How to Optimize Sensor Data Fusion Using Hall Effect Sensors

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly from their initial application in magnetic field measurement to become integral components in modern sensing systems. These sensors operate on the principle of the Hall Effect, where a voltage difference is generated perpendicular to both the current flow and magnetic field when a conductor carrying current is placed in a magnetic field. This fundamental principle has enabled the development of robust, non-contact sensing solutions across various industries.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations were primarily focused on simple magnetic field detection, but technological progress has led to the integration of signal conditioning circuits, temperature compensation mechanisms, and digital interfaces directly into sensor packages. Modern Hall Effect sensors now offer enhanced sensitivity, improved linearity, reduced power consumption, and miniaturized form factors, making them suitable for increasingly demanding applications.

Current market trends indicate a growing demand for high-precision sensing solutions in automotive systems, industrial automation, consumer electronics, and IoT devices. Hall Effect sensors have become particularly valuable in these sectors due to their reliability, durability, and ability to operate in harsh environments. The automotive industry, for instance, utilizes these sensors for position detection in throttle control, gear selection, and steering angle measurement, where accurate data is critical for vehicle safety and performance.

The primary objective of optimizing sensor data fusion using Hall Effect sensors is to enhance the accuracy, reliability, and efficiency of multi-sensor systems. By effectively combining data from multiple Hall Effect sensors with other sensing modalities, it becomes possible to overcome individual sensor limitations and achieve more comprehensive environmental perception. This optimization aims to reduce measurement uncertainties, minimize noise effects, and improve system robustness against environmental variations.

Technical goals for Hall Effect sensor data fusion include developing advanced algorithms capable of real-time data integration, implementing efficient filtering techniques to eliminate noise and outliers, and creating adaptive calibration methods that account for sensor drift and environmental changes. Additionally, there is a focus on reducing computational complexity to enable implementation on resource-constrained embedded systems while maintaining high performance levels.

Looking forward, the trajectory of Hall Effect sensor technology points toward further miniaturization, increased integration with MEMS devices, and the incorporation of machine learning techniques for intelligent sensor fusion. These developments are expected to expand the application scope of Hall Effect sensors and enhance their role in emerging technologies such as autonomous vehicles, advanced robotics, and smart infrastructure systems.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations were primarily focused on simple magnetic field detection, but technological progress has led to the integration of signal conditioning circuits, temperature compensation mechanisms, and digital interfaces directly into sensor packages. Modern Hall Effect sensors now offer enhanced sensitivity, improved linearity, reduced power consumption, and miniaturized form factors, making them suitable for increasingly demanding applications.

Current market trends indicate a growing demand for high-precision sensing solutions in automotive systems, industrial automation, consumer electronics, and IoT devices. Hall Effect sensors have become particularly valuable in these sectors due to their reliability, durability, and ability to operate in harsh environments. The automotive industry, for instance, utilizes these sensors for position detection in throttle control, gear selection, and steering angle measurement, where accurate data is critical for vehicle safety and performance.

The primary objective of optimizing sensor data fusion using Hall Effect sensors is to enhance the accuracy, reliability, and efficiency of multi-sensor systems. By effectively combining data from multiple Hall Effect sensors with other sensing modalities, it becomes possible to overcome individual sensor limitations and achieve more comprehensive environmental perception. This optimization aims to reduce measurement uncertainties, minimize noise effects, and improve system robustness against environmental variations.

Technical goals for Hall Effect sensor data fusion include developing advanced algorithms capable of real-time data integration, implementing efficient filtering techniques to eliminate noise and outliers, and creating adaptive calibration methods that account for sensor drift and environmental changes. Additionally, there is a focus on reducing computational complexity to enable implementation on resource-constrained embedded systems while maintaining high performance levels.

Looking forward, the trajectory of Hall Effect sensor technology points toward further miniaturization, increased integration with MEMS devices, and the incorporation of machine learning techniques for intelligent sensor fusion. These developments are expected to expand the application scope of Hall Effect sensors and enhance their role in emerging technologies such as autonomous vehicles, advanced robotics, and smart infrastructure systems.

Market Applications and Demand Analysis for Sensor Fusion

The sensor fusion market is experiencing robust growth driven by increasing demand for high-precision sensing technologies across multiple industries. The global sensor fusion market was valued at approximately $3.67 billion in 2020 and is projected to reach $8.95 billion by 2026, growing at a CAGR of 16.2% during the forecast period. This growth is primarily fueled by the expanding applications of sensor fusion technologies in automotive safety systems, consumer electronics, industrial automation, and healthcare devices.

In the automotive sector, sensor fusion incorporating Hall effect sensors has become critical for advanced driver assistance systems (ADAS) and autonomous driving technologies. The automotive sensor fusion market alone is expected to grow at a CAGR of 19.8% through 2027, with Hall effect sensor integration playing a pivotal role in wheel speed detection, steering angle measurement, and position sensing applications. Major automotive manufacturers are increasingly adopting these technologies to enhance vehicle safety and performance.

Consumer electronics represents another significant market for sensor fusion technologies. The integration of Hall effect sensors with other sensing modalities has enabled more accurate motion detection, orientation sensing, and proximity detection in smartphones, wearables, and gaming devices. Market analysis indicates that approximately 2.5 billion consumer electronic devices incorporating sensor fusion technologies were shipped in 2021, with this number expected to double by 2025.

Industrial automation applications are driving substantial demand for sensor fusion solutions that incorporate Hall effect sensors. These technologies enable precise position control, speed monitoring, and current sensing in manufacturing equipment. The industrial sensor fusion market segment is growing at 14.7% annually, with particularly strong adoption in robotics and smart factory implementations.

Healthcare and medical devices represent an emerging but rapidly growing application area for sensor fusion technologies. Hall effect sensors combined with other sensing modalities are being utilized in medical imaging equipment, surgical robots, and wearable health monitoring devices. This segment is projected to grow at over 20% annually through 2026.

Regionally, North America currently leads the sensor fusion market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing industrial automation and consumer electronics manufacturing in countries like China, Japan, and South Korea.

Key market challenges include the need for miniaturization, power efficiency improvements, and cost reduction to enable wider adoption across price-sensitive applications. Additionally, there is growing demand for sensor fusion solutions that can operate reliably in harsh environmental conditions, particularly for automotive and industrial applications.

In the automotive sector, sensor fusion incorporating Hall effect sensors has become critical for advanced driver assistance systems (ADAS) and autonomous driving technologies. The automotive sensor fusion market alone is expected to grow at a CAGR of 19.8% through 2027, with Hall effect sensor integration playing a pivotal role in wheel speed detection, steering angle measurement, and position sensing applications. Major automotive manufacturers are increasingly adopting these technologies to enhance vehicle safety and performance.

Consumer electronics represents another significant market for sensor fusion technologies. The integration of Hall effect sensors with other sensing modalities has enabled more accurate motion detection, orientation sensing, and proximity detection in smartphones, wearables, and gaming devices. Market analysis indicates that approximately 2.5 billion consumer electronic devices incorporating sensor fusion technologies were shipped in 2021, with this number expected to double by 2025.

Industrial automation applications are driving substantial demand for sensor fusion solutions that incorporate Hall effect sensors. These technologies enable precise position control, speed monitoring, and current sensing in manufacturing equipment. The industrial sensor fusion market segment is growing at 14.7% annually, with particularly strong adoption in robotics and smart factory implementations.

Healthcare and medical devices represent an emerging but rapidly growing application area for sensor fusion technologies. Hall effect sensors combined with other sensing modalities are being utilized in medical imaging equipment, surgical robots, and wearable health monitoring devices. This segment is projected to grow at over 20% annually through 2026.

Regionally, North America currently leads the sensor fusion market with approximately 35% market share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing industrial automation and consumer electronics manufacturing in countries like China, Japan, and South Korea.

Key market challenges include the need for miniaturization, power efficiency improvements, and cost reduction to enable wider adoption across price-sensitive applications. Additionally, there is growing demand for sensor fusion solutions that can operate reliably in harsh environmental conditions, particularly for automotive and industrial applications.

Current Challenges in Hall Effect Sensor Data Fusion

Despite significant advancements in Hall effect sensor technology, data fusion implementations face several persistent challenges that impede optimal performance in complex sensing environments. Signal noise remains a primary obstacle, with Hall sensors being particularly susceptible to electromagnetic interference (EMI) from nearby electronic components, power lines, and wireless communications. This noise can significantly degrade measurement accuracy, especially in industrial environments where multiple electromagnetic sources operate simultaneously.

Calibration complexity presents another substantial hurdle. Hall effect sensors exhibit inherent non-linearities and temperature dependencies that require sophisticated calibration procedures. When multiple sensors are deployed in a fusion architecture, maintaining consistent calibration across the sensor network becomes exponentially more difficult, particularly when sensors operate under varying environmental conditions.

Data synchronization issues frequently compromise fusion quality. In multi-sensor systems, even minor timing discrepancies between different sensor readings can lead to significant errors in the fused output. This challenge becomes more pronounced in high-speed applications where millisecond-level synchronization is essential for accurate data interpretation.

Computational resource limitations constrain real-time processing capabilities, particularly in embedded systems with restricted processing power and memory. Advanced fusion algorithms often require substantial computational resources, creating a tension between fusion sophistication and system responsiveness that engineers must carefully balance.

Sensor drift and aging effects introduce long-term reliability concerns. Hall effect sensors gradually experience parameter shifts over time due to material degradation and environmental exposure. These changes occur at different rates across a sensor network, making it difficult to maintain consistent fusion performance without regular recalibration or compensation algorithms.

Cross-sensitivity to unintended physical parameters represents another significant challenge. While Hall sensors primarily respond to magnetic fields, they also exhibit sensitivity to temperature variations, mechanical stress, and humidity. These secondary influences can introduce measurement errors that are difficult to isolate and compensate for in fusion algorithms.

Integration complexity with other sensor types further complicates fusion implementations. Modern systems often combine Hall effect sensors with complementary technologies like accelerometers, gyroscopes, or optical sensors. Each sensor type operates on different physical principles with unique error characteristics, making unified fusion frameworks challenging to design and optimize.

Power consumption constraints limit deployment options, particularly in battery-operated or energy-harvesting applications. The continuous operation required for effective sensor fusion can drain power resources quickly, necessitating careful trade-offs between sensing frequency, processing complexity, and energy efficiency.

Calibration complexity presents another substantial hurdle. Hall effect sensors exhibit inherent non-linearities and temperature dependencies that require sophisticated calibration procedures. When multiple sensors are deployed in a fusion architecture, maintaining consistent calibration across the sensor network becomes exponentially more difficult, particularly when sensors operate under varying environmental conditions.

Data synchronization issues frequently compromise fusion quality. In multi-sensor systems, even minor timing discrepancies between different sensor readings can lead to significant errors in the fused output. This challenge becomes more pronounced in high-speed applications where millisecond-level synchronization is essential for accurate data interpretation.

Computational resource limitations constrain real-time processing capabilities, particularly in embedded systems with restricted processing power and memory. Advanced fusion algorithms often require substantial computational resources, creating a tension between fusion sophistication and system responsiveness that engineers must carefully balance.

Sensor drift and aging effects introduce long-term reliability concerns. Hall effect sensors gradually experience parameter shifts over time due to material degradation and environmental exposure. These changes occur at different rates across a sensor network, making it difficult to maintain consistent fusion performance without regular recalibration or compensation algorithms.

Cross-sensitivity to unintended physical parameters represents another significant challenge. While Hall sensors primarily respond to magnetic fields, they also exhibit sensitivity to temperature variations, mechanical stress, and humidity. These secondary influences can introduce measurement errors that are difficult to isolate and compensate for in fusion algorithms.

Integration complexity with other sensor types further complicates fusion implementations. Modern systems often combine Hall effect sensors with complementary technologies like accelerometers, gyroscopes, or optical sensors. Each sensor type operates on different physical principles with unique error characteristics, making unified fusion frameworks challenging to design and optimize.

Power consumption constraints limit deployment options, particularly in battery-operated or energy-harvesting applications. The continuous operation required for effective sensor fusion can drain power resources quickly, necessitating careful trade-offs between sensing frequency, processing complexity, and energy efficiency.

Existing Data Fusion Algorithms and Methodologies

01 Hall Effect Sensor Integration in Data Fusion Systems

Hall effect sensors can be integrated into data fusion systems to provide accurate position and motion detection. These systems combine data from multiple sensors to enhance measurement accuracy and reliability. The fusion of Hall effect sensor data with other sensor inputs allows for more robust detection capabilities in various applications including automotive systems, industrial automation, and consumer electronics.- Hall Effect Sensor Integration in Data Fusion Systems: Hall effect sensors can be integrated into data fusion systems to provide accurate position and motion detection. These systems combine data from multiple sensors to enhance measurement accuracy and reliability. The fusion of Hall effect sensor data with other sensor inputs allows for more robust detection in various environmental conditions and applications, particularly in automotive and industrial control systems.

- Multi-Axis Hall Effect Sensor Arrays for Enhanced Detection: Multi-axis Hall effect sensor arrays can be implemented to detect magnetic fields in multiple dimensions simultaneously. By arranging Hall sensors in different orientations, these arrays provide comprehensive spatial data that can be fused to determine precise position, orientation, and movement. This approach improves the accuracy of motion tracking and enables more sophisticated control mechanisms in robotics and navigation systems.

- Signal Processing Techniques for Hall Sensor Data Fusion: Advanced signal processing techniques are essential for effective Hall effect sensor data fusion. These include filtering algorithms, calibration methods, and noise reduction techniques that enhance the quality of sensor outputs before fusion. Kalman filtering and other statistical approaches can be applied to combine data from Hall sensors with complementary sensors, resulting in more reliable measurements even in challenging electromagnetic environments.

- Hall Effect Sensor Design Optimization for Fusion Applications: Specialized Hall effect sensor designs can optimize performance in data fusion applications. These designs focus on improving sensitivity, reducing temperature drift, and enhancing linearity of response. Integrated circuit implementations that combine Hall elements with on-chip signal conditioning and processing capabilities facilitate seamless integration into fusion systems, while minimizing size and power requirements.

- Industrial and Automotive Applications of Hall Sensor Data Fusion: Hall effect sensor data fusion finds significant applications in industrial automation and automotive systems. In these contexts, Hall sensors provide critical inputs for position detection, speed measurement, and current sensing. When fused with data from other sensor types, they enable advanced functionalities such as predictive maintenance, precise motor control, vehicle stability systems, and autonomous navigation features that require redundant and complementary sensing capabilities.

02 Multi-Axis Hall Effect Sensor Arrays for Position Detection

Multi-axis Hall effect sensor arrays enable comprehensive position detection by measuring magnetic fields in multiple directions simultaneously. These arrays can be configured to detect rotational and linear movements with high precision. By fusing data from multiple sensing elements within the array, the system can determine complex motion patterns and provide enhanced spatial awareness for navigation and control applications.Expand Specific Solutions03 Signal Processing Techniques for Hall Effect Sensor Data

Advanced signal processing techniques are essential for optimizing Hall effect sensor data fusion. These techniques include filtering algorithms, calibration methods, and noise reduction approaches that enhance the quality of sensor outputs. By applying sophisticated processing to raw Hall effect sensor signals, systems can achieve improved accuracy, reduced latency, and better performance in challenging electromagnetic environments.Expand Specific Solutions04 Hall Effect Sensors in Vehicle Navigation and Control Systems

Hall effect sensors play a crucial role in vehicle navigation and control systems through data fusion with other sensing technologies. These sensors provide reliable measurements of wheel speed, steering angle, and other parameters critical for vehicle stability and autonomous operation. The fusion of Hall effect sensor data with inputs from accelerometers, gyroscopes, and GPS enables comprehensive vehicle state estimation and precise control.Expand Specific Solutions05 Miniaturized Hall Effect Sensor Integration for IoT and Wearable Applications

Miniaturized Hall effect sensors are being integrated into IoT devices and wearable technology through innovative data fusion approaches. These compact sensors enable motion tracking, proximity detection, and orientation sensing in space-constrained applications. By fusing Hall effect sensor data with information from other miniaturized sensors, these systems can provide comprehensive environmental awareness while maintaining low power consumption and small form factors.Expand Specific Solutions

Leading Companies in Hall Effect Sensor Technology

Sensor data fusion using Hall Effect sensors is currently in a growth phase, with the market expected to reach significant expansion due to increasing applications in automotive, industrial automation, and consumer electronics sectors. The global market is projected to grow substantially as demand for precise position sensing and contactless measurements rises. Technologically, industry leaders like Infineon Technologies, STMicroelectronics, and Allegro MicroSystems have achieved considerable maturity in developing advanced Hall Effect sensor solutions, while Robert Bosch GmbH and Honeywell International are pioneering integrated fusion algorithms that combine Hall Effect data with other sensor inputs. Companies such as ams-OSRAM and Asahi Kasei Microdevices are focusing on miniaturization and power efficiency, creating a competitive landscape where innovation in signal processing and multi-sensor integration capabilities determines market leadership.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive sensor data fusion framework for Hall Effect sensors that leverages their expertise in automotive and industrial applications. Their approach utilizes a multi-layer fusion architecture where raw Hall sensor data is first pre-processed to remove noise and compensate for temperature variations. The system then employs proprietary algorithms to fuse data from multiple Hall sensors positioned at strategic locations to create a complete magnetic field map. Bosch's solution incorporates adaptive Kalman filtering techniques that dynamically adjust to changing environmental conditions, significantly improving measurement accuracy in noisy environments. Their sensor fusion platform also integrates Hall Effect data with complementary sensor technologies such as accelerometers and gyroscopes to provide context-aware sensing capabilities. Bosch has implemented this technology in their automotive systems where precise position sensing is critical for safety applications[2][5]. The company has also developed specialized ASICs that perform sensor fusion calculations with minimal latency, enabling real-time control applications.

Strengths: Extensive experience in automotive-grade sensor systems with proven reliability in harsh environments; comprehensive fusion approach that integrates multiple sensor types. Weaknesses: Solutions tend to be optimized for specific applications rather than providing general-purpose flexibility; higher implementation costs compared to simpler approaches.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed an advanced sensor fusion framework for Hall Effect sensors that leverages their expertise in mixed-signal semiconductor design. Their approach utilizes a modular architecture where specialized front-end processing handles initial signal conditioning before passing data to a configurable fusion engine. ST's solution incorporates proprietary algorithms that combine time-domain and frequency-domain analysis to extract maximum information from Hall sensor signals. Their platform implements adaptive filtering techniques that dynamically adjust to changing noise conditions, significantly improving signal-to-noise ratio in challenging environments. ST has pioneered the integration of Hall Effect sensors with inertial measurement units (IMUs) to create comprehensive motion and position sensing solutions. Their fusion algorithms leverage contextual information from multiple sensor types to enhance measurement accuracy and reliability. ST's latest generation Hall sensor systems incorporate embedded machine learning capabilities that enable pattern recognition and anomaly detection directly at the sensor level. The company has successfully deployed these technologies in automotive applications for precise position sensing in safety-critical systems, achieving sub-millimeter accuracy with robust fault detection capabilities[8][10].

Strengths: Excellent integration with other sensor types in comprehensive fusion solutions; robust performance in electromagnetically noisy environments. Weaknesses: More complex firmware development requirements; higher computational demands for advanced fusion modes.

Key Patents and Research in Hall Effect Sensor Fusion

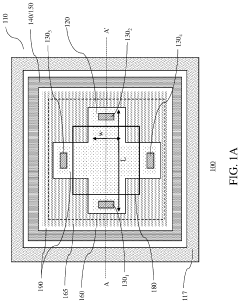

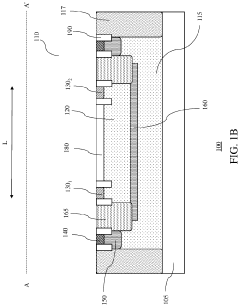

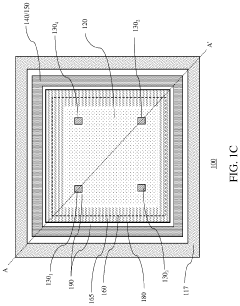

Hall effect sensors with tunable sensitivity and/or resistance

PatentActiveUS11047930B2

Innovation

- A Hall effect sensor design with a tunable Hall plate thickness, achieved through adjustable implants in the separation layer and bias voltage applied to the separation layer, allowing for customizable current sensitivity and resistance, enabling high voltage and current sensitivity in the same device.

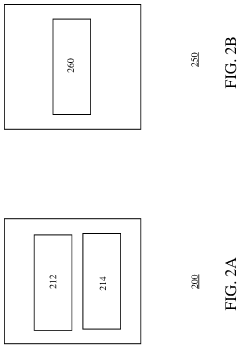

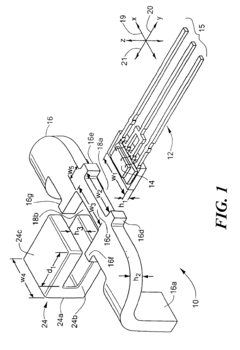

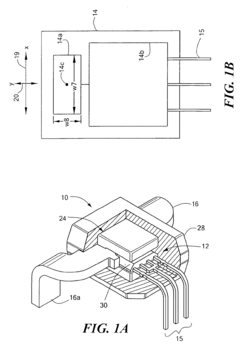

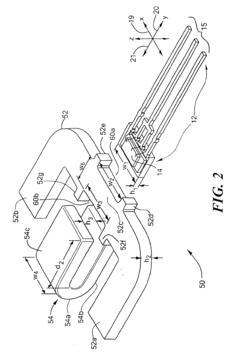

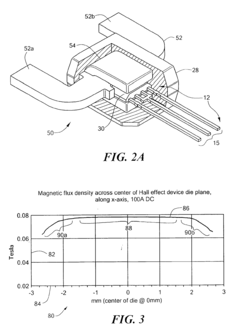

Integrated current sensor

PatentInactiveEP2264471A2

Innovation

- An integrated current sensor design featuring a C-shaped magnetic core with a Hall effect sensor and conductor notches for precise mechanical positioning, reducing susceptibility to external fields and enhancing sensitivity and uniformity, while incorporating signal processing circuitry for improved performance.

Noise Reduction and Calibration Techniques

Noise reduction and calibration are critical aspects of optimizing Hall effect sensor data fusion systems. Environmental electromagnetic interference, thermal drift, and inherent sensor limitations can significantly degrade measurement accuracy. Implementing digital filtering techniques such as Kalman filters, moving average filters, or wavelet transforms can effectively reduce random noise while preserving essential signal characteristics. These methods analyze the statistical properties of incoming data streams to separate genuine signals from unwanted noise components.

Advanced signal processing algorithms like adaptive noise cancellation can dynamically adjust to changing noise profiles, making them particularly valuable in variable environments where Hall effect sensors operate. For persistent periodic noise, notch filters targeting specific frequencies can be implemented to eliminate known interference sources without affecting the overall signal integrity.

Sensor calibration represents another crucial dimension of optimization. Factory calibration provides a baseline but often proves insufficient for high-precision applications. Multi-point calibration techniques that account for non-linearity across the sensor's operating range deliver superior results compared to simple offset and gain adjustments. Temperature compensation algorithms are essential as Hall effect sensors exhibit significant thermal sensitivity, with output variations of up to 0.1% per degree Celsius in some models.

Cross-axis sensitivity calibration addresses the challenge of magnetic field vectors affecting multiple sensor axes simultaneously. Mathematical models can be developed to characterize and compensate for these interdependencies, significantly improving measurement accuracy in three-dimensional magnetic field sensing applications. Runtime auto-calibration mechanisms that periodically adjust sensor parameters based on reference measurements ensure long-term stability and compensate for sensor drift over time.

Sensor fusion algorithms must incorporate calibration data intelligently. Weighted averaging techniques can assign greater importance to sensors demonstrating higher accuracy under specific conditions. Bayesian methods provide a robust framework for combining multiple sensor readings while accounting for individual sensor error characteristics and confidence levels. These probabilistic approaches are particularly valuable when integrating Hall effect sensors with complementary technologies like accelerometers or gyroscopes.

Hardware considerations also play a vital role in noise reduction. Proper shielding, grounding techniques, and careful PCB layout can significantly reduce electromagnetic interference before it enters the signal processing chain. Differential sensing configurations, where two Hall elements are arranged to measure the same field from opposite directions, can effectively cancel common-mode noise while reinforcing the desired signal.

Advanced signal processing algorithms like adaptive noise cancellation can dynamically adjust to changing noise profiles, making them particularly valuable in variable environments where Hall effect sensors operate. For persistent periodic noise, notch filters targeting specific frequencies can be implemented to eliminate known interference sources without affecting the overall signal integrity.

Sensor calibration represents another crucial dimension of optimization. Factory calibration provides a baseline but often proves insufficient for high-precision applications. Multi-point calibration techniques that account for non-linearity across the sensor's operating range deliver superior results compared to simple offset and gain adjustments. Temperature compensation algorithms are essential as Hall effect sensors exhibit significant thermal sensitivity, with output variations of up to 0.1% per degree Celsius in some models.

Cross-axis sensitivity calibration addresses the challenge of magnetic field vectors affecting multiple sensor axes simultaneously. Mathematical models can be developed to characterize and compensate for these interdependencies, significantly improving measurement accuracy in three-dimensional magnetic field sensing applications. Runtime auto-calibration mechanisms that periodically adjust sensor parameters based on reference measurements ensure long-term stability and compensate for sensor drift over time.

Sensor fusion algorithms must incorporate calibration data intelligently. Weighted averaging techniques can assign greater importance to sensors demonstrating higher accuracy under specific conditions. Bayesian methods provide a robust framework for combining multiple sensor readings while accounting for individual sensor error characteristics and confidence levels. These probabilistic approaches are particularly valuable when integrating Hall effect sensors with complementary technologies like accelerometers or gyroscopes.

Hardware considerations also play a vital role in noise reduction. Proper shielding, grounding techniques, and careful PCB layout can significantly reduce electromagnetic interference before it enters the signal processing chain. Differential sensing configurations, where two Hall elements are arranged to measure the same field from opposite directions, can effectively cancel common-mode noise while reinforcing the desired signal.

Power Consumption and Miniaturization Considerations

Power consumption and miniaturization represent critical considerations in the optimization of Hall effect sensor data fusion systems. The energy efficiency of these systems directly impacts their viability in battery-powered applications, particularly in IoT devices, wearables, and autonomous systems where operational longevity is paramount. Current Hall effect sensors typically consume between 1-5 mA during active operation, which can be prohibitive for long-term deployment scenarios without frequent battery replacement or recharging.

Advanced power management techniques have emerged as essential strategies for optimization. These include implementing sleep modes that can reduce consumption to microamp levels during periods of inactivity, duty cycling operations that activate sensors only when measurements are required, and adaptive sampling rates that adjust based on detected activity levels. Such approaches have demonstrated power reductions of up to 80% in field tests while maintaining acceptable data quality.

Miniaturization trends have driven significant innovations in Hall effect sensor packaging. Modern integrated circuits now combine multiple Hall effect sensors, signal conditioning circuitry, and data fusion algorithms within single packages as small as 2×2 mm. This integration not only reduces the physical footprint but also minimizes power losses associated with signal transmission between discrete components. The reduced trace lengths in these integrated solutions further contribute to lower electromagnetic interference and improved signal integrity.

System-on-chip (SoC) solutions specifically designed for sensor fusion applications have begun incorporating Hall effect sensors alongside other sensing modalities. These highly integrated platforms feature dedicated low-power processing units that handle preliminary data fusion operations without waking the main system processor. This architectural approach has shown power savings of 40-60% compared to traditional implementations where all processing occurs on the main CPU.

Energy harvesting technologies present promising complementary solutions for extending the operational life of Hall effect sensor networks. Ambient energy sources such as vibration, temperature differentials, and even magnetic field variations can be harnessed to supplement battery power. Recent research demonstrates that piezoelectric and thermoelectric harvesters can generate 10-100 μW/cm², sufficient to power intermittent Hall sensor operations in specific applications.

The trade-offs between power consumption, physical size, and measurement accuracy require careful consideration during system design. Higher sensitivity Hall effect sensors typically demand more power but allow for smaller sensing elements. Conversely, lower power variants may require larger sensing areas or sacrifice measurement frequency. Optimization therefore necessitates application-specific balancing of these competing factors through comprehensive power budgeting and form factor analysis during the design phase.

Advanced power management techniques have emerged as essential strategies for optimization. These include implementing sleep modes that can reduce consumption to microamp levels during periods of inactivity, duty cycling operations that activate sensors only when measurements are required, and adaptive sampling rates that adjust based on detected activity levels. Such approaches have demonstrated power reductions of up to 80% in field tests while maintaining acceptable data quality.

Miniaturization trends have driven significant innovations in Hall effect sensor packaging. Modern integrated circuits now combine multiple Hall effect sensors, signal conditioning circuitry, and data fusion algorithms within single packages as small as 2×2 mm. This integration not only reduces the physical footprint but also minimizes power losses associated with signal transmission between discrete components. The reduced trace lengths in these integrated solutions further contribute to lower electromagnetic interference and improved signal integrity.

System-on-chip (SoC) solutions specifically designed for sensor fusion applications have begun incorporating Hall effect sensors alongside other sensing modalities. These highly integrated platforms feature dedicated low-power processing units that handle preliminary data fusion operations without waking the main system processor. This architectural approach has shown power savings of 40-60% compared to traditional implementations where all processing occurs on the main CPU.

Energy harvesting technologies present promising complementary solutions for extending the operational life of Hall effect sensor networks. Ambient energy sources such as vibration, temperature differentials, and even magnetic field variations can be harnessed to supplement battery power. Recent research demonstrates that piezoelectric and thermoelectric harvesters can generate 10-100 μW/cm², sufficient to power intermittent Hall sensor operations in specific applications.

The trade-offs between power consumption, physical size, and measurement accuracy require careful consideration during system design. Higher sensitivity Hall effect sensors typically demand more power but allow for smaller sensing elements. Conversely, lower power variants may require larger sensing areas or sacrifice measurement frequency. Optimization therefore necessitates application-specific balancing of these competing factors through comprehensive power budgeting and form factor analysis during the design phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!