Optimizing Hall Effect Sensors for Advanced Robotics Applications

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly from their initial application in measuring magnetic fields to becoming integral components in modern robotics systems. The technology leverages the Hall Effect principle, where a voltage difference is generated across an electrical conductor transverse to an electric current when placed in a magnetic field. This fundamental physical phenomenon has enabled the development of sensors that can detect position, proximity, speed, and current without physical contact.

The evolution of Hall Effect sensors has been marked by several significant advancements. Early implementations were primarily focused on simple magnetic field detection, but miniaturization and integration with semiconductor technology in the 1950s and 1960s expanded their application scope. The 1980s and 1990s witnessed further refinements in sensitivity, reliability, and manufacturing processes, leading to widespread adoption in automotive and industrial applications.

In the last two decades, Hall Effect sensors have undergone transformative improvements in precision, response time, and environmental resilience. Modern sensors feature enhanced temperature stability, reduced power consumption, and improved signal-to-noise ratios, making them increasingly suitable for demanding robotics applications.

The robotics industry presents unique challenges that require specialized sensor capabilities. Advanced robotics systems demand sensors that can operate with high accuracy in dynamic environments, maintain performance across varying temperatures, and integrate seamlessly with complex control systems. Additionally, the miniaturization trend in robotics necessitates compact sensors that can be deployed in space-constrained applications without compromising functionality.

The primary technical objective for optimizing Hall Effect sensors in robotics applications is to enhance their precision and reliability while minimizing size and power requirements. This involves improving magnetic field sensitivity to detect subtle movements and positions, reducing susceptibility to external electromagnetic interference, and developing robust calibration methods to maintain accuracy over time.

Another critical goal is to develop sensors capable of multi-dimensional magnetic field measurement, enabling more sophisticated motion detection and spatial awareness in robotic systems. This advancement would significantly enhance the capabilities of collaborative robots, autonomous vehicles, and precision manufacturing equipment.

The integration of Hall Effect sensors with advanced signal processing algorithms and machine learning techniques represents an emerging trend with substantial potential. These technological combinations could enable predictive maintenance capabilities, adaptive calibration, and enhanced environmental adaptability, further expanding the utility of Hall Effect sensors in next-generation robotics applications.

The evolution of Hall Effect sensors has been marked by several significant advancements. Early implementations were primarily focused on simple magnetic field detection, but miniaturization and integration with semiconductor technology in the 1950s and 1960s expanded their application scope. The 1980s and 1990s witnessed further refinements in sensitivity, reliability, and manufacturing processes, leading to widespread adoption in automotive and industrial applications.

In the last two decades, Hall Effect sensors have undergone transformative improvements in precision, response time, and environmental resilience. Modern sensors feature enhanced temperature stability, reduced power consumption, and improved signal-to-noise ratios, making them increasingly suitable for demanding robotics applications.

The robotics industry presents unique challenges that require specialized sensor capabilities. Advanced robotics systems demand sensors that can operate with high accuracy in dynamic environments, maintain performance across varying temperatures, and integrate seamlessly with complex control systems. Additionally, the miniaturization trend in robotics necessitates compact sensors that can be deployed in space-constrained applications without compromising functionality.

The primary technical objective for optimizing Hall Effect sensors in robotics applications is to enhance their precision and reliability while minimizing size and power requirements. This involves improving magnetic field sensitivity to detect subtle movements and positions, reducing susceptibility to external electromagnetic interference, and developing robust calibration methods to maintain accuracy over time.

Another critical goal is to develop sensors capable of multi-dimensional magnetic field measurement, enabling more sophisticated motion detection and spatial awareness in robotic systems. This advancement would significantly enhance the capabilities of collaborative robots, autonomous vehicles, and precision manufacturing equipment.

The integration of Hall Effect sensors with advanced signal processing algorithms and machine learning techniques represents an emerging trend with substantial potential. These technological combinations could enable predictive maintenance capabilities, adaptive calibration, and enhanced environmental adaptability, further expanding the utility of Hall Effect sensors in next-generation robotics applications.

Robotics Market Demand Analysis

The global robotics market is experiencing unprecedented growth, with advanced sensing technologies like Hall Effect sensors playing a crucial role in this expansion. Current market analysis indicates that the robotics industry is projected to reach $260 billion by 2030, with a compound annual growth rate (CAGR) of approximately 26% between 2023 and 2030. This remarkable growth is primarily driven by increasing automation demands across manufacturing, healthcare, logistics, and consumer sectors.

Within this expanding market, the demand for high-precision sensors has become particularly significant. Hall Effect sensors, which detect magnetic fields and convert them into measurable electrical signals, are experiencing heightened demand due to their reliability in position sensing, speed detection, and current measurement applications in robotics. Market research shows that the global Hall Effect sensor market specifically for robotics applications is growing at 22% annually, outpacing the broader sensor market.

Manufacturing remains the largest sector for robotics implementation, accounting for approximately 47% of the total market. Here, Hall Effect sensors are increasingly sought for their ability to enable precise motion control and position feedback in robotic arms and automated assembly systems. The automotive manufacturing subsector alone has increased its adoption of sensor-equipped robots by 35% over the past three years.

Healthcare robotics represents the fastest-growing segment, with a 31% annual growth rate. Surgical robots, rehabilitation systems, and automated medication dispensers all require the high precision that optimized Hall Effect sensors provide. Market surveys indicate that 78% of healthcare facilities plan to increase their robotics investments within the next five years, with sensor technology quality cited as a critical decision factor.

Consumer robotics, including household cleaning robots and entertainment devices, has seen a 65% market expansion since 2020. This sector particularly values miniaturized Hall Effect sensors that maintain high performance while fitting into compact designs. Consumer expectations for reliability and longevity in these devices directly correlate with sensor quality and optimization.

Geographically, Asia-Pacific leads robotics market growth at 29% annually, with China, Japan, and South Korea as primary drivers. North America follows at 24% growth, with particular strength in healthcare and logistics robotics. European markets show 21% growth, with emphasis on precision manufacturing applications.

The market analysis clearly indicates that optimized Hall Effect sensors represent a critical component in meeting the evolving demands of the robotics industry. Manufacturers who can deliver sensors with enhanced accuracy, reduced power consumption, improved temperature stability, and miniaturized form factors are positioned to capture significant market share in this rapidly expanding field.

Within this expanding market, the demand for high-precision sensors has become particularly significant. Hall Effect sensors, which detect magnetic fields and convert them into measurable electrical signals, are experiencing heightened demand due to their reliability in position sensing, speed detection, and current measurement applications in robotics. Market research shows that the global Hall Effect sensor market specifically for robotics applications is growing at 22% annually, outpacing the broader sensor market.

Manufacturing remains the largest sector for robotics implementation, accounting for approximately 47% of the total market. Here, Hall Effect sensors are increasingly sought for their ability to enable precise motion control and position feedback in robotic arms and automated assembly systems. The automotive manufacturing subsector alone has increased its adoption of sensor-equipped robots by 35% over the past three years.

Healthcare robotics represents the fastest-growing segment, with a 31% annual growth rate. Surgical robots, rehabilitation systems, and automated medication dispensers all require the high precision that optimized Hall Effect sensors provide. Market surveys indicate that 78% of healthcare facilities plan to increase their robotics investments within the next five years, with sensor technology quality cited as a critical decision factor.

Consumer robotics, including household cleaning robots and entertainment devices, has seen a 65% market expansion since 2020. This sector particularly values miniaturized Hall Effect sensors that maintain high performance while fitting into compact designs. Consumer expectations for reliability and longevity in these devices directly correlate with sensor quality and optimization.

Geographically, Asia-Pacific leads robotics market growth at 29% annually, with China, Japan, and South Korea as primary drivers. North America follows at 24% growth, with particular strength in healthcare and logistics robotics. European markets show 21% growth, with emphasis on precision manufacturing applications.

The market analysis clearly indicates that optimized Hall Effect sensors represent a critical component in meeting the evolving demands of the robotics industry. Manufacturers who can deliver sensors with enhanced accuracy, reduced power consumption, improved temperature stability, and miniaturized form factors are positioned to capture significant market share in this rapidly expanding field.

Current State and Challenges in Hall Sensor Technology

Hall Effect sensors have evolved significantly over the past decade, with current technology offering impressive sensitivity, reliability, and miniaturization capabilities. Modern Hall sensors typically achieve sensitivities ranging from 1 to 100 mV/mT, with some advanced models reaching up to 300 mV/mT. Resolution capabilities have improved to detect magnetic field changes as small as 1 μT, making them increasingly suitable for precision robotics applications.

Despite these advancements, Hall Effect sensors face several critical challenges when applied to advanced robotics. Temperature drift remains a significant issue, with typical drift coefficients ranging from 0.02% to 0.1% per degree Celsius, affecting measurement accuracy in variable temperature environments common in robotics operations. This becomes particularly problematic in industrial robots operating in environments with significant temperature fluctuations.

Power consumption presents another challenge, especially for battery-powered robotic systems. Current Hall sensors typically consume between 1-10 mA during operation, which can be prohibitive for small-scale or autonomous robots with limited power resources. While low-power variants exist, they often sacrifice performance parameters such as response time or sensitivity.

Interference susceptibility continues to be a limiting factor, as Hall sensors can be affected by external magnetic fields, electromagnetic interference (EMI), and nearby ferromagnetic materials. In robotics applications where multiple motors, actuators, and power systems operate in close proximity, this can lead to significant measurement errors without proper shielding and compensation techniques.

The integration density of Hall sensors also presents challenges for miniaturized robotic applications. Current packaging technologies limit how densely these sensors can be arranged, with typical dimensions ranging from 1×1×0.5 mm to 4×4×1.5 mm for surface-mount packages. This constrains their implementation in micro-robotics or applications requiring high-density sensor arrays.

Geographically, Hall sensor technology development is concentrated primarily in East Asia (particularly Japan and South Korea), Western Europe (Germany and Switzerland), and North America (USA). Japan leads in miniaturization technologies, while German manufacturers excel in high-precision industrial applications. Recent years have seen China rapidly expanding its capabilities in mass production of cost-effective Hall sensors, though often with lower performance specifications.

Response time limitations also impact real-time control systems in advanced robotics. Typical Hall sensors exhibit response times between 1-10 microseconds, which may be insufficient for ultra-high-speed robotic movements or precise motion control applications requiring faster feedback loops.

Despite these advancements, Hall Effect sensors face several critical challenges when applied to advanced robotics. Temperature drift remains a significant issue, with typical drift coefficients ranging from 0.02% to 0.1% per degree Celsius, affecting measurement accuracy in variable temperature environments common in robotics operations. This becomes particularly problematic in industrial robots operating in environments with significant temperature fluctuations.

Power consumption presents another challenge, especially for battery-powered robotic systems. Current Hall sensors typically consume between 1-10 mA during operation, which can be prohibitive for small-scale or autonomous robots with limited power resources. While low-power variants exist, they often sacrifice performance parameters such as response time or sensitivity.

Interference susceptibility continues to be a limiting factor, as Hall sensors can be affected by external magnetic fields, electromagnetic interference (EMI), and nearby ferromagnetic materials. In robotics applications where multiple motors, actuators, and power systems operate in close proximity, this can lead to significant measurement errors without proper shielding and compensation techniques.

The integration density of Hall sensors also presents challenges for miniaturized robotic applications. Current packaging technologies limit how densely these sensors can be arranged, with typical dimensions ranging from 1×1×0.5 mm to 4×4×1.5 mm for surface-mount packages. This constrains their implementation in micro-robotics or applications requiring high-density sensor arrays.

Geographically, Hall sensor technology development is concentrated primarily in East Asia (particularly Japan and South Korea), Western Europe (Germany and Switzerland), and North America (USA). Japan leads in miniaturization technologies, while German manufacturers excel in high-precision industrial applications. Recent years have seen China rapidly expanding its capabilities in mass production of cost-effective Hall sensors, though often with lower performance specifications.

Response time limitations also impact real-time control systems in advanced robotics. Typical Hall sensors exhibit response times between 1-10 microseconds, which may be insufficient for ultra-high-speed robotic movements or precise motion control applications requiring faster feedback loops.

Current Hall Sensor Implementation Solutions

01 Magnetic field sensing optimization techniques

Various techniques can be employed to optimize Hall effect sensors for improved magnetic field sensing. These include specialized sensor designs, calibration methods, and signal processing algorithms that enhance sensitivity and accuracy. Advanced configurations such as differential sensing arrangements and integrated circuit designs help minimize interference and noise, resulting in more precise magnetic field measurements across various applications.- Design optimization for sensitivity enhancement: Hall effect sensors can be optimized by improving their sensitivity through specific design modifications. This includes optimizing the geometry of the sensing element, using specialized materials with high carrier mobility, and implementing advanced semiconductor structures. These design improvements allow for better detection of magnetic fields, resulting in more accurate measurements and improved signal-to-noise ratios in various applications.

- Temperature compensation techniques: Temperature variations can significantly affect Hall effect sensor performance. Optimization techniques include implementing temperature compensation circuits, using materials with low temperature coefficients, and designing self-calibrating systems that adjust for thermal drift. These methods ensure consistent sensor output across a wide temperature range, maintaining measurement accuracy in changing environmental conditions.

- Integration with signal processing circuits: Optimizing Hall effect sensors often involves integrating advanced signal processing circuits directly with the sensing element. This includes on-chip amplification, filtering, analog-to-digital conversion, and digital signal processing capabilities. Such integration reduces noise, improves response time, and enables more sophisticated measurement capabilities while minimizing the overall footprint of the sensing system.

- Power consumption reduction strategies: Minimizing power consumption is crucial for Hall effect sensors, especially in battery-powered applications. Optimization techniques include implementing power-saving modes, duty-cycling operation, reducing supply voltage requirements, and designing efficient biasing circuits. These approaches extend battery life while maintaining sensor performance, making them suitable for portable and IoT applications.

- Packaging and shielding improvements: Optimizing the packaging and shielding of Hall effect sensors enhances their performance in challenging environments. This includes developing specialized encapsulation methods, implementing magnetic shields to prevent interference from external fields, and designing packages that minimize mechanical stress on the sensing element. These improvements increase sensor reliability, accuracy, and longevity in industrial and automotive applications.

02 Temperature compensation and stability enhancement

Hall effect sensors can be optimized through temperature compensation techniques that maintain measurement accuracy across varying environmental conditions. This involves implementing specialized circuitry, materials with low temperature coefficients, and algorithmic corrections to counteract thermal drift. These approaches ensure stable sensor performance and reliable output signals regardless of temperature fluctuations in the operating environment.Expand Specific Solutions03 Structural and material improvements for Hall sensors

Optimizing the physical structure and materials used in Hall effect sensors significantly enhances their performance. This includes using specialized semiconductor materials, optimizing the geometry of sensing elements, and implementing advanced packaging techniques. These structural improvements lead to increased sensitivity, better linearity, reduced power consumption, and enhanced durability in challenging environments.Expand Specific Solutions04 Power efficiency and miniaturization techniques

Hall effect sensors can be optimized for power efficiency and reduced size through various design approaches. These include implementing low-power operating modes, optimizing biasing currents, using advanced fabrication techniques for miniaturization, and integrating multiple functions into single packages. These improvements make Hall sensors suitable for battery-powered applications and space-constrained installations while maintaining measurement performance.Expand Specific Solutions05 Application-specific optimization for automotive and industrial use

Hall effect sensors can be specifically optimized for automotive and industrial applications through ruggedized designs, enhanced interference immunity, and specialized output configurations. These optimizations include protective coatings, filtering circuits, programmable thresholds, and diagnostic capabilities that ensure reliable operation in harsh environments with electromagnetic interference, vibration, and extreme temperatures.Expand Specific Solutions

Key Players in Hall Sensor and Robotics Industries

The Hall Effect Sensors market for advanced robotics applications is currently in a growth phase, with increasing demand driven by automation trends. The market size is expanding rapidly, projected to reach significant value as robotics adoption accelerates across industrial, healthcare, and consumer sectors. Technologically, the field shows varying maturity levels with established players like Honeywell International and Allegro MicroSystems leading with advanced sensor solutions, while Texas Instruments and Infineon Technologies contribute significant innovations in semiconductor integration. STMicroelectronics and Robert Bosch GmbH are advancing application-specific optimizations for robotics use cases. The competitive landscape features both specialized sensor manufacturers and diversified technology conglomerates, with emerging players from Asia, particularly Chinese companies like Nanjing Xinjie Zhongxu Microelectronics, gaining market share through cost-effective solutions.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensor solutions specifically optimized for robotics applications, featuring their proprietary SmartSense technology. This technology integrates signal conditioning, temperature compensation, and digital processing capabilities directly into the sensor package. Their SPS (Smart Position Sensor) series utilizes Hall effect principles with enhanced magnetic field sensitivity (>5mV/G) and response times under 1ms, critical for real-time robotic control systems. Honeywell's sensors incorporate dual-die redundancy architecture that maintains operational integrity even if one sensing element fails, providing 99.999% reliability rates in industrial environments. The company has also pioneered miniaturized 3D Hall effect sensors with dimensions under 2.0 x 3.0 x 1.0mm that can detect magnetic field vectors in all spatial dimensions, enabling precise rotational and linear position sensing for robotic joints and end effectors. Their latest generation incorporates adaptive power management that reduces power consumption by up to 70% during standby modes while maintaining microsecond response times when activated.

Strengths: Industry-leading temperature stability (±0.02%/°C drift) and exceptional accuracy (±0.1% linearity) across wide operating ranges (-40°C to +150°C). Comprehensive integration options with major robotics control systems and protocols. Weaknesses: Higher cost compared to commodity sensors, and proprietary interfaces may require specific implementation knowledge. Some advanced features require dedicated power management considerations.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed a comprehensive Hall effect sensor portfolio specifically engineered for advanced robotics applications. Their A1369 series features proprietary chopper stabilization technology that significantly reduces the temperature drift to less than 15 ppm/°C, addressing one of the key challenges in precision robotics. The company's integrated circuit design combines Hall sensing elements with advanced signal processing on a single silicon die, enabling high-speed sampling rates exceeding 20 kHz for real-time motion control. Allegro's sensors incorporate programmable sensitivity ranges (1mV/G to 20mV/G) that can be dynamically adjusted based on the specific robotic application requirements. Their patented BiCMOS process technology allows for high-resolution position detection (12-bit resolution) while maintaining low power consumption (typically <10mA at 5V). For collaborative robots, Allegro has developed specialized current sensors based on Hall effect principles that provide contactless current measurement with isolation ratings up to 4.8kVrms, enabling safe human-robot interaction through precise torque monitoring and collision detection capabilities.

Strengths: Superior noise immunity with integrated filtering capabilities reducing electromagnetic interference effects by >40dB. Excellent long-term stability with drift rates below 0.1% over 10-year operational lifespans. Comprehensive development ecosystem including evaluation boards and software libraries. Weaknesses: Limited customization options for specialized robotics applications. Higher power consumption compared to some competing technologies when operating in continuous high-speed sampling modes.

Core Hall Effect Sensing Innovations

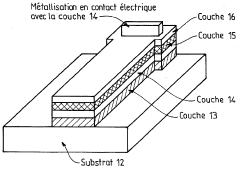

Hall-effect sensor

PatentWO2002019442A1

Innovation

- A Hall effect sensor with a multilayer structure featuring a thin active layer of semiconductor material on an insulating or semi-insulating substrate, with electrical insulation from the substrate and optimized doping rates to operate in the exhaustion regime, utilizing materials like hexagonal silicon carbide or GaN-based nitrides, ensuring low temperature sensitivity and high Hall coefficient across elevated temperatures.

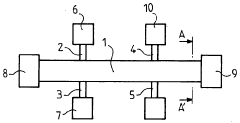

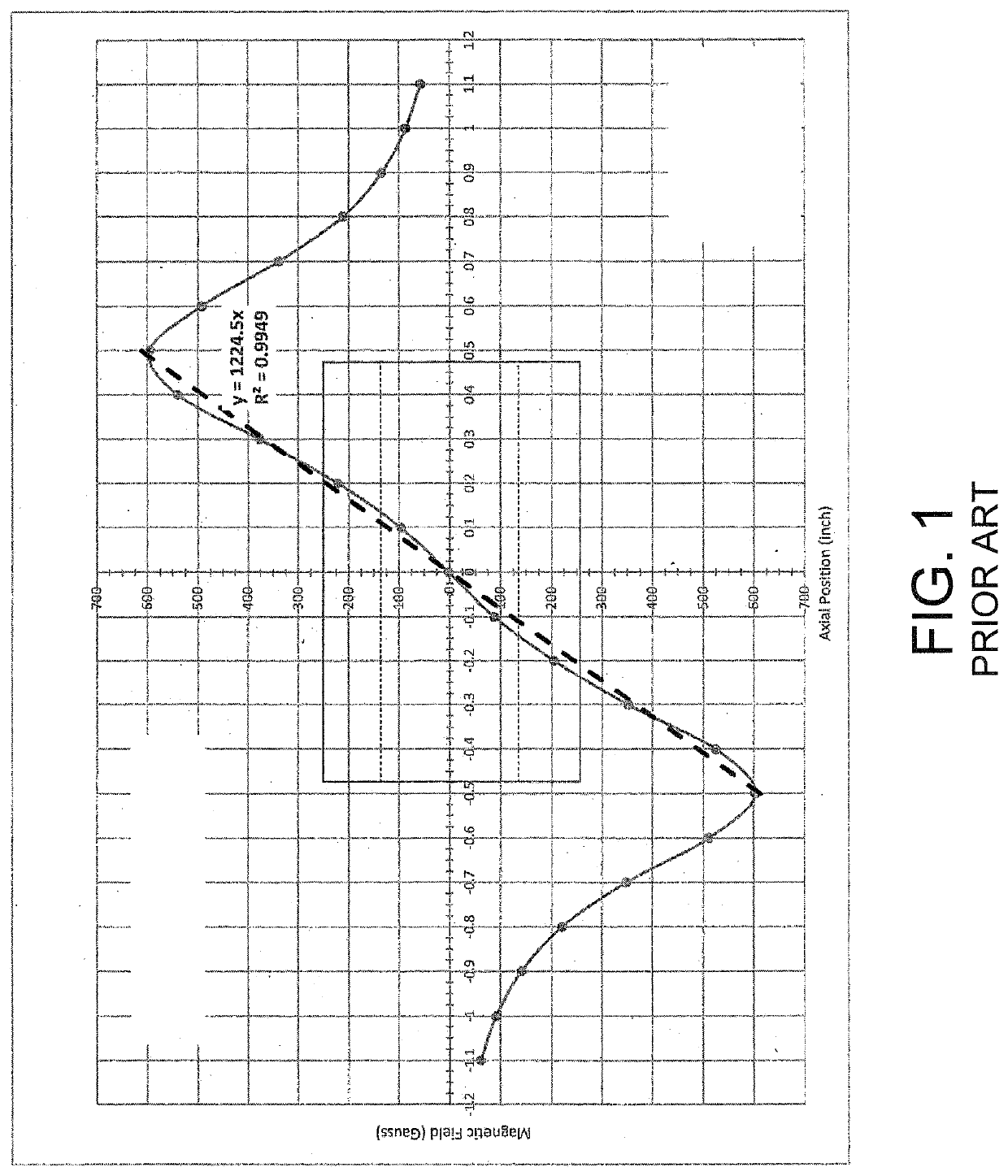

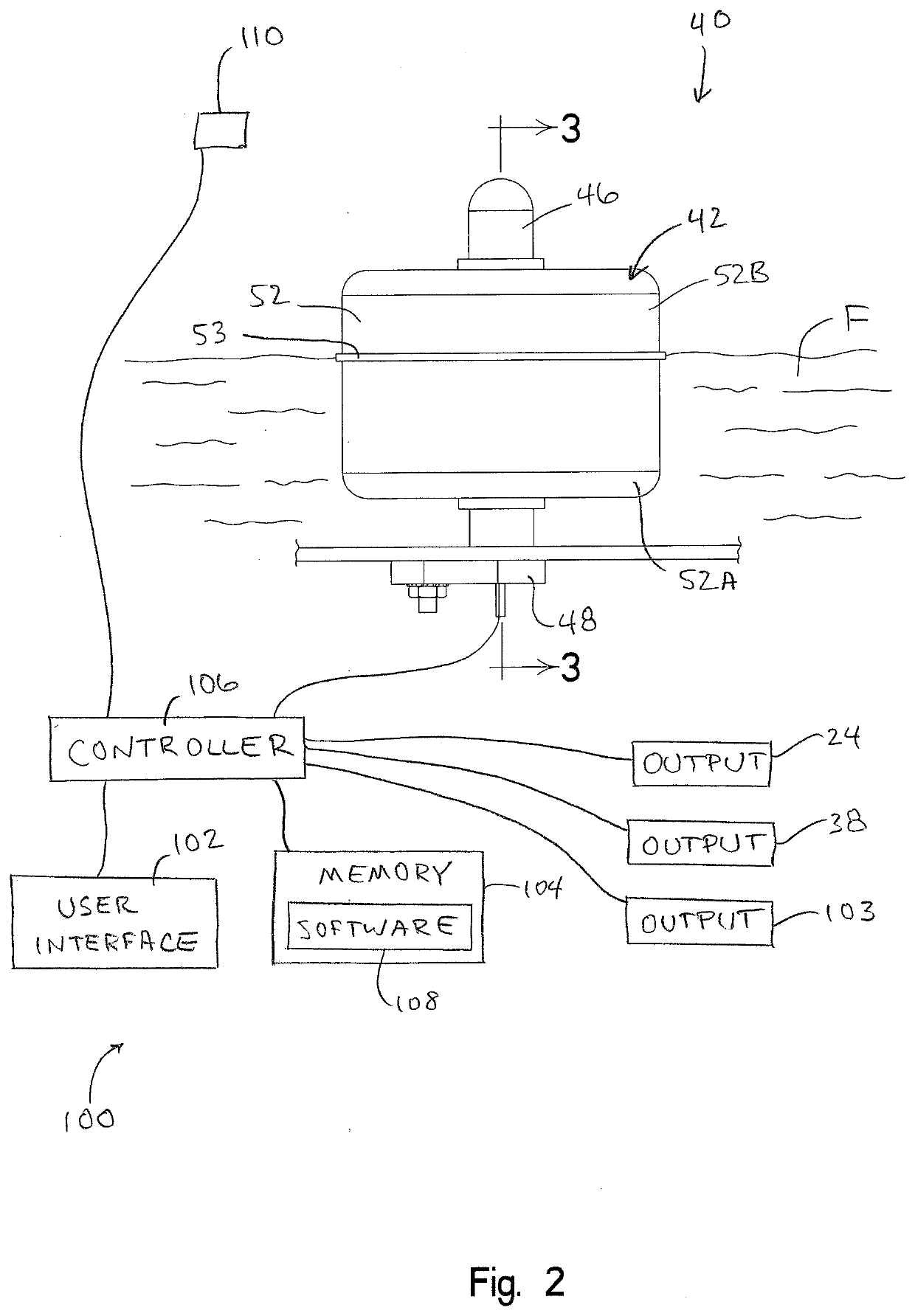

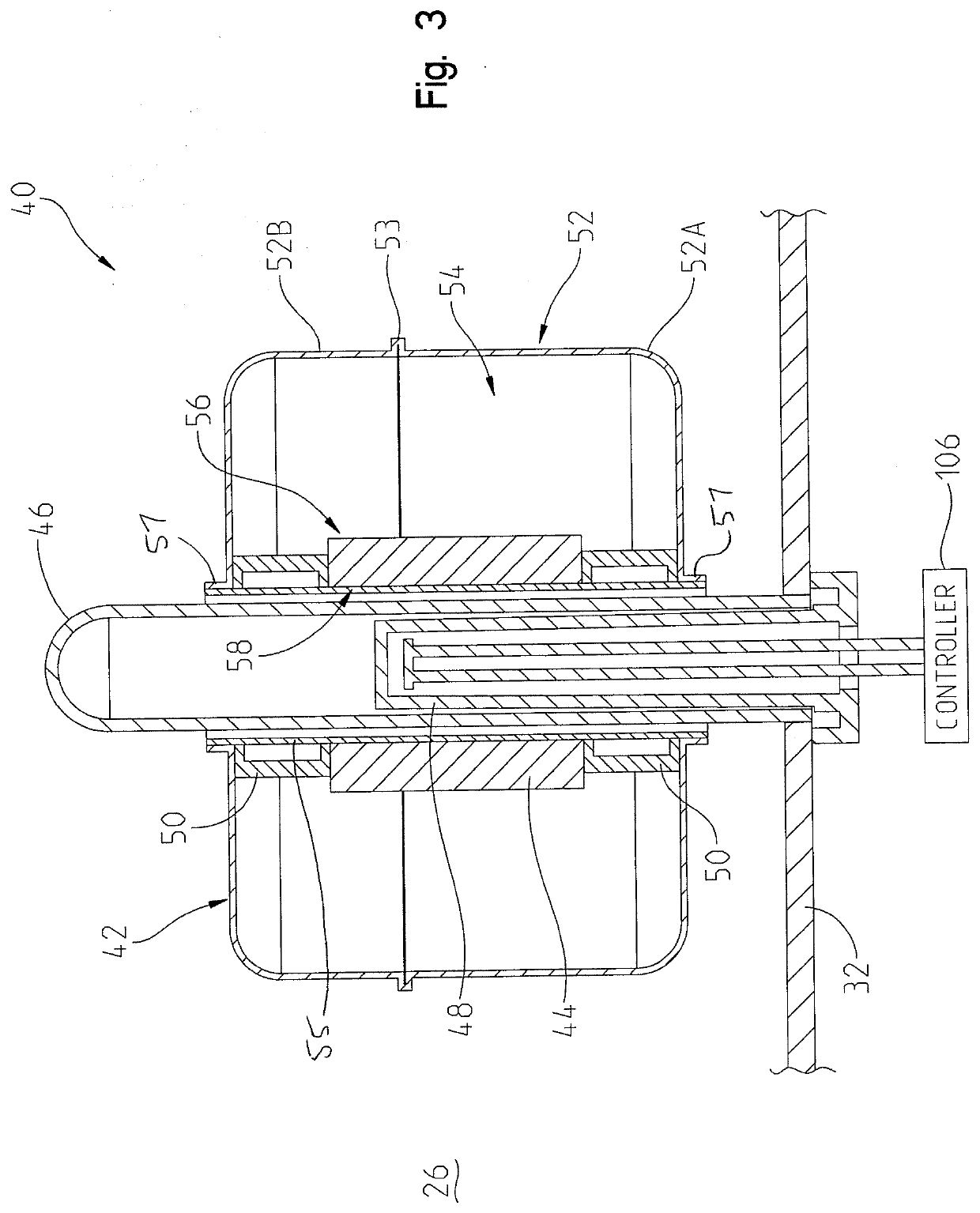

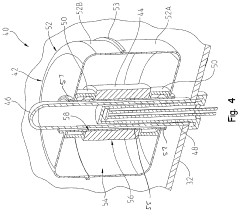

Monitoring with a radially magnetized magnet and hall effect sensor

PatentActiveUS20210348962A1

Innovation

- A radially magnetized magnet integrated into a float with a Hall effect sensor that produces a continuously variable signal, allowing for precise fluid level measurement and detection of operational states, while being resilient to fouling and insensitive to food residue, scale buildup, and corrosion.

Integration Challenges with Robot Control Systems

The integration of Hall Effect sensors into robotic control systems presents significant challenges that require careful consideration during system design and implementation. One primary challenge stems from signal conditioning requirements, as Hall Effect sensor outputs often need amplification and filtering before they can be effectively utilized by robot control systems. The raw signals from these sensors are typically in the millivolt range and susceptible to noise, necessitating sophisticated signal processing circuits that can maintain signal integrity while operating in electromagnetically noisy robotic environments.

Compatibility issues between Hall Effect sensors and various robot control architectures represent another substantial hurdle. Many robotic systems employ proprietary control interfaces or specialized communication protocols that may not readily accommodate analog sensor inputs. Engineers must develop custom interface solutions or signal conversion modules to ensure seamless data flow between sensors and control systems, adding complexity to the overall system design.

Power management considerations also significantly impact integration efforts. Hall Effect sensors require stable power supplies to maintain measurement accuracy, yet robotic systems often experience power fluctuations during operation. These fluctuations can introduce measurement errors if not properly managed through voltage regulation and power conditioning circuits. Additionally, in battery-operated robots, the continuous operation of multiple Hall Effect sensors can contribute to power drain, necessitating careful power budgeting and potentially implementing power-saving modes.

Calibration and drift compensation mechanisms present ongoing integration challenges. Environmental factors such as temperature variations and electromagnetic interference can cause sensor drift over time, requiring periodic recalibration or implementation of dynamic compensation algorithms. These algorithms must be integrated into the robot's control software, adding computational overhead and complexity to the system.

Real-time performance requirements further complicate integration efforts. Advanced robotics applications often demand high-speed sensor feedback for precise motion control and position sensing. The sampling rate, processing latency, and update frequency of Hall Effect sensor systems must align with the robot's control loop timing requirements. Any mismatch can result in control instabilities or reduced performance, particularly in high-precision applications like robotic surgery or automated manufacturing.

Physical integration constraints also pose significant challenges. The placement of Hall Effect sensors within robotic joints or actuators must consider magnetic field orientation, interference from nearby ferromagnetic components, and mechanical constraints. Engineers must often develop custom mounting solutions that maintain optimal sensor positioning while accommodating the robot's mechanical design and movement envelope.

Compatibility issues between Hall Effect sensors and various robot control architectures represent another substantial hurdle. Many robotic systems employ proprietary control interfaces or specialized communication protocols that may not readily accommodate analog sensor inputs. Engineers must develop custom interface solutions or signal conversion modules to ensure seamless data flow between sensors and control systems, adding complexity to the overall system design.

Power management considerations also significantly impact integration efforts. Hall Effect sensors require stable power supplies to maintain measurement accuracy, yet robotic systems often experience power fluctuations during operation. These fluctuations can introduce measurement errors if not properly managed through voltage regulation and power conditioning circuits. Additionally, in battery-operated robots, the continuous operation of multiple Hall Effect sensors can contribute to power drain, necessitating careful power budgeting and potentially implementing power-saving modes.

Calibration and drift compensation mechanisms present ongoing integration challenges. Environmental factors such as temperature variations and electromagnetic interference can cause sensor drift over time, requiring periodic recalibration or implementation of dynamic compensation algorithms. These algorithms must be integrated into the robot's control software, adding computational overhead and complexity to the system.

Real-time performance requirements further complicate integration efforts. Advanced robotics applications often demand high-speed sensor feedback for precise motion control and position sensing. The sampling rate, processing latency, and update frequency of Hall Effect sensor systems must align with the robot's control loop timing requirements. Any mismatch can result in control instabilities or reduced performance, particularly in high-precision applications like robotic surgery or automated manufacturing.

Physical integration constraints also pose significant challenges. The placement of Hall Effect sensors within robotic joints or actuators must consider magnetic field orientation, interference from nearby ferromagnetic components, and mechanical constraints. Engineers must often develop custom mounting solutions that maintain optimal sensor positioning while accommodating the robot's mechanical design and movement envelope.

Environmental Factors Affecting Sensor Performance

Hall Effect sensors in robotics applications are significantly influenced by various environmental factors that can alter their performance characteristics and reliability. Temperature variations represent one of the most critical environmental challenges, as they directly impact the sensor's output voltage and sensitivity. In extreme temperature conditions, ranging from -40°C to +150°C commonly encountered in industrial robotics, the Hall voltage can drift by up to 10-15%, potentially leading to inaccurate position detection and control errors if not properly compensated.

Electromagnetic interference (EMI) constitutes another substantial environmental concern, particularly in robotics environments where multiple motors, power electronics, and communication systems operate simultaneously. External magnetic fields from nearby components can introduce measurement errors of 5-8% in unshielded Hall sensors, necessitating proper shielding techniques and strategic sensor placement within the robotic system architecture.

Humidity and moisture exposure present significant challenges for Hall Effect sensor implementation in robotics. While the semiconductor element itself is typically protected within an encapsulation, connector interfaces and circuit boards remain vulnerable to moisture-induced corrosion and short circuits. In environments with relative humidity exceeding 85%, accelerated degradation of sensor components has been documented, with failure rates increasing by approximately 30% compared to controlled conditions.

Mechanical stress and vibration, common in dynamic robotic applications, can induce mechanical deformation of the Hall element, altering its electrical properties and introducing measurement errors. Continuous vibration at frequencies between 10-500 Hz, typical in industrial robotics, can lead to fatigue in sensor mounting points and internal connections, potentially causing intermittent failures or permanent damage over extended operation periods.

Dust and particulate contamination represent a significant concern in manufacturing and outdoor robotic applications. While the sensing element itself is typically sealed, accumulation of conductive particles around connection points can create leakage paths and degrade signal integrity. Testing has shown that in heavily contaminated environments, signal-to-noise ratios can deteriorate by up to 12dB, significantly reducing the effective sensing range and precision.

Atmospheric pressure variations, particularly relevant for robotics deployed in aerospace or underwater applications, can affect the mechanical properties of sensor packaging and potentially alter calibration parameters. Pressure differentials exceeding 2 atmospheres have been shown to induce stress on sensor components, potentially leading to long-term drift in calibration parameters if not properly accounted for in the sensor design and compensation algorithms.

Electromagnetic interference (EMI) constitutes another substantial environmental concern, particularly in robotics environments where multiple motors, power electronics, and communication systems operate simultaneously. External magnetic fields from nearby components can introduce measurement errors of 5-8% in unshielded Hall sensors, necessitating proper shielding techniques and strategic sensor placement within the robotic system architecture.

Humidity and moisture exposure present significant challenges for Hall Effect sensor implementation in robotics. While the semiconductor element itself is typically protected within an encapsulation, connector interfaces and circuit boards remain vulnerable to moisture-induced corrosion and short circuits. In environments with relative humidity exceeding 85%, accelerated degradation of sensor components has been documented, with failure rates increasing by approximately 30% compared to controlled conditions.

Mechanical stress and vibration, common in dynamic robotic applications, can induce mechanical deformation of the Hall element, altering its electrical properties and introducing measurement errors. Continuous vibration at frequencies between 10-500 Hz, typical in industrial robotics, can lead to fatigue in sensor mounting points and internal connections, potentially causing intermittent failures or permanent damage over extended operation periods.

Dust and particulate contamination represent a significant concern in manufacturing and outdoor robotic applications. While the sensing element itself is typically sealed, accumulation of conductive particles around connection points can create leakage paths and degrade signal integrity. Testing has shown that in heavily contaminated environments, signal-to-noise ratios can deteriorate by up to 12dB, significantly reducing the effective sensing range and precision.

Atmospheric pressure variations, particularly relevant for robotics deployed in aerospace or underwater applications, can affect the mechanical properties of sensor packaging and potentially alter calibration parameters. Pressure differentials exceeding 2 atmospheres have been shown to induce stress on sensor components, potentially leading to long-term drift in calibration parameters if not properly accounted for in the sensor design and compensation algorithms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!