How to Enhance Real-Time Data from Hall Effect Sensors

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental principle has remained unchanged, but the implementation and application technologies have advanced significantly over the past decades.

The evolution of Hall Effect sensors has been marked by several key technological milestones. Initially limited to laboratory applications, these sensors gained commercial traction in the 1950s with the advent of semiconductor technology. The 1980s and 1990s witnessed significant miniaturization and integration capabilities, leading to their widespread adoption in automotive and industrial applications. Recent advancements have focused on enhancing sensitivity, reducing power consumption, and improving signal-to-noise ratios.

Current Hall Effect sensor technology faces several limitations in real-time data acquisition and processing. Traditional sensors often struggle with response time, accuracy in dynamic environments, and susceptibility to temperature variations and electromagnetic interference. These challenges become particularly pronounced in applications requiring high-speed, high-precision measurements such as automotive safety systems, industrial automation, and consumer electronics.

The primary objective of enhancing real-time data from Hall Effect sensors is to overcome these limitations by developing technologies that improve data acquisition speed, accuracy, and reliability. This involves addressing both hardware and software aspects of sensor systems, including sensor design, signal conditioning circuits, and data processing algorithms.

From a market perspective, the demand for enhanced Hall Effect sensors is driven by the growing need for precise motion control, position sensing, and current measurement in various industries. The automotive sector, in particular, requires increasingly sophisticated sensors for advanced driver assistance systems (ADAS) and electric vehicle applications. Similarly, Industry 4.0 initiatives are pushing for more capable sensors to enable smarter manufacturing processes.

Looking forward, the technological goals include developing Hall Effect sensors with higher bandwidth, improved linearity, reduced hysteresis, and better temperature stability. Additionally, there is a focus on creating more integrated solutions that combine sensing elements with advanced signal processing capabilities, potentially incorporating artificial intelligence for real-time data enhancement and predictive analytics.

The evolution of Hall Effect sensors has been marked by several key technological milestones. Initially limited to laboratory applications, these sensors gained commercial traction in the 1950s with the advent of semiconductor technology. The 1980s and 1990s witnessed significant miniaturization and integration capabilities, leading to their widespread adoption in automotive and industrial applications. Recent advancements have focused on enhancing sensitivity, reducing power consumption, and improving signal-to-noise ratios.

Current Hall Effect sensor technology faces several limitations in real-time data acquisition and processing. Traditional sensors often struggle with response time, accuracy in dynamic environments, and susceptibility to temperature variations and electromagnetic interference. These challenges become particularly pronounced in applications requiring high-speed, high-precision measurements such as automotive safety systems, industrial automation, and consumer electronics.

The primary objective of enhancing real-time data from Hall Effect sensors is to overcome these limitations by developing technologies that improve data acquisition speed, accuracy, and reliability. This involves addressing both hardware and software aspects of sensor systems, including sensor design, signal conditioning circuits, and data processing algorithms.

From a market perspective, the demand for enhanced Hall Effect sensors is driven by the growing need for precise motion control, position sensing, and current measurement in various industries. The automotive sector, in particular, requires increasingly sophisticated sensors for advanced driver assistance systems (ADAS) and electric vehicle applications. Similarly, Industry 4.0 initiatives are pushing for more capable sensors to enable smarter manufacturing processes.

Looking forward, the technological goals include developing Hall Effect sensors with higher bandwidth, improved linearity, reduced hysteresis, and better temperature stability. Additionally, there is a focus on creating more integrated solutions that combine sensing elements with advanced signal processing capabilities, potentially incorporating artificial intelligence for real-time data enhancement and predictive analytics.

Market Demand Analysis for Real-Time Hall Sensor Applications

The global market for Hall effect sensors is experiencing robust growth, driven primarily by the increasing demand for real-time data acquisition across multiple industries. Current market analysis indicates that the automotive sector represents the largest application segment, where Hall sensors are extensively utilized in advanced driver assistance systems (ADAS), electric power steering, and battery management systems. The demand for enhanced real-time capabilities stems from the automotive industry's shift toward autonomous driving technologies, which require ultra-responsive sensing mechanisms with minimal latency.

Industrial automation constitutes another significant market segment, where real-time Hall sensor applications are becoming increasingly critical for precise motion control, position detection, and current monitoring. Manufacturing facilities implementing Industry 4.0 principles are particularly focused on sensors that can deliver instantaneous feedback for closed-loop control systems, thereby improving production efficiency and reducing downtime.

Consumer electronics represents a rapidly expanding application area, with smartphones, wearables, and smart home devices incorporating Hall sensors for proximity detection and gesture recognition. The market demand in this sector is characterized by requirements for miniaturization, low power consumption, and high-speed response capabilities.

Healthcare applications are emerging as a promising growth segment, with medical devices utilizing Hall sensors for precise fluid flow measurement, position sensing in robotic surgery equipment, and non-invasive monitoring systems. The critical nature of these applications necessitates real-time data processing with exceptional reliability and accuracy.

Market research indicates that the demand for enhanced real-time Hall sensor solutions is being shaped by several key trends. First, there is growing emphasis on edge computing capabilities integrated directly with sensing elements, reducing latency by processing data at the source rather than transmitting it to centralized systems. Second, customers increasingly require sensors with self-diagnostic features that can report their operational status in real time, ensuring system integrity.

The market is also witnessing increased demand for Hall sensors with improved signal-to-noise ratios and higher sampling rates, particularly in applications involving high-speed motion detection or precise current measurement. Additionally, there is significant interest in sensor fusion technologies that combine Hall effect measurements with data from other sensing modalities to provide more comprehensive real-time insights.

Regional analysis reveals that Asia-Pacific currently leads the market for real-time Hall sensor applications, driven by the region's dominant position in electronics manufacturing and automotive production. North America and Europe follow closely, with demand primarily fueled by industrial automation and healthcare applications requiring advanced sensing capabilities.

Industrial automation constitutes another significant market segment, where real-time Hall sensor applications are becoming increasingly critical for precise motion control, position detection, and current monitoring. Manufacturing facilities implementing Industry 4.0 principles are particularly focused on sensors that can deliver instantaneous feedback for closed-loop control systems, thereby improving production efficiency and reducing downtime.

Consumer electronics represents a rapidly expanding application area, with smartphones, wearables, and smart home devices incorporating Hall sensors for proximity detection and gesture recognition. The market demand in this sector is characterized by requirements for miniaturization, low power consumption, and high-speed response capabilities.

Healthcare applications are emerging as a promising growth segment, with medical devices utilizing Hall sensors for precise fluid flow measurement, position sensing in robotic surgery equipment, and non-invasive monitoring systems. The critical nature of these applications necessitates real-time data processing with exceptional reliability and accuracy.

Market research indicates that the demand for enhanced real-time Hall sensor solutions is being shaped by several key trends. First, there is growing emphasis on edge computing capabilities integrated directly with sensing elements, reducing latency by processing data at the source rather than transmitting it to centralized systems. Second, customers increasingly require sensors with self-diagnostic features that can report their operational status in real time, ensuring system integrity.

The market is also witnessing increased demand for Hall sensors with improved signal-to-noise ratios and higher sampling rates, particularly in applications involving high-speed motion detection or precise current measurement. Additionally, there is significant interest in sensor fusion technologies that combine Hall effect measurements with data from other sensing modalities to provide more comprehensive real-time insights.

Regional analysis reveals that Asia-Pacific currently leads the market for real-time Hall sensor applications, driven by the region's dominant position in electronics manufacturing and automotive production. North America and Europe follow closely, with demand primarily fueled by industrial automation and healthcare applications requiring advanced sensing capabilities.

Current Limitations and Challenges in Hall Effect Sensing

Hall Effect sensors, while widely adopted across various industries for their non-contact measurement capabilities, face several significant limitations that impede their optimal performance in real-time data acquisition and processing. The primary challenge lies in their inherent signal-to-noise ratio (SNR) constraints, particularly in environments with electromagnetic interference (EMI). Industrial settings with high-power equipment generate substantial electromagnetic noise that can mask the relatively weak Hall voltage signals, leading to degraded measurement accuracy.

Temperature dependency presents another critical limitation, as Hall Effect sensors exhibit sensitivity variations across different temperature ranges. This thermal drift can cause measurement errors of up to 0.1% per degree Celsius in some sensor models, making reliable real-time data acquisition problematic in applications with fluctuating ambient conditions or those requiring high precision.

Bandwidth limitations constitute a significant barrier to real-time performance enhancement. Most commercial Hall Effect sensors operate effectively within a frequency range of DC to approximately 25 kHz, which proves insufficient for applications requiring high-speed data acquisition such as motor control systems operating at elevated RPMs or power electronics with rapid switching frequencies.

Resolution constraints further complicate real-time data enhancement efforts. Standard Hall Effect sensors typically offer resolution in the milliTesla range, which falls short for applications demanding detection of minute magnetic field variations. This limitation becomes particularly problematic in precision positioning systems and advanced scientific instrumentation where microtesla or nanotesla sensitivity is required.

Power consumption issues present challenges for battery-operated or energy-efficient systems. Traditional Hall Effect sensor circuits require continuous power for operation, with typical consumption ranging from 1-10 mA, making them less suitable for IoT applications or wireless sensor networks where power efficiency is paramount.

Calibration complexity and drift over time represent persistent challenges. Hall Effect sensors require initial calibration to account for manufacturing variations, and their characteristics can drift over extended operational periods due to aging effects and environmental stressors. This necessitates periodic recalibration, which interrupts continuous operation and adds maintenance overhead.

Integration challenges with digital systems create bottlenecks in data processing pipelines. Many Hall Effect sensors output analog signals that require additional conversion stages before digital processing, introducing latency and potential signal degradation that compromises real-time performance. The analog-to-digital conversion process itself introduces quantization errors and sampling limitations that can mask subtle signal variations.

Temperature dependency presents another critical limitation, as Hall Effect sensors exhibit sensitivity variations across different temperature ranges. This thermal drift can cause measurement errors of up to 0.1% per degree Celsius in some sensor models, making reliable real-time data acquisition problematic in applications with fluctuating ambient conditions or those requiring high precision.

Bandwidth limitations constitute a significant barrier to real-time performance enhancement. Most commercial Hall Effect sensors operate effectively within a frequency range of DC to approximately 25 kHz, which proves insufficient for applications requiring high-speed data acquisition such as motor control systems operating at elevated RPMs or power electronics with rapid switching frequencies.

Resolution constraints further complicate real-time data enhancement efforts. Standard Hall Effect sensors typically offer resolution in the milliTesla range, which falls short for applications demanding detection of minute magnetic field variations. This limitation becomes particularly problematic in precision positioning systems and advanced scientific instrumentation where microtesla or nanotesla sensitivity is required.

Power consumption issues present challenges for battery-operated or energy-efficient systems. Traditional Hall Effect sensor circuits require continuous power for operation, with typical consumption ranging from 1-10 mA, making them less suitable for IoT applications or wireless sensor networks where power efficiency is paramount.

Calibration complexity and drift over time represent persistent challenges. Hall Effect sensors require initial calibration to account for manufacturing variations, and their characteristics can drift over extended operational periods due to aging effects and environmental stressors. This necessitates periodic recalibration, which interrupts continuous operation and adds maintenance overhead.

Integration challenges with digital systems create bottlenecks in data processing pipelines. Many Hall Effect sensors output analog signals that require additional conversion stages before digital processing, introducing latency and potential signal degradation that compromises real-time performance. The analog-to-digital conversion process itself introduces quantization errors and sampling limitations that can mask subtle signal variations.

Current Solutions for Real-Time Hall Sensor Data Enhancement

01 Real-time data acquisition and processing systems

Hall effect sensors can be integrated into systems that acquire and process data in real-time, enabling immediate analysis and response to magnetic field changes. These systems typically include signal conditioning circuits, analog-to-digital converters, and microprocessors that handle the continuous stream of data from the sensors. The real-time processing capabilities allow for applications in motion control, position sensing, and current monitoring where instantaneous feedback is critical.- Real-time data acquisition and processing systems: Hall effect sensors can be integrated into systems that acquire and process data in real-time, enabling immediate analysis and response to magnetic field changes. These systems typically include signal conditioning circuits, analog-to-digital converters, and microprocessors that handle the continuous stream of sensor data. Real-time processing allows for applications requiring immediate feedback such as position monitoring, speed detection, and current measurement with minimal latency.

- Wireless transmission of Hall sensor data: Hall effect sensors can be configured to wirelessly transmit real-time data to monitoring stations or control systems. This capability eliminates the need for physical connections, allowing for remote sensing applications and deployment in hard-to-reach locations. Wireless transmission technologies used include Bluetooth, Wi-Fi, and proprietary RF protocols, enabling continuous monitoring of magnetic field data from multiple sensors simultaneously.

- Automotive and industrial monitoring applications: Hall effect sensors provide real-time data for various automotive and industrial applications, including motor control, current sensing, and position detection. These sensors enable continuous monitoring of critical parameters such as rotational speed, torque, and power consumption. The real-time data allows for precise control of electric motors, efficient energy management, and early detection of mechanical failures in industrial equipment and vehicles.

- Enhanced accuracy through signal processing techniques: Advanced signal processing techniques can be applied to Hall effect sensor data to improve accuracy and reliability in real-time applications. These techniques include digital filtering, temperature compensation, and noise reduction algorithms that enhance the quality of the sensor output. By implementing these methods, the sensors can provide more precise measurements even in challenging environments with electromagnetic interference or temperature variations.

- Integration with IoT and smart systems: Hall effect sensors are increasingly being integrated into Internet of Things (IoT) platforms and smart systems, providing real-time magnetic field data for connected applications. This integration enables continuous monitoring, data logging, and automated responses based on predefined thresholds. The sensor data can be visualized through dashboards, analyzed using machine learning algorithms, and used to trigger alerts or actions in smart home, industrial automation, and energy management systems.

02 Wireless transmission of Hall sensor data

Hall effect sensors can be configured to wirelessly transmit real-time data to monitoring stations or control systems. This wireless capability eliminates the need for physical connections, allowing for more flexible installation and remote monitoring. The systems typically incorporate low-power wireless protocols to ensure efficient data transmission while maintaining battery life in portable applications. This approach is particularly valuable in environments where wired connections are impractical or impossible.Expand Specific Solutions03 Integration with IoT and smart systems

Hall effect sensors are increasingly being integrated into Internet of Things (IoT) ecosystems and smart systems, providing real-time magnetic field data that can be used for various applications. These smart systems can include cloud connectivity for data storage and analysis, enabling advanced features such as predictive maintenance, remote monitoring, and automated responses to specific conditions. The continuous data stream from Hall sensors allows for more intelligent decision-making in industrial automation, smart buildings, and consumer electronics.Expand Specific Solutions04 High-precision real-time measurement techniques

Advanced techniques for improving the precision and accuracy of real-time data from Hall effect sensors have been developed. These include methods for temperature compensation, noise reduction, and signal amplification that enhance the quality of the real-time data. Some systems employ multiple sensors in arrays or differential configurations to increase sensitivity and reduce environmental interference. These high-precision measurement techniques enable applications in scientific research, medical devices, and high-end industrial equipment where data accuracy is paramount.Expand Specific Solutions05 Real-time feedback control systems

Hall effect sensors are utilized in closed-loop feedback control systems that require real-time data for immediate adjustments. These systems continuously monitor magnetic fields or related parameters and use the data to make instantaneous control decisions. Applications include motor control systems, power management in electric vehicles, and industrial automation where precise control based on real-time magnetic field measurements is essential. The feedback mechanisms often incorporate advanced algorithms to optimize performance and efficiency based on the continuous data stream.Expand Specific Solutions

Major Industry Players in Hall Effect Sensor Development

The Hall Effect sensor real-time data enhancement market is currently in a growth phase, with increasing demand across automotive, industrial, and consumer electronics sectors. The global market size is estimated to reach $2.5 billion by 2025, growing at a CAGR of approximately 8%. Leading players demonstrate varying levels of technical maturity, with Texas Instruments, Infineon Technologies, and Allegro MicroSystems showing advanced capabilities in signal processing and noise reduction techniques. STMicroelectronics and Honeywell have developed robust solutions for harsh environments, while emerging players like Sensata Technologies are focusing on specialized applications. Academic institutions including Tokyo Institute of Technology and Harbin Institute of Technology are contributing significant research advancements, particularly in miniaturization and power efficiency, creating a competitive ecosystem balancing established manufacturers and innovative newcomers.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed an integrated approach to enhancing real-time data from Hall effect sensors through their DRV5x series. Their solution combines high-precision Hall sensing elements with advanced signal conditioning on a single chip. TI's chopper-stabilized amplifier design reduces offset drift to less than 2μV/°C, enabling stable measurements across wide temperature ranges. The company has implemented programmable digital filters with adjustable bandwidth from DC to 20kHz, allowing users to optimize the trade-off between response time and noise immunity based on application requirements. TI's sensors feature integrated 12-bit ADCs with sampling rates up to 400kSPS, providing high-resolution digital output directly from the sensor. Their latest generation includes on-chip temperature sensors with ±2°C accuracy for real-time temperature compensation, significantly improving measurement stability. TI has also developed power management techniques that reduce current consumption to as low as 25μA in low-power mode while maintaining the ability to wake up within 50μs when magnetic events are detected, making their solutions ideal for battery-powered applications requiring continuous monitoring.

Strengths: Excellent integration of sensing and processing elements; highly configurable to suit various applications; good balance of performance and power efficiency. Weaknesses: More complex implementation than basic Hall sensors; requires microcontroller interface for full feature utilization; premium pricing for advanced models.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed advanced Hall-effect sensor solutions with integrated signal conditioning circuits that significantly enhance real-time data quality. Their proprietary technology includes chopper stabilization techniques that reduce temperature-related drift and offset errors by up to 90% compared to conventional sensors. The company's QuietMotion™ platform incorporates dual Hall-effect elements with differential sensing architecture to cancel common-mode noise and improve signal-to-noise ratio by approximately 40dB. Allegro has also pioneered integrated current sensing solutions that combine Hall-effect sensors with precision analog circuitry on a single die, enabling sampling rates exceeding 200kHz while maintaining linearity within ±0.5%. Their latest generation sensors feature on-chip digital signal processing capabilities that implement adaptive filtering algorithms to dynamically adjust bandwidth based on detected signal characteristics, reducing latency to under 2μs for critical applications while maintaining robust noise immunity.

Strengths: Industry-leading signal-to-noise ratio performance; extremely low latency suitable for safety-critical applications; excellent temperature stability across -40°C to +150°C range. Weaknesses: Higher cost compared to basic Hall sensors; requires more complex implementation; some solutions have higher power consumption than simpler alternatives.

Key Technical Innovations in Hall Effect Signal Processing

Method and system for measuring electric current

PatentInactiveEP2776852A1

Innovation

- A system using a Hall effect current sensor with a compensation device that applies an operation approximating the inverse of a Play operator to correct for magnetic hysteresis, allowing for real-time processing and combining hysteresis compensation with offset and gain error corrections, maintaining low consumption and cost similar to conventional sensors.

Hall effect sensor with reduced offset

PatentWO2012087623A1

Innovation

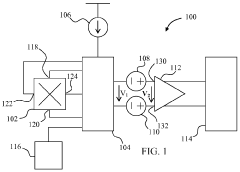

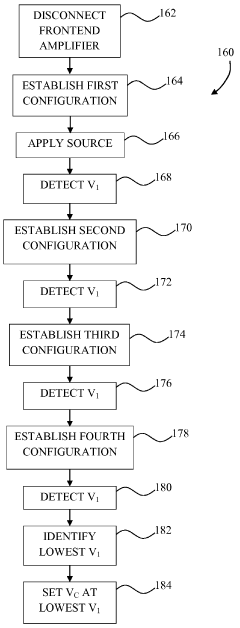

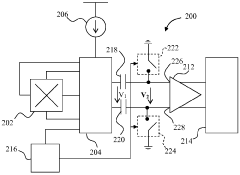

- A Hall Effect sensor circuit with a switch matrix and two cancellation voltage sources is used to reduce offset voltages by establishing a combined voltage that cancels out the DC offset, allowing for reduced dynamic range in the front-end amplifier and backend circuitry, thereby minimizing power dissipation and circuit complexity.

Noise Reduction Techniques for Hall Effect Sensors

Noise reduction in Hall Effect sensors is critical for enhancing real-time data quality and reliability. Electromagnetic interference (EMI) represents one of the most significant noise sources affecting these sensors, particularly in industrial environments where heavy machinery and power systems generate substantial electromagnetic fields. Advanced filtering techniques have been developed to address this challenge, including digital filters such as Kalman filters that can predict and eliminate random noise patterns by continuously comparing measured values against expected outcomes.

Hardware-based solutions play an equally important role in noise reduction strategies. Differential sensing configurations, where two Hall sensors are positioned to detect the same magnetic field but with opposite polarities, allow common-mode noise to be effectively canceled when the signals are combined. This approach has shown particular effectiveness in automotive applications where sensors operate in electromagnetically noisy environments.

Signal conditioning circuits represent another critical component in noise reduction architecture. These circuits typically incorporate low-pass filters to remove high-frequency noise while preserving the essential signal characteristics. Modern implementations often feature programmable cutoff frequencies that can be dynamically adjusted based on the operating environment or specific application requirements, providing adaptive noise rejection capabilities.

Shielding techniques have evolved significantly in recent years, with specialized materials and designs offering superior protection against external electromagnetic fields. Mu-metal shields, composed of nickel-iron alloys with high magnetic permeability, create effective barriers against low-frequency magnetic interference. For higher frequency noise, copper or aluminum enclosures provide excellent electrical shielding through the skin effect phenomenon.

Software-based compensation algorithms represent the cutting edge of noise reduction technology for Hall Effect sensors. These algorithms leverage machine learning techniques to identify and characterize noise patterns specific to particular environments or applications. By creating noise profiles that can be subtracted from the raw signal, these systems achieve significantly improved signal-to-noise ratios compared to traditional filtering methods. Real-time adaptive algorithms can continuously adjust their parameters based on changing environmental conditions, maintaining optimal performance across varying operating scenarios.

Proper grounding strategies remain fundamental to effective noise reduction. Star grounding configurations help prevent ground loops that can introduce noise into sensitive measurement circuits. In multi-sensor systems, synchronized sampling techniques can be employed to minimize the impact of periodic noise sources by ensuring measurements occur at optimal points in the noise cycle.

Hardware-based solutions play an equally important role in noise reduction strategies. Differential sensing configurations, where two Hall sensors are positioned to detect the same magnetic field but with opposite polarities, allow common-mode noise to be effectively canceled when the signals are combined. This approach has shown particular effectiveness in automotive applications where sensors operate in electromagnetically noisy environments.

Signal conditioning circuits represent another critical component in noise reduction architecture. These circuits typically incorporate low-pass filters to remove high-frequency noise while preserving the essential signal characteristics. Modern implementations often feature programmable cutoff frequencies that can be dynamically adjusted based on the operating environment or specific application requirements, providing adaptive noise rejection capabilities.

Shielding techniques have evolved significantly in recent years, with specialized materials and designs offering superior protection against external electromagnetic fields. Mu-metal shields, composed of nickel-iron alloys with high magnetic permeability, create effective barriers against low-frequency magnetic interference. For higher frequency noise, copper or aluminum enclosures provide excellent electrical shielding through the skin effect phenomenon.

Software-based compensation algorithms represent the cutting edge of noise reduction technology for Hall Effect sensors. These algorithms leverage machine learning techniques to identify and characterize noise patterns specific to particular environments or applications. By creating noise profiles that can be subtracted from the raw signal, these systems achieve significantly improved signal-to-noise ratios compared to traditional filtering methods. Real-time adaptive algorithms can continuously adjust their parameters based on changing environmental conditions, maintaining optimal performance across varying operating scenarios.

Proper grounding strategies remain fundamental to effective noise reduction. Star grounding configurations help prevent ground loops that can introduce noise into sensitive measurement circuits. In multi-sensor systems, synchronized sampling techniques can be employed to minimize the impact of periodic noise sources by ensuring measurements occur at optimal points in the noise cycle.

Integration with IoT and Industry 4.0 Systems

The integration of Hall Effect sensors with IoT and Industry 4.0 systems represents a significant advancement in real-time data enhancement capabilities. These sensors, when connected to broader industrial networks, enable continuous monitoring and analysis of magnetic field measurements across manufacturing environments. The IoT infrastructure provides the necessary connectivity backbone, allowing Hall Effect sensors to transmit data wirelessly to cloud platforms where advanced analytics can be performed.

In modern Industry 4.0 frameworks, Hall Effect sensors serve as critical data sources within larger sensor networks. Their integration typically follows a multi-tier architecture: sensors at the edge level collect magnetic field data, edge computing devices perform initial processing to reduce latency, and cloud systems handle complex analytics and long-term storage. This hierarchical approach optimizes both real-time responsiveness and comprehensive data analysis capabilities.

Protocols such as MQTT, OPC UA, and AMQP have emerged as preferred communication standards for Hall Effect sensor integration, offering lightweight messaging capabilities suitable for constrained IoT environments. These protocols enable efficient data transmission while maintaining reliability across industrial networks with varying bandwidth constraints. Additionally, time-sensitive networking (TSN) technologies are increasingly being deployed to ensure deterministic data delivery for critical applications.

Security considerations become paramount when integrating Hall Effect sensors into IoT ecosystems. Implementation of end-to-end encryption, secure boot mechanisms, and certificate-based authentication helps protect sensitive industrial data from unauthorized access. Many modern integration solutions also incorporate anomaly detection algorithms to identify potential security breaches or sensor malfunctions.

The value of Hall Effect sensor integration extends beyond basic monitoring capabilities. When properly integrated with Industry 4.0 systems, these sensors contribute to predictive maintenance programs by detecting subtle changes in magnetic fields that may indicate impending equipment failure. Machine learning algorithms can analyze historical sensor data to establish baseline performance patterns and identify deviations that warrant maintenance intervention.

Digital twin technology represents another frontier in Hall Effect sensor integration. By creating virtual representations of physical systems incorporating Hall Effect measurements, engineers can simulate system behavior under various conditions, optimize performance parameters, and test modifications without disrupting production. This capability significantly enhances both operational efficiency and innovation potential within industrial environments.

In modern Industry 4.0 frameworks, Hall Effect sensors serve as critical data sources within larger sensor networks. Their integration typically follows a multi-tier architecture: sensors at the edge level collect magnetic field data, edge computing devices perform initial processing to reduce latency, and cloud systems handle complex analytics and long-term storage. This hierarchical approach optimizes both real-time responsiveness and comprehensive data analysis capabilities.

Protocols such as MQTT, OPC UA, and AMQP have emerged as preferred communication standards for Hall Effect sensor integration, offering lightweight messaging capabilities suitable for constrained IoT environments. These protocols enable efficient data transmission while maintaining reliability across industrial networks with varying bandwidth constraints. Additionally, time-sensitive networking (TSN) technologies are increasingly being deployed to ensure deterministic data delivery for critical applications.

Security considerations become paramount when integrating Hall Effect sensors into IoT ecosystems. Implementation of end-to-end encryption, secure boot mechanisms, and certificate-based authentication helps protect sensitive industrial data from unauthorized access. Many modern integration solutions also incorporate anomaly detection algorithms to identify potential security breaches or sensor malfunctions.

The value of Hall Effect sensor integration extends beyond basic monitoring capabilities. When properly integrated with Industry 4.0 systems, these sensors contribute to predictive maintenance programs by detecting subtle changes in magnetic fields that may indicate impending equipment failure. Machine learning algorithms can analyze historical sensor data to establish baseline performance patterns and identify deviations that warrant maintenance intervention.

Digital twin technology represents another frontier in Hall Effect sensor integration. By creating virtual representations of physical systems incorporating Hall Effect measurements, engineers can simulate system behavior under various conditions, optimize performance parameters, and test modifications without disrupting production. This capability significantly enhances both operational efficiency and innovation potential within industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!