Comparing Hall Effect Sensors for Robust Cyber-Physical Systems

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensor Technology Background and Objectives

Hall Effect sensors, discovered by Edwin Hall in 1879, have evolved significantly over the past century to become fundamental components in modern cyber-physical systems (CPS). These sensors operate on the principle of the Hall Effect, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This physical phenomenon has enabled the development of robust, non-contact sensing solutions that are critical in environments requiring high reliability and durability.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations were primarily analog devices with limited sensitivity and significant temperature drift. The 1970s saw the integration of Hall Effect elements with amplifiers and signal conditioning circuits, while the 1980s and 1990s brought digital Hall Effect sensors with improved precision and programmability. Recent developments have focused on miniaturization, enhanced sensitivity, and integration with other sensing technologies.

In the context of cyber-physical systems, Hall Effect sensors serve as crucial interfaces between the physical and digital domains. They provide essential feedback for control systems in applications ranging from automotive systems and industrial automation to consumer electronics and medical devices. Their non-contact operation offers advantages in harsh environments where mechanical wear is a concern, while their solid-state construction contributes to exceptional reliability and longevity.

The primary objectives of modern Hall Effect sensor technology development are centered around enhancing performance metrics critical for robust CPS implementations. These include improving sensitivity to detect smaller magnetic field changes, reducing power consumption for battery-powered and energy-efficient applications, and enhancing immunity to electromagnetic interference in noisy industrial environments. Additionally, there is a growing focus on developing sensors with wider operating temperature ranges and improved linearity across these ranges.

Another significant technological trend is the integration of Hall Effect sensors with advanced signal processing capabilities and communication interfaces. This integration enables real-time data analysis, self-calibration, and seamless connectivity with other system components, facilitating more sophisticated control algorithms and predictive maintenance strategies in CPS applications.

The miniaturization of Hall Effect sensors has also been a consistent trend, with modern sensors achieving form factors suitable for increasingly compact devices. This miniaturization, coupled with enhanced durability and reliability, has expanded the application scope of these sensors in emerging CPS domains such as wearable technology, robotics, and autonomous vehicles.

Looking forward, the technology roadmap for Hall Effect sensors in CPS applications is focused on developing multi-axis sensing capabilities, improving energy harvesting for self-powered operation, and enhancing integration with artificial intelligence for smarter sensing solutions. These advancements aim to address the growing demands for more intelligent, autonomous, and reliable cyber-physical systems across various industries.

The evolution of Hall Effect sensor technology has been marked by several significant advancements. Early implementations were primarily analog devices with limited sensitivity and significant temperature drift. The 1970s saw the integration of Hall Effect elements with amplifiers and signal conditioning circuits, while the 1980s and 1990s brought digital Hall Effect sensors with improved precision and programmability. Recent developments have focused on miniaturization, enhanced sensitivity, and integration with other sensing technologies.

In the context of cyber-physical systems, Hall Effect sensors serve as crucial interfaces between the physical and digital domains. They provide essential feedback for control systems in applications ranging from automotive systems and industrial automation to consumer electronics and medical devices. Their non-contact operation offers advantages in harsh environments where mechanical wear is a concern, while their solid-state construction contributes to exceptional reliability and longevity.

The primary objectives of modern Hall Effect sensor technology development are centered around enhancing performance metrics critical for robust CPS implementations. These include improving sensitivity to detect smaller magnetic field changes, reducing power consumption for battery-powered and energy-efficient applications, and enhancing immunity to electromagnetic interference in noisy industrial environments. Additionally, there is a growing focus on developing sensors with wider operating temperature ranges and improved linearity across these ranges.

Another significant technological trend is the integration of Hall Effect sensors with advanced signal processing capabilities and communication interfaces. This integration enables real-time data analysis, self-calibration, and seamless connectivity with other system components, facilitating more sophisticated control algorithms and predictive maintenance strategies in CPS applications.

The miniaturization of Hall Effect sensors has also been a consistent trend, with modern sensors achieving form factors suitable for increasingly compact devices. This miniaturization, coupled with enhanced durability and reliability, has expanded the application scope of these sensors in emerging CPS domains such as wearable technology, robotics, and autonomous vehicles.

Looking forward, the technology roadmap for Hall Effect sensors in CPS applications is focused on developing multi-axis sensing capabilities, improving energy harvesting for self-powered operation, and enhancing integration with artificial intelligence for smarter sensing solutions. These advancements aim to address the growing demands for more intelligent, autonomous, and reliable cyber-physical systems across various industries.

Market Demand Analysis for CPS Sensing Solutions

The market for sensing solutions in Cyber-Physical Systems (CPS) has experienced significant growth over the past decade, driven by increasing automation across industries and the proliferation of IoT applications. Hall Effect sensors, in particular, have emerged as critical components in robust CPS implementations due to their non-contact measurement capabilities, reliability in harsh environments, and compatibility with digital systems.

Current market analysis indicates that the global Hall Effect sensor market is valued at approximately 2.1 billion USD, with projections suggesting a compound annual growth rate of 8.3% through 2028. This growth is primarily fueled by expanding applications in automotive systems, industrial automation, consumer electronics, and emerging smart infrastructure deployments.

Within the automotive sector, which accounts for nearly 40% of Hall Effect sensor demand, these sensors are increasingly utilized for position detection, speed measurement, and current sensing applications. The industry's shift toward electric vehicles has further accelerated demand, as these vehicles require more sophisticated sensing solutions for motor control and battery management systems.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly implementing CPS solutions to enhance operational efficiency and enable predictive maintenance. Hall Effect sensors provide crucial data points for monitoring equipment performance and detecting potential failures before they occur, thereby reducing downtime and maintenance costs.

Consumer electronics applications, including smartphones, wearables, and smart home devices, constitute a rapidly growing market segment for Hall Effect sensing solutions. These applications typically require miniaturized sensors with low power consumption characteristics, driving innovation in sensor design and manufacturing processes.

Market research indicates that end-users are increasingly prioritizing sensor reliability and accuracy in mission-critical CPS applications. This trend has led to growing demand for advanced Hall Effect sensors with enhanced temperature stability, improved signal-to-noise ratios, and built-in diagnostic capabilities. Additionally, there is increasing market preference for integrated sensor solutions that combine Hall Effect elements with signal processing circuitry and communication interfaces.

Regional analysis shows North America and Europe leading in adoption of high-performance Hall Effect sensors for advanced CPS implementations, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing automotive production. China, in particular, has emerged as both a major consumer and producer of Hall Effect sensing technologies.

Market challenges include price sensitivity in competitive segments, technical limitations in extreme operating environments, and increasing requirements for cybersecurity in connected sensor networks. These challenges present opportunities for differentiation through innovation in sensor design, manufacturing processes, and integration capabilities.

Current market analysis indicates that the global Hall Effect sensor market is valued at approximately 2.1 billion USD, with projections suggesting a compound annual growth rate of 8.3% through 2028. This growth is primarily fueled by expanding applications in automotive systems, industrial automation, consumer electronics, and emerging smart infrastructure deployments.

Within the automotive sector, which accounts for nearly 40% of Hall Effect sensor demand, these sensors are increasingly utilized for position detection, speed measurement, and current sensing applications. The industry's shift toward electric vehicles has further accelerated demand, as these vehicles require more sophisticated sensing solutions for motor control and battery management systems.

Industrial automation represents another significant market segment, with manufacturing facilities increasingly implementing CPS solutions to enhance operational efficiency and enable predictive maintenance. Hall Effect sensors provide crucial data points for monitoring equipment performance and detecting potential failures before they occur, thereby reducing downtime and maintenance costs.

Consumer electronics applications, including smartphones, wearables, and smart home devices, constitute a rapidly growing market segment for Hall Effect sensing solutions. These applications typically require miniaturized sensors with low power consumption characteristics, driving innovation in sensor design and manufacturing processes.

Market research indicates that end-users are increasingly prioritizing sensor reliability and accuracy in mission-critical CPS applications. This trend has led to growing demand for advanced Hall Effect sensors with enhanced temperature stability, improved signal-to-noise ratios, and built-in diagnostic capabilities. Additionally, there is increasing market preference for integrated sensor solutions that combine Hall Effect elements with signal processing circuitry and communication interfaces.

Regional analysis shows North America and Europe leading in adoption of high-performance Hall Effect sensors for advanced CPS implementations, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing automotive production. China, in particular, has emerged as both a major consumer and producer of Hall Effect sensing technologies.

Market challenges include price sensitivity in competitive segments, technical limitations in extreme operating environments, and increasing requirements for cybersecurity in connected sensor networks. These challenges present opportunities for differentiation through innovation in sensor design, manufacturing processes, and integration capabilities.

Current State and Challenges in Hall Effect Sensing

Hall Effect sensing technology has evolved significantly over the past decades, establishing itself as a cornerstone in modern cyber-physical systems. Currently, the global market for Hall Effect sensors is experiencing robust growth, with applications spanning automotive, industrial, consumer electronics, and aerospace sectors. The technology has matured from simple magnetic field detection to sophisticated integrated solutions capable of high-precision measurements in challenging environments.

Despite this progress, several significant challenges persist in Hall Effect sensing technology. Temperature drift remains a primary concern, as sensor performance can vary considerably across operating temperature ranges, affecting measurement accuracy in real-world applications. This is particularly problematic in automotive and industrial environments where temperature fluctuations are common and reliability is paramount.

Signal-to-noise ratio (SNR) limitations present another substantial challenge, especially in environments with electromagnetic interference. As cyber-physical systems become more compact and densely integrated, sensors must maintain performance integrity despite proximity to motors, power lines, and other electronic components that generate magnetic fields.

Power consumption considerations have become increasingly important as more applications move toward battery operation or energy harvesting. Traditional Hall Effect sensors often require continuous power, limiting their suitability for low-power applications such as IoT devices and wearable technology.

Miniaturization trends across industries have created demand for smaller sensors without compromising performance. Current manufacturing processes face difficulties in maintaining consistent sensitivity and accuracy as sensor dimensions decrease. This challenge is compounded by the need for multi-axis sensing capabilities in increasingly compact form factors.

Integration complexity presents significant hurdles for system designers. Modern cyber-physical systems require sensors that can seamlessly interface with various microcontrollers and processing units, often necessitating additional signal conditioning circuitry that increases system complexity and cost.

Geographically, Hall Effect sensor technology development is concentrated in regions with strong semiconductor manufacturing capabilities. North America, Europe (particularly Germany), Japan, and increasingly China lead in research and production. This distribution has created supply chain vulnerabilities, as highlighted by recent global semiconductor shortages affecting sensor availability.

Emerging applications in robotics, autonomous vehicles, and advanced manufacturing systems are pushing the boundaries of current Hall Effect sensing capabilities, demanding higher precision, faster response times, and greater reliability under extreme conditions. These applications require sensors that can provide not just discrete position information but continuous, high-resolution data for sophisticated control algorithms.

Despite this progress, several significant challenges persist in Hall Effect sensing technology. Temperature drift remains a primary concern, as sensor performance can vary considerably across operating temperature ranges, affecting measurement accuracy in real-world applications. This is particularly problematic in automotive and industrial environments where temperature fluctuations are common and reliability is paramount.

Signal-to-noise ratio (SNR) limitations present another substantial challenge, especially in environments with electromagnetic interference. As cyber-physical systems become more compact and densely integrated, sensors must maintain performance integrity despite proximity to motors, power lines, and other electronic components that generate magnetic fields.

Power consumption considerations have become increasingly important as more applications move toward battery operation or energy harvesting. Traditional Hall Effect sensors often require continuous power, limiting their suitability for low-power applications such as IoT devices and wearable technology.

Miniaturization trends across industries have created demand for smaller sensors without compromising performance. Current manufacturing processes face difficulties in maintaining consistent sensitivity and accuracy as sensor dimensions decrease. This challenge is compounded by the need for multi-axis sensing capabilities in increasingly compact form factors.

Integration complexity presents significant hurdles for system designers. Modern cyber-physical systems require sensors that can seamlessly interface with various microcontrollers and processing units, often necessitating additional signal conditioning circuitry that increases system complexity and cost.

Geographically, Hall Effect sensor technology development is concentrated in regions with strong semiconductor manufacturing capabilities. North America, Europe (particularly Germany), Japan, and increasingly China lead in research and production. This distribution has created supply chain vulnerabilities, as highlighted by recent global semiconductor shortages affecting sensor availability.

Emerging applications in robotics, autonomous vehicles, and advanced manufacturing systems are pushing the boundaries of current Hall Effect sensing capabilities, demanding higher precision, faster response times, and greater reliability under extreme conditions. These applications require sensors that can provide not just discrete position information but continuous, high-resolution data for sophisticated control algorithms.

Current Hall Effect Sensor Implementation Approaches

01 Environmental robustness and protection mechanisms

Hall effect sensors can be designed with protective features to enhance their robustness against harsh environmental conditions. These include encapsulation techniques, protective coatings, and specialized packaging that shield the sensor from moisture, dust, temperature variations, and mechanical stress. Such protection mechanisms ensure reliable operation in challenging industrial environments and extend the sensor's operational lifespan.- Environmental robustness and protection mechanisms: Hall effect sensors can be designed with protective features to enhance their robustness against harsh environmental conditions. These include encapsulation techniques, protective coatings, and specialized packaging that shield the sensor from moisture, dust, chemicals, and mechanical stress. Some designs incorporate temperature compensation circuits to maintain accuracy across wide temperature ranges, while others feature hermetic sealing to prevent contamination that could degrade sensor performance over time.

- Electromagnetic interference resistance: Improving robustness against electromagnetic interference (EMI) is critical for Hall effect sensors operating in electrically noisy environments. Advanced designs incorporate shielding structures, differential sensing configurations, and specialized filtering circuits to reject common-mode noise. Some sensors utilize integrated compensation techniques that dynamically adjust for external magnetic field disturbances, while others employ specialized circuit topologies that inherently provide better immunity to electromagnetic interference.

- Structural and mechanical durability: Hall effect sensors can be engineered for enhanced mechanical robustness through specialized mounting techniques, vibration-resistant designs, and impact-resistant housings. Some implementations use flexible substrates or shock-absorbing materials to withstand mechanical stress and vibration. Advanced manufacturing processes create sensors with improved resistance to thermal cycling, mechanical fatigue, and physical deformation, making them suitable for high-vibration environments like automotive and industrial applications.

- Circuit design for reliability enhancement: Robust Hall effect sensor designs incorporate specialized circuit architectures that improve reliability and fault tolerance. These include redundant sensing elements, self-diagnostic capabilities, and error detection mechanisms. Some designs feature adaptive calibration systems that compensate for aging effects and drift over time. Advanced signal processing techniques can filter out anomalous readings and provide consistent output even under suboptimal conditions, while power management circuits protect against voltage spikes and brownout conditions.

- Manufacturing and quality control techniques: Specialized manufacturing processes and quality control methods significantly enhance Hall effect sensor robustness. These include precision semiconductor fabrication techniques, automated testing procedures, and burn-in processes that identify early failure modes. Some manufacturers employ statistical process control to ensure consistent performance characteristics across production batches. Advanced calibration techniques during manufacturing can compensate for material variations and process tolerances, resulting in sensors with more predictable behavior under stress conditions.

02 Temperature compensation techniques

Advanced temperature compensation techniques are implemented in Hall effect sensors to maintain measurement accuracy across wide temperature ranges. These include integrated temperature sensors, calibration circuits, and specialized materials with stable magnetic properties. Such compensation methods ensure consistent sensor performance despite thermal variations, making them suitable for applications with fluctuating environmental temperatures.Expand Specific Solutions03 Electromagnetic interference resistance

Hall effect sensors can be designed with features to resist electromagnetic interference (EMI) and maintain signal integrity in noisy environments. These include shielding techniques, differential sensing configurations, and specialized filtering circuits. Such EMI resistance ensures accurate measurements even in proximity to motors, power lines, or other sources of electromagnetic noise, enhancing the overall robustness of the sensing system.Expand Specific Solutions04 Mechanical stress resistance and mounting solutions

Specialized mechanical designs and mounting solutions enhance the robustness of Hall effect sensors against vibration, shock, and mechanical stress. These include flexible mounting brackets, vibration isolation techniques, and stress-relieving sensor structures. Such mechanical robustness ensures reliable operation in high-vibration environments like automotive applications and industrial machinery.Expand Specific Solutions05 Enhanced sensitivity and signal processing

Advanced signal processing techniques and enhanced sensitivity designs improve the robustness of Hall effect sensors by increasing signal-to-noise ratio and measurement accuracy. These include integrated amplifiers, digital signal processing, and specialized magnetic concentrators. Such enhancements allow for reliable detection even with weak magnetic fields or in the presence of interference, contributing to overall sensor robustness in diverse applications.Expand Specific Solutions

Key Industry Players in Hall Effect Sensor Manufacturing

The Hall Effect Sensor market is currently in a growth phase, with increasing adoption in cyber-physical systems requiring robust sensing solutions. The global market size is projected to expand significantly due to rising demand in automotive, industrial automation, and consumer electronics sectors. Technologically, companies like Honeywell, Allegro MicroSystems, and Texas Instruments lead with advanced sensor designs offering enhanced sensitivity and reliability. Bosch and TDK-Micronas have established strong positions in automotive applications, while Paragraf represents emerging innovation with graphene-based Hall sensors. Allegro and Monolithic Power Systems are advancing integrated solutions combining Hall sensing with signal processing capabilities. The competitive landscape shows established players focusing on miniaturization and precision, while newer entrants differentiate through novel materials and manufacturing techniques to address emerging CPS requirements.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Hall effect sensors with integrated signal conditioning and temperature compensation for robust cyber-physical systems. Their SmartSensor technology combines Hall effect sensing elements with microprocessors to provide digital output signals that are less susceptible to electromagnetic interference. Honeywell's sensors feature programmable sensitivity and offset calibration that can be adjusted in-system to maintain accuracy over time and environmental changes. Their TruStability™ platform incorporates redundant sensing elements and built-in diagnostics for fault detection, critical for safety-critical applications in aerospace and industrial control systems[1]. Honeywell has also pioneered miniaturized packaging techniques that reduce the physical footprint while maintaining thermal stability, with some sensors operating reliably in temperatures ranging from -40°C to +150°C[3].

Strengths: Superior reliability in harsh environments with industry-leading temperature stability; comprehensive diagnostic capabilities for safety-critical applications; long operational life exceeding 20 million cycles. Weaknesses: Higher cost compared to basic Hall sensors; more complex integration requirements; higher power consumption in some fully-featured models.

Allegro MicroSystems LLC

Technical Solution: Allegro MicroSystems has developed proprietary Hall-effect technology called "Vertical Hall Technology" that enables sensing in three dimensions with a single IC. Their sensors incorporate advanced chopper stabilization techniques to minimize temperature drift and offset errors, achieving accuracy within ±1% across their operating temperature range. Allegro's A1367 sensor family features integrated fault detection circuitry that continuously monitors sensor operation and provides dedicated fault output pins for immediate system notification[2]. For cyber-physical systems requiring high reliability, Allegro has implemented redundant sensing elements with majority voting algorithms to prevent single-point failures. Their sensors also incorporate on-chip EEPROM for storing calibration data and operational parameters, allowing for field programmability and adaptation to specific application requirements[4]. Allegro's latest generation incorporates advanced signal processing algorithms that filter out noise and transient disturbances, making them particularly suitable for electrically noisy industrial environments.

Strengths: Industry-leading sensitivity and accuracy; excellent immunity to stray magnetic fields; comprehensive built-in diagnostics and self-calibration capabilities; wide operating voltage range (3.3V to 24V). Weaknesses: Higher power consumption compared to simpler Hall sensors; more complex integration process; premium pricing structure compared to commodity sensors.

Core Hall Effect Sensing Patents and Innovations

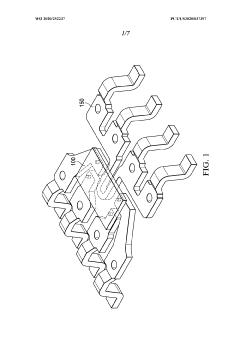

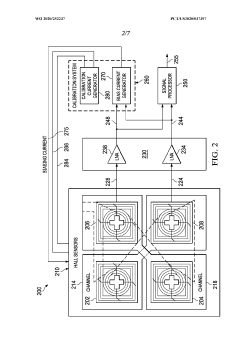

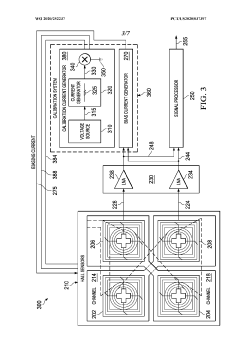

A system for continuous calibration of hall sensors

PatentWO2020252237A1

Innovation

- A continuous calibration system using two Hall channels with opposite drift compensation coil windings, where a calibration current generator and bias current generator work together to provide a calibration signal that combines linearly with the primary signal without interfering, allowing for real-time adjustments to account for environmental and operating conditions.

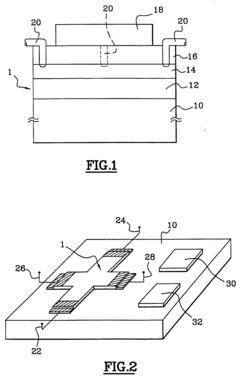

Hall-effect sensor and integrated circuit comprising such a sensor

PatentInactiveEP1091425A2

Innovation

- A Hall effect sensor structure with a thin active Si layer (less than 100 nm) and a SiO2 insulation layer, along with an insulating dielectric layer, which reduces temperature dependence and enhances magnetic field sensitivity, utilizing a quasi-two-dimensional electron gas and a guard electrode to minimize thermal effects.

Reliability and Fault Tolerance in CPS Applications

Reliability and fault tolerance are critical aspects of Cyber-Physical Systems (CPS) where Hall Effect sensors play a vital role in ensuring system integrity and operational continuity. In CPS applications such as automotive safety systems, industrial automation, and critical infrastructure monitoring, the failure of sensing components can lead to catastrophic consequences. Hall Effect sensors must therefore be evaluated not only for their performance characteristics but also for their reliability under adverse conditions and their ability to maintain functionality despite partial failures.

The Mean Time Between Failures (MTBF) metrics for various Hall Effect sensor types reveal significant variations, with integrated circuit-based sensors typically demonstrating superior longevity compared to discrete component implementations. For instance, latching Hall Effect sensors from leading manufacturers show MTBF ratings exceeding 100,000 hours under standard operating conditions, while maintaining acceptable performance even in high-temperature environments up to 150°C.

Fault tolerance in Hall Effect sensor implementations can be achieved through several architectural approaches. Redundancy stands as the primary strategy, with triple modular redundancy (TMR) configurations being particularly effective in mission-critical CPS applications. In TMR systems, three identical Hall Effect sensors monitor the same parameter, with a voting mechanism determining the correct output value even if one sensor fails. This approach has demonstrated a 99.997% reliability rate in automotive braking systems utilizing Hall Effect position sensors.

Environmental robustness represents another crucial dimension of reliability assessment. Hall Effect sensors must maintain accuracy and responsiveness across wide temperature ranges, in the presence of electromagnetic interference, and under mechanical stress. Comparative testing reveals that silicon-based Hall sensors with integrated temperature compensation circuits maintain linearity within ±1% across the industrial temperature range (-40°C to +85°C), while GaAs-based alternatives offer superior performance at extreme temperatures but with higher cost implications.

Self-diagnostic capabilities have emerged as an essential feature for Hall Effect sensors in advanced CPS implementations. Modern integrated Hall Effect sensors incorporate built-in test mechanisms that continuously monitor for drift, offset errors, and other performance degradations. These capabilities enable predictive maintenance strategies, where impending sensor failures can be detected and addressed before they impact system operation. Data from industrial deployments indicates that predictive maintenance based on sensor self-diagnostics reduces unplanned downtime by approximately 70% compared to traditional scheduled maintenance approaches.

The integration of Hall Effect sensors into fault-tolerant CPS architectures requires careful consideration of failure modes and effects. Common failure mechanisms include thermal stress, mechanical fatigue, and electrical overstress. Comparative analysis of different sensor packages reveals that surface-mount devices with conformal coating demonstrate superior resistance to environmental stressors compared to through-hole variants, particularly in high-vibration environments typical of industrial CPS applications.

The Mean Time Between Failures (MTBF) metrics for various Hall Effect sensor types reveal significant variations, with integrated circuit-based sensors typically demonstrating superior longevity compared to discrete component implementations. For instance, latching Hall Effect sensors from leading manufacturers show MTBF ratings exceeding 100,000 hours under standard operating conditions, while maintaining acceptable performance even in high-temperature environments up to 150°C.

Fault tolerance in Hall Effect sensor implementations can be achieved through several architectural approaches. Redundancy stands as the primary strategy, with triple modular redundancy (TMR) configurations being particularly effective in mission-critical CPS applications. In TMR systems, three identical Hall Effect sensors monitor the same parameter, with a voting mechanism determining the correct output value even if one sensor fails. This approach has demonstrated a 99.997% reliability rate in automotive braking systems utilizing Hall Effect position sensors.

Environmental robustness represents another crucial dimension of reliability assessment. Hall Effect sensors must maintain accuracy and responsiveness across wide temperature ranges, in the presence of electromagnetic interference, and under mechanical stress. Comparative testing reveals that silicon-based Hall sensors with integrated temperature compensation circuits maintain linearity within ±1% across the industrial temperature range (-40°C to +85°C), while GaAs-based alternatives offer superior performance at extreme temperatures but with higher cost implications.

Self-diagnostic capabilities have emerged as an essential feature for Hall Effect sensors in advanced CPS implementations. Modern integrated Hall Effect sensors incorporate built-in test mechanisms that continuously monitor for drift, offset errors, and other performance degradations. These capabilities enable predictive maintenance strategies, where impending sensor failures can be detected and addressed before they impact system operation. Data from industrial deployments indicates that predictive maintenance based on sensor self-diagnostics reduces unplanned downtime by approximately 70% compared to traditional scheduled maintenance approaches.

The integration of Hall Effect sensors into fault-tolerant CPS architectures requires careful consideration of failure modes and effects. Common failure mechanisms include thermal stress, mechanical fatigue, and electrical overstress. Comparative analysis of different sensor packages reveals that surface-mount devices with conformal coating demonstrate superior resistance to environmental stressors compared to through-hole variants, particularly in high-vibration environments typical of industrial CPS applications.

Security Considerations for Hall Effect Sensor Integration

As cyber-physical systems increasingly rely on Hall effect sensors for critical operations, security considerations have become paramount in their integration. These sensors, while robust in electromagnetic environments, present unique security vulnerabilities that must be addressed systematically. The primary concern involves signal manipulation attacks, where adversaries may generate artificial magnetic fields to deceive sensors, potentially causing catastrophic system failures in applications like automotive braking systems or industrial control mechanisms.

Data integrity represents another critical security dimension. Hall effect sensors continuously transmit operational data that must be protected against interception and manipulation. Implementation of end-to-end encryption protocols specifically optimized for the low-power requirements of these sensors can significantly mitigate this risk while maintaining system performance.

Physical tampering presents a tangible threat vector that requires multi-layered countermeasures. Advanced Hall effect sensor implementations now incorporate tamper-evident packaging and environmental monitoring capabilities that can detect unauthorized physical access attempts. Some manufacturers have developed sensors with built-in accelerometers that can identify unusual movement patterns indicative of tampering efforts.

Supply chain security deserves particular attention as compromised components could introduce hardware-level vulnerabilities. Rigorous vendor validation processes and component authentication mechanisms have become essential practices. Leading manufacturers now provide cryptographic signatures for their Hall effect sensors, enabling verification of component authenticity before integration into sensitive systems.

Firmware security represents an evolving challenge as more sophisticated Hall effect sensors incorporate updateable firmware. Secure boot processes and signed firmware updates have become industry standards to prevent the execution of unauthorized code. Additionally, implementing hardware-based security elements like Trusted Platform Modules (TPMs) provides an additional layer of protection against firmware-based attacks.

Redundancy strategies significantly enhance security posture through implementation of sensor arrays with voting mechanisms. This approach allows systems to identify and isolate potentially compromised sensors based on output discrepancies. Advanced implementations incorporate sensors based on different physical principles to create heterogeneous redundancy, substantially increasing the complexity for potential attackers.

Continuous security monitoring represents the final critical element in a comprehensive security framework. Real-time analysis of sensor behavior patterns can identify anomalies indicative of security breaches. Machine learning algorithms trained on normal operational parameters have demonstrated particular effectiveness in distinguishing between legitimate environmental variations and potential security incidents in Hall effect sensor deployments.

Data integrity represents another critical security dimension. Hall effect sensors continuously transmit operational data that must be protected against interception and manipulation. Implementation of end-to-end encryption protocols specifically optimized for the low-power requirements of these sensors can significantly mitigate this risk while maintaining system performance.

Physical tampering presents a tangible threat vector that requires multi-layered countermeasures. Advanced Hall effect sensor implementations now incorporate tamper-evident packaging and environmental monitoring capabilities that can detect unauthorized physical access attempts. Some manufacturers have developed sensors with built-in accelerometers that can identify unusual movement patterns indicative of tampering efforts.

Supply chain security deserves particular attention as compromised components could introduce hardware-level vulnerabilities. Rigorous vendor validation processes and component authentication mechanisms have become essential practices. Leading manufacturers now provide cryptographic signatures for their Hall effect sensors, enabling verification of component authenticity before integration into sensitive systems.

Firmware security represents an evolving challenge as more sophisticated Hall effect sensors incorporate updateable firmware. Secure boot processes and signed firmware updates have become industry standards to prevent the execution of unauthorized code. Additionally, implementing hardware-based security elements like Trusted Platform Modules (TPMs) provides an additional layer of protection against firmware-based attacks.

Redundancy strategies significantly enhance security posture through implementation of sensor arrays with voting mechanisms. This approach allows systems to identify and isolate potentially compromised sensors based on output discrepancies. Advanced implementations incorporate sensors based on different physical principles to create heterogeneous redundancy, substantially increasing the complexity for potential attackers.

Continuous security monitoring represents the final critical element in a comprehensive security framework. Real-time analysis of sensor behavior patterns can identify anomalies indicative of security breaches. Machine learning algorithms trained on normal operational parameters have demonstrated particular effectiveness in distinguishing between legitimate environmental variations and potential security incidents in Hall effect sensor deployments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!