Advanced Measurement Methods For Accurate Seebeck And Thermal Conductivity Data

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Measurement Background and Objectives

Thermoelectric materials have garnered significant attention over the past decades due to their unique ability to convert heat directly into electricity through the Seebeck effect, or conversely, to generate a temperature gradient when electricity is applied through the Peltier effect. The efficiency of thermoelectric devices is primarily determined by the dimensionless figure of merit ZT, which depends on the Seebeck coefficient, electrical conductivity, and thermal conductivity of the material. Accurate measurement of these parameters is therefore crucial for the development and optimization of high-performance thermoelectric materials.

The historical development of thermoelectric measurement techniques dates back to the early 19th century when Thomas Johann Seebeck first observed the phenomenon in 1821. Since then, measurement methodologies have evolved significantly, from rudimentary setups to sophisticated automated systems capable of measuring multiple parameters simultaneously under various conditions. Despite these advancements, achieving high accuracy and reproducibility in thermoelectric measurements remains challenging due to the complex interplay of thermal and electrical phenomena.

Current measurement techniques for Seebeck coefficient and thermal conductivity face several limitations. Traditional steady-state methods often suffer from heat losses and contact resistance issues, while transient techniques may introduce measurement artifacts due to non-equilibrium conditions. Additionally, the temperature dependence of these properties necessitates measurements across wide temperature ranges, further complicating the experimental setup and data interpretation.

The primary objective of this technical research is to investigate and evaluate advanced measurement methods that can provide more accurate and reliable data for Seebeck coefficient and thermal conductivity. This includes exploring novel experimental setups, innovative sensor technologies, and improved data analysis algorithms that can minimize systematic errors and enhance measurement precision.

Furthermore, this research aims to establish standardized protocols for thermoelectric measurements to ensure consistency and comparability of results across different laboratories and research groups. This standardization is essential for accelerating material discovery and optimization processes in the thermoelectric field.

Another key goal is to develop measurement techniques capable of characterizing emerging nanostructured thermoelectric materials, which often exhibit size-dependent properties that cannot be accurately measured using conventional methods. This includes addressing challenges related to sample preparation, temperature control at nanoscale, and signal detection from small-volume specimens.

By advancing measurement methodologies for thermoelectric properties, this research ultimately seeks to facilitate the development of more efficient thermoelectric materials and devices, contributing to broader efforts in waste heat recovery, solid-state cooling, and sustainable energy generation technologies.

The historical development of thermoelectric measurement techniques dates back to the early 19th century when Thomas Johann Seebeck first observed the phenomenon in 1821. Since then, measurement methodologies have evolved significantly, from rudimentary setups to sophisticated automated systems capable of measuring multiple parameters simultaneously under various conditions. Despite these advancements, achieving high accuracy and reproducibility in thermoelectric measurements remains challenging due to the complex interplay of thermal and electrical phenomena.

Current measurement techniques for Seebeck coefficient and thermal conductivity face several limitations. Traditional steady-state methods often suffer from heat losses and contact resistance issues, while transient techniques may introduce measurement artifacts due to non-equilibrium conditions. Additionally, the temperature dependence of these properties necessitates measurements across wide temperature ranges, further complicating the experimental setup and data interpretation.

The primary objective of this technical research is to investigate and evaluate advanced measurement methods that can provide more accurate and reliable data for Seebeck coefficient and thermal conductivity. This includes exploring novel experimental setups, innovative sensor technologies, and improved data analysis algorithms that can minimize systematic errors and enhance measurement precision.

Furthermore, this research aims to establish standardized protocols for thermoelectric measurements to ensure consistency and comparability of results across different laboratories and research groups. This standardization is essential for accelerating material discovery and optimization processes in the thermoelectric field.

Another key goal is to develop measurement techniques capable of characterizing emerging nanostructured thermoelectric materials, which often exhibit size-dependent properties that cannot be accurately measured using conventional methods. This includes addressing challenges related to sample preparation, temperature control at nanoscale, and signal detection from small-volume specimens.

By advancing measurement methodologies for thermoelectric properties, this research ultimately seeks to facilitate the development of more efficient thermoelectric materials and devices, contributing to broader efforts in waste heat recovery, solid-state cooling, and sustainable energy generation technologies.

Market Analysis for Precision Thermoelectric Characterization

The global market for thermoelectric characterization equipment is experiencing robust growth, driven by increasing demand for precise measurement of Seebeck coefficients and thermal conductivity across multiple industries. Current market valuation stands at approximately 320 million USD with a compound annual growth rate of 6.8% projected through 2028, according to recent industry analyses.

The semiconductor and electronics sectors represent the largest market segments, collectively accounting for over 45% of the total market share. This dominance stems from the critical need for accurate thermal property measurements in developing next-generation electronic components with improved thermal management capabilities. The automotive industry follows closely, representing about 22% of the market, as manufacturers increasingly incorporate thermoelectric materials in vehicle systems for energy recovery and climate control applications.

Geographically, North America and Asia-Pacific regions lead the market, with respective shares of 36% and 34%. Europe accounts for approximately 24%, while the remaining 6% is distributed across other regions. China and South Korea have emerged as particularly fast-growing markets, with annual growth rates exceeding 9%, primarily due to substantial investments in semiconductor manufacturing and renewable energy technologies.

The customer base for precision thermoelectric characterization equipment can be segmented into three primary categories: research institutions (38%), industrial R&D facilities (42%), and quality control departments (20%). Research institutions primarily focus on fundamental material science and novel thermoelectric compounds, while industrial R&D facilities concentrate on practical applications and product development. Quality control departments utilize these technologies to ensure consistency in material properties during production processes.

Market demand is increasingly shifting toward integrated measurement systems that can simultaneously characterize multiple thermoelectric parameters with high accuracy and repeatability. Customers are willing to pay premium prices for systems offering automation, data analytics capabilities, and compatibility with existing laboratory information management systems. The average selling price for comprehensive thermoelectric characterization systems ranges from 75,000 to 250,000 USD, depending on measurement capabilities, accuracy levels, and automation features.

Industry surveys indicate that measurement accuracy and reproducibility remain the most critical purchasing factors, with 87% of customers ranking these as "extremely important." Other significant factors include measurement speed (68%), ease of use (62%), and after-sales support (58%). This underscores the market's prioritization of precision and reliability over cost considerations in this specialized equipment segment.

The semiconductor and electronics sectors represent the largest market segments, collectively accounting for over 45% of the total market share. This dominance stems from the critical need for accurate thermal property measurements in developing next-generation electronic components with improved thermal management capabilities. The automotive industry follows closely, representing about 22% of the market, as manufacturers increasingly incorporate thermoelectric materials in vehicle systems for energy recovery and climate control applications.

Geographically, North America and Asia-Pacific regions lead the market, with respective shares of 36% and 34%. Europe accounts for approximately 24%, while the remaining 6% is distributed across other regions. China and South Korea have emerged as particularly fast-growing markets, with annual growth rates exceeding 9%, primarily due to substantial investments in semiconductor manufacturing and renewable energy technologies.

The customer base for precision thermoelectric characterization equipment can be segmented into three primary categories: research institutions (38%), industrial R&D facilities (42%), and quality control departments (20%). Research institutions primarily focus on fundamental material science and novel thermoelectric compounds, while industrial R&D facilities concentrate on practical applications and product development. Quality control departments utilize these technologies to ensure consistency in material properties during production processes.

Market demand is increasingly shifting toward integrated measurement systems that can simultaneously characterize multiple thermoelectric parameters with high accuracy and repeatability. Customers are willing to pay premium prices for systems offering automation, data analytics capabilities, and compatibility with existing laboratory information management systems. The average selling price for comprehensive thermoelectric characterization systems ranges from 75,000 to 250,000 USD, depending on measurement capabilities, accuracy levels, and automation features.

Industry surveys indicate that measurement accuracy and reproducibility remain the most critical purchasing factors, with 87% of customers ranking these as "extremely important." Other significant factors include measurement speed (68%), ease of use (62%), and after-sales support (58%). This underscores the market's prioritization of precision and reliability over cost considerations in this specialized equipment segment.

Current Challenges in Seebeck and Thermal Conductivity Measurement

The accurate measurement of Seebeck coefficient and thermal conductivity presents significant challenges that impede progress in thermoelectric materials research. Traditional measurement techniques often suffer from systematic errors due to temperature gradient uncertainties, particularly in the Seebeck coefficient determination where even small temperature measurement inaccuracies can lead to substantial errors in the final values. Contact resistance between probes and samples introduces additional measurement artifacts that are difficult to quantify and eliminate.

Sample preparation remains a critical bottleneck, as measurements require specific geometries and surface conditions that may not represent real-world applications. Thin films and nanostructured materials pose particular difficulties due to their small thermal mass and the challenge of establishing stable temperature gradients across microscale dimensions. The thermal and electrical contact quality between the sample and measurement apparatus significantly influences results, yet achieving consistent, low-resistance contacts remains problematic across different material systems.

Temperature stability represents another fundamental challenge, as fluctuations during measurement can introduce noise and drift that mask the true material properties. This becomes especially problematic for materials exhibiting strong temperature-dependent behavior or when measuring near phase transitions. The measurement environment, including ambient temperature, humidity, and electromagnetic interference, further complicates obtaining reproducible data.

Cross-sensitivity between thermal and electrical measurements presents a methodological challenge, as the application of electrical current for Seebeck measurements can induce Joule heating that distorts the thermal gradient. Similarly, thermal conductivity measurements can be affected by radiative and convective heat losses that are difficult to account for mathematically, particularly at elevated temperatures where radiation becomes significant.

Calibration standards for thermoelectric measurements remain inadequate, with limited availability of reference materials that span the full range of properties encountered in advanced thermoelectric systems. This hampers inter-laboratory comparisons and validation of new measurement techniques. The lack of standardized measurement protocols further exacerbates this issue, leading to significant variations in reported values for identical materials across different research groups.

Time-dependent phenomena introduce additional complexity, as some materials exhibit aging effects or property changes during the measurement process itself. High-throughput screening methods, essential for accelerating materials discovery, remain underdeveloped for thermoelectric properties, limiting the pace of innovation in this field. These challenges collectively highlight the need for advanced measurement methodologies that can provide more accurate, reproducible, and relevant data for thermoelectric materials development.

Sample preparation remains a critical bottleneck, as measurements require specific geometries and surface conditions that may not represent real-world applications. Thin films and nanostructured materials pose particular difficulties due to their small thermal mass and the challenge of establishing stable temperature gradients across microscale dimensions. The thermal and electrical contact quality between the sample and measurement apparatus significantly influences results, yet achieving consistent, low-resistance contacts remains problematic across different material systems.

Temperature stability represents another fundamental challenge, as fluctuations during measurement can introduce noise and drift that mask the true material properties. This becomes especially problematic for materials exhibiting strong temperature-dependent behavior or when measuring near phase transitions. The measurement environment, including ambient temperature, humidity, and electromagnetic interference, further complicates obtaining reproducible data.

Cross-sensitivity between thermal and electrical measurements presents a methodological challenge, as the application of electrical current for Seebeck measurements can induce Joule heating that distorts the thermal gradient. Similarly, thermal conductivity measurements can be affected by radiative and convective heat losses that are difficult to account for mathematically, particularly at elevated temperatures where radiation becomes significant.

Calibration standards for thermoelectric measurements remain inadequate, with limited availability of reference materials that span the full range of properties encountered in advanced thermoelectric systems. This hampers inter-laboratory comparisons and validation of new measurement techniques. The lack of standardized measurement protocols further exacerbates this issue, leading to significant variations in reported values for identical materials across different research groups.

Time-dependent phenomena introduce additional complexity, as some materials exhibit aging effects or property changes during the measurement process itself. High-throughput screening methods, essential for accelerating materials discovery, remain underdeveloped for thermoelectric properties, limiting the pace of innovation in this field. These challenges collectively highlight the need for advanced measurement methodologies that can provide more accurate, reproducible, and relevant data for thermoelectric materials development.

State-of-the-Art Measurement Methodologies

01 Seebeck coefficient measurement techniques

Various techniques are employed to measure the Seebeck coefficient with high accuracy. These methods typically involve creating a temperature gradient across a sample and measuring the resulting voltage difference. Advanced setups include precise temperature control systems, high-sensitivity voltage measurement devices, and specialized sample holders to minimize measurement errors. Some techniques utilize simultaneous measurement of multiple parameters to improve accuracy and reliability of the Seebeck coefficient determination.- Seebeck coefficient measurement techniques: Various techniques are employed to measure the Seebeck coefficient with high accuracy. These methods typically involve creating a temperature gradient across a sample and measuring the resulting voltage difference. Advanced setups include precise temperature control systems, high-sensitivity voltage measurement instruments, and specialized sample holders to minimize measurement errors. Some techniques utilize simultaneous measurement of multiple parameters to improve accuracy and reliability of the Seebeck coefficient determination.

- Thermal conductivity measurement methods: Accurate measurement of thermal conductivity involves several established methods, including steady-state techniques and transient methods. These approaches require precise control of heat flow and temperature measurement at multiple points. Advanced systems incorporate reference materials for calibration, vacuum chambers to eliminate convection effects, and sophisticated data analysis algorithms to account for heat losses. Improvements in sensor technology and measurement protocols have significantly enhanced the accuracy of thermal conductivity measurements.

- Integrated measurement systems for thermoelectric properties: Integrated measurement systems enable simultaneous determination of multiple thermoelectric parameters, including both Seebeck coefficient and thermal conductivity. These comprehensive systems provide consistent measurement conditions, reducing systematic errors that might occur when using separate instruments. The integrated approach often incorporates automated measurement sequences, temperature stabilization mechanisms, and unified data processing algorithms to ensure high accuracy and reproducibility of results.

- Error reduction and calibration methods: Achieving high accuracy in thermoelectric measurements requires sophisticated error reduction and calibration techniques. These include the use of reference materials with well-established properties, compensation for contact resistance effects, elimination of thermal and electrical noise, and correction for radiation heat losses. Advanced calibration protocols involve multiple measurement cycles under varying conditions to identify and quantify systematic errors, allowing for their mathematical correction in the final results.

- Specialized equipment for high-precision measurements: High-precision measurements of thermoelectric properties rely on specialized equipment designed to minimize measurement uncertainties. These systems feature advanced temperature controllers with stability in the millikelvin range, ultra-sensitive voltage measurement capabilities, and sophisticated sample mounting arrangements that ensure excellent thermal and electrical contacts. Some equipment incorporates vacuum or controlled atmosphere chambers to eliminate environmental influences, while others use differential measurement techniques to cancel out common-mode errors.

02 Thermal conductivity measurement apparatus

Specialized apparatus designed for measuring thermal conductivity with high precision typically include heat source components, temperature sensors, and thermal insulation systems. These devices often employ the steady-state or transient methods to determine thermal conductivity values. Advanced systems may incorporate vacuum chambers to eliminate convective heat transfer, reference materials for calibration, and automated data acquisition systems to reduce human error and improve measurement accuracy.Expand Specific Solutions03 Combined measurement systems for thermoelectric properties

Integrated systems that simultaneously measure multiple thermoelectric parameters, including both Seebeck coefficient and thermal conductivity, provide more consistent and accurate results. These systems ensure that measurements are taken under identical conditions, reducing systematic errors. The combined approach often includes temperature gradient control, electrical resistance measurement, and heat flow monitoring in a single apparatus. This integration allows for more comprehensive characterization of thermoelectric materials and improves the accuracy of figure-of-merit calculations.Expand Specific Solutions04 Error reduction and calibration methods

Various techniques are employed to enhance measurement accuracy through error reduction and calibration. These include the use of reference materials with known properties, statistical analysis of multiple measurements, compensation for contact resistance and heat losses, and environmental control to eliminate external influences. Advanced calibration procedures may involve comparison with standard samples, temperature stabilization protocols, and correction algorithms to account for systematic errors in the measurement system.Expand Specific Solutions05 Novel measurement methodologies for enhanced accuracy

Innovative approaches to measuring thermoelectric properties focus on overcoming traditional limitations and improving accuracy. These include non-contact measurement techniques, micro/nano-scale measurement methods, high-temperature measurement systems, and approaches that minimize thermal and electrical contact resistances. Some novel methodologies employ pulsed measurements, frequency domain analysis, or optical techniques to determine thermal and electrical properties with greater precision, particularly for challenging sample geometries or extreme operating conditions.Expand Specific Solutions

Leading Research Institutions and Equipment Manufacturers

The advanced measurement methods for accurate Seebeck and thermal conductivity data market is currently in a growth phase, with increasing demand driven by thermoelectric materials research and applications. The global market size is expanding as energy harvesting technologies gain prominence, estimated to reach several hundred million dollars by 2025. Leading academic institutions like Huazhong University of Science & Technology, California Institute of Technology, and Tsinghua University are advancing fundamental research, while companies such as Netzsch Gerätebau GmbH, Advance Riko, and EKO Instruments are commercializing measurement technologies. Samsung Electronics and NEC are integrating these technologies into broader thermal management solutions. The technology is approaching maturity in laboratory settings but still evolving for industrial applications, with ongoing improvements in measurement accuracy, repeatability, and high-temperature capabilities.

Advanced Industrial Science & Technology

Technical Solution: AIST has developed a comprehensive suite of measurement technologies for accurate thermoelectric characterization. Their approach combines multiple measurement principles to cross-validate results and minimize systematic errors. For Seebeck coefficient determination, AIST employs a differential temperature method with nano-volt resolution and temperature control within ±0.05K. Their thermal conductivity measurement system utilizes a hybrid approach combining steady-state and transient techniques, with specialized algorithms to separate electronic and lattice contributions to thermal transport. AIST has pioneered the development of reference materials specifically calibrated for thermoelectric measurements, establishing traceability chains to international measurement standards. Their measurement systems incorporate uncertainty quantification frameworks that provide comprehensive error analysis for each measurement, accounting for both random and systematic contributions. Recent innovations include the development of micro-probe techniques for spatial mapping of thermoelectric properties with resolution down to 10 micrometers, enabling detailed characterization of compositionally graded materials and interfaces.

Strengths: Comprehensive uncertainty quantification providing confidence intervals for measurements; established reference materials enhancing measurement traceability; advanced spatial mapping capabilities for heterogeneous materials. Weaknesses: Systems primarily designed for research environments rather than industrial testing; complex measurement protocols requiring specialized knowledge; higher initial investment compared to commercial alternatives.

Netzsch Gerätebau GmbH

Technical Solution: Netzsch has developed comprehensive thermal analysis systems specifically designed for precise Seebeck coefficient and thermal conductivity measurements. Their LFA (Laser Flash Apparatus) technology employs a non-contact, laser-based method that measures thermal diffusivity directly, from which thermal conductivity is calculated using specific heat capacity and density values. For Seebeck coefficient measurements, Netzsch's SBA (Seebeck Coefficient and Electrical Conductivity Analyzer) systems utilize a differential temperature method with precisely controlled temperature gradients and high-resolution voltage measurements. Their integrated ZEM series combines both measurements in a single platform, allowing simultaneous characterization of thermoelectric materials from room temperature up to 1500°C with accuracy within 3-5%. Netzsch's systems incorporate reference material calibration protocols and automated measurement sequences to minimize operator error and ensure reproducibility across different laboratories.

Strengths: Industry-leading measurement accuracy (±3% for thermal conductivity, ±5% for Seebeck coefficient); comprehensive temperature range capability (80K to 1500°C); integrated software for data analysis and material property calculation. Weaknesses: High equipment cost limiting accessibility; requires specialized training for optimal operation; measurement times can be lengthy for high-precision results.

Critical Patents and Literature in Advanced Thermoelectric Metrology

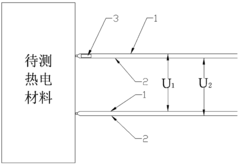

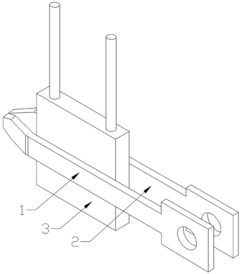

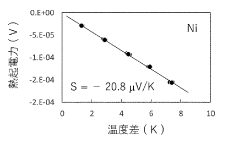

Method for high precision measurement of Seebeck coefficient of thermoelectric material

PatentActiveCN108761172A

Innovation

- A test probe composed of copper and constantan is used, and the detection contact point is formed by welding, and a group of probes is heated, the temperature difference is used to detect the voltage difference, and the accurate Seebeck coefficient is obtained through signal amplification and analog-to-digital conversion.

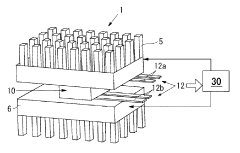

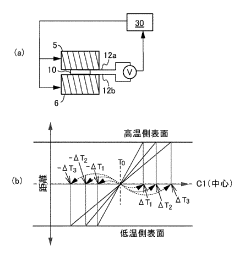

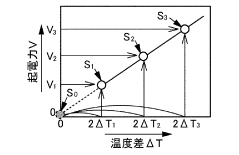

Device and method for measuring seebeck coefficient

PatentActiveJP2020134237A

Innovation

- A method and apparatus using high and low temperature variable heat sources, such as Peltier elements, are employed to independently control temperature differences across a plate-shaped sample, allowing for accurate measurement of electromotive force while maintaining a constant temperature at the center, enabling precise calculation of the Seebeck coefficient.

Standardization and Calibration Protocols

Standardization and calibration protocols represent a critical foundation for ensuring the reliability and reproducibility of Seebeck coefficient and thermal conductivity measurements. The thermoelectric research community has recognized the urgent need for unified measurement standards, as inconsistencies between laboratories have historically led to significant data variations, sometimes exceeding 20% for identical materials. These discrepancies undermine scientific progress and industrial applications of thermoelectric technologies.

The National Institute of Standards and Technology (NIST) has developed reference materials specifically for thermoelectric measurements, including SRM 3451 for Seebeck coefficient calibration and SRM 8420 for thermal conductivity validation. These standards provide researchers with reliable benchmarks against which to calibrate their measurement systems, significantly reducing systematic errors in data collection.

Round-robin testing programs have emerged as an effective approach to standardization, wherein identical samples circulate among multiple laboratories for comparative measurements. The European Metrology Programme for Innovation and Research (EMPIR) has coordinated several such initiatives, revealing common sources of measurement error and establishing best practices for equipment calibration. These collaborative efforts have led to the development of detailed procedural guidelines that address temperature gradient control, contact resistance minimization, and environmental condition management.

Temperature calibration represents a particularly critical aspect of standardization protocols. High-precision thermocouples must undergo regular calibration against primary or secondary temperature standards, with documented traceability to national metrology institutes. The measurement community now recommends calibration intervals not exceeding six months for active research equipment, with verification measurements using reference materials before each significant experimental campaign.

Electrical measurement calibration for Seebeck coefficient determination requires attention to voltage offset compensation, thermoelectric effects in measurement circuits, and reference junction stability. Modern protocols incorporate automated verification sequences that detect drift and system instability before they compromise experimental data. Software-based calibration management systems now track calibration histories and automatically flag measurements taken with out-of-calibration equipment.

For thermal conductivity measurements, calibration protocols have evolved to address the unique challenges of different measurement techniques. Laser flash methods require calibration of both detector response and pulse characteristics, while steady-state techniques demand careful calibration of heat flux sensors and thermal guards. Multi-parameter calibration approaches have demonstrated superior accuracy by accounting for interdependent measurement variables and their combined uncertainties.

The National Institute of Standards and Technology (NIST) has developed reference materials specifically for thermoelectric measurements, including SRM 3451 for Seebeck coefficient calibration and SRM 8420 for thermal conductivity validation. These standards provide researchers with reliable benchmarks against which to calibrate their measurement systems, significantly reducing systematic errors in data collection.

Round-robin testing programs have emerged as an effective approach to standardization, wherein identical samples circulate among multiple laboratories for comparative measurements. The European Metrology Programme for Innovation and Research (EMPIR) has coordinated several such initiatives, revealing common sources of measurement error and establishing best practices for equipment calibration. These collaborative efforts have led to the development of detailed procedural guidelines that address temperature gradient control, contact resistance minimization, and environmental condition management.

Temperature calibration represents a particularly critical aspect of standardization protocols. High-precision thermocouples must undergo regular calibration against primary or secondary temperature standards, with documented traceability to national metrology institutes. The measurement community now recommends calibration intervals not exceeding six months for active research equipment, with verification measurements using reference materials before each significant experimental campaign.

Electrical measurement calibration for Seebeck coefficient determination requires attention to voltage offset compensation, thermoelectric effects in measurement circuits, and reference junction stability. Modern protocols incorporate automated verification sequences that detect drift and system instability before they compromise experimental data. Software-based calibration management systems now track calibration histories and automatically flag measurements taken with out-of-calibration equipment.

For thermal conductivity measurements, calibration protocols have evolved to address the unique challenges of different measurement techniques. Laser flash methods require calibration of both detector response and pulse characteristics, while steady-state techniques demand careful calibration of heat flux sensors and thermal guards. Multi-parameter calibration approaches have demonstrated superior accuracy by accounting for interdependent measurement variables and their combined uncertainties.

Materials Science Impact and Applications

The accurate measurement of Seebeck coefficient and thermal conductivity has revolutionized materials science, enabling significant advancements across multiple industries. These thermoelectric properties serve as fundamental parameters for developing high-performance materials with applications ranging from energy harvesting to thermal management systems.

In the renewable energy sector, materials with optimized Seebeck coefficients have facilitated the development of more efficient thermoelectric generators, converting waste heat into usable electricity. This capability has particular relevance in automotive applications, where thermoelectric devices can recover energy from exhaust systems, potentially improving fuel efficiency by 3-5% in conventional vehicles and extending the range of electric vehicles.

Electronics cooling represents another critical application area benefiting from precise thermal conductivity measurements. As device miniaturization continues and power densities increase, materials with tailored thermal properties have become essential for managing heat dissipation in microprocessors, LEDs, and power electronics. Advanced thermal interface materials developed through accurate characterization have reduced junction temperatures by up to 15°C in high-performance computing applications.

The aerospace industry has leveraged these measurement techniques to develop specialized materials for thermal protection systems. Spacecraft heat shields and engine components require materials with precisely engineered thermal properties to withstand extreme temperature gradients. Accurate Seebeck and thermal conductivity data have enabled the design of materials that maintain structural integrity while providing thermal insulation or conductivity as needed.

Medical technology has also benefited substantially from these advancements. Thermal therapy devices utilize materials with well-characterized thermal properties to deliver precise temperature control for treatments ranging from hyperthermia cancer therapy to cryosurgery. Additionally, thermoelectric cooling systems in portable medical devices rely on materials optimized through accurate Seebeck coefficient measurements.

Building and construction applications have expanded with the development of advanced insulation materials and phase-change materials for thermal energy storage. These innovations, guided by precise thermal conductivity measurements, contribute to improved energy efficiency in buildings, potentially reducing heating and cooling energy consumption by 20-30%.

The impact extends to emerging technologies like flexible electronics and wearable devices, where thermal management presents unique challenges due to form factor constraints and human interface requirements. Materials characterized through advanced measurement methods have enabled the development of comfortable, efficient wearable systems with improved battery life and performance reliability.

In the renewable energy sector, materials with optimized Seebeck coefficients have facilitated the development of more efficient thermoelectric generators, converting waste heat into usable electricity. This capability has particular relevance in automotive applications, where thermoelectric devices can recover energy from exhaust systems, potentially improving fuel efficiency by 3-5% in conventional vehicles and extending the range of electric vehicles.

Electronics cooling represents another critical application area benefiting from precise thermal conductivity measurements. As device miniaturization continues and power densities increase, materials with tailored thermal properties have become essential for managing heat dissipation in microprocessors, LEDs, and power electronics. Advanced thermal interface materials developed through accurate characterization have reduced junction temperatures by up to 15°C in high-performance computing applications.

The aerospace industry has leveraged these measurement techniques to develop specialized materials for thermal protection systems. Spacecraft heat shields and engine components require materials with precisely engineered thermal properties to withstand extreme temperature gradients. Accurate Seebeck and thermal conductivity data have enabled the design of materials that maintain structural integrity while providing thermal insulation or conductivity as needed.

Medical technology has also benefited substantially from these advancements. Thermal therapy devices utilize materials with well-characterized thermal properties to deliver precise temperature control for treatments ranging from hyperthermia cancer therapy to cryosurgery. Additionally, thermoelectric cooling systems in portable medical devices rely on materials optimized through accurate Seebeck coefficient measurements.

Building and construction applications have expanded with the development of advanced insulation materials and phase-change materials for thermal energy storage. These innovations, guided by precise thermal conductivity measurements, contribute to improved energy efficiency in buildings, potentially reducing heating and cooling energy consumption by 20-30%.

The impact extends to emerging technologies like flexible electronics and wearable devices, where thermal management presents unique challenges due to form factor constraints and human interface requirements. Materials characterized through advanced measurement methods have enabled the development of comfortable, efficient wearable systems with improved battery life and performance reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!