption in China, Japan, and South Korea.

Competitive landscape assessment identifies four distinct tiers of market players. Tier 1 comprises established wearable technology leaders like Apple, Samsung, and Fitbit (Google), controlling 47% of market share. Tier 2 includes specialized fitness device manufacturers such as Garmin and Polar, holding 28% market share. Tier 3 encompasses emerging technology startups focusing on niche applications, while Tier 4 consists of white-label manufacturers primarily serving regional markets.

Price sensitivity analysis reveals optimal price points between $149-$299 for mainstream consumer devices and $299-$499 for premium offerings. Consumer willingness to pay increases significantly when Hall Effect sensors enable unique functionality rather than merely enhancing existing features.

Distribution channel examination shows direct-to-consumer online sales as the fastest-growing channel at 34% annual growth, while traditional retail partnerships remain important for brand visibility and consumer education. Strategic partnerships with fitness applications, health insurers, and corporate wellness programs represent emerging distribution opportunities with significant growth potential.

Current Challenges in Hall Effect Sensor Integration

Despite the promising benefits of Hall Effect sensors in wearable fitness devices, several significant challenges impede their widespread integration. Miniaturization remains a primary obstacle, as these sensors must fit within increasingly compact wearable form factors without compromising performance. Current Hall Effect sensors often require more space than alternative sensing technologies, creating design constraints for manufacturers seeking to develop sleek, unobtrusive fitness devices.

Power consumption presents another critical challenge. Wearable fitness devices typically operate on small batteries with limited capacity, necessitating extremely power-efficient components. Traditional Hall Effect sensors consume relatively high power compared to other sensing technologies, potentially reducing device battery life. While low-power variants exist, they often sacrifice sensitivity or response time, creating difficult engineering trade-offs.

Signal interference poses significant technical hurdles in wearable applications. Hall Effect sensors are susceptible to electromagnetic interference from nearby electronic components, wireless communication modules, and external environmental sources. This susceptibility can lead to measurement inaccuracies in real-world usage scenarios, particularly in urban environments with high electromagnetic pollution.

Temperature sensitivity further complicates integration efforts. Hall Effect sensors exhibit output variations with temperature fluctuations, which is particularly problematic for wearables that operate across diverse environmental conditions and in direct contact with the human body. Compensation algorithms add computational overhead and complexity to already resource-constrained devices.

Manufacturing consistency presents scale-up challenges. Variations in sensor characteristics between production batches necessitate individual calibration procedures, increasing production costs and complexity. This calibration requirement becomes particularly burdensome in mass-production scenarios typical of consumer wearables.

Cost considerations remain significant, especially for consumer-grade fitness devices targeting competitive price points. While Hall Effect sensor prices have decreased, they still represent a premium component compared to alternative technologies, forcing difficult cost-benefit analyses during product development.

Integration complexity also poses challenges for development teams. Incorporating Hall Effect sensors requires specialized expertise in magnetic sensing, signal conditioning, and noise filtering. Many wearable device manufacturers lack this specific knowledge, creating barriers to adoption and extending development timelines.

Data processing requirements add further complications. Raw Hall Effect sensor outputs typically require sophisticated filtering and interpretation algorithms to extract meaningful fitness metrics. These algorithms demand computational resources that may strain the limited processing capabilities of wearable devices, potentially affecting overall system performance.

Power consumption presents another critical challenge. Wearable fitness devices typically operate on small batteries with limited capacity, necessitating extremely power-efficient components. Traditional Hall Effect sensors consume relatively high power compared to other sensing technologies, potentially reducing device battery life. While low-power variants exist, they often sacrifice sensitivity or response time, creating difficult engineering trade-offs.

Signal interference poses significant technical hurdles in wearable applications. Hall Effect sensors are susceptible to electromagnetic interference from nearby electronic components, wireless communication modules, and external environmental sources. This susceptibility can lead to measurement inaccuracies in real-world usage scenarios, particularly in urban environments with high electromagnetic pollution.

Temperature sensitivity further complicates integration efforts. Hall Effect sensors exhibit output variations with temperature fluctuations, which is particularly problematic for wearables that operate across diverse environmental conditions and in direct contact with the human body. Compensation algorithms add computational overhead and complexity to already resource-constrained devices.

Manufacturing consistency presents scale-up challenges. Variations in sensor characteristics between production batches necessitate individual calibration procedures, increasing production costs and complexity. This calibration requirement becomes particularly burdensome in mass-production scenarios typical of consumer wearables.

Cost considerations remain significant, especially for consumer-grade fitness devices targeting competitive price points. While Hall Effect sensor prices have decreased, they still represent a premium component compared to alternative technologies, forcing difficult cost-benefit analyses during product development.

Integration complexity also poses challenges for development teams. Incorporating Hall Effect sensors requires specialized expertise in magnetic sensing, signal conditioning, and noise filtering. Many wearable device manufacturers lack this specific knowledge, creating barriers to adoption and extending development timelines.

Data processing requirements add further complications. Raw Hall Effect sensor outputs typically require sophisticated filtering and interpretation algorithms to extract meaningful fitness metrics. These algorithms demand computational resources that may strain the limited processing capabilities of wearable devices, potentially affecting overall system performance.

Existing Hall Effect Implementation Solutions

01 Non-contact measurement and detection capabilities

Hall Effect sensors offer significant benefits in non-contact measurement applications. They can detect magnetic fields without physical contact with the target, enabling reliable position sensing, proximity detection, and current measurement without mechanical wear. This contactless operation ensures longer operational life and improved reliability in harsh environments where physical contact sensors would deteriorate quickly.- Non-contact measurement and detection capabilities: Hall Effect sensors offer significant benefits in non-contact measurement applications. They can detect magnetic fields without physical contact with the target, enabling reliable position sensing, proximity detection, and current measurement without mechanical wear. This contactless operation ensures longer operational life and improved reliability in harsh environments where physical contact sensors might fail.

- Enhanced durability and reliability in harsh environments: Hall Effect sensors demonstrate exceptional durability in challenging operating conditions. They are resistant to dust, dirt, vibration, and moisture, making them suitable for automotive, industrial, and outdoor applications. Their solid-state construction with no moving parts eliminates mechanical wear and tear, resulting in extended service life and reduced maintenance requirements even under extreme temperature variations.

- Precision in speed and position sensing applications: Hall Effect sensors provide high accuracy in speed and position sensing applications. They can precisely detect rotational speed, linear position, and angular displacement with minimal signal degradation over time. This precision makes them ideal for automotive systems like anti-lock braking, engine timing control, and electronic throttle control, as well as industrial automation where exact positioning is critical.

- Integration advantages in electronic systems: Hall Effect sensors offer excellent integration capabilities with modern electronic systems. Their compact size and compatibility with integrated circuit technology allow for miniaturization of sensing solutions. They can be easily incorporated into microelectronic packages, providing digital output signals that interface directly with microcontrollers and processing systems without complex signal conditioning, simplifying system design and reducing component count.

- Energy efficiency and low power consumption: Hall Effect sensors are characterized by their low power consumption, making them ideal for battery-powered and energy-efficient applications. They require minimal current to operate effectively and can be designed with power-saving sleep modes when not actively sensing. This energy efficiency extends battery life in portable devices and contributes to overall system power optimization in applications ranging from consumer electronics to automotive systems.

02 Enhanced durability and reliability in harsh environments

Hall Effect sensors demonstrate exceptional durability in challenging operating conditions. Their solid-state construction with no moving parts makes them resistant to vibration, shock, dust, and moisture. This robustness allows them to function reliably in extreme temperatures, high humidity, and industrial environments where conventional sensors might fail, resulting in reduced maintenance requirements and extended service life.Expand Specific Solutions03 Precision in position and speed sensing applications

Hall Effect sensors provide high accuracy in position and speed sensing applications. They can detect minute changes in magnetic field strength, allowing for precise measurement of linear and rotational movement. This precision makes them ideal for automotive applications like crankshaft position sensing, industrial automation for motor speed control, and consumer electronics requiring exact position feedback, delivering consistent performance across varying operating conditions.Expand Specific Solutions04 Low power consumption and integration capabilities

Hall Effect sensors offer significant advantages in terms of energy efficiency and system integration. They typically require minimal power to operate, making them suitable for battery-powered and energy-efficient applications. Their compact size and compatibility with standard semiconductor manufacturing processes allow for easy integration into integrated circuits and microelectronic systems, enabling the development of smaller, more efficient devices with reduced component count.Expand Specific Solutions05 Versatility across multiple industries and applications

Hall Effect sensors demonstrate exceptional versatility across diverse industries. They are widely used in automotive systems for wheel speed sensing and throttle position monitoring, in industrial automation for proximity detection and current sensing, in consumer electronics for position detection, and in medical devices for precise control mechanisms. Their adaptability to different magnetic field strengths and configurations allows for customization to specific application requirements.Expand Specific Solutions

Leading Manufacturers and Competitors Analysis

The Hall Effect sensor integration in wearable fitness devices market is currently in a growth phase, with an estimated market size exceeding $2 billion and expanding at 15-20% annually. The technology has reached moderate maturity, with key players demonstrating varying levels of innovation. Apple and Samsung lead with comprehensive sensor integration in their smartwatches and fitness bands, while Nike and Adidas focus on sport-specific applications. Specialized companies like In & Motion and Coolplay (Beijing Kuwan Tribe) are developing niche applications with advanced motion tracking capabilities. Bose and Honeywell contribute significant sensor technology improvements, while academic institutions such as Hong Kong Polytechnic University and Shanghai University collaborate with industry partners to advance miniaturization and power efficiency for next-generation wearables.

NIKE Innovate CV

Technical Solution: Nike has developed a sophisticated Hall Effect sensor implementation for their connected fitness devices and smart footwear. Their approach integrates these sensors within their Nike Adapt self-lacing technology and Nike Run Club ecosystem. The Hall Effect sensors are strategically positioned to detect precise foot positioning, stride characteristics, and running dynamics. Nike's technology uses these sensors to measure not only step count but also force distribution across the foot during various activities, providing insights into running efficiency and potential injury risks. Their implementation combines Hall Effect sensors with pressure sensors to create comprehensive foot mapping that adapts to different running surfaces and styles. Nike has also developed machine learning algorithms that analyze the sensor data to provide personalized coaching recommendations through their digital platforms. The system can detect subtle changes in running form over time, allowing for early intervention when movement patterns suggest potential injury development.

Strengths: Excellent integration with footwear that provides unique biomechanical insights not available in wrist-worn devices; robust ecosystem of coaching tools that leverage sensor data effectively. Weaknesses: Limited battery life in smart footwear implementations; higher cost compared to traditional fitness tracking solutions.

Apple, Inc.

Technical Solution: Apple has integrated Hall Effect sensors in their wearable fitness devices, particularly in the Apple Watch series, to enhance motion tracking capabilities. Their approach combines Hall Effect sensors with accelerometers and gyroscopes to create a comprehensive motion sensing system. The Hall Effect sensors detect magnetic field changes when the user moves, providing precise positional data that complements inertial measurements. Apple's implementation uses these sensors for accurate step counting, workout recognition, and posture detection. Their proprietary algorithms process the Hall Effect sensor data alongside other sensor inputs to filter out noise and improve measurement accuracy in various environmental conditions. This multi-sensor fusion approach enables the Apple Watch to distinguish between different types of physical activities with high precision while maintaining energy efficiency through selective sensor activation based on detected movement patterns.

Strengths: Superior sensor fusion algorithms that combine Hall Effect data with other sensors for comprehensive activity tracking; excellent power management that extends battery life while maintaining tracking accuracy. Weaknesses: Proprietary closed ecosystem limits integration with non-Apple devices; higher manufacturing costs compared to simpler sensor implementations.

Key Patents and Technical Innovations

Stretchable sensor

PatentWO2021144572A1

Innovation

- A stretchable sensor system using magnets and magnetic sensors, such as Hall Effect sensors, fixed to the elastomer to measure deformation by determining the positional relationship between magnets and sensors, providing low noise and fast response times.

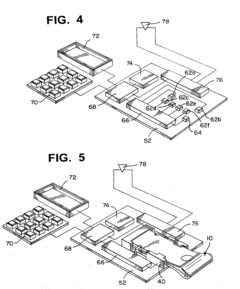

Key-Card Access System for Providing Selective Access to Medical Equipment

PatentInactiveUS20100096451A1

Innovation

- A keycard-controlled access system utilizing Hall-effect transducers and a processing circuit to generate an electronic pattern matching the embedded magnets on the keycard, with additional transducers to detect stray magnetic fields and prevent access if interference is detected, ensuring secure and accurate access to electronic medical devices.

Power Consumption Optimization Strategies

Power consumption remains a critical challenge for wearable fitness devices integrating Hall Effect sensors. These sensors, while offering precise motion tracking and position detection capabilities, can significantly impact battery life if not properly optimized. Several strategies have emerged to address this concern, balancing performance requirements with energy efficiency.

Duty-cycling techniques represent one of the most effective approaches for power optimization. By activating Hall Effect sensors only when necessary and keeping them in low-power or sleep modes during periods of inactivity, manufacturers can achieve substantial energy savings. Advanced algorithms can predict usage patterns and dynamically adjust sampling rates based on user activity levels, further enhancing power efficiency without compromising functionality.

Sensor fusion methodologies offer another promising avenue for power optimization. By intelligently combining data from Hall Effect sensors with information from other lower-power sensors (such as accelerometers), wearable devices can maintain accurate tracking while reducing the operational burden on more power-intensive components. This complementary sensing approach allows the system to rely on Hall Effect sensors only when their unique capabilities are truly needed.

Circuit-level optimizations have also yielded significant improvements in power consumption. The development of ultra-low-power Hall Effect sensor variants specifically designed for wearable applications has reduced baseline power requirements. Additionally, advanced power management integrated circuits (PMICs) can precisely control voltage levels and current delivery to these sensors, eliminating unnecessary power expenditure while ensuring reliable operation.

Signal processing enhancements contribute substantially to power efficiency. Implementing edge computing techniques allows for preliminary data processing directly on the sensor or in low-power microcontrollers, reducing the energy costs associated with continuous data transmission to the main processor. Furthermore, adaptive filtering algorithms can maintain signal quality while minimizing computational overhead.

Material science innovations have enabled more efficient magnetic field detection with lower power requirements. Novel magnetic materials with enhanced sensitivity allow Hall Effect sensors to operate at lower current levels while maintaining detection accuracy. Similarly, advances in semiconductor fabrication have produced Hall Effect ICs with significantly reduced power footprints compared to previous generations.

The integration of energy harvesting technologies represents an emerging frontier in power optimization. By capturing energy from body heat, movement, or ambient light, wearable devices can supplement battery power and extend operational time between charges. Though still evolving, these technologies show particular promise for fitness wearables, where user movement provides a natural energy source.

Duty-cycling techniques represent one of the most effective approaches for power optimization. By activating Hall Effect sensors only when necessary and keeping them in low-power or sleep modes during periods of inactivity, manufacturers can achieve substantial energy savings. Advanced algorithms can predict usage patterns and dynamically adjust sampling rates based on user activity levels, further enhancing power efficiency without compromising functionality.

Sensor fusion methodologies offer another promising avenue for power optimization. By intelligently combining data from Hall Effect sensors with information from other lower-power sensors (such as accelerometers), wearable devices can maintain accurate tracking while reducing the operational burden on more power-intensive components. This complementary sensing approach allows the system to rely on Hall Effect sensors only when their unique capabilities are truly needed.

Circuit-level optimizations have also yielded significant improvements in power consumption. The development of ultra-low-power Hall Effect sensor variants specifically designed for wearable applications has reduced baseline power requirements. Additionally, advanced power management integrated circuits (PMICs) can precisely control voltage levels and current delivery to these sensors, eliminating unnecessary power expenditure while ensuring reliable operation.

Signal processing enhancements contribute substantially to power efficiency. Implementing edge computing techniques allows for preliminary data processing directly on the sensor or in low-power microcontrollers, reducing the energy costs associated with continuous data transmission to the main processor. Furthermore, adaptive filtering algorithms can maintain signal quality while minimizing computational overhead.

Material science innovations have enabled more efficient magnetic field detection with lower power requirements. Novel magnetic materials with enhanced sensitivity allow Hall Effect sensors to operate at lower current levels while maintaining detection accuracy. Similarly, advances in semiconductor fabrication have produced Hall Effect ICs with significantly reduced power footprints compared to previous generations.

The integration of energy harvesting technologies represents an emerging frontier in power optimization. By capturing energy from body heat, movement, or ambient light, wearable devices can supplement battery power and extend operational time between charges. Though still evolving, these technologies show particular promise for fitness wearables, where user movement provides a natural energy source.

Miniaturization and Form Factor Considerations

The integration of Hall Effect sensors into wearable fitness devices presents significant challenges and opportunities related to miniaturization and form factor considerations. As these sensors become increasingly important for precise motion tracking and biometric monitoring, manufacturers must address several critical design constraints to ensure successful implementation.

The physical dimensions of Hall Effect sensors have undergone remarkable reduction in recent years, with the latest MEMS-based sensors measuring less than 1mm² in some cases. This miniaturization trend enables integration into increasingly compact wearable form factors such as rings, thin wristbands, and even smart textiles. However, the challenge lies in maintaining sensor performance while reducing size, as smaller sensors typically face signal-to-noise ratio degradation that can compromise measurement accuracy.

Power consumption represents another crucial consideration in the miniaturization equation. Traditional Hall Effect sensors required continuous power, limiting their application in battery-constrained wearable devices. Recent advancements have produced ultra-low-power variants that consume under 10μA during active sensing and can enter sub-1μA sleep modes when inactive. These improvements extend battery life while allowing for smaller battery components, further reducing the overall device footprint.

Heat dissipation concerns also influence form factor design decisions. Densely packed components in miniaturized wearables can create thermal management challenges, potentially affecting both sensor performance and user comfort. Engineers must implement thermal isolation techniques and optimize circuit layouts to minimize heat generation near Hall Effect sensors, as their performance characteristics can drift with temperature variations.

Flexible and conformal form factors represent the next frontier in wearable fitness devices. Recent developments in flexible substrate technologies allow Hall Effect sensors to be incorporated into non-rigid wearables that conform to body contours. This advancement enables more comfortable, less obtrusive designs while maintaining precise measurement capabilities. Companies like Flex Electronics and MC10 have demonstrated prototype devices with bendable Hall Effect sensor arrays that maintain calibration despite repeated flexing.

Manufacturing scalability presents additional challenges as devices shrink. Surface-mount technology (SMT) has evolved to accommodate components with pitches below 0.4mm, but assembly yield rates decline as dimensions decrease. Advanced packaging technologies such as wafer-level chip-scale packaging (WLCSP) help address these challenges by eliminating traditional packaging overhead, allowing Hall Effect sensors to be integrated with minimal footprint impact.

The ergonomic implications of sensor placement must also be carefully considered. Optimal positioning for magnetic field detection must be balanced against user comfort and aesthetic considerations. This has led to innovative multi-layer designs where sensors are strategically embedded within the device structure rather than mounted on the surface, preserving external design while maintaining functionality.

The physical dimensions of Hall Effect sensors have undergone remarkable reduction in recent years, with the latest MEMS-based sensors measuring less than 1mm² in some cases. This miniaturization trend enables integration into increasingly compact wearable form factors such as rings, thin wristbands, and even smart textiles. However, the challenge lies in maintaining sensor performance while reducing size, as smaller sensors typically face signal-to-noise ratio degradation that can compromise measurement accuracy.

Power consumption represents another crucial consideration in the miniaturization equation. Traditional Hall Effect sensors required continuous power, limiting their application in battery-constrained wearable devices. Recent advancements have produced ultra-low-power variants that consume under 10μA during active sensing and can enter sub-1μA sleep modes when inactive. These improvements extend battery life while allowing for smaller battery components, further reducing the overall device footprint.

Heat dissipation concerns also influence form factor design decisions. Densely packed components in miniaturized wearables can create thermal management challenges, potentially affecting both sensor performance and user comfort. Engineers must implement thermal isolation techniques and optimize circuit layouts to minimize heat generation near Hall Effect sensors, as their performance characteristics can drift with temperature variations.

Flexible and conformal form factors represent the next frontier in wearable fitness devices. Recent developments in flexible substrate technologies allow Hall Effect sensors to be incorporated into non-rigid wearables that conform to body contours. This advancement enables more comfortable, less obtrusive designs while maintaining precise measurement capabilities. Companies like Flex Electronics and MC10 have demonstrated prototype devices with bendable Hall Effect sensor arrays that maintain calibration despite repeated flexing.

Manufacturing scalability presents additional challenges as devices shrink. Surface-mount technology (SMT) has evolved to accommodate components with pitches below 0.4mm, but assembly yield rates decline as dimensions decrease. Advanced packaging technologies such as wafer-level chip-scale packaging (WLCSP) help address these challenges by eliminating traditional packaging overhead, allowing Hall Effect sensors to be integrated with minimal footprint impact.

The ergonomic implications of sensor placement must also be carefully considered. Optimal positioning for magnetic field detection must be balanced against user comfort and aesthetic considerations. This has led to innovative multi-layer designs where sensors are strategically embedded within the device structure rather than mounted on the surface, preserving external design while maintaining functionality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!