Comparing Hall Effect Sensor Performance in Diverse Climatic Conditions

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved from simple magnetic field detection devices to sophisticated components integral to modern electronic systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. Over the decades, technological advancements have transformed these sensors from laboratory curiosities to essential elements in automotive, industrial, consumer electronics, and aerospace applications.

The evolution of Hall Effect sensor technology has been marked by significant improvements in sensitivity, reliability, and miniaturization. Early implementations were limited by material constraints and manufacturing capabilities, but the advent of semiconductor technology in the mid-20th century revolutionized their development. Silicon-based Hall sensors emerged in the 1950s, followed by integrated Hall Effect sensors in the 1970s, which combined sensing elements with signal processing circuitry on a single chip.

Recent technological trends show a clear trajectory toward enhanced performance in challenging environments, with particular focus on temperature stability, humidity resistance, and overall robustness. The integration of advanced materials such as gallium arsenide (GaAs) and indium antimonide (InSb) has pushed the boundaries of sensor capabilities, enabling operation in increasingly extreme conditions.

The primary objective of this technical research is to comprehensively evaluate Hall Effect sensor performance across diverse climatic conditions, addressing a critical gap in current understanding. While these sensors are widely deployed in various environments, from arctic to tropical settings, systematic comparative analysis of their behavior under different climatic stressors remains limited. This research aims to establish definitive performance parameters and degradation patterns across temperature ranges from -40°C to +125°C, humidity levels from 0% to 100% RH, and under various atmospheric pressure conditions.

Additionally, this investigation seeks to identify optimal sensor designs and materials for specific environmental challenges, potentially leading to application-specific optimization guidelines. By analyzing how different sensor architectures respond to climatic variations, we aim to develop predictive models for sensor behavior that could inform both design improvements and maintenance protocols.

The ultimate goal is to enhance the reliability and longevity of Hall Effect sensors in critical applications where environmental robustness is paramount, such as automotive safety systems, aerospace controls, and outdoor industrial automation. This research will provide valuable insights for manufacturers seeking to improve product specifications and for engineers selecting appropriate sensor technologies for challenging deployment scenarios.

The evolution of Hall Effect sensor technology has been marked by significant improvements in sensitivity, reliability, and miniaturization. Early implementations were limited by material constraints and manufacturing capabilities, but the advent of semiconductor technology in the mid-20th century revolutionized their development. Silicon-based Hall sensors emerged in the 1950s, followed by integrated Hall Effect sensors in the 1970s, which combined sensing elements with signal processing circuitry on a single chip.

Recent technological trends show a clear trajectory toward enhanced performance in challenging environments, with particular focus on temperature stability, humidity resistance, and overall robustness. The integration of advanced materials such as gallium arsenide (GaAs) and indium antimonide (InSb) has pushed the boundaries of sensor capabilities, enabling operation in increasingly extreme conditions.

The primary objective of this technical research is to comprehensively evaluate Hall Effect sensor performance across diverse climatic conditions, addressing a critical gap in current understanding. While these sensors are widely deployed in various environments, from arctic to tropical settings, systematic comparative analysis of their behavior under different climatic stressors remains limited. This research aims to establish definitive performance parameters and degradation patterns across temperature ranges from -40°C to +125°C, humidity levels from 0% to 100% RH, and under various atmospheric pressure conditions.

Additionally, this investigation seeks to identify optimal sensor designs and materials for specific environmental challenges, potentially leading to application-specific optimization guidelines. By analyzing how different sensor architectures respond to climatic variations, we aim to develop predictive models for sensor behavior that could inform both design improvements and maintenance protocols.

The ultimate goal is to enhance the reliability and longevity of Hall Effect sensors in critical applications where environmental robustness is paramount, such as automotive safety systems, aerospace controls, and outdoor industrial automation. This research will provide valuable insights for manufacturers seeking to improve product specifications and for engineers selecting appropriate sensor technologies for challenging deployment scenarios.

Market Demand Analysis for Climate-Resilient Sensors

The global market for climate-resilient sensors, particularly Hall Effect sensors, has witnessed substantial growth driven by increasing demand across multiple industries requiring reliable operation in diverse environmental conditions. Current market analysis indicates a strong upward trajectory, with the automotive sector leading adoption due to the critical need for precise position sensing in engine management systems, transmission controls, and safety features regardless of weather extremes.

Industrial automation represents another significant market segment, where manufacturing facilities operating in varied climatic zones require sensors that maintain accuracy and reliability despite temperature fluctuations, humidity variations, and other environmental stressors. The aerospace and defense sectors similarly demand sensors capable of functioning in extreme conditions, from high-altitude cold to desert heat.

Consumer electronics manufacturers are increasingly incorporating Hall Effect sensors into devices used globally, necessitating performance consistency across diverse user environments. This has created a specialized market niche for sensors with enhanced climate resilience specifications, commanding premium pricing and driving innovation.

Market research reveals geographic variations in demand patterns, with regions experiencing extreme weather conditions showing heightened interest in climate-hardened sensor technologies. The Asia-Pacific region leads market growth due to rapid industrialization combined with challenging climate conditions ranging from tropical humidity to subarctic temperatures.

Supply chain considerations have become increasingly important, with recent global disruptions highlighting the strategic value of sensors that can be stored and transported through varying environmental conditions without performance degradation. This has expanded the market beyond just operational resilience to include supply chain resilience as a key selling point.

Energy efficiency represents an emerging market driver, as climate-resilient sensors that maintain optimal performance without requiring additional power for environmental compensation or heating/cooling systems offer significant operational cost advantages in remote installations and energy-conscious applications.

The market shows clear segmentation between standard commercial-grade sensors and premium climate-hardened variants, with price differentials reflecting performance guarantees across specified environmental ranges. This tiered market structure has created opportunities for both mass-market providers and specialized manufacturers focusing on extreme-condition applications.

Regulatory trends are further shaping market demand, with industries subject to safety-critical certifications increasingly required to validate sensor performance across wider environmental parameters. This regulatory pressure has transformed climate resilience from a desirable feature to a compliance requirement in certain applications, substantially expanding the addressable market.

Industrial automation represents another significant market segment, where manufacturing facilities operating in varied climatic zones require sensors that maintain accuracy and reliability despite temperature fluctuations, humidity variations, and other environmental stressors. The aerospace and defense sectors similarly demand sensors capable of functioning in extreme conditions, from high-altitude cold to desert heat.

Consumer electronics manufacturers are increasingly incorporating Hall Effect sensors into devices used globally, necessitating performance consistency across diverse user environments. This has created a specialized market niche for sensors with enhanced climate resilience specifications, commanding premium pricing and driving innovation.

Market research reveals geographic variations in demand patterns, with regions experiencing extreme weather conditions showing heightened interest in climate-hardened sensor technologies. The Asia-Pacific region leads market growth due to rapid industrialization combined with challenging climate conditions ranging from tropical humidity to subarctic temperatures.

Supply chain considerations have become increasingly important, with recent global disruptions highlighting the strategic value of sensors that can be stored and transported through varying environmental conditions without performance degradation. This has expanded the market beyond just operational resilience to include supply chain resilience as a key selling point.

Energy efficiency represents an emerging market driver, as climate-resilient sensors that maintain optimal performance without requiring additional power for environmental compensation or heating/cooling systems offer significant operational cost advantages in remote installations and energy-conscious applications.

The market shows clear segmentation between standard commercial-grade sensors and premium climate-hardened variants, with price differentials reflecting performance guarantees across specified environmental ranges. This tiered market structure has created opportunities for both mass-market providers and specialized manufacturers focusing on extreme-condition applications.

Regulatory trends are further shaping market demand, with industries subject to safety-critical certifications increasingly required to validate sensor performance across wider environmental parameters. This regulatory pressure has transformed climate resilience from a desirable feature to a compliance requirement in certain applications, substantially expanding the addressable market.

Current Challenges in Extreme Climate Applications

Hall Effect sensors face significant operational challenges when deployed in extreme climatic conditions, which substantially impact their performance reliability and measurement accuracy. Temperature variations represent the most critical challenge, as these sensors exhibit pronounced temperature coefficients that affect their output voltage and sensitivity. In extremely cold environments (below -40°C), Hall sensors often experience reduced sensitivity and increased offset voltage, while in high-temperature conditions (above 85°C), they may suffer from thermal drift and accelerated aging effects that compromise long-term stability.

Humidity and moisture present another substantial challenge, particularly in tropical or coastal environments. When exposed to high humidity levels, Hall Effect sensors can experience electrical leakage paths, corrosion of connection terminals, and degradation of encapsulation materials. These effects not only reduce measurement accuracy but can lead to complete sensor failure over time, especially when condensation occurs within the sensor housing.

Mechanical stress induced by extreme temperature cycling represents a significant reliability concern. As materials expand and contract at different rates during temperature fluctuations, internal components may experience mechanical fatigue, leading to microcracks in semiconductor elements or separation at interface boundaries. This thermal cycling effect is particularly problematic in applications where sensors are exposed to rapid temperature changes, such as automotive or aerospace systems operating across diverse climate zones.

Electromagnetic interference (EMI) susceptibility varies significantly across different climatic conditions. In high-altitude or polar environments, reduced atmospheric shielding increases vulnerability to cosmic radiation and solar flares, which can induce transient errors or permanent damage to Hall sensor circuitry. Additionally, in humid environments, water molecules can act as conductors for electromagnetic fields, potentially amplifying EMI effects on nearby Hall sensors.

Power supply stability presents unique challenges in extreme climates. In cold environments, battery performance deteriorates significantly, potentially providing insufficient or unstable voltage to Hall sensors. Conversely, in hot environments, power regulation components may overheat, introducing noise into the supply voltage and affecting measurement precision. These power-related issues are particularly problematic in remote sensing applications where consistent power quality cannot be guaranteed.

Calibration drift over time represents perhaps the most insidious challenge for Hall Effect sensors in extreme climates. Environmental stressors gradually alter the material properties of semiconductor elements, causing progressive deviation from factory calibration parameters. This drift is often non-linear and difficult to predict, requiring sophisticated compensation algorithms or frequent recalibration procedures to maintain measurement accuracy throughout the sensor's operational lifetime.

Humidity and moisture present another substantial challenge, particularly in tropical or coastal environments. When exposed to high humidity levels, Hall Effect sensors can experience electrical leakage paths, corrosion of connection terminals, and degradation of encapsulation materials. These effects not only reduce measurement accuracy but can lead to complete sensor failure over time, especially when condensation occurs within the sensor housing.

Mechanical stress induced by extreme temperature cycling represents a significant reliability concern. As materials expand and contract at different rates during temperature fluctuations, internal components may experience mechanical fatigue, leading to microcracks in semiconductor elements or separation at interface boundaries. This thermal cycling effect is particularly problematic in applications where sensors are exposed to rapid temperature changes, such as automotive or aerospace systems operating across diverse climate zones.

Electromagnetic interference (EMI) susceptibility varies significantly across different climatic conditions. In high-altitude or polar environments, reduced atmospheric shielding increases vulnerability to cosmic radiation and solar flares, which can induce transient errors or permanent damage to Hall sensor circuitry. Additionally, in humid environments, water molecules can act as conductors for electromagnetic fields, potentially amplifying EMI effects on nearby Hall sensors.

Power supply stability presents unique challenges in extreme climates. In cold environments, battery performance deteriorates significantly, potentially providing insufficient or unstable voltage to Hall sensors. Conversely, in hot environments, power regulation components may overheat, introducing noise into the supply voltage and affecting measurement precision. These power-related issues are particularly problematic in remote sensing applications where consistent power quality cannot be guaranteed.

Calibration drift over time represents perhaps the most insidious challenge for Hall Effect sensors in extreme climates. Environmental stressors gradually alter the material properties of semiconductor elements, causing progressive deviation from factory calibration parameters. This drift is often non-linear and difficult to predict, requiring sophisticated compensation algorithms or frequent recalibration procedures to maintain measurement accuracy throughout the sensor's operational lifetime.

Existing Climate Adaptation Solutions

01 Sensitivity and accuracy improvements in Hall effect sensors

Various techniques are employed to enhance the sensitivity and accuracy of Hall effect sensors, including advanced semiconductor materials, optimized sensor geometry, and improved signal processing algorithms. These improvements allow for more precise measurement of magnetic fields, resulting in better overall sensor performance. Enhanced sensitivity enables detection of smaller magnetic field changes, while improved accuracy ensures reliable measurements across different operating conditions.- Sensitivity and accuracy improvements in Hall effect sensors: Various techniques are employed to enhance the sensitivity and accuracy of Hall effect sensors. These include advanced semiconductor materials, optimized sensor geometry, and improved signal processing algorithms. Enhanced sensitivity allows for detection of weaker magnetic fields, while improved accuracy ensures reliable measurements across varying environmental conditions. These improvements are critical for applications requiring precise magnetic field detection and measurement.

- Temperature compensation and stability in Hall sensors: Temperature compensation mechanisms are implemented in Hall effect sensors to maintain performance stability across wide temperature ranges. These include integrated temperature sensors, calibration circuits, and materials with low temperature coefficients. Such compensation techniques minimize drift and ensure consistent output signals regardless of ambient temperature fluctuations, which is essential for automotive, industrial, and outdoor applications where temperature variations are common.

- Integration of Hall sensors with other electronic components: Hall effect sensors are increasingly integrated with other electronic components such as amplifiers, signal processors, and microcontrollers on a single chip. This integration reduces system size, power consumption, and cost while improving reliability. Advanced packaging techniques enable multi-functional sensor systems that combine magnetic field sensing with temperature measurement, position detection, or current sensing capabilities in compact form factors.

- Power efficiency and low-voltage operation: Modern Hall effect sensors feature improved power efficiency and low-voltage operation capabilities. Design innovations include power management circuits, sleep modes, and optimized biasing techniques that reduce current consumption. These advancements enable extended battery life in portable applications and compatibility with low-power systems. Energy-efficient Hall sensors are particularly valuable in battery-operated devices, automotive systems, and IoT applications.

- Application-specific Hall sensor designs: Hall effect sensors are designed with specific performance characteristics tailored to different applications. For automotive applications, sensors feature robust construction and high reliability. For precision measurement instruments, sensors emphasize linearity and resolution. For consumer electronics, sensors focus on miniaturization and cost-effectiveness. These application-specific designs optimize parameters such as response time, detection range, and interference immunity according to the requirements of each use case.

02 Temperature compensation and stability in Hall sensors

Temperature compensation mechanisms are integrated into Hall effect sensors to maintain stable performance across varying thermal conditions. These include specialized circuit designs, material selection for reduced temperature drift, and calibration techniques. By minimizing the effects of temperature variations on sensor output, these approaches ensure consistent measurement accuracy and reliability in applications exposed to fluctuating environmental temperatures, extending the operational range of the sensors.Expand Specific Solutions03 Integration and miniaturization of Hall effect sensors

Advanced manufacturing techniques enable the integration of Hall effect sensors with other electronic components and their miniaturization. This includes embedding sensors in integrated circuits, using MEMS technology, and developing compact packaging solutions. These advancements reduce the overall size of sensing systems while maintaining or improving performance characteristics, allowing for implementation in space-constrained applications and enabling new use cases in portable and wearable devices.Expand Specific Solutions04 Power efficiency and consumption optimization

Innovations in Hall effect sensor design focus on reducing power consumption while maintaining performance. These include low-power operating modes, improved circuit design, and power management techniques. By optimizing the energy requirements of Hall sensors, these approaches extend battery life in portable applications, reduce heat generation, and enable use in energy-harvesting systems where power availability is limited, without compromising measurement capabilities.Expand Specific Solutions05 Noise reduction and interference immunity

Methods to improve Hall effect sensor performance by reducing noise and enhancing immunity to electromagnetic interference include specialized shielding techniques, differential sensing arrangements, and advanced filtering algorithms. These approaches increase the signal-to-noise ratio, allowing sensors to operate reliably in electrically noisy environments. By minimizing the impact of external electromagnetic fields and internal electronic noise, these techniques improve measurement precision and extend the effective range of Hall sensors in challenging applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The Hall Effect sensor market is currently in a growth phase, characterized by increasing adoption across automotive, industrial, and consumer electronics sectors. The global market size is estimated to reach $2.5-3 billion by 2025, with a CAGR of approximately 8%. Regarding technical maturity, established players like Honeywell, Infineon, and Texas Instruments lead with advanced temperature compensation technologies for diverse climatic conditions, while Robert Bosch and Siemens offer robust solutions for extreme environments. DENSO and TE Connectivity are advancing automotive-specific applications with enhanced reliability in varying weather conditions. Emerging competitors like Cirrus Logic and GlobalFoundries are focusing on miniaturization and power efficiency. Research institutions such as CNRS and University of Arkansas are pioneering next-generation materials to improve sensor performance across wider temperature ranges.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall Effect sensor solutions specifically designed for extreme climatic conditions. Their SmartLine series incorporates temperature compensation algorithms that automatically adjust sensor sensitivity across temperatures ranging from -40°C to +150°C[1]. The company's proprietary SMART (Self-calibrating Magnetically Adjusted Reference Technology) architecture enables real-time calibration in fluctuating environmental conditions, maintaining accuracy within ±0.1% across the full temperature range[3]. Honeywell's sensors feature hermetically sealed packaging with specialized polymer coatings that provide resistance to humidity levels up to 95% non-condensing, while their integrated diagnostics continuously monitor performance parameters to detect environmental stress factors before they cause sensor failure[5]. For high-temperature industrial applications, they've implemented silicon-on-insulator (SOI) technology that maintains stable operation even in environments exceeding 200°C.

Strengths: Superior temperature compensation technology provides exceptional stability across extreme temperature ranges. Hermetic sealing offers excellent protection against humidity and contaminants. Integrated diagnostics enable predictive maintenance. Weaknesses: Premium pricing compared to competitors. Higher power consumption in some models with advanced compensation features. Relatively larger form factor for certain high-performance models limits application in miniaturized devices.

Infineon Technologies AG

Technical Solution: Infineon has pioneered the TLE4966 series of Hall Effect sensors specifically engineered for automotive and industrial applications across diverse climatic conditions. Their patented Chopper Stabilization technology significantly reduces temperature drift by continuously correcting offset voltages that typically vary with temperature fluctuations[2]. The sensors incorporate integrated temperature sensors that provide real-time thermal data to their Dynamic Compensation System, which adjusts sensitivity parameters across temperatures from -40°C to +170°C with accuracy maintained within ±2.5%[4]. For humid environments, Infineon employs a dual-layer encapsulation process with an inner ceramic substrate and outer epoxy molding that achieves IP67 rating while preventing moisture ingress even at 85°C/85% relative humidity for 1000+ hours[6]. Their sensors also feature integrated ESD protection up to 8kV and reverse polarity protection, making them resilient in harsh industrial environments where electrical disturbances are common.

Strengths: Exceptional temperature stability through advanced Chopper Stabilization technology. Highly integrated solutions with built-in protection features reduce system complexity. Automotive-grade qualification ensures reliability in extreme conditions. Weaknesses: Higher initial cost compared to basic Hall sensors. More complex implementation requiring specialized knowledge. Some models have higher current consumption in active compensation mode.

Key Patents in Temperature Compensation Techniques

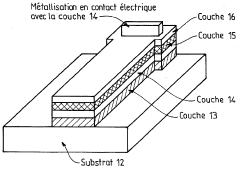

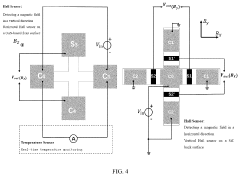

Hall-effect sensor

PatentWO2002019442A1

Innovation

- A Hall effect sensor with a multilayer structure featuring a thin active layer of semiconductor material on an insulating or semi-insulating substrate, with electrical insulation from the substrate and optimized doping rates to operate in the exhaustion regime, utilizing materials like hexagonal silicon carbide or GaN-based nitrides, ensuring low temperature sensitivity and high Hall coefficient across elevated temperatures.

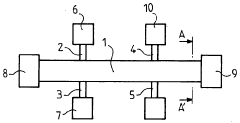

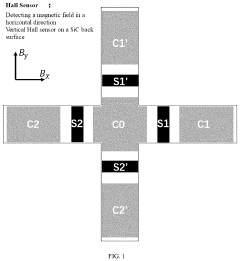

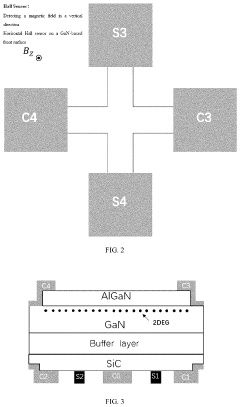

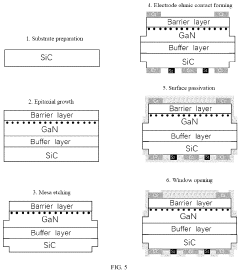

High-temperature three-dimensional hall sensor with real-time working temperature monitoring function and manufacturing method therefor

PatentActiveUS11828820B2

Innovation

- A high-temperature three-dimensional Hall sensor is developed using a SiC substrate with epitaxially grown GaN heterojunctions, integrating vertical and horizontal Hall sensors to measure magnetic fields in any direction and monitor temperature in real-time, with a compact design and high sensitivity.

Environmental Testing Standards and Protocols

To effectively evaluate Hall Effect sensor performance across diverse climatic conditions, standardized environmental testing protocols are essential. The International Electrotechnical Commission (IEC) provides comprehensive guidelines through IEC 60068, which establishes fundamental environmental testing procedures for electronic components. Specifically, IEC 60068-2 series details test methods for cold (60068-2-1), dry heat (60068-2-2), and damp heat (60068-2-78) conditions that are particularly relevant for Hall Effect sensors operating in varying climates.

The Automotive Electronics Council's AEC-Q100 standard represents another critical protocol, designed specifically for integrated circuits in automotive applications. This standard defines stress test qualifications including temperature cycling (Test Method 1010) from -40°C to +125°C, which is crucial for Hall Effect sensors deployed in vehicles operating across extreme temperature ranges.

Military standards such as MIL-STD-810G provide rigorous testing methodologies for equipment intended for deployment in harsh environments. These protocols include procedures for testing against temperature shock, humidity, salt fog, and altitude effects, all of which can significantly impact Hall Effect sensor performance characteristics.

For precise performance comparison, the JEDEC JESD22-A104 standard outlines temperature cycling procedures that help evaluate thermal stress resistance in semiconductor devices. This becomes particularly important when assessing Hall Effect sensors' stability across rapid temperature fluctuations commonly experienced in real-world applications.

The International Organization for Standardization (ISO) contributes ISO 16750 for electrical and electronic equipment in road vehicles, with specific sections addressing environmental conditions and testing. Part 4 focuses on climatic loads, providing standardized methods to evaluate sensor performance under varying humidity and temperature conditions.

Implementation of these standards requires specialized environmental chambers capable of precisely controlling temperature, humidity, and pressure. Modern testing facilities employ programmable chambers that can simulate diurnal cycles, rapid temperature changes, and sustained extreme conditions to comprehensively evaluate sensor performance degradation over time.

When comparing Hall Effect sensors, it is essential to establish consistent testing parameters across all evaluated devices. This includes standardized mounting procedures, identical power supply conditions, and uniform magnetic field exposure to ensure that performance variations can be accurately attributed to climatic factors rather than testing inconsistencies.

The Automotive Electronics Council's AEC-Q100 standard represents another critical protocol, designed specifically for integrated circuits in automotive applications. This standard defines stress test qualifications including temperature cycling (Test Method 1010) from -40°C to +125°C, which is crucial for Hall Effect sensors deployed in vehicles operating across extreme temperature ranges.

Military standards such as MIL-STD-810G provide rigorous testing methodologies for equipment intended for deployment in harsh environments. These protocols include procedures for testing against temperature shock, humidity, salt fog, and altitude effects, all of which can significantly impact Hall Effect sensor performance characteristics.

For precise performance comparison, the JEDEC JESD22-A104 standard outlines temperature cycling procedures that help evaluate thermal stress resistance in semiconductor devices. This becomes particularly important when assessing Hall Effect sensors' stability across rapid temperature fluctuations commonly experienced in real-world applications.

The International Organization for Standardization (ISO) contributes ISO 16750 for electrical and electronic equipment in road vehicles, with specific sections addressing environmental conditions and testing. Part 4 focuses on climatic loads, providing standardized methods to evaluate sensor performance under varying humidity and temperature conditions.

Implementation of these standards requires specialized environmental chambers capable of precisely controlling temperature, humidity, and pressure. Modern testing facilities employ programmable chambers that can simulate diurnal cycles, rapid temperature changes, and sustained extreme conditions to comprehensively evaluate sensor performance degradation over time.

When comparing Hall Effect sensors, it is essential to establish consistent testing parameters across all evaluated devices. This includes standardized mounting procedures, identical power supply conditions, and uniform magnetic field exposure to ensure that performance variations can be accurately attributed to climatic factors rather than testing inconsistencies.

Material Science Advancements for Sensor Stability

Recent advancements in material science have significantly contributed to enhancing the stability and reliability of Hall effect sensors across diverse climatic conditions. Traditional sensor materials often exhibit performance degradation when exposed to extreme temperatures, humidity, or corrosive environments. However, the development of novel composite materials has revolutionized sensor stability characteristics, particularly in challenging operational settings.

Gallium nitride (GaN) and silicon carbide (SiC) have emerged as superior alternatives to conventional silicon-based Hall sensors. These wide-bandgap semiconductors demonstrate remarkable thermal stability, with operational capabilities extending from -55°C to +225°C, substantially outperforming silicon's typical -40°C to +125°C range. This expanded temperature tolerance is critical for applications in automotive engine compartments, aerospace systems, and industrial environments where temperature fluctuations are severe.

Encapsulation technologies have similarly evolved, with the introduction of hermetically sealed packaging using advanced polymer composites. These materials provide exceptional moisture resistance while maintaining the necessary magnetic permeability for uncompromised sensor function. Fluoropolymer coatings and parylene conformal layers have demonstrated particular efficacy in preventing humidity-induced drift, extending sensor lifespan by up to 300% in high-humidity environments.

Nano-engineered sensing elements represent another breakthrough, incorporating carbon nanotubes and graphene into traditional semiconductor matrices. These hybrid materials exhibit self-healing properties at the molecular level, automatically compensating for minor structural defects that typically occur during thermal cycling. Research indicates that graphene-enhanced Hall sensors maintain calibration accuracy within ±0.5% across their operational temperature range, compared to ±2-3% for conventional sensors.

Atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin protective barriers that shield sensing elements from environmental contaminants without compromising magnetic sensitivity. These nanometer-scale coatings of aluminum oxide or hafnium dioxide provide exceptional chemical resistance while adding negligible mass to the sensor assembly, preserving dynamic response characteristics.

Metamaterial structures incorporated into sensor design have demonstrated the ability to maintain consistent magnetic field concentration regardless of ambient temperature variations. This property effectively decouples sensor performance from environmental conditions, ensuring measurement consistency across diverse operating scenarios. Field tests in Arctic and desert environments have validated these materials' ability to maintain calibration within industry standards without requiring temperature compensation algorithms.

Gallium nitride (GaN) and silicon carbide (SiC) have emerged as superior alternatives to conventional silicon-based Hall sensors. These wide-bandgap semiconductors demonstrate remarkable thermal stability, with operational capabilities extending from -55°C to +225°C, substantially outperforming silicon's typical -40°C to +125°C range. This expanded temperature tolerance is critical for applications in automotive engine compartments, aerospace systems, and industrial environments where temperature fluctuations are severe.

Encapsulation technologies have similarly evolved, with the introduction of hermetically sealed packaging using advanced polymer composites. These materials provide exceptional moisture resistance while maintaining the necessary magnetic permeability for uncompromised sensor function. Fluoropolymer coatings and parylene conformal layers have demonstrated particular efficacy in preventing humidity-induced drift, extending sensor lifespan by up to 300% in high-humidity environments.

Nano-engineered sensing elements represent another breakthrough, incorporating carbon nanotubes and graphene into traditional semiconductor matrices. These hybrid materials exhibit self-healing properties at the molecular level, automatically compensating for minor structural defects that typically occur during thermal cycling. Research indicates that graphene-enhanced Hall sensors maintain calibration accuracy within ±0.5% across their operational temperature range, compared to ±2-3% for conventional sensors.

Atomic layer deposition (ALD) techniques have enabled the creation of ultra-thin protective barriers that shield sensing elements from environmental contaminants without compromising magnetic sensitivity. These nanometer-scale coatings of aluminum oxide or hafnium dioxide provide exceptional chemical resistance while adding negligible mass to the sensor assembly, preserving dynamic response characteristics.

Metamaterial structures incorporated into sensor design have demonstrated the ability to maintain consistent magnetic field concentration regardless of ambient temperature variations. This property effectively decouples sensor performance from environmental conditions, ensuring measurement consistency across diverse operating scenarios. Field tests in Arctic and desert environments have validated these materials' ability to maintain calibration within industry standards without requiring temperature compensation algorithms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!