How to Assure Reliability in Hall Effect Sensors for Smart Grids

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors have evolved significantly since their discovery by Edwin Hall in 1879. Initially utilized for basic magnetic field detection, these sensors have transformed into sophisticated devices capable of precise current and position measurements in modern electrical systems. The technology leverages the Hall Effect principle, where a voltage difference is generated across an electrical conductor transverse to an electric current when placed in a magnetic field. This fundamental physical phenomenon has enabled the development of robust, non-contact sensing solutions that are increasingly vital in smart grid infrastructure.

The evolution of Hall Effect sensors has been marked by several technological breakthroughs, including the integration with semiconductor materials in the 1950s, the development of integrated circuits incorporating Hall elements in the 1970s, and recent advancements in miniaturization and digital signal processing capabilities. These innovations have progressively enhanced sensor sensitivity, accuracy, and reliability, making them suitable for demanding applications in power distribution networks.

In smart grid environments, Hall Effect sensors serve critical functions in monitoring current flow, detecting faults, and enabling precise power management. The technology's trajectory indicates a continuous push toward higher precision, greater temperature stability, and enhanced immunity to electromagnetic interference—all crucial factors for reliable operation in the complex and dynamic conditions of modern electrical grids.

The primary technical objectives for Hall Effect sensors in smart grid applications center on ensuring consistent performance under varying environmental conditions, extending operational lifespan, improving signal-to-noise ratios, and developing advanced self-diagnostic capabilities. Additionally, there is a growing emphasis on reducing power consumption while maintaining or enhancing measurement accuracy, particularly important for remote or energy-harvesting applications within smart grid infrastructure.

Research and development efforts are increasingly focused on addressing the specific challenges posed by smart grid environments, including wide temperature fluctuations, electromagnetic interference from nearby power lines, mechanical stress from installation and maintenance activities, and the need for long-term stability without recalibration. These factors directly impact sensor reliability and, consequently, the overall resilience of smart grid systems.

The convergence of Hall Effect sensor technology with Internet of Things (IoT) capabilities represents another significant trend, enabling real-time monitoring and predictive maintenance through continuous data collection and analysis. This integration supports the broader objectives of smart grid development, including improved energy efficiency, reduced downtime, and enhanced grid management through data-driven decision making.

As smart grids continue to expand globally, ensuring the reliability of Hall Effect sensors becomes increasingly critical to maintaining grid stability, optimizing power distribution, and supporting the integration of renewable energy sources. The technology's continued evolution will likely focus on enhancing robustness against environmental stressors while improving measurement precision and communication capabilities.

The evolution of Hall Effect sensors has been marked by several technological breakthroughs, including the integration with semiconductor materials in the 1950s, the development of integrated circuits incorporating Hall elements in the 1970s, and recent advancements in miniaturization and digital signal processing capabilities. These innovations have progressively enhanced sensor sensitivity, accuracy, and reliability, making them suitable for demanding applications in power distribution networks.

In smart grid environments, Hall Effect sensors serve critical functions in monitoring current flow, detecting faults, and enabling precise power management. The technology's trajectory indicates a continuous push toward higher precision, greater temperature stability, and enhanced immunity to electromagnetic interference—all crucial factors for reliable operation in the complex and dynamic conditions of modern electrical grids.

The primary technical objectives for Hall Effect sensors in smart grid applications center on ensuring consistent performance under varying environmental conditions, extending operational lifespan, improving signal-to-noise ratios, and developing advanced self-diagnostic capabilities. Additionally, there is a growing emphasis on reducing power consumption while maintaining or enhancing measurement accuracy, particularly important for remote or energy-harvesting applications within smart grid infrastructure.

Research and development efforts are increasingly focused on addressing the specific challenges posed by smart grid environments, including wide temperature fluctuations, electromagnetic interference from nearby power lines, mechanical stress from installation and maintenance activities, and the need for long-term stability without recalibration. These factors directly impact sensor reliability and, consequently, the overall resilience of smart grid systems.

The convergence of Hall Effect sensor technology with Internet of Things (IoT) capabilities represents another significant trend, enabling real-time monitoring and predictive maintenance through continuous data collection and analysis. This integration supports the broader objectives of smart grid development, including improved energy efficiency, reduced downtime, and enhanced grid management through data-driven decision making.

As smart grids continue to expand globally, ensuring the reliability of Hall Effect sensors becomes increasingly critical to maintaining grid stability, optimizing power distribution, and supporting the integration of renewable energy sources. The technology's continued evolution will likely focus on enhancing robustness against environmental stressors while improving measurement precision and communication capabilities.

Smart Grid Market Requirements Analysis

The smart grid market is experiencing rapid growth globally, driven by the increasing need for efficient energy management and distribution systems. According to recent market research, the global smart grid market is projected to reach $92.1 billion by 2026, growing at a CAGR of 15.8% from 2021. This expansion is fueled by government initiatives promoting renewable energy integration, rising energy demand, and the need for grid modernization.

For Hall Effect sensors in smart grids, market requirements are becoming increasingly stringent. These sensors play a critical role in current measurement, power monitoring, and fault detection within smart grid infrastructure. Utility companies demand sensors with exceptional reliability, as failures can lead to significant downtime, maintenance costs, and potential safety hazards.

Primary market requirements include extended operational lifespans of 15-20 years to match grid infrastructure investments. This necessitates sensors that can withstand harsh environmental conditions including temperature extremes (-40°C to +125°C), humidity variations, and electromagnetic interference common in power distribution environments.

Accuracy requirements are equally demanding, with utilities typically requiring measurement precision of ±0.5% or better across varying load conditions. This precision is essential for effective energy management, billing accuracy, and grid stability maintenance. Additionally, the market demands sensors with self-diagnostic capabilities to predict potential failures before they occur, minimizing unexpected outages.

Interoperability has emerged as another critical market requirement. Hall Effect sensors must seamlessly integrate with existing SCADA systems, IoT platforms, and emerging grid management software. This compatibility ensures data can flow efficiently across the smart grid ecosystem, enabling real-time monitoring and control.

Cost considerations remain significant despite the high-reliability requirements. The large-scale deployment across distribution networks necessitates competitive pricing, with utilities seeking sensors that balance performance with cost-effectiveness. The total cost of ownership, including installation, maintenance, and replacement costs, is a key decision factor for procurement departments.

Regulatory compliance adds another layer of market requirements. Hall Effect sensors must meet regional grid codes, safety standards (such as IEC 61000 for electromagnetic compatibility), and increasingly stringent cybersecurity requirements to prevent unauthorized access to critical infrastructure monitoring systems.

As renewable energy sources continue to proliferate, the market increasingly requires sensors capable of handling bidirectional power flows and rapid fluctuations characteristic of distributed energy resources. This adaptability to changing grid dynamics represents a growing segment of market demand that sensor manufacturers must address to remain competitive.

For Hall Effect sensors in smart grids, market requirements are becoming increasingly stringent. These sensors play a critical role in current measurement, power monitoring, and fault detection within smart grid infrastructure. Utility companies demand sensors with exceptional reliability, as failures can lead to significant downtime, maintenance costs, and potential safety hazards.

Primary market requirements include extended operational lifespans of 15-20 years to match grid infrastructure investments. This necessitates sensors that can withstand harsh environmental conditions including temperature extremes (-40°C to +125°C), humidity variations, and electromagnetic interference common in power distribution environments.

Accuracy requirements are equally demanding, with utilities typically requiring measurement precision of ±0.5% or better across varying load conditions. This precision is essential for effective energy management, billing accuracy, and grid stability maintenance. Additionally, the market demands sensors with self-diagnostic capabilities to predict potential failures before they occur, minimizing unexpected outages.

Interoperability has emerged as another critical market requirement. Hall Effect sensors must seamlessly integrate with existing SCADA systems, IoT platforms, and emerging grid management software. This compatibility ensures data can flow efficiently across the smart grid ecosystem, enabling real-time monitoring and control.

Cost considerations remain significant despite the high-reliability requirements. The large-scale deployment across distribution networks necessitates competitive pricing, with utilities seeking sensors that balance performance with cost-effectiveness. The total cost of ownership, including installation, maintenance, and replacement costs, is a key decision factor for procurement departments.

Regulatory compliance adds another layer of market requirements. Hall Effect sensors must meet regional grid codes, safety standards (such as IEC 61000 for electromagnetic compatibility), and increasingly stringent cybersecurity requirements to prevent unauthorized access to critical infrastructure monitoring systems.

As renewable energy sources continue to proliferate, the market increasingly requires sensors capable of handling bidirectional power flows and rapid fluctuations characteristic of distributed energy resources. This adaptability to changing grid dynamics represents a growing segment of market demand that sensor manufacturers must address to remain competitive.

Current Challenges in Hall Sensor Reliability

Despite significant advancements in Hall effect sensor technology, several critical challenges persist in ensuring their reliability within smart grid applications. The harsh operating environments of power distribution systems expose these sensors to extreme temperature variations, ranging from -40°C to over 85°C, which can significantly impact sensor calibration and measurement accuracy. These temperature fluctuations cause drift in the sensor's output, leading to potential misreadings and compromised grid monitoring capabilities.

Electromagnetic interference (EMI) presents another substantial challenge, as smart grid environments are inherently saturated with electromagnetic fields from power lines, transformers, and switching equipment. These interfering signals can corrupt the relatively weak Hall voltage signals, resulting in measurement errors that compromise the integrity of power quality monitoring and fault detection systems.

Long-term stability issues further complicate reliability assurance. Hall sensors deployed in smart grid infrastructure are expected to maintain consistent performance over operational lifespans of 15-20 years with minimal maintenance. However, material degradation, particularly in the semiconductor elements, leads to sensitivity drift over time. Research indicates that sensitivity can decrease by up to 2-3% annually under typical grid conditions, gradually reducing measurement accuracy below acceptable thresholds.

Power supply variations within the grid environment pose additional challenges. Hall sensors require stable power sources to maintain measurement precision, yet they must often operate in conditions where supply voltage fluctuates. These variations can introduce measurement errors if compensation mechanisms are inadequate, particularly during grid disturbances when accurate sensing is most critical.

Mechanical stress factors also significantly impact reliability. Vibrations from nearby equipment, thermal expansion/contraction cycles, and physical impacts can alter the sensor's mechanical properties, affecting the Hall element's position relative to magnetic fields and potentially causing misalignment that degrades measurement accuracy.

Integration challenges with digital systems represent another key concern. As smart grids increasingly rely on digital communication protocols, Hall sensors must provide reliable analog-to-digital conversion with sufficient resolution and noise immunity. Signal processing limitations in current sensor designs often struggle to maintain signal integrity across the complex communication networks typical in modern grid systems.

Calibration drift remains perhaps the most persistent challenge, requiring sophisticated compensation algorithms that can adapt to changing environmental conditions while maintaining measurement accuracy. Current calibration methods typically require periodic manual intervention, which increases maintenance costs and introduces potential downtime in critical monitoring systems.

Electromagnetic interference (EMI) presents another substantial challenge, as smart grid environments are inherently saturated with electromagnetic fields from power lines, transformers, and switching equipment. These interfering signals can corrupt the relatively weak Hall voltage signals, resulting in measurement errors that compromise the integrity of power quality monitoring and fault detection systems.

Long-term stability issues further complicate reliability assurance. Hall sensors deployed in smart grid infrastructure are expected to maintain consistent performance over operational lifespans of 15-20 years with minimal maintenance. However, material degradation, particularly in the semiconductor elements, leads to sensitivity drift over time. Research indicates that sensitivity can decrease by up to 2-3% annually under typical grid conditions, gradually reducing measurement accuracy below acceptable thresholds.

Power supply variations within the grid environment pose additional challenges. Hall sensors require stable power sources to maintain measurement precision, yet they must often operate in conditions where supply voltage fluctuates. These variations can introduce measurement errors if compensation mechanisms are inadequate, particularly during grid disturbances when accurate sensing is most critical.

Mechanical stress factors also significantly impact reliability. Vibrations from nearby equipment, thermal expansion/contraction cycles, and physical impacts can alter the sensor's mechanical properties, affecting the Hall element's position relative to magnetic fields and potentially causing misalignment that degrades measurement accuracy.

Integration challenges with digital systems represent another key concern. As smart grids increasingly rely on digital communication protocols, Hall sensors must provide reliable analog-to-digital conversion with sufficient resolution and noise immunity. Signal processing limitations in current sensor designs often struggle to maintain signal integrity across the complex communication networks typical in modern grid systems.

Calibration drift remains perhaps the most persistent challenge, requiring sophisticated compensation algorithms that can adapt to changing environmental conditions while maintaining measurement accuracy. Current calibration methods typically require periodic manual intervention, which increases maintenance costs and introduces potential downtime in critical monitoring systems.

Current Reliability Assurance Methods

01 Environmental and Temperature Effects on Hall Sensors

Hall effect sensors are susceptible to environmental factors, particularly temperature variations which can affect their reliability. Various designs incorporate temperature compensation mechanisms to maintain accuracy across wide operating temperature ranges. These sensors often include calibration systems that adjust for thermal drift and environmental changes to ensure consistent performance in harsh conditions.- Environmental and operational reliability factors: Hall effect sensors face reliability challenges in harsh environments. Factors affecting reliability include temperature variations, humidity, mechanical stress, and electromagnetic interference. Design considerations must account for these environmental factors to ensure consistent sensor performance over time. Protective packaging and specialized materials can enhance sensor durability in extreme conditions.

- Calibration and drift compensation techniques: Maintaining Hall effect sensor reliability requires addressing signal drift and calibration issues. Advanced calibration techniques can compensate for temperature-induced drift and aging effects. Self-calibration circuits and algorithms help maintain measurement accuracy over the sensor's lifetime. Periodic recalibration procedures and built-in testing capabilities ensure consistent performance in critical applications.

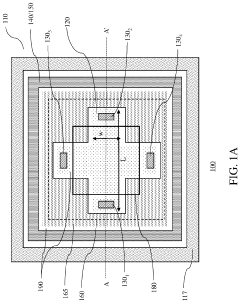

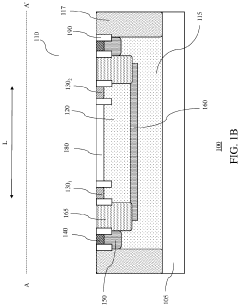

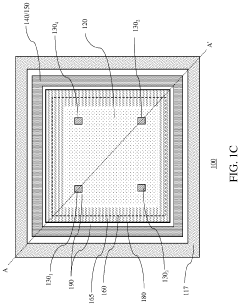

- Structural design improvements for reliability: Structural innovations in Hall effect sensors enhance reliability through improved physical design. This includes optimized semiconductor materials, enhanced packaging techniques, and mechanical stress isolation. Integrated protection features guard against overvoltage and current surges. Miniaturization techniques maintain reliability while reducing size, and specialized mounting configurations minimize mechanical stress transfer.

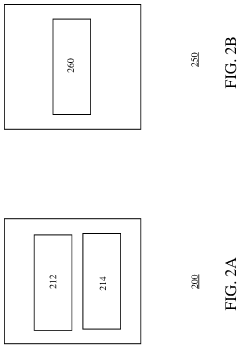

- Fault detection and redundancy systems: Ensuring Hall effect sensor reliability in critical applications involves implementing fault detection mechanisms and redundancy systems. Self-diagnostic capabilities can identify sensor malfunctions before system failure occurs. Redundant sensor arrays with voting mechanisms provide fail-operational capabilities. Error detection circuits monitor sensor output for anomalies, and backup systems activate when primary sensors fail, maintaining system functionality.

- Signal processing and noise immunity: Enhancing Hall effect sensor reliability through advanced signal processing techniques improves noise immunity and measurement accuracy. Digital filtering algorithms reduce electromagnetic interference effects. Chopper stabilization techniques minimize offset drift. Differential sensing configurations reject common-mode noise. Integrated amplification and conditioning circuits improve signal-to-noise ratio, while adaptive filtering responds to changing noise environments.

02 Packaging and Protection Techniques

The reliability of Hall effect sensors is significantly influenced by their packaging design. Advanced encapsulation methods protect the sensitive semiconductor elements from moisture, contaminants, and mechanical stress. Some designs incorporate specialized housings with protective coatings or sealed chambers to enhance durability and extend operational lifespan in challenging environments.Expand Specific Solutions03 Fault Detection and Diagnostic Systems

Modern Hall effect sensors incorporate built-in fault detection mechanisms to monitor operational status and identify potential failures. These diagnostic systems can detect issues such as short circuits, open circuits, or signal degradation. Some designs include redundant sensing elements or self-test capabilities that periodically verify proper functioning, enhancing overall system reliability and safety.Expand Specific Solutions04 Signal Processing and Noise Reduction

Reliability improvements in Hall effect sensors often focus on signal processing techniques to reduce noise and interference. Advanced filtering algorithms, digital signal processing, and amplification circuits help maintain signal integrity even in electromagnetically noisy environments. Some designs incorporate chopper stabilization or spinning current techniques to minimize offset errors and drift, resulting in more stable and reliable sensor outputs.Expand Specific Solutions05 Material Selection and Manufacturing Processes

The choice of semiconductor materials and manufacturing processes significantly impacts Hall sensor reliability. High-quality materials with consistent magnetic properties and low defect densities improve sensor stability and longevity. Advanced fabrication techniques, including precision doping profiles and specialized deposition methods, enhance sensor performance characteristics and reduce failure rates under continuous operation.Expand Specific Solutions

Major Players in Smart Grid Sensor Industry

The Hall Effect sensor market for smart grids is in a growth phase, with increasing adoption driven by the need for reliable power monitoring and control systems. The global market size is expanding rapidly as smart grid implementations accelerate worldwide. From a technological maturity perspective, companies like Texas Instruments, Infineon Technologies, and Honeywell lead with advanced sensor solutions featuring enhanced reliability and precision. Robert Bosch and STMicroelectronics are developing innovative approaches to improve sensor durability under grid fluctuations. Emerging players like Paragraf are introducing graphene-based Hall sensors with superior temperature stability. The competitive landscape shows established semiconductor manufacturers focusing on integration capabilities while specialized sensor companies target niche applications requiring extreme reliability in challenging grid environments.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a comprehensive approach to Hall Effect sensor reliability for smart grid applications centered on their DRV5x family of sensors. Their solution incorporates multiple redundancy systems with dual Hall elements and comparative circuitry that continuously monitors sensor performance. TI implements advanced temperature compensation techniques using on-chip temperature sensors and calibration algorithms that automatically adjust for thermal drift, maintaining accuracy across -40°C to +125°C operating ranges. Their sensors feature integrated diagnostics that perform real-time self-tests and fault detection, with programmable alert thresholds that can trigger before complete failure occurs. For smart grid applications specifically, TI has enhanced EMI/RFI immunity through specialized shielding and filtering circuits that protect against the electromagnetic interference common in power distribution environments. Their sensors also incorporate advanced power management features that reduce self-heating effects while maintaining rapid response times needed for fault current detection[1][3].

Strengths: Superior temperature stability and integrated diagnostics provide excellent reliability in harsh grid environments. Comprehensive EMI protection specifically designed for power systems. Weaknesses: Higher power consumption compared to some competitors, and implementation complexity requires more sophisticated integration support.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed the STGAP series of Hall Effect sensors with enhanced reliability features specifically for smart grid applications. Their approach centers on a triaxial sensing architecture that measures magnetic fields in three dimensions, enabling detection of sensor misalignment and external field interference that could compromise measurements. ST implements advanced BiCMOS fabrication technology that integrates both bipolar and CMOS elements on a single die, allowing analog sensing precision with digital processing capabilities. Their sensors feature dynamic offset cancellation techniques that continuously sample and subtract background magnetic fields, maintaining accuracy even as environmental conditions change. For smart grid applications, ST has developed specialized overvoltage protection circuits with transient voltage suppressors rated to withstand 6kV surge events conforming to IEC 61000-4-5 standards. Their sensors incorporate redundant power supply architectures with automatic failover capabilities, ensuring continuous operation even during brownout conditions. ST's solution also includes non-volatile memory that stores calibration data and operational parameters, enabling the sensor to recover proper operation after power cycling without requiring recalibration[6][8].

Strengths: Triaxial sensing provides superior immunity to external magnetic interference and installation misalignment. Integrated overvoltage protection specifically designed for grid environments. Weaknesses: Higher power consumption than some competitors, and more complex calibration requirements during installation.

Key Patents and Innovations in Hall Sensor Technology

Hall effect sensors with tunable sensitivity and/or resistance

PatentActiveUS20200292631A1

Innovation

- A Hall effect sensor design with a tunable Hall plate thickness, achieved through adjustable implants in the separation layer and bias voltage applied to the separation layer, allowing for customizable current sensitivity and resistance, enabling high voltage and current sensitivity within the same device.

Method for increasing the reliability of transducers

PatentActiveUS20160047680A1

Innovation

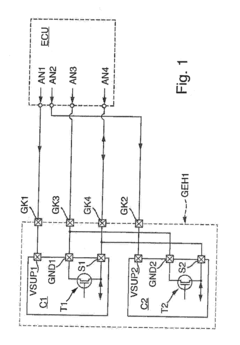

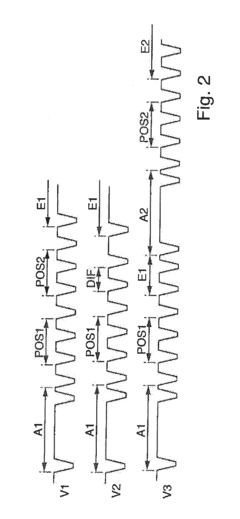

- A method involving two integrated circuits (ICs) with monolithically integrated sensor components and controllable switches for bidirectional data transmission, where signals from both ICs are combined and analyzed in a control unit, allowing for redundancy and easy switching off of faulty ICs without replacing the entire package, using a master/slave configuration and SENT protocol compliance.

Environmental Impact and Sustainability Considerations

The environmental impact of Hall Effect sensors in smart grid applications extends beyond their primary function of electrical measurement. These sensors contribute to sustainability through their role in optimizing energy distribution and consumption. By providing accurate real-time data on current flow, Hall Effect sensors enable smart grids to balance loads more effectively, reducing energy waste and associated carbon emissions. This optimization capability directly supports global initiatives for energy efficiency and carbon footprint reduction in electrical infrastructure.

Manufacturing processes for Hall Effect sensors involve several materials with varying environmental implications. The semiconductor materials, primarily silicon and gallium compounds, require energy-intensive extraction and processing methods. Additionally, rare earth elements used in some sensor configurations present sustainability challenges due to their limited availability and environmentally problematic mining practices. The electronics industry must address these concerns through responsible sourcing and development of alternative materials with lower environmental impact.

The lifecycle assessment of Hall Effect sensors reveals both challenges and opportunities for sustainability. While their long operational lifespan (typically 10-15 years) reduces replacement frequency and associated waste, end-of-life disposal presents environmental concerns due to electronic components containing potentially hazardous materials. Implementing effective recycling programs specifically designed for smart grid components can significantly mitigate these impacts, recovering valuable materials and preventing contamination of landfills.

Energy consumption during operation represents another environmental consideration. Though individual Hall Effect sensors consume minimal power (typically in the milliwatt range), their cumulative impact across extensive smart grid deployments becomes significant. Manufacturers are responding with increasingly energy-efficient designs, including low-power sleep modes and energy harvesting capabilities that reduce dependence on external power sources.

Reliability improvements in Hall Effect sensors also yield environmental benefits. Enhanced durability reduces replacement frequency, decreasing manufacturing demand and associated resource consumption. Additionally, more reliable sensors minimize maintenance visits, reducing vehicle emissions associated with service calls. The development of self-diagnostic capabilities further supports this trend by enabling predictive maintenance rather than reactive replacement.

The integration of Hall Effect sensors in smart grids ultimately contributes to broader environmental goals by enabling more efficient renewable energy integration. These sensors provide the precise monitoring capabilities necessary for managing the variable output of solar and wind generation, facilitating higher renewable energy penetration in electrical grids and supporting the transition away from fossil fuel dependence.

Manufacturing processes for Hall Effect sensors involve several materials with varying environmental implications. The semiconductor materials, primarily silicon and gallium compounds, require energy-intensive extraction and processing methods. Additionally, rare earth elements used in some sensor configurations present sustainability challenges due to their limited availability and environmentally problematic mining practices. The electronics industry must address these concerns through responsible sourcing and development of alternative materials with lower environmental impact.

The lifecycle assessment of Hall Effect sensors reveals both challenges and opportunities for sustainability. While their long operational lifespan (typically 10-15 years) reduces replacement frequency and associated waste, end-of-life disposal presents environmental concerns due to electronic components containing potentially hazardous materials. Implementing effective recycling programs specifically designed for smart grid components can significantly mitigate these impacts, recovering valuable materials and preventing contamination of landfills.

Energy consumption during operation represents another environmental consideration. Though individual Hall Effect sensors consume minimal power (typically in the milliwatt range), their cumulative impact across extensive smart grid deployments becomes significant. Manufacturers are responding with increasingly energy-efficient designs, including low-power sleep modes and energy harvesting capabilities that reduce dependence on external power sources.

Reliability improvements in Hall Effect sensors also yield environmental benefits. Enhanced durability reduces replacement frequency, decreasing manufacturing demand and associated resource consumption. Additionally, more reliable sensors minimize maintenance visits, reducing vehicle emissions associated with service calls. The development of self-diagnostic capabilities further supports this trend by enabling predictive maintenance rather than reactive replacement.

The integration of Hall Effect sensors in smart grids ultimately contributes to broader environmental goals by enabling more efficient renewable energy integration. These sensors provide the precise monitoring capabilities necessary for managing the variable output of solar and wind generation, facilitating higher renewable energy penetration in electrical grids and supporting the transition away from fossil fuel dependence.

Standardization and Certification Requirements

The standardization and certification landscape for Hall Effect sensors in smart grid applications is complex but essential for ensuring system-wide reliability and interoperability. Key international standards governing these sensors include IEC 61000 series for electromagnetic compatibility, IEC 62053 for electricity metering equipment, and IEEE 1459 for power measurement definitions. These standards establish baseline performance requirements, testing methodologies, and acceptable tolerance ranges that manufacturers must adhere to.

National regulatory frameworks further complement these international standards, with organizations like NIST in the United States, BSI in the United Kingdom, and DIN in Germany developing country-specific certification requirements. These requirements often address unique regional grid characteristics, environmental conditions, and safety regulations that may impact sensor performance and reliability.

Certification processes typically involve rigorous testing across multiple parameters including accuracy under varying magnetic field strengths, temperature stability, long-term drift characteristics, and immunity to electromagnetic interference. Third-party testing laboratories such as UL, TÜV, and KEMA provide independent verification of compliance, which is increasingly becoming a prerequisite for market entry in most developed economies.

Smart grid applications demand additional certification requirements beyond those for standard industrial sensors. These include cybersecurity certifications (such as IEC 62351), interoperability standards (IEC 61850), and grid code compliance certifications that verify sensors can maintain accuracy during grid disturbances. The emergence of these specialized requirements reflects the critical role Hall Effect sensors play in grid stability and energy management systems.

Manufacturers seeking to deploy Hall Effect sensors in smart grid environments must navigate a multi-stage certification process, beginning with design validation against relevant standards, followed by type testing of production samples, and culminating in regular production quality assurance testing. This process typically requires 6-18 months to complete, representing a significant investment but one that substantially reduces deployment risks and liability concerns.

Industry consortia like the Smart Grid Interoperability Panel (SGIP) and the SunSpec Alliance are working to harmonize these requirements across jurisdictions, potentially reducing certification costs and accelerating market entry. However, regional variations remain significant, with emerging markets often adopting modified versions of international standards that reflect their infrastructure development priorities and technical capabilities.

National regulatory frameworks further complement these international standards, with organizations like NIST in the United States, BSI in the United Kingdom, and DIN in Germany developing country-specific certification requirements. These requirements often address unique regional grid characteristics, environmental conditions, and safety regulations that may impact sensor performance and reliability.

Certification processes typically involve rigorous testing across multiple parameters including accuracy under varying magnetic field strengths, temperature stability, long-term drift characteristics, and immunity to electromagnetic interference. Third-party testing laboratories such as UL, TÜV, and KEMA provide independent verification of compliance, which is increasingly becoming a prerequisite for market entry in most developed economies.

Smart grid applications demand additional certification requirements beyond those for standard industrial sensors. These include cybersecurity certifications (such as IEC 62351), interoperability standards (IEC 61850), and grid code compliance certifications that verify sensors can maintain accuracy during grid disturbances. The emergence of these specialized requirements reflects the critical role Hall Effect sensors play in grid stability and energy management systems.

Manufacturers seeking to deploy Hall Effect sensors in smart grid environments must navigate a multi-stage certification process, beginning with design validation against relevant standards, followed by type testing of production samples, and culminating in regular production quality assurance testing. This process typically requires 6-18 months to complete, representing a significant investment but one that substantially reduces deployment risks and liability concerns.

Industry consortia like the Smart Grid Interoperability Panel (SGIP) and the SunSpec Alliance are working to harmonize these requirements across jurisdictions, potentially reducing certification costs and accelerating market entry. However, regional variations remain significant, with emerging markets often adopting modified versions of international standards that reflect their infrastructure development priorities and technical capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!