Assessing the Role of Hall Effect Sensors in Next-Gen Transportation

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Evolution and Objectives

The Hall effect, discovered by Edwin Hall in 1879, represents one of the fundamental principles in electromagnetic theory that has evolved into a critical sensing technology. Initially confined to laboratory experiments and theoretical physics, Hall effect sensors have undergone remarkable transformation over the past century, particularly accelerating in development since the 1950s with the advent of semiconductor technology.

The evolution of Hall effect sensors can be traced through distinct technological phases. Early implementations utilized basic semiconductor materials with limited sensitivity and significant temperature drift issues. The 1970s and 1980s witnessed significant improvements in material science, introducing more stable compounds and integrated temperature compensation mechanisms. By the 1990s, miniaturization efforts led to the development of surface-mount Hall sensors, dramatically reducing their physical footprint while improving reliability.

The 2000s marked a pivotal shift toward smart Hall effect sensors featuring integrated signal processing capabilities, digital outputs, and programmable parameters. Recent advancements have focused on enhancing sensitivity, reducing power consumption, and improving electromagnetic interference resistance—critical factors for transportation applications operating in challenging environments.

In the transportation sector specifically, Hall effect sensors have evolved from simple speed detection devices to sophisticated components integral to multiple vehicle systems. Their progression from analog to digital interfaces has enabled seamless integration with modern vehicle electronic control units (ECUs) and advanced driver assistance systems (ADAS).

The primary technological objectives for next-generation Hall effect sensors in transportation applications center around several key imperatives. First, achieving ultra-high reliability under extreme conditions, including wide temperature ranges (-40°C to 150°C) and exposure to vibration, moisture, and electromagnetic interference. Second, further miniaturization to accommodate the increasing density of electronic components in modern vehicles while maintaining or improving performance characteristics.

Additionally, enhancing energy efficiency represents a critical objective, particularly for electric and autonomous vehicles where power management directly impacts range and operational duration. Improved sensitivity at lower magnetic field strengths would enable more precise measurements and expanded application scenarios. Integration capabilities with other sensor technologies and communication protocols are becoming increasingly important as vehicles evolve into complex networks of interconnected systems.

The technological trajectory aims to develop Hall effect sensors capable of supporting the demanding requirements of autonomous driving systems, including redundancy features, self-diagnostic capabilities, and fail-operational modes that ensure safety-critical functions remain operational even during partial system failures.

The evolution of Hall effect sensors can be traced through distinct technological phases. Early implementations utilized basic semiconductor materials with limited sensitivity and significant temperature drift issues. The 1970s and 1980s witnessed significant improvements in material science, introducing more stable compounds and integrated temperature compensation mechanisms. By the 1990s, miniaturization efforts led to the development of surface-mount Hall sensors, dramatically reducing their physical footprint while improving reliability.

The 2000s marked a pivotal shift toward smart Hall effect sensors featuring integrated signal processing capabilities, digital outputs, and programmable parameters. Recent advancements have focused on enhancing sensitivity, reducing power consumption, and improving electromagnetic interference resistance—critical factors for transportation applications operating in challenging environments.

In the transportation sector specifically, Hall effect sensors have evolved from simple speed detection devices to sophisticated components integral to multiple vehicle systems. Their progression from analog to digital interfaces has enabled seamless integration with modern vehicle electronic control units (ECUs) and advanced driver assistance systems (ADAS).

The primary technological objectives for next-generation Hall effect sensors in transportation applications center around several key imperatives. First, achieving ultra-high reliability under extreme conditions, including wide temperature ranges (-40°C to 150°C) and exposure to vibration, moisture, and electromagnetic interference. Second, further miniaturization to accommodate the increasing density of electronic components in modern vehicles while maintaining or improving performance characteristics.

Additionally, enhancing energy efficiency represents a critical objective, particularly for electric and autonomous vehicles where power management directly impacts range and operational duration. Improved sensitivity at lower magnetic field strengths would enable more precise measurements and expanded application scenarios. Integration capabilities with other sensor technologies and communication protocols are becoming increasingly important as vehicles evolve into complex networks of interconnected systems.

The technological trajectory aims to develop Hall effect sensors capable of supporting the demanding requirements of autonomous driving systems, including redundancy features, self-diagnostic capabilities, and fail-operational modes that ensure safety-critical functions remain operational even during partial system failures.

Transportation Market Demand Analysis

The global transportation market is experiencing a significant shift towards advanced sensing technologies, with Hall Effect sensors emerging as a critical component in next-generation transportation systems. Current market analysis indicates that the automotive sector alone represents over $250 billion in potential applications for magnetic sensing technologies, with Hall Effect sensors capturing approximately 30% of this segment due to their reliability and cost-effectiveness.

Consumer demand for safer, more efficient, and increasingly autonomous vehicles is driving the adoption of Hall Effect sensors across multiple transportation subsystems. Safety features such as anti-lock braking systems, electronic stability control, and advanced driver assistance systems (ADAS) all rely heavily on precise position and speed detection capabilities that Hall Effect sensors provide. Market research shows that vehicles now contain an average of 70-100 sensors per unit, with this number projected to increase by 20% annually as autonomous features become more prevalent.

Beyond personal vehicles, commercial transportation sectors including shipping, aviation, and rail systems are rapidly integrating Hall Effect sensor technology to improve operational efficiency and safety. The commercial transportation sensor market is growing at a compound annual growth rate of 8.7%, with magnetic sensing technologies representing one of the fastest-growing segments.

Emerging transportation technologies such as electric vehicles (EVs) and hybrid electric vehicles (HEVs) present particularly strong growth opportunities for Hall Effect sensor applications. These vehicles require sophisticated battery management systems, motor control units, and power distribution systems—all areas where Hall Effect sensors excel at current and position monitoring. The EV market is expected to reach 26 million units annually by 2030, creating substantial demand for these sensing technologies.

Urban mobility solutions including e-bikes, scooters, and other micromobility options represent another expanding market segment, with an estimated 50 million units requiring position and speed sensing annually. These applications favor Hall Effect sensors for their compact size, durability, and low power consumption characteristics.

Regional analysis reveals that Asia-Pacific markets, particularly China, Japan, and South Korea, are leading in Hall Effect sensor adoption for transportation applications, followed by Europe and North America. This geographic distribution aligns with regional strengths in automotive manufacturing and electric vehicle production.

Market forecasts indicate that the transportation-specific Hall Effect sensor market will grow from $1.8 billion in 2023 to approximately $3.2 billion by 2028, representing a significant opportunity for sensor manufacturers and transportation technology integrators who can address the increasing demand for more sophisticated, reliable, and cost-effective sensing solutions.

Consumer demand for safer, more efficient, and increasingly autonomous vehicles is driving the adoption of Hall Effect sensors across multiple transportation subsystems. Safety features such as anti-lock braking systems, electronic stability control, and advanced driver assistance systems (ADAS) all rely heavily on precise position and speed detection capabilities that Hall Effect sensors provide. Market research shows that vehicles now contain an average of 70-100 sensors per unit, with this number projected to increase by 20% annually as autonomous features become more prevalent.

Beyond personal vehicles, commercial transportation sectors including shipping, aviation, and rail systems are rapidly integrating Hall Effect sensor technology to improve operational efficiency and safety. The commercial transportation sensor market is growing at a compound annual growth rate of 8.7%, with magnetic sensing technologies representing one of the fastest-growing segments.

Emerging transportation technologies such as electric vehicles (EVs) and hybrid electric vehicles (HEVs) present particularly strong growth opportunities for Hall Effect sensor applications. These vehicles require sophisticated battery management systems, motor control units, and power distribution systems—all areas where Hall Effect sensors excel at current and position monitoring. The EV market is expected to reach 26 million units annually by 2030, creating substantial demand for these sensing technologies.

Urban mobility solutions including e-bikes, scooters, and other micromobility options represent another expanding market segment, with an estimated 50 million units requiring position and speed sensing annually. These applications favor Hall Effect sensors for their compact size, durability, and low power consumption characteristics.

Regional analysis reveals that Asia-Pacific markets, particularly China, Japan, and South Korea, are leading in Hall Effect sensor adoption for transportation applications, followed by Europe and North America. This geographic distribution aligns with regional strengths in automotive manufacturing and electric vehicle production.

Market forecasts indicate that the transportation-specific Hall Effect sensor market will grow from $1.8 billion in 2023 to approximately $3.2 billion by 2028, representing a significant opportunity for sensor manufacturers and transportation technology integrators who can address the increasing demand for more sophisticated, reliable, and cost-effective sensing solutions.

Current Capabilities and Technical Barriers

Hall Effect sensors in next-generation transportation systems currently demonstrate significant capabilities across multiple applications. These sensors excel in non-contact position sensing with high reliability in harsh automotive environments, offering operational temperature ranges from -40°C to 150°C. Modern Hall sensors achieve resolution capabilities down to micrometers, with response times in microseconds, making them ideal for real-time control systems in vehicles. Their compact form factor (some as small as 1mm²) enables integration into space-constrained automotive components.

The durability of these sensors is remarkable, with many rated for operational lifespans exceeding 15 years or billions of switching cycles, crucial for transportation applications. Current Hall Effect sensors demonstrate excellent immunity to environmental contaminants like dust, oil, and vibration compared to optical or mechanical alternatives. Power efficiency has also improved significantly, with some variants operating on less than 10mW, supporting the energy constraints of electric vehicles.

Despite these advances, several technical barriers limit the full potential of Hall Effect sensors in next-generation transportation. Temperature drift remains a significant challenge, with sensitivity variations of up to 0.1% per degree Celsius affecting measurement accuracy in extreme conditions. Cross-axis sensitivity issues create measurement errors when magnetic fields aren't perfectly aligned with the sensing axis, particularly problematic in dynamic vehicle environments.

Integration complexity presents another barrier, as Hall sensors require precise positioning relative to magnets and careful shielding from external magnetic interference, complicating manufacturing processes. The limited sensing range (typically under 20mm) restricts applications requiring longer-distance measurements. Additionally, hysteresis effects in some Hall sensors can cause measurement inconsistencies during bidirectional movements, affecting precision in critical safety systems.

Signal processing requirements pose challenges, as raw Hall sensor outputs often need complex conditioning and amplification, increasing system complexity and cost. Material limitations also exist, with current semiconductor materials limiting maximum operating temperatures and long-term stability. For advanced autonomous vehicles, the relatively low bandwidth of conventional Hall sensors (typically below 20kHz) restricts their use in ultra-high-speed applications.

Miniaturization efforts face physical constraints as reducing sensor size often compromises sensitivity and signal-to-noise ratio. Finally, cost factors remain significant, with high-precision Hall Effect sensors incorporating temperature compensation and advanced signal processing commanding premium prices that challenge mass adoption in consumer vehicles.

The durability of these sensors is remarkable, with many rated for operational lifespans exceeding 15 years or billions of switching cycles, crucial for transportation applications. Current Hall Effect sensors demonstrate excellent immunity to environmental contaminants like dust, oil, and vibration compared to optical or mechanical alternatives. Power efficiency has also improved significantly, with some variants operating on less than 10mW, supporting the energy constraints of electric vehicles.

Despite these advances, several technical barriers limit the full potential of Hall Effect sensors in next-generation transportation. Temperature drift remains a significant challenge, with sensitivity variations of up to 0.1% per degree Celsius affecting measurement accuracy in extreme conditions. Cross-axis sensitivity issues create measurement errors when magnetic fields aren't perfectly aligned with the sensing axis, particularly problematic in dynamic vehicle environments.

Integration complexity presents another barrier, as Hall sensors require precise positioning relative to magnets and careful shielding from external magnetic interference, complicating manufacturing processes. The limited sensing range (typically under 20mm) restricts applications requiring longer-distance measurements. Additionally, hysteresis effects in some Hall sensors can cause measurement inconsistencies during bidirectional movements, affecting precision in critical safety systems.

Signal processing requirements pose challenges, as raw Hall sensor outputs often need complex conditioning and amplification, increasing system complexity and cost. Material limitations also exist, with current semiconductor materials limiting maximum operating temperatures and long-term stability. For advanced autonomous vehicles, the relatively low bandwidth of conventional Hall sensors (typically below 20kHz) restricts their use in ultra-high-speed applications.

Miniaturization efforts face physical constraints as reducing sensor size often compromises sensitivity and signal-to-noise ratio. Finally, cost factors remain significant, with high-precision Hall Effect sensors incorporating temperature compensation and advanced signal processing commanding premium prices that challenge mass adoption in consumer vehicles.

Current Implementation Architectures

01 Hall Effect Sensor Design and Structure

Hall effect sensors are designed with specific structures to optimize their performance. These designs include various semiconductor materials, packaging configurations, and integration with other components. The structure of the sensor affects its sensitivity, stability, and reliability in detecting magnetic fields. Advanced designs may incorporate multiple sensing elements or specialized geometries to enhance performance characteristics.- Hall Effect Sensor Design and Structure: Hall effect sensors are designed with specific structures to optimize their performance in detecting magnetic fields. These designs include various semiconductor materials, electrode configurations, and packaging techniques that enhance sensitivity and reliability. The structure often incorporates magnetic flux concentrators to amplify the magnetic field and improve detection capabilities. Advanced designs may include integrated circuits that combine the Hall element with signal processing components on a single chip.

- Measurement and Detection Applications: Hall effect sensors are widely used for measurement and detection applications across various industries. They can detect position, proximity, speed, and current by measuring changes in magnetic fields. These sensors are employed in automotive systems for wheel speed sensing, throttle position detection, and crankshaft positioning. In industrial applications, they monitor motor speeds, detect gear tooth movement, and measure current in power systems. Their non-contact operation makes them ideal for harsh environments where mechanical wear is a concern.

- Signal Processing and Conditioning: Signal processing and conditioning are crucial aspects of Hall effect sensor systems. Various techniques are employed to amplify the small Hall voltage, filter noise, and convert the signal to a usable output format. Advanced signal conditioning circuits compensate for temperature drift, offset voltage, and other environmental factors that could affect measurement accuracy. Digital signal processing may be integrated to provide calibration, linearization, and communication capabilities, enhancing the overall performance and reliability of the sensor system.

- Magnetic Field Enhancement and Shielding: Enhancing magnetic field sensitivity while providing appropriate shielding is essential for Hall effect sensor performance. Various techniques are employed to concentrate magnetic flux through the sensing element, including the use of ferromagnetic materials and specific geometric configurations. Shielding methods protect the sensor from external magnetic interference that could compromise measurement accuracy. These enhancements allow for detection of weaker magnetic fields and operation in electromagnetically noisy environments, expanding the range of potential applications.

- Integration with Electronic Systems: Hall effect sensors are increasingly integrated with larger electronic systems to provide comprehensive sensing solutions. This integration includes embedding sensors in microelectronic packages, connecting them to microcontrollers or processors, and incorporating them into complex control systems. Modern designs feature digital interfaces such as I2C, SPI, or PWM outputs that facilitate direct communication with host systems. The integration extends to power management circuits that optimize energy consumption, making these sensors suitable for battery-powered and energy-efficient applications.

02 Magnetic Field Detection and Measurement

Hall effect sensors operate by detecting and measuring magnetic fields based on the Hall effect principle. These sensors can measure both static and dynamic magnetic fields with high precision. The measurement capabilities include detecting field strength, direction, and variations. Various techniques are employed to improve the sensitivity and accuracy of magnetic field detection, including signal amplification and noise reduction methods.Expand Specific Solutions03 Applications in Position and Motion Sensing

Hall effect sensors are widely used for position and motion sensing applications. They can detect the presence, position, displacement, or movement of objects when coupled with magnets. These sensors are employed in automotive systems, industrial equipment, consumer electronics, and robotics. They provide non-contact measurement capabilities, making them suitable for harsh environments and applications requiring long operational lifetimes.Expand Specific Solutions04 Signal Processing and Conditioning

Signal processing and conditioning are essential aspects of Hall effect sensor systems. Various techniques are employed to amplify, filter, and process the raw Hall voltage signal to improve accuracy and reduce noise. This includes analog and digital signal processing methods, temperature compensation, and calibration techniques. Advanced signal conditioning circuits help overcome limitations such as offset voltage, temperature drift, and external interference.Expand Specific Solutions05 Integration with Electronic Systems

Hall effect sensors are integrated into various electronic systems and circuits to provide magnetic sensing capabilities. This integration includes embedding sensors in integrated circuits, combining them with microcontrollers, and incorporating them into larger sensing systems. Modern designs focus on miniaturization, power efficiency, and compatibility with digital interfaces. The integration enables applications in smart devices, automotive electronics, industrial automation, and IoT systems.Expand Specific Solutions

Leading Hall Effect Sensor Manufacturers and Integrators

The Hall Effect Sensors market in next-generation transportation is currently in a growth phase, with an expanding market size driven by increasing demand for precise position sensing and contactless measurement in automotive applications. The technology has reached moderate maturity but continues to evolve with advancements in miniaturization and sensitivity. Key players shaping the competitive landscape include established industrial giants like Honeywell International, Robert Bosch GmbH, and Infineon Technologies AG, alongside specialized sensor manufacturers such as Allegro MicroSystems and Melexis Technologies. Automotive OEMs including GM Global Technology and Ford Global Technologies are integrating these sensors into advanced vehicle systems, while semiconductor companies like Texas Instruments and Littelfuse are developing complementary technologies to enhance sensor performance in transportation applications.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive Hall effect sensor portfolio specifically engineered for next-generation transportation applications. Their technology integrates Hall sensing elements with sophisticated ASIC (Application-Specific Integrated Circuit) processing in a single package, enabling high-precision measurements in challenging automotive environments. Bosch's Hall sensors feature advanced temperature compensation algorithms that maintain accuracy from -40°C to +150°C, essential for reliable operation in various vehicle locations. Their sensors implement dual-die redundancy architecture with independent signal paths, supporting functional safety requirements up to ASIL D classification. Bosch has pioneered the integration of Hall effect sensors with other sensing technologies (such as accelerometers) in multi-sensor modules that provide comprehensive motion and position data for advanced driver assistance systems. Their latest generation sensors incorporate machine learning algorithms that continuously adapt to changing environmental conditions, improving detection reliability in diverse operating scenarios.

Strengths: Exceptional reliability in harsh automotive environments; comprehensive functional safety features; extensive integration capabilities with vehicle systems. Weaknesses: Higher system complexity requiring specialized expertise for implementation; premium pricing compared to standard sensors; proprietary interfaces may limit interoperability with third-party systems.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed specialized Hall effect sensor solutions for next-generation transportation applications, focusing on high integration and energy efficiency. Their DRV5000 family incorporates Hall sensing elements with advanced signal conditioning circuitry and digital interfaces in compact packages suitable for space-constrained automotive applications. TI's Hall sensors feature chopper-stabilized amplifiers that minimize offset drift over temperature and time, ensuring consistent performance throughout vehicle lifetime. Their technology includes programmable threshold detection with hysteresis control, enabling precise switching points for applications like gear position detection and valve control in transportation systems. TI has also pioneered low-power Hall effect sensing solutions that consume under 1mA in active mode and feature sleep modes drawing less than 5μA, making them ideal for battery-powered transportation applications. Their sensors incorporate advanced EMC protection features, including integrated voltage regulators and filtering components that ensure reliable operation in electrically noisy vehicle environments.

Strengths: Excellent energy efficiency supporting battery-powered applications; high integration level reducing external component requirements; robust EMC performance in noisy environments. Weaknesses: More limited measurement range compared to some competitors; fewer automotive-specific safety certifications; less specialized for high-precision angle measurement applications.

Key Patents and Technical Innovations

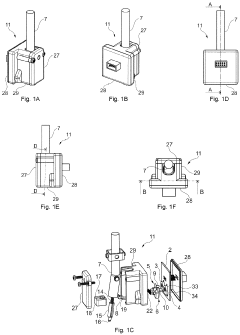

System for signal transmission to a moving object

PatentWO2007101356A8

Innovation

- A system utilizing a magnetic field generator with a Hall sensor that interacts with a moving object without contact, providing reliable and wear-free signal transmission, capable of handling complex information and interference filtering, and suitable for retrofitting existing systems.

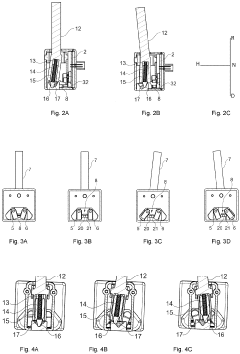

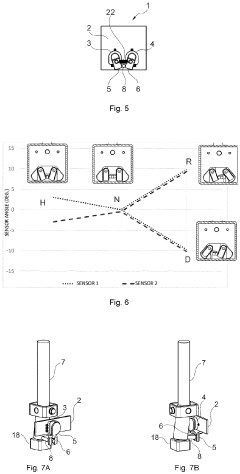

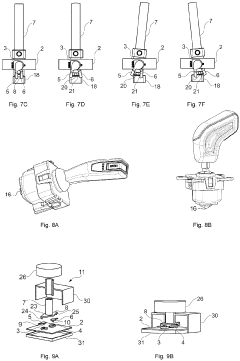

Detection systems and gearshift devices comprising such detection systems

PatentPendingEP4382777A1

Innovation

- A detection system comprising contact sensors and sensor actuators arranged on an electronics carrier plane, with an engaging element that moves to detect position changes along both degrees of freedom, utilizing potentiometers for reliable and simple position determination.

Safety and Reliability Standards

The integration of Hall Effect sensors in next-generation transportation systems necessitates adherence to rigorous safety and reliability standards. These standards are critical as they directly impact passenger safety, system integrity, and overall operational efficiency. Currently, the automotive industry follows standards such as ISO 26262 for functional safety of electrical and electronic systems, which categorizes safety integrity levels based on risk assessment. Hall Effect sensors deployed in critical vehicle systems must meet ASIL (Automotive Safety Integrity Level) requirements, particularly ASIL C or D for steering, braking, and propulsion systems.

Reliability standards for Hall Effect sensors in transportation applications typically require operational lifespans exceeding 15 years or 150,000 miles under varying environmental conditions. The AEC-Q100 qualification, specifically designed for automotive-grade integrated circuits, defines stress test qualifications for Hall Effect sensors, categorizing them into different grades based on operating temperature ranges. Grade 0 components must function reliably from -40°C to +150°C, essential for sensors positioned near high-temperature areas like engines or brake systems.

Environmental robustness certifications such as IP67 or IP68 are increasingly becoming standard requirements, ensuring sensors can withstand dust, moisture, and temporary immersion. This is particularly crucial for external vehicle applications where sensors are exposed to harsh weather conditions and road contaminants. Additionally, EMC (Electromagnetic Compatibility) standards including IEC 61000 series ensure Hall Effect sensors maintain accuracy and reliability even when subjected to electromagnetic interference from nearby electronic systems.

Vibration and shock resistance standards (ISO 16750) are equally important, as transportation environments subject sensors to continuous mechanical stress. Hall Effect sensors must demonstrate resilience to these forces without calibration drift or mechanical failure. The industry is also witnessing a shift toward more stringent MTBF (Mean Time Between Failures) requirements, with expectations now exceeding 1 million hours for critical applications.

Emerging transportation technologies like autonomous vehicles are driving the development of new standards specifically addressing redundancy and fail-safe operations. These standards require sensors to include self-diagnostic capabilities and graceful degradation modes, ensuring system safety even during component failure. Organizations including IEEE, SAE, and ISO are actively developing specialized standards for sensors in autonomous transportation systems, with particular emphasis on real-time performance monitoring and predictive maintenance protocols.

Compliance with these evolving standards represents both a challenge and opportunity for Hall Effect sensor manufacturers, as meeting higher reliability benchmarks can differentiate products in an increasingly competitive market while ensuring the safety of next-generation transportation systems.

Reliability standards for Hall Effect sensors in transportation applications typically require operational lifespans exceeding 15 years or 150,000 miles under varying environmental conditions. The AEC-Q100 qualification, specifically designed for automotive-grade integrated circuits, defines stress test qualifications for Hall Effect sensors, categorizing them into different grades based on operating temperature ranges. Grade 0 components must function reliably from -40°C to +150°C, essential for sensors positioned near high-temperature areas like engines or brake systems.

Environmental robustness certifications such as IP67 or IP68 are increasingly becoming standard requirements, ensuring sensors can withstand dust, moisture, and temporary immersion. This is particularly crucial for external vehicle applications where sensors are exposed to harsh weather conditions and road contaminants. Additionally, EMC (Electromagnetic Compatibility) standards including IEC 61000 series ensure Hall Effect sensors maintain accuracy and reliability even when subjected to electromagnetic interference from nearby electronic systems.

Vibration and shock resistance standards (ISO 16750) are equally important, as transportation environments subject sensors to continuous mechanical stress. Hall Effect sensors must demonstrate resilience to these forces without calibration drift or mechanical failure. The industry is also witnessing a shift toward more stringent MTBF (Mean Time Between Failures) requirements, with expectations now exceeding 1 million hours for critical applications.

Emerging transportation technologies like autonomous vehicles are driving the development of new standards specifically addressing redundancy and fail-safe operations. These standards require sensors to include self-diagnostic capabilities and graceful degradation modes, ensuring system safety even during component failure. Organizations including IEEE, SAE, and ISO are actively developing specialized standards for sensors in autonomous transportation systems, with particular emphasis on real-time performance monitoring and predictive maintenance protocols.

Compliance with these evolving standards represents both a challenge and opportunity for Hall Effect sensor manufacturers, as meeting higher reliability benchmarks can differentiate products in an increasingly competitive market while ensuring the safety of next-generation transportation systems.

Environmental Impact and Sustainability Considerations

The integration of Hall Effect sensors in next-generation transportation systems presents significant environmental and sustainability implications that warrant careful consideration. These sensors, while small in physical footprint, contribute to broader environmental impacts throughout their lifecycle - from raw material extraction to manufacturing, operation, and eventual disposal.

Manufacturing Hall Effect sensors requires various materials including semiconductors, rare earth elements, and metals. The extraction processes for these materials often involve energy-intensive mining operations that can lead to habitat disruption, water pollution, and carbon emissions. However, compared to alternative sensing technologies, Hall Effect sensors generally require fewer rare materials and can be manufactured using more standardized semiconductor processes, potentially reducing their environmental footprint.

During operation, Hall Effect sensors offer notable sustainability advantages. Their non-contact measurement capabilities eliminate mechanical wear, extending vehicle component lifespans and reducing maintenance waste. Additionally, their low power consumption contributes to improved energy efficiency in transportation systems, particularly in electric vehicles where power management is critical for maximizing range and battery life.

The sensors' role in enabling more precise control systems directly supports environmental goals in transportation. By facilitating more accurate motor control in electric vehicles, optimizing regenerative braking systems, and supporting advanced battery management, Hall Effect sensors help maximize energy efficiency and reduce emissions. In public transportation systems, these sensors enable smoother acceleration and deceleration profiles, further reducing energy consumption across fleets.

Looking toward end-of-life considerations, Hall Effect sensors present both challenges and opportunities. Their integration into complex electronic systems can complicate recycling efforts, but their relatively simple construction compared to other sensor types may facilitate material recovery. The semiconductor industry has been developing more sustainable manufacturing processes and recycling technologies that could benefit Hall Effect sensor lifecycle management.

From a broader sustainability perspective, Hall Effect sensors contribute to transportation electrification efforts by enabling more efficient and reliable electric drivetrains. Their role in supporting autonomous vehicle technologies may also lead to optimization of traffic flows and vehicle routing, potentially reducing overall energy consumption and emissions in transportation networks.

As transportation systems evolve, manufacturers should prioritize designing Hall Effect sensor implementations with circular economy principles in mind, considering future disassembly, component reuse, and material recovery. Industry standards for environmental performance of these sensors could drive further innovations in sustainable design and manufacturing processes.

Manufacturing Hall Effect sensors requires various materials including semiconductors, rare earth elements, and metals. The extraction processes for these materials often involve energy-intensive mining operations that can lead to habitat disruption, water pollution, and carbon emissions. However, compared to alternative sensing technologies, Hall Effect sensors generally require fewer rare materials and can be manufactured using more standardized semiconductor processes, potentially reducing their environmental footprint.

During operation, Hall Effect sensors offer notable sustainability advantages. Their non-contact measurement capabilities eliminate mechanical wear, extending vehicle component lifespans and reducing maintenance waste. Additionally, their low power consumption contributes to improved energy efficiency in transportation systems, particularly in electric vehicles where power management is critical for maximizing range and battery life.

The sensors' role in enabling more precise control systems directly supports environmental goals in transportation. By facilitating more accurate motor control in electric vehicles, optimizing regenerative braking systems, and supporting advanced battery management, Hall Effect sensors help maximize energy efficiency and reduce emissions. In public transportation systems, these sensors enable smoother acceleration and deceleration profiles, further reducing energy consumption across fleets.

Looking toward end-of-life considerations, Hall Effect sensors present both challenges and opportunities. Their integration into complex electronic systems can complicate recycling efforts, but their relatively simple construction compared to other sensor types may facilitate material recovery. The semiconductor industry has been developing more sustainable manufacturing processes and recycling technologies that could benefit Hall Effect sensor lifecycle management.

From a broader sustainability perspective, Hall Effect sensors contribute to transportation electrification efforts by enabling more efficient and reliable electric drivetrains. Their role in supporting autonomous vehicle technologies may also lead to optimization of traffic flows and vehicle routing, potentially reducing overall energy consumption and emissions in transportation networks.

As transportation systems evolve, manufacturers should prioritize designing Hall Effect sensor implementations with circular economy principles in mind, considering future disassembly, component reuse, and material recovery. Industry standards for environmental performance of these sensors could drive further innovations in sustainable design and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!