Hall Effect Sensors: Measuring Robustness in High-Stress Scenarios

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Evolution and Objectives

The Hall effect, discovered by Edwin Hall in 1879, represents a fundamental principle in magnetic sensing technology. This phenomenon occurs when a magnetic field perpendicular to a current-carrying conductor creates a voltage difference across the conductor. Over the past century, this principle has evolved from a laboratory curiosity into a cornerstone of modern sensing technology, with Hall effect sensors now ubiquitous across numerous industries.

The evolution of Hall effect sensors has been marked by several significant technological breakthroughs. Early implementations in the mid-20th century were primarily limited to laboratory applications due to material limitations and sensitivity issues. The 1970s saw the integration of Hall effect elements with semiconductor technology, enabling miniaturization and improved performance characteristics. By the 1990s, advancements in integrated circuit technology facilitated the development of programmable Hall effect sensors with enhanced signal processing capabilities.

Recent decades have witnessed exponential growth in Hall effect sensor applications, particularly in automotive systems, industrial automation, consumer electronics, and aerospace. This expansion has been driven by continuous improvements in sensor robustness, accuracy, and reliability, alongside significant reductions in size and power consumption. Modern Hall effect sensors incorporate sophisticated temperature compensation, digital interfaces, and advanced packaging technologies that enable operation in increasingly demanding environments.

The current technological trajectory focuses on enhancing sensor performance under extreme conditions. High-temperature applications in automotive powertrains, aerospace systems, and industrial processes demand sensors capable of maintaining accuracy and reliability at temperatures exceeding 150°C. Similarly, high-vibration environments present challenges for sensor stability and longevity, necessitating innovations in packaging and mounting technologies.

The primary objective in advancing Hall effect sensor technology for high-stress scenarios centers on developing robust sensing solutions that maintain measurement accuracy and reliability under extreme conditions. This includes enhancing resistance to thermal stress, mechanical shock, vibration, electromagnetic interference, and chemical exposure. Achieving these objectives requires interdisciplinary approaches combining materials science, semiconductor physics, packaging technology, and signal processing.

Looking forward, the technological roadmap for Hall effect sensors aims to push operational boundaries while maintaining cost-effectiveness. Key goals include extending temperature range capabilities beyond 200°C, improving immunity to electromagnetic interference in noisy industrial environments, enhancing vibration resistance for aerospace and automotive applications, and developing self-diagnostic capabilities to predict potential failures before they occur. These advancements will enable new applications in emerging fields such as electric vehicles, renewable energy systems, and advanced manufacturing processes.

The evolution of Hall effect sensors has been marked by several significant technological breakthroughs. Early implementations in the mid-20th century were primarily limited to laboratory applications due to material limitations and sensitivity issues. The 1970s saw the integration of Hall effect elements with semiconductor technology, enabling miniaturization and improved performance characteristics. By the 1990s, advancements in integrated circuit technology facilitated the development of programmable Hall effect sensors with enhanced signal processing capabilities.

Recent decades have witnessed exponential growth in Hall effect sensor applications, particularly in automotive systems, industrial automation, consumer electronics, and aerospace. This expansion has been driven by continuous improvements in sensor robustness, accuracy, and reliability, alongside significant reductions in size and power consumption. Modern Hall effect sensors incorporate sophisticated temperature compensation, digital interfaces, and advanced packaging technologies that enable operation in increasingly demanding environments.

The current technological trajectory focuses on enhancing sensor performance under extreme conditions. High-temperature applications in automotive powertrains, aerospace systems, and industrial processes demand sensors capable of maintaining accuracy and reliability at temperatures exceeding 150°C. Similarly, high-vibration environments present challenges for sensor stability and longevity, necessitating innovations in packaging and mounting technologies.

The primary objective in advancing Hall effect sensor technology for high-stress scenarios centers on developing robust sensing solutions that maintain measurement accuracy and reliability under extreme conditions. This includes enhancing resistance to thermal stress, mechanical shock, vibration, electromagnetic interference, and chemical exposure. Achieving these objectives requires interdisciplinary approaches combining materials science, semiconductor physics, packaging technology, and signal processing.

Looking forward, the technological roadmap for Hall effect sensors aims to push operational boundaries while maintaining cost-effectiveness. Key goals include extending temperature range capabilities beyond 200°C, improving immunity to electromagnetic interference in noisy industrial environments, enhancing vibration resistance for aerospace and automotive applications, and developing self-diagnostic capabilities to predict potential failures before they occur. These advancements will enable new applications in emerging fields such as electric vehicles, renewable energy systems, and advanced manufacturing processes.

Market Demand Analysis for Robust Sensing Solutions

The global market for robust sensing solutions, particularly Hall Effect sensors capable of withstanding high-stress environments, has experienced significant growth driven by industrial automation, automotive safety systems, and aerospace applications. Current market valuations indicate the global Hall Effect sensor market exceeds $2 billion, with projections showing a compound annual growth rate between 7-9% through 2028, primarily fueled by demand for reliable sensors in extreme operating conditions.

Industrial sectors represent the largest market segment, where manufacturing processes increasingly require sensors that maintain accuracy despite exposure to vibration, temperature fluctuations, and electromagnetic interference. The automotive industry follows closely, with demand accelerating due to the transition toward electric vehicles and advanced driver assistance systems (ADAS), both requiring precise magnetic field measurements in challenging environments.

Aerospace and defense applications constitute a premium segment with stringent requirements for sensor robustness, creating substantial value despite lower unit volumes. These sectors demand sensors capable of maintaining calibration and performance integrity under extreme temperature variations, radiation exposure, and mechanical stress.

Regional analysis reveals North America and Europe currently lead market consumption of high-performance Hall sensors, though Asia-Pacific markets demonstrate the fastest growth trajectory, particularly in China, South Korea, and India. This growth correlates directly with these regions' expanding manufacturing bases and automotive production capabilities.

Customer requirements increasingly emphasize extended operational temperature ranges (-55°C to +150°C), enhanced vibration resistance (20G continuous), and improved electromagnetic compatibility. Market research indicates customers are willing to pay premium prices (30-40% above standard sensors) for solutions that demonstrably reduce system failures in critical applications.

Emerging application areas creating new demand include renewable energy systems, particularly wind turbines operating in harsh weather conditions, and medical devices requiring reliable operation in specialized environments. The Internet of Things (IoT) and Industry 4.0 initiatives further drive demand for sensors capable of long-term deployment in remote or difficult-to-service locations.

Market feedback indicates significant unmet needs in miniaturization while maintaining robustness, reduced power consumption for battery-operated devices, and improved signal-to-noise ratios in electromagnetically noisy environments. These requirements present both challenges and opportunities for technological innovation in Hall Effect sensor design and manufacturing.

Industrial sectors represent the largest market segment, where manufacturing processes increasingly require sensors that maintain accuracy despite exposure to vibration, temperature fluctuations, and electromagnetic interference. The automotive industry follows closely, with demand accelerating due to the transition toward electric vehicles and advanced driver assistance systems (ADAS), both requiring precise magnetic field measurements in challenging environments.

Aerospace and defense applications constitute a premium segment with stringent requirements for sensor robustness, creating substantial value despite lower unit volumes. These sectors demand sensors capable of maintaining calibration and performance integrity under extreme temperature variations, radiation exposure, and mechanical stress.

Regional analysis reveals North America and Europe currently lead market consumption of high-performance Hall sensors, though Asia-Pacific markets demonstrate the fastest growth trajectory, particularly in China, South Korea, and India. This growth correlates directly with these regions' expanding manufacturing bases and automotive production capabilities.

Customer requirements increasingly emphasize extended operational temperature ranges (-55°C to +150°C), enhanced vibration resistance (20G continuous), and improved electromagnetic compatibility. Market research indicates customers are willing to pay premium prices (30-40% above standard sensors) for solutions that demonstrably reduce system failures in critical applications.

Emerging application areas creating new demand include renewable energy systems, particularly wind turbines operating in harsh weather conditions, and medical devices requiring reliable operation in specialized environments. The Internet of Things (IoT) and Industry 4.0 initiatives further drive demand for sensors capable of long-term deployment in remote or difficult-to-service locations.

Market feedback indicates significant unmet needs in miniaturization while maintaining robustness, reduced power consumption for battery-operated devices, and improved signal-to-noise ratios in electromagnetically noisy environments. These requirements present both challenges and opportunities for technological innovation in Hall Effect sensor design and manufacturing.

Technical Challenges in High-Stress Environments

Hall Effect sensors face significant challenges when deployed in high-stress environments that push these devices to their operational limits. Temperature extremes represent one of the most critical challenges, with many industrial and automotive applications requiring reliable operation from -40°C to over 150°C. At high temperatures, semiconductor properties change dramatically, affecting carrier mobility and concentration, which directly impacts sensor sensitivity and output linearity. Conversely, extremely low temperatures can cause mechanical stress due to thermal contraction and alter magnetic properties of materials.

Mechanical stress and vibration pose another substantial challenge, particularly in automotive, aerospace, and heavy machinery applications. Constant vibration can lead to fatigue in sensor components, while shock events may cause immediate physical damage or misalignment of sensing elements. These mechanical factors can gradually degrade sensor performance or cause catastrophic failure in severe cases.

Electromagnetic interference (EMI) presents a persistent challenge in environments with high electrical noise, such as near electric motors, power lines, or wireless communication equipment. Hall Effect sensors, being inherently sensitive to magnetic fields, must distinguish between the target magnetic field and unwanted electromagnetic noise. Without proper shielding and filtering, EMI can introduce significant measurement errors or completely overwhelm the sensor signal.

Harsh chemical environments introduce additional complications, as corrosive substances can deteriorate sensor packaging and electrical connections. In applications like chemical processing plants or underwater deployments, exposure to acids, bases, or saltwater accelerates material degradation, potentially leading to electrical shorts or open circuits.

Power supply instability in high-stress environments further complicates sensor operation. Voltage spikes, brownouts, or noisy power rails can directly affect sensor output accuracy. This is particularly problematic in battery-powered applications or systems with fluctuating power availability, where maintaining consistent reference voltages becomes challenging.

Long-term reliability under continuous stress represents perhaps the most complex challenge. The combined effects of temperature cycling, mechanical stress, EMI exposure, and chemical degradation accelerate aging mechanisms in semiconductor materials and packaging. Predicting the long-term behavior of Hall Effect sensors under these combined stressors remains difficult, as failure mechanisms often interact in non-linear ways.

These technical challenges necessitate specialized design approaches, including advanced packaging technologies, temperature compensation circuits, robust filtering algorithms, and comprehensive testing methodologies that accurately simulate real-world high-stress conditions.

Mechanical stress and vibration pose another substantial challenge, particularly in automotive, aerospace, and heavy machinery applications. Constant vibration can lead to fatigue in sensor components, while shock events may cause immediate physical damage or misalignment of sensing elements. These mechanical factors can gradually degrade sensor performance or cause catastrophic failure in severe cases.

Electromagnetic interference (EMI) presents a persistent challenge in environments with high electrical noise, such as near electric motors, power lines, or wireless communication equipment. Hall Effect sensors, being inherently sensitive to magnetic fields, must distinguish between the target magnetic field and unwanted electromagnetic noise. Without proper shielding and filtering, EMI can introduce significant measurement errors or completely overwhelm the sensor signal.

Harsh chemical environments introduce additional complications, as corrosive substances can deteriorate sensor packaging and electrical connections. In applications like chemical processing plants or underwater deployments, exposure to acids, bases, or saltwater accelerates material degradation, potentially leading to electrical shorts or open circuits.

Power supply instability in high-stress environments further complicates sensor operation. Voltage spikes, brownouts, or noisy power rails can directly affect sensor output accuracy. This is particularly problematic in battery-powered applications or systems with fluctuating power availability, where maintaining consistent reference voltages becomes challenging.

Long-term reliability under continuous stress represents perhaps the most complex challenge. The combined effects of temperature cycling, mechanical stress, EMI exposure, and chemical degradation accelerate aging mechanisms in semiconductor materials and packaging. Predicting the long-term behavior of Hall Effect sensors under these combined stressors remains difficult, as failure mechanisms often interact in non-linear ways.

These technical challenges necessitate specialized design approaches, including advanced packaging technologies, temperature compensation circuits, robust filtering algorithms, and comprehensive testing methodologies that accurately simulate real-world high-stress conditions.

Current Robustness Enhancement Methodologies

01 Environmental robustness and protection mechanisms

Hall effect sensors can be designed with protective features to enhance their robustness against harsh environmental conditions. These include encapsulation techniques, protective coatings, and specialized packaging that shield the sensor from moisture, dust, temperature extremes, and mechanical stress. Some designs incorporate temperature compensation circuits to maintain accuracy across varying environmental conditions, while others use hermetic sealing to prevent contamination that could affect sensor performance and longevity.- Environmental robustness and protection mechanisms: Hall effect sensors can be designed with protective features to enhance their robustness against environmental factors such as temperature variations, humidity, and mechanical stress. These protection mechanisms include specialized packaging, encapsulation materials, and structural designs that shield the sensor elements from external influences. Such protective measures ensure reliable operation in harsh environments while maintaining measurement accuracy and extending the sensor's operational lifetime.

- Electromagnetic interference resistance: Hall effect sensors can be engineered to withstand electromagnetic interference (EMI) through various design approaches. These include specialized shielding techniques, differential sensing configurations, and integrated filtering circuits that minimize the impact of external magnetic fields and electrical noise. Enhanced EMI resistance ensures measurement stability and accuracy in environments with high electromagnetic noise, making these sensors suitable for automotive, industrial, and power electronics applications.

- Temperature compensation techniques: Advanced temperature compensation techniques can be implemented in Hall effect sensors to maintain measurement accuracy across wide temperature ranges. These include integrated temperature sensors, calibration circuits, and specialized materials with stable magnetic properties. Such compensation methods counteract the natural temperature drift of semiconductor materials, ensuring consistent sensor performance in applications exposed to significant temperature variations.

- Structural design for mechanical robustness: Hall effect sensors can be designed with enhanced mechanical robustness through specialized mounting structures, stress-relieving features, and impact-resistant packaging. These structural improvements protect the sensitive semiconductor elements from mechanical shocks, vibration, and physical deformation. Robust mechanical designs ensure reliable operation in high-vibration environments such as automotive applications, industrial machinery, and aerospace systems.

- Fault detection and diagnostic capabilities: Modern Hall effect sensors can incorporate built-in fault detection and diagnostic capabilities to enhance system reliability. These features include self-test functions, redundant sensing elements, and error detection circuits that continuously monitor sensor performance. When potential failures or degradation are detected, the sensor can provide warning signals or enter fail-safe modes, improving overall system robustness and preventing catastrophic failures in critical applications.

02 Circuit design for improved reliability

Advanced circuit designs can significantly enhance the robustness of Hall effect sensors. These include differential amplification techniques to reduce common-mode noise, chopper stabilization to minimize offset drift, and integrated filtering to reject electromagnetic interference. Some designs incorporate redundant sensing elements and fault detection mechanisms that enable continuous operation even when parts of the circuit are compromised. These circuit-level improvements help maintain signal integrity and measurement accuracy in challenging operating environments.Expand Specific Solutions03 Structural enhancements for mechanical durability

Structural design elements can be incorporated to improve the mechanical robustness of Hall effect sensors. These include shock-absorbing mounting systems, vibration-resistant housings, and reinforced connection points that protect against physical damage. Some sensors utilize flexible substrates or stress-relieving structures to accommodate thermal expansion and mechanical deformation without compromising functionality. These structural enhancements enable reliable operation in high-vibration environments such as automotive and industrial applications.Expand Specific Solutions04 Self-diagnostic and calibration capabilities

Modern Hall effect sensors can incorporate self-diagnostic and calibration features that enhance their robustness by detecting and compensating for potential issues. These include built-in test circuits that continuously monitor sensor health, automatic offset compensation mechanisms, and dynamic recalibration capabilities that adjust for drift over time. Some advanced designs include error detection algorithms that can identify when measurements fall outside expected parameters, triggering alerts or failsafe modes to prevent system failures based on inaccurate readings.Expand Specific Solutions05 Power management and surge protection

Robust Hall effect sensors incorporate power management and surge protection features to withstand electrical anomalies. These include transient voltage suppressors, current limiting circuits, and reverse polarity protection that shield sensitive components from damage. Some designs feature low-power operating modes that reduce heat generation and extend sensor life, while others implement isolation barriers between sensing elements and output stages to prevent propagation of electrical faults. These protective measures ensure reliable operation even in environments with unstable power supplies or electromagnetic interference.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Hall Effect Sensors market is currently in a growth phase, with increasing demand driven by automotive, industrial, and consumer electronics applications. The global market size is estimated to reach $2.5 billion by 2026, growing at a CAGR of approximately 8%. From a technological maturity perspective, the landscape features established leaders like Texas Instruments, Infineon Technologies, and Allegro MicroSystems who have developed robust sensor solutions for high-stress environments. STMicroelectronics and Robert Bosch GmbH are advancing innovations in temperature compensation and signal processing to enhance reliability. Emerging players like Melexis and specialized manufacturers such as Lake Shore Cryotronics are focusing on niche applications requiring extreme durability. Research institutions including Fraunhofer-Gesellschaft and CNRS are exploring novel materials and designs to further improve sensor robustness in challenging operational conditions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed advanced Hall Effect sensor solutions specifically designed for high-stress environments. Their DRV5000 family of Hall Effect sensors features enhanced robustness through integrated temperature compensation circuits that maintain accuracy across extreme temperature ranges (-40°C to +150°C). TI implements chopper stabilization techniques to reduce offset drift and improve long-term stability in fluctuating environmental conditions. Their sensors incorporate on-chip ESD protection up to 8kV HBM (Human Body Model) and integrated diagnostics for fault detection. TI's Hall Effect sensors also feature specialized packaging with silicon stress isolation structures that minimize mechanical stress effects on sensor readings, particularly important in automotive and industrial applications where vibration and thermal cycling are common. The company has implemented advanced signal processing algorithms that filter noise and provide reliable measurements even in electromagnetically noisy environments[1][3].

Strengths: Superior temperature stability and compensation techniques allow for consistent performance across extreme conditions. Integrated diagnostics provide real-time monitoring of sensor health. Weaknesses: Higher power consumption compared to some competitors, and premium pricing may limit adoption in cost-sensitive applications.

Infineon Technologies AG

Technical Solution: Infineon has pioneered robust Hall Effect sensor technology with their TLE4xxx and TLI4xxx series specifically engineered for high-stress automotive and industrial environments. Their sensors employ a unique vertical Hall technology that provides 3D magnetic field sensing capabilities while maintaining stability under mechanical stress. Infineon implements a patented stress-cancellation design where multiple sensing elements are arranged in a way that mechanical stress effects cancel each other out. Their Hall sensors feature integrated temperature sensors and compensation circuits that adjust sensitivity and offset across temperatures from -40°C to +170°C. For high-vibration environments, Infineon uses specialized die-attach materials and packaging techniques that absorb mechanical shock while maintaining electrical performance. Their sensors incorporate advanced digital signal processing with programmable filters to eliminate noise in harsh electromagnetic environments. Infineon's Hall Effect sensors also feature redundant sensing elements with built-in self-test capabilities for safety-critical applications[2][5].

Strengths: Industry-leading stress compensation techniques and exceptional temperature stability. Vertical Hall technology enables compact 3D sensing capabilities. Weaknesses: Higher complexity in implementation requiring more sophisticated calibration procedures, and relatively higher cost compared to simpler Hall sensor solutions.

Critical Patents and Research in Sensor Hardening

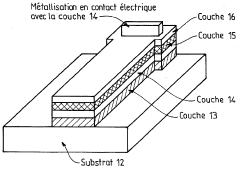

Hall-effect sensor

PatentWO2002019442A1

Innovation

- A Hall effect sensor with a multilayer structure featuring a thin active layer of semiconductor material on an insulating or semi-insulating substrate, with electrical insulation from the substrate and optimized doping rates to operate in the exhaustion regime, utilizing materials like hexagonal silicon carbide or GaN-based nitrides, ensuring low temperature sensitivity and high Hall coefficient across elevated temperatures.

Hall-effect sensor

PatentInactiveEP1314211A1

Innovation

- A Hall effect sensor with a multilayer structure featuring a thin active layer of semiconductor material on an insulating or semi-insulating substrate, where the active layer is electrically insulated and doped to operate in the exhaustion regime, utilizing materials like hexagonal silicon carbide or GaN-based nitrides, with a substrate of the same or different semiconductor type, ensuring high Hall coefficient and low temperature sensitivity.

Material Science Advancements for Sensor Durability

Recent advancements in material science have significantly contributed to enhancing the durability and performance of Hall Effect sensors in high-stress environments. Traditional sensor materials often face limitations when exposed to extreme conditions, leading to degraded performance or complete failure. The evolution of specialized composite materials has addressed these challenges by providing superior thermal stability, mechanical strength, and resistance to environmental factors.

Ceramic-polymer composites represent a breakthrough in sensor housing materials, offering exceptional thermal resistance up to 300°C while maintaining dimensional stability. These composites incorporate aluminum nitride and silicon carbide particles within high-performance polymers like polyetheretherketone (PEEK), creating a protective barrier against thermal shock and mechanical stress. Research indicates these materials can withstand up to 10,000 thermal cycles without significant degradation.

Thin-film technology has revolutionized the sensing element itself, with developments in magnetoresistive materials that maintain sensitivity under extreme conditions. Multilayer structures combining permalloy (Ni80Fe20) with tantalum or ruthenium buffer layers have demonstrated 40% higher stress resistance compared to conventional Hall elements. These structures distribute mechanical stress more effectively, preventing micro-fractures that typically lead to sensor failure.

Encapsulation technologies have similarly evolved, with hermetic sealing methods using glass-to-metal or ceramic-to-metal seals achieving leak rates below 10^-9 atm-cc/sec. Advanced epoxy formulations incorporating silica nanoparticles have improved adhesion strength by 35% while reducing moisture penetration by an order of magnitude. These improvements directly address the common failure modes of delamination and moisture-induced corrosion.

Nanomaterials represent the cutting edge of sensor durability enhancement. Carbon nanotube reinforced polymers used in sensor packaging demonstrate a 60% improvement in impact resistance while maintaining electrical insulation properties. Graphene-based protective coatings, applied through chemical vapor deposition, provide exceptional chemical resistance while being only a few atoms thick, preserving sensor sensitivity.

Surface treatment technologies, including plasma-enhanced chemical vapor deposition (PECVD) of silicon carbide and diamond-like carbon coatings, have extended sensor lifespans in corrosive environments by up to 300%. These coatings form an impermeable barrier against aggressive chemicals while maintaining thermal conductivity, crucial for temperature-sensitive Hall Effect measurements.

The integration of these material advances has resulted in Hall Effect sensors capable of operating reliably in environments previously considered prohibitive, including automotive engine compartments, aerospace applications, and industrial processing equipment where temperatures exceed 200°C and mechanical vibrations reach 30g.

Ceramic-polymer composites represent a breakthrough in sensor housing materials, offering exceptional thermal resistance up to 300°C while maintaining dimensional stability. These composites incorporate aluminum nitride and silicon carbide particles within high-performance polymers like polyetheretherketone (PEEK), creating a protective barrier against thermal shock and mechanical stress. Research indicates these materials can withstand up to 10,000 thermal cycles without significant degradation.

Thin-film technology has revolutionized the sensing element itself, with developments in magnetoresistive materials that maintain sensitivity under extreme conditions. Multilayer structures combining permalloy (Ni80Fe20) with tantalum or ruthenium buffer layers have demonstrated 40% higher stress resistance compared to conventional Hall elements. These structures distribute mechanical stress more effectively, preventing micro-fractures that typically lead to sensor failure.

Encapsulation technologies have similarly evolved, with hermetic sealing methods using glass-to-metal or ceramic-to-metal seals achieving leak rates below 10^-9 atm-cc/sec. Advanced epoxy formulations incorporating silica nanoparticles have improved adhesion strength by 35% while reducing moisture penetration by an order of magnitude. These improvements directly address the common failure modes of delamination and moisture-induced corrosion.

Nanomaterials represent the cutting edge of sensor durability enhancement. Carbon nanotube reinforced polymers used in sensor packaging demonstrate a 60% improvement in impact resistance while maintaining electrical insulation properties. Graphene-based protective coatings, applied through chemical vapor deposition, provide exceptional chemical resistance while being only a few atoms thick, preserving sensor sensitivity.

Surface treatment technologies, including plasma-enhanced chemical vapor deposition (PECVD) of silicon carbide and diamond-like carbon coatings, have extended sensor lifespans in corrosive environments by up to 300%. These coatings form an impermeable barrier against aggressive chemicals while maintaining thermal conductivity, crucial for temperature-sensitive Hall Effect measurements.

The integration of these material advances has resulted in Hall Effect sensors capable of operating reliably in environments previously considered prohibitive, including automotive engine compartments, aerospace applications, and industrial processing equipment where temperatures exceed 200°C and mechanical vibrations reach 30g.

Reliability Testing Standards and Protocols

Reliability testing standards for Hall Effect sensors in high-stress environments follow rigorous protocols established by international organizations such as IEC, IEEE, AEC, and ISO. The IEC 60749 series specifically addresses semiconductor device testing methods, with sections dedicated to environmental and mechanical stress testing applicable to Hall sensors. Similarly, the AEC-Q100 standard, developed by the Automotive Electronics Council, outlines stress test qualification requirements for integrated circuits in automotive applications, where Hall sensors are frequently deployed.

Temperature cycling tests (per IEC 60749-25) evaluate sensor performance across extreme temperature ranges, typically from -65°C to +150°C, with dwell times of 15 minutes and transition rates of 15°C/minute. These tests typically require 1,000 cycles for automotive-grade sensors. High-temperature operating life (HTOL) testing subjects sensors to maximum rated temperature while electrically biased for 1,000 hours, assessing long-term reliability under thermal stress.

Mechanical shock testing protocols (IEC 60749-10) expose sensors to acceleration forces of 1,500g to 2,000g for durations of 0.5ms to 1ms across multiple axes. Vibration testing (IEC 60749-12) subjects devices to sinusoidal or random vibrations across frequency ranges of 10Hz to 2,000Hz with acceleration levels up to 20g, simulating real-world operational conditions in industrial and automotive environments.

Humidity testing standards include temperature humidity bias (THB) testing at 85°C/85% relative humidity for 1,000 hours under bias conditions. Salt spray testing (ISO 9227) evaluates corrosion resistance by exposing sensors to salt fog environments for periods ranging from 96 to 1,000 hours, particularly important for sensors deployed in marine or roadside applications.

Electromagnetic compatibility (EMC) testing follows IEC 61000-4 standards, assessing sensor immunity to electromagnetic interference across frequency ranges from 80MHz to 1GHz at field strengths up to 30V/m. Electrostatic discharge (ESD) testing per IEC 61000-4-2 evaluates protection against discharges up to 8kV (contact) and 15kV (air), critical for maintaining sensor accuracy in environments prone to static electricity.

Industry-specific standards supplement these general protocols. For automotive applications, the ISO 16750 series addresses environmental conditions and electrical testing specific to vehicle electronics. For aerospace applications, MIL-STD-883 provides test methods for microelectronic devices under extreme conditions, including radiation testing protocols essential for space-deployed Hall sensors.

Temperature cycling tests (per IEC 60749-25) evaluate sensor performance across extreme temperature ranges, typically from -65°C to +150°C, with dwell times of 15 minutes and transition rates of 15°C/minute. These tests typically require 1,000 cycles for automotive-grade sensors. High-temperature operating life (HTOL) testing subjects sensors to maximum rated temperature while electrically biased for 1,000 hours, assessing long-term reliability under thermal stress.

Mechanical shock testing protocols (IEC 60749-10) expose sensors to acceleration forces of 1,500g to 2,000g for durations of 0.5ms to 1ms across multiple axes. Vibration testing (IEC 60749-12) subjects devices to sinusoidal or random vibrations across frequency ranges of 10Hz to 2,000Hz with acceleration levels up to 20g, simulating real-world operational conditions in industrial and automotive environments.

Humidity testing standards include temperature humidity bias (THB) testing at 85°C/85% relative humidity for 1,000 hours under bias conditions. Salt spray testing (ISO 9227) evaluates corrosion resistance by exposing sensors to salt fog environments for periods ranging from 96 to 1,000 hours, particularly important for sensors deployed in marine or roadside applications.

Electromagnetic compatibility (EMC) testing follows IEC 61000-4 standards, assessing sensor immunity to electromagnetic interference across frequency ranges from 80MHz to 1GHz at field strengths up to 30V/m. Electrostatic discharge (ESD) testing per IEC 61000-4-2 evaluates protection against discharges up to 8kV (contact) and 15kV (air), critical for maintaining sensor accuracy in environments prone to static electricity.

Industry-specific standards supplement these general protocols. For automotive applications, the ISO 16750 series addresses environmental conditions and electrical testing specific to vehicle electronics. For aerospace applications, MIL-STD-883 provides test methods for microelectronic devices under extreme conditions, including radiation testing protocols essential for space-deployed Hall sensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!