Materials Doping Strategies To Balance Electrical Conductivity And Seebeck Coefficient

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Doping Background and Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, offering significant potential for waste heat recovery and sustainable energy generation. The historical development of thermoelectric technology dates back to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821, followed by the Peltier effect in 1834. However, widespread practical applications remained limited until the mid-20th century due to efficiency constraints.

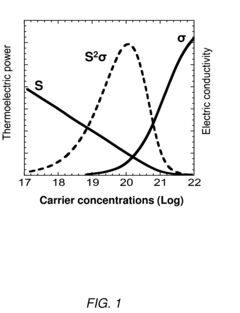

The fundamental challenge in thermoelectric materials lies in the inherent coupling between electrical conductivity and the Seebeck coefficient, which typically exhibit opposing trends when manipulated. This interdependence is captured in the figure of merit ZT = S²σT/κ, where S represents the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. Maximizing ZT requires simultaneous optimization of these parameters, presenting a complex materials science challenge.

Recent decades have witnessed accelerated research in thermoelectric materials, driven by environmental concerns and energy efficiency imperatives. The evolution of doping strategies has progressed from simple elemental substitutions to sophisticated band engineering approaches, enabling unprecedented control over electronic and thermal transport properties. This technological progression has elevated thermoelectric conversion efficiencies from less than 5% to exceeding 10% in laboratory settings.

Current global trends indicate growing interest in thermoelectric technology across automotive, industrial, and consumer electronics sectors. Market projections suggest a compound annual growth rate of approximately 8-10% for thermoelectric applications over the next decade, underscoring the economic potential of advances in this field. The increasing focus on carbon neutrality and energy harvesting further amplifies the strategic importance of thermoelectric materials research.

The primary objective of materials doping strategies is to decouple the traditionally interdependent parameters of electrical conductivity and Seebeck coefficient, allowing for simultaneous optimization. This involves developing novel approaches to manipulate electronic band structure, carrier concentration, and scattering mechanisms without compromising other thermoelectric properties. Specific goals include achieving ZT values consistently above 2.0 for commercial applications and developing materials that maintain high performance across broader temperature ranges.

Additional technical objectives include enhancing material stability under thermal cycling, reducing reliance on rare or toxic elements, and developing scalable synthesis methods compatible with existing manufacturing infrastructure. The ultimate aim is to position thermoelectric technology as a viable, cost-effective solution for waste heat recovery across multiple industrial sectors and temperature regimes, contributing significantly to global energy efficiency initiatives.

The fundamental challenge in thermoelectric materials lies in the inherent coupling between electrical conductivity and the Seebeck coefficient, which typically exhibit opposing trends when manipulated. This interdependence is captured in the figure of merit ZT = S²σT/κ, where S represents the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity. Maximizing ZT requires simultaneous optimization of these parameters, presenting a complex materials science challenge.

Recent decades have witnessed accelerated research in thermoelectric materials, driven by environmental concerns and energy efficiency imperatives. The evolution of doping strategies has progressed from simple elemental substitutions to sophisticated band engineering approaches, enabling unprecedented control over electronic and thermal transport properties. This technological progression has elevated thermoelectric conversion efficiencies from less than 5% to exceeding 10% in laboratory settings.

Current global trends indicate growing interest in thermoelectric technology across automotive, industrial, and consumer electronics sectors. Market projections suggest a compound annual growth rate of approximately 8-10% for thermoelectric applications over the next decade, underscoring the economic potential of advances in this field. The increasing focus on carbon neutrality and energy harvesting further amplifies the strategic importance of thermoelectric materials research.

The primary objective of materials doping strategies is to decouple the traditionally interdependent parameters of electrical conductivity and Seebeck coefficient, allowing for simultaneous optimization. This involves developing novel approaches to manipulate electronic band structure, carrier concentration, and scattering mechanisms without compromising other thermoelectric properties. Specific goals include achieving ZT values consistently above 2.0 for commercial applications and developing materials that maintain high performance across broader temperature ranges.

Additional technical objectives include enhancing material stability under thermal cycling, reducing reliance on rare or toxic elements, and developing scalable synthesis methods compatible with existing manufacturing infrastructure. The ultimate aim is to position thermoelectric technology as a viable, cost-effective solution for waste heat recovery across multiple industrial sectors and temperature regimes, contributing significantly to global energy efficiency initiatives.

Market Analysis for High-Efficiency Thermoelectric Applications

The global thermoelectric market is experiencing significant growth, driven by increasing demand for energy-efficient technologies and waste heat recovery systems. Current market valuations place the thermoelectric materials and devices sector at approximately 600 million USD in 2023, with projections indicating growth to reach 1.2 billion USD by 2030, representing a compound annual growth rate of 10.4%.

High-efficiency thermoelectric applications are gaining traction across multiple industries, with automotive and industrial sectors leading adoption. The automotive industry represents nearly 35% of the current market share, implementing thermoelectric generators to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions.

Consumer electronics manufacturers are increasingly incorporating thermoelectric cooling solutions, creating a rapidly expanding market segment with 15% annual growth. This trend is particularly evident in portable cooling devices, temperature-controlled containers, and specialized electronic components requiring precise thermal management.

Industrial waste heat recovery represents the most promising growth sector, with potential applications in power plants, manufacturing facilities, and chemical processing plants. Studies indicate that industrial processes waste approximately 20-50% of consumed energy as heat, presenting a substantial opportunity for thermoelectric harvesting technologies.

Materials innovation focusing on balancing electrical conductivity and Seebeck coefficient is directly addressing market demands for higher efficiency. Current commercial thermoelectric materials achieve ZT values (figure of merit) between 1-2, but market analysis indicates that achieving ZT values of 2-3 would unlock new application segments worth an estimated 500 million USD annually.

Regional market distribution shows North America and Asia-Pacific dominating with 30% and 45% market share respectively. China has emerged as both the largest producer and consumer of thermoelectric materials, driven by government initiatives promoting energy efficiency and industrial modernization.

Market barriers include high initial costs, with current thermoelectric solutions priced at 5-10 times conventional alternatives, limiting widespread adoption. However, price sensitivity analysis suggests that a 30% reduction in production costs would trigger exponential market growth, particularly in consumer applications.

Customer requirements analysis reveals efficiency as the primary purchasing factor, followed by durability and cost. End-users consistently indicate willingness to pay premium prices for thermoelectric solutions that demonstrate efficiency improvements of 20% or greater over previous generations, highlighting the direct market value of advanced doping strategies that successfully balance electrical conductivity and Seebeck coefficient.

High-efficiency thermoelectric applications are gaining traction across multiple industries, with automotive and industrial sectors leading adoption. The automotive industry represents nearly 35% of the current market share, implementing thermoelectric generators to convert waste heat from exhaust systems into usable electricity, thereby improving fuel efficiency and reducing emissions.

Consumer electronics manufacturers are increasingly incorporating thermoelectric cooling solutions, creating a rapidly expanding market segment with 15% annual growth. This trend is particularly evident in portable cooling devices, temperature-controlled containers, and specialized electronic components requiring precise thermal management.

Industrial waste heat recovery represents the most promising growth sector, with potential applications in power plants, manufacturing facilities, and chemical processing plants. Studies indicate that industrial processes waste approximately 20-50% of consumed energy as heat, presenting a substantial opportunity for thermoelectric harvesting technologies.

Materials innovation focusing on balancing electrical conductivity and Seebeck coefficient is directly addressing market demands for higher efficiency. Current commercial thermoelectric materials achieve ZT values (figure of merit) between 1-2, but market analysis indicates that achieving ZT values of 2-3 would unlock new application segments worth an estimated 500 million USD annually.

Regional market distribution shows North America and Asia-Pacific dominating with 30% and 45% market share respectively. China has emerged as both the largest producer and consumer of thermoelectric materials, driven by government initiatives promoting energy efficiency and industrial modernization.

Market barriers include high initial costs, with current thermoelectric solutions priced at 5-10 times conventional alternatives, limiting widespread adoption. However, price sensitivity analysis suggests that a 30% reduction in production costs would trigger exponential market growth, particularly in consumer applications.

Customer requirements analysis reveals efficiency as the primary purchasing factor, followed by durability and cost. End-users consistently indicate willingness to pay premium prices for thermoelectric solutions that demonstrate efficiency improvements of 20% or greater over previous generations, highlighting the direct market value of advanced doping strategies that successfully balance electrical conductivity and Seebeck coefficient.

Current Challenges in Conductivity-Seebeck Coefficient Trade-off

The fundamental challenge in thermoelectric materials development lies in the inherent coupling between electrical conductivity and the Seebeck coefficient, creating a seemingly insurmountable trade-off. This interdependence stems from the Pisarenko relation, which dictates that as carrier concentration increases to enhance electrical conductivity, the Seebeck coefficient inevitably decreases. This inverse relationship severely constrains the power factor optimization, which requires both parameters to be maximized simultaneously.

Current doping strategies face significant limitations in addressing this trade-off. Conventional approaches typically involve introducing dopants that either increase carrier concentration or modify band structure. However, these methods often produce one-dimensional improvements—enhancing electrical conductivity at the expense of the Seebeck coefficient, or vice versa—rather than achieving simultaneous optimization of both parameters.

Material complexity presents another substantial challenge. Different material systems respond uniquely to doping interventions, with complex interactions between dopants and host lattices that can produce unpredictable outcomes. For instance, dopants may introduce scattering centers that reduce carrier mobility, offsetting gains in carrier concentration. Additionally, the formation of secondary phases or defect clusters can compromise overall thermoelectric performance.

Energy filtering mechanisms, while theoretically promising for decoupling these parameters, have proven difficult to implement consistently across different material systems. The precise engineering of potential barriers at optimal energy levels remains elusive in practical applications, limiting the effectiveness of this approach.

Temperature stability represents a critical challenge for doping strategies. Many promising dopants exhibit excellent performance at specific temperature ranges but lose effectiveness at higher operating temperatures due to dopant migration, oxidation, or other degradation mechanisms. This temperature-dependent behavior significantly restricts the practical application range of thermoelectric devices.

Nanoscale engineering approaches, including quantum confinement effects and energy filtering at interfaces, offer potential pathways to overcome the trade-off but face substantial manufacturing challenges. Controlling dopant distribution and interface properties at the nanoscale remains prohibitively complex for large-scale production.

The absence of comprehensive theoretical models that accurately predict the combined effects of different doping strategies further complicates research efforts. Current models often fail to account for the complex interplay between electronic structure, phonon transport, and defect chemistry in doped materials, limiting researchers' ability to design optimal doping strategies through computational approaches.

Current doping strategies face significant limitations in addressing this trade-off. Conventional approaches typically involve introducing dopants that either increase carrier concentration or modify band structure. However, these methods often produce one-dimensional improvements—enhancing electrical conductivity at the expense of the Seebeck coefficient, or vice versa—rather than achieving simultaneous optimization of both parameters.

Material complexity presents another substantial challenge. Different material systems respond uniquely to doping interventions, with complex interactions between dopants and host lattices that can produce unpredictable outcomes. For instance, dopants may introduce scattering centers that reduce carrier mobility, offsetting gains in carrier concentration. Additionally, the formation of secondary phases or defect clusters can compromise overall thermoelectric performance.

Energy filtering mechanisms, while theoretically promising for decoupling these parameters, have proven difficult to implement consistently across different material systems. The precise engineering of potential barriers at optimal energy levels remains elusive in practical applications, limiting the effectiveness of this approach.

Temperature stability represents a critical challenge for doping strategies. Many promising dopants exhibit excellent performance at specific temperature ranges but lose effectiveness at higher operating temperatures due to dopant migration, oxidation, or other degradation mechanisms. This temperature-dependent behavior significantly restricts the practical application range of thermoelectric devices.

Nanoscale engineering approaches, including quantum confinement effects and energy filtering at interfaces, offer potential pathways to overcome the trade-off but face substantial manufacturing challenges. Controlling dopant distribution and interface properties at the nanoscale remains prohibitively complex for large-scale production.

The absence of comprehensive theoretical models that accurately predict the combined effects of different doping strategies further complicates research efforts. Current models often fail to account for the complex interplay between electronic structure, phonon transport, and defect chemistry in doped materials, limiting researchers' ability to design optimal doping strategies through computational approaches.

State-of-the-Art Doping Approaches for Performance Optimization

01 Doping with nanostructured materials

Incorporating nanostructured materials such as carbon nanotubes, graphene, or nanoparticles into thermoelectric materials can significantly enhance both electrical conductivity and Seebeck coefficient. These nanomaterials create additional electron pathways while simultaneously introducing energy filtering effects that can selectively scatter charge carriers based on their energy, leading to improved thermoelectric performance. The nanostructuring approach also helps reduce thermal conductivity through increased phonon scattering at interfaces.- Metal doping strategies for thermoelectric materials: Metal doping is a key strategy to enhance both electrical conductivity and Seebeck coefficient in thermoelectric materials. By introducing specific metal elements into the host material, carrier concentration can be optimized to achieve higher power factors. This approach often involves doping with transition metals or rare earth elements that can modify the electronic band structure while maintaining thermal properties. The controlled introduction of these dopants can create energy filtering effects that simultaneously improve electrical conductivity without significantly compromising the Seebeck coefficient.

- Nanostructuring and composite formation approaches: Nanostructuring and composite formation represent effective strategies for enhancing thermoelectric performance. By creating nanostructured materials or composites with carefully designed interfaces, phonon scattering can be increased while preserving electron transport. This approach allows for the decoupling of electrical and thermal properties, enabling simultaneous improvement of electrical conductivity and Seebeck coefficient. Techniques include incorporation of nanoinclusions, quantum dots, or formation of heterostructures that create energy filtering effects at interfaces, leading to enhanced power factors.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based materials offer unique opportunities for thermoelectric applications through strategic doping approaches. These materials can be modified through molecular doping, redox doping, or acid-base interactions to optimize carrier concentration and mobility. The flexibility in molecular design allows for tuning of the electronic structure to enhance both electrical conductivity and Seebeck coefficient. Conducting polymers with controlled doping levels can achieve improved power factors while maintaining advantages such as flexibility, light weight, and solution processability.

- Two-dimensional and layered material doping: Two-dimensional and layered materials present unique opportunities for thermoelectric performance enhancement through selective doping strategies. These materials, including graphene derivatives, transition metal dichalcogenides, and other 2D structures, can be modified through intercalation doping, substitutional doping, or surface functionalization. Their anisotropic nature allows for selective modification of electrical transport properties while maintaining favorable Seebeck characteristics. The confined electron transport in these structures can lead to quantum confinement effects that enhance the power factor.

- Band engineering and electronic structure modification: Band engineering approaches focus on modifying the electronic structure of materials to optimize thermoelectric properties. This includes strategies such as resonant level doping, band convergence, and energy filtering to enhance the Seebeck coefficient while maintaining good electrical conductivity. By introducing specific dopants that create resonant states near the Fermi level or by engineering band structures with high density of states, the power factor can be significantly improved. These approaches often involve careful selection of dopants that can modify the electronic density of states without introducing excessive scattering.

02 Heterogeneous element doping strategies

Strategic doping with heterogeneous elements can optimize the carrier concentration and mobility in thermoelectric materials. By introducing specific dopants such as halogens, transition metals, or rare earth elements, the electronic band structure can be modified to enhance the power factor (S²σ). Different dopants can be selected based on the base material to either increase carrier concentration or improve carrier mobility, with some dopants capable of simultaneously enhancing both electrical conductivity and Seebeck coefficient through band engineering.Expand Specific Solutions03 Composite material systems

Developing composite material systems by combining different thermoelectric materials or adding secondary phases can create synergistic effects that enhance both electrical conductivity and Seebeck coefficient. These composites often feature interfaces between dissimilar materials that allow high electrical conductivity while creating energy barriers that filter low-energy carriers, thereby increasing the Seebeck coefficient. The strategic combination of organic and inorganic materials or different semiconductor types can lead to enhanced power factors through complementary properties.Expand Specific Solutions04 Defect engineering and vacancy control

Controlling defects and vacancies in crystal structures provides a powerful approach to optimize thermoelectric properties. By intentionally creating specific types of defects or controlling vacancy concentrations, carrier concentration and mobility can be tuned independently. Point defects, dislocations, and grain boundaries can be engineered to scatter phonons (reducing thermal conductivity) while maintaining electron transport. This approach allows for decoupling the typically interdependent electrical conductivity and Seebeck coefficient.Expand Specific Solutions05 Band structure engineering

Modifying the electronic band structure of materials through doping or alloying can optimize the relationship between electrical conductivity and Seebeck coefficient. Techniques include convergence of electronic bands, increasing band degeneracy, introducing resonant levels, or creating quantum confinement effects. These approaches can increase the density of states near the Fermi level, which enhances the Seebeck coefficient without significantly reducing electrical conductivity. Band engineering strategies often focus on creating complex band structures with multiple valleys or bands contributing to transport.Expand Specific Solutions

Leading Research Groups and Companies in Thermoelectric Technology

The thermoelectric materials market for balancing electrical conductivity and Seebeck coefficient is currently in a growth phase, with increasing demand driven by energy efficiency applications. The global market is projected to reach significant scale as technologies mature from research to commercialization. Leading companies like Samsung Electronics, Toyota Motor Corp., and Infineon Technologies are investing heavily in advanced doping strategies, while specialized players such as ZT Plus LLC focus exclusively on thermoelectric optimization. Research institutions including MIT, KIST, and Shanghai Institute of Ceramics collaborate with industrial partners like Sumitomo Chemical and BASF to overcome the fundamental trade-off between conductivity and Seebeck coefficient. The technology is approaching commercial viability in niche applications, with broader adoption expected as materials performance improves through novel doping approaches.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed proprietary thermoelectric materials with optimized doping strategies primarily for automotive waste heat recovery applications. Their research focuses on silicide-based materials, particularly magnesium silicide and higher manganese silicides, which offer a balance of performance, cost, and environmental compatibility. Toyota's approach involves precise control of dopant concentration gradients across the material to create beneficial internal fields that enhance carrier transport[2]. Their materials employ dual-doping strategies where different dopants target specific aspects of the electronic structure - one optimizing carrier concentration while another modifies the band structure to enhance the Seebeck coefficient. Toyota has successfully demonstrated thermoelectric generators using these materials in vehicle exhaust systems, achieving power densities of 38 W/kg[5]. Their manufacturing process incorporates mechanical alloying and spark plasma sintering to create nanostructured bulk materials with controlled interfaces that scatter phonons more effectively than charge carriers. Toyota's latest generation materials achieve ZT values of approximately 1.4 at operating temperatures relevant to automotive applications.

Strengths: Materials optimized for real-world automotive applications; established manufacturing processes suitable for mass production; focus on environmentally friendly, abundant materials. Weaknesses: Performance still below theoretical limits; materials must withstand harsh automotive operating conditions; cost-performance balance still challenging for widespread adoption.

ZT Plus LLC

Technical Solution: ZT Plus LLC has developed advanced doping strategies for thermoelectric materials focusing on nanostructured bulk materials. Their proprietary technology involves precise control of dopant concentration and distribution to optimize the power factor (S²σ) while minimizing thermal conductivity. The company employs a multi-scale approach combining atomic-level doping with nano-inclusions that create energy filtering effects to enhance the Seebeck coefficient without significantly reducing electrical conductivity[1]. Their materials demonstrate ZT values exceeding 2.0 at operating temperatures, representing a significant improvement over conventional bulk thermoelectrics. ZT Plus utilizes modulation doping techniques where carriers are spatially separated from their parent dopants, reducing ionized impurity scattering while maintaining high carrier concentration[3]. Their manufacturing process incorporates ball milling and hot pressing to create nanostructured bulk materials with controlled grain boundaries that scatter phonons more effectively than electrons.

Strengths: Achieves higher ZT values through proprietary nanostructuring techniques; maintains manufacturing scalability for commercial applications; materials show enhanced stability at high operating temperatures. Weaknesses: Higher production costs compared to conventional thermoelectric materials; complex manufacturing process requires precise control; potential challenges in material integration with existing technologies.

Critical Patents and Literature on Balanced Thermoelectric Properties

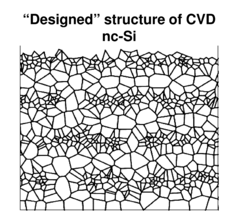

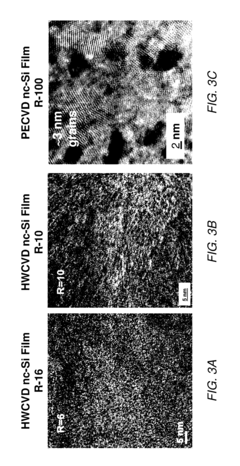

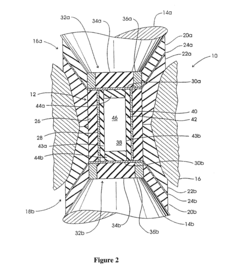

CVD Nanocrystalline Silicon Thermoelectric Material

PatentInactiveUS20160372651A1

Innovation

- A three-step process involving the deposition of doped nanocrystalline silicon thin films using hot-wire or plasma-enhanced chemical vapor deposition (CVD) with controlled H2:SiH4 ratios, followed by ion implantation and annealing, to achieve controllable grain sizes and dopant distribution, resulting in a germanium-free thermoelectric material with high electrical conductivity and low thermal conductivity.

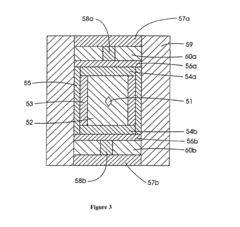

Affecting the thermoelectric figure of merit (ZT) and the power factor by high pressure, high temperature sintering

PatentInactiveUS20130001480A1

Innovation

- Applying elevated pressure (sintering pressure) and temperature (sintering temperature) to thermoelectric materials for a sufficient duration to enhance their ZT and power factor, which can persist at ambient conditions for extended periods, using HPHT treatments to alter the material's composition and defect structure.

Materials Sustainability and Environmental Impact Assessment

The sustainability implications of materials doping strategies for thermoelectric applications represent a critical dimension that must be evaluated alongside performance metrics. Current doping approaches often rely on rare, toxic, or environmentally problematic elements such as lead, tellurium, and various heavy metals that pose significant environmental and health concerns throughout their lifecycle.

When assessing the environmental impact of doped thermoelectric materials, lifecycle analysis reveals multiple pressure points. Mining operations for dopant elements frequently result in habitat destruction, water pollution, and substantial carbon emissions. Processing these materials typically requires energy-intensive methods and hazardous chemicals, further increasing the environmental footprint of thermoelectric devices.

The recyclability of doped materials presents another sustainability challenge. Complex material compositions with multiple dopants often complicate end-of-life recovery and reprocessing efforts. The intimate mixing of elements at the atomic scale makes separation particularly difficult, potentially rendering these advanced materials unsuitable for circular economy models.

Recent research has begun exploring more sustainable doping alternatives. Earth-abundant elements such as tin, zinc, and manganese are being investigated as potential substitutes for more problematic dopants. These alternatives aim to maintain the delicate balance between electrical conductivity and Seebeck coefficient while reducing environmental impact. Biomass-derived carbon materials have also shown promise as dopants in certain thermoelectric systems, offering renewable sourcing options.

Manufacturing innovations are equally important for sustainability improvements. Techniques such as solution processing and additive manufacturing can significantly reduce material waste and energy consumption compared to traditional methods. These approaches also enable more precise dopant distribution, potentially reducing the quantity of critical materials required.

Policy considerations increasingly influence material selection strategies. Regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) are restricting the use of certain toxic elements commonly employed as dopants. Forward-thinking research must anticipate these regulatory trends and develop compliant alternatives that maintain performance standards.

The ultimate sustainability goal involves developing thermoelectric materials that balance performance metrics with environmental considerations across their entire lifecycle. This holistic approach requires interdisciplinary collaboration between materials scientists, environmental engineers, and policy experts to create truly sustainable thermoelectric technologies that can contribute to global energy efficiency without introducing new environmental burdens.

When assessing the environmental impact of doped thermoelectric materials, lifecycle analysis reveals multiple pressure points. Mining operations for dopant elements frequently result in habitat destruction, water pollution, and substantial carbon emissions. Processing these materials typically requires energy-intensive methods and hazardous chemicals, further increasing the environmental footprint of thermoelectric devices.

The recyclability of doped materials presents another sustainability challenge. Complex material compositions with multiple dopants often complicate end-of-life recovery and reprocessing efforts. The intimate mixing of elements at the atomic scale makes separation particularly difficult, potentially rendering these advanced materials unsuitable for circular economy models.

Recent research has begun exploring more sustainable doping alternatives. Earth-abundant elements such as tin, zinc, and manganese are being investigated as potential substitutes for more problematic dopants. These alternatives aim to maintain the delicate balance between electrical conductivity and Seebeck coefficient while reducing environmental impact. Biomass-derived carbon materials have also shown promise as dopants in certain thermoelectric systems, offering renewable sourcing options.

Manufacturing innovations are equally important for sustainability improvements. Techniques such as solution processing and additive manufacturing can significantly reduce material waste and energy consumption compared to traditional methods. These approaches also enable more precise dopant distribution, potentially reducing the quantity of critical materials required.

Policy considerations increasingly influence material selection strategies. Regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) are restricting the use of certain toxic elements commonly employed as dopants. Forward-thinking research must anticipate these regulatory trends and develop compliant alternatives that maintain performance standards.

The ultimate sustainability goal involves developing thermoelectric materials that balance performance metrics with environmental considerations across their entire lifecycle. This holistic approach requires interdisciplinary collaboration between materials scientists, environmental engineers, and policy experts to create truly sustainable thermoelectric technologies that can contribute to global energy efficiency without introducing new environmental burdens.

Scalability and Manufacturing Considerations for Doped Materials

The scalability of doping strategies for thermoelectric materials represents a critical bridge between laboratory innovation and commercial viability. Current manufacturing processes for doped thermoelectric materials often involve complex multi-step procedures including high-temperature solid-state reactions, ball milling, hot pressing, and spark plasma sintering. These processes, while effective at laboratory scale, present significant challenges when scaled to industrial production volumes.

A key consideration in manufacturing scalability is the uniformity of dopant distribution throughout the host material. Non-uniform doping can create localized variations in electrical conductivity and Seebeck coefficient, resulting in suboptimal thermoelectric performance. Advanced mixing techniques such as mechanical alloying and solution-based processing have demonstrated improved homogeneity but require careful optimization to maintain consistency across larger batch sizes.

Cost factors significantly impact commercial viability of doped thermoelectric materials. Many high-performance dopants utilize rare earth elements or precious metals, which introduce substantial raw material costs. Manufacturing economics must balance material performance against production expenses, potentially necessitating compromise solutions that utilize more abundant dopant alternatives despite marginally reduced performance characteristics.

Energy consumption during manufacturing presents another critical consideration. Many current doping processes require extended high-temperature treatments, contributing significantly to production costs and environmental impact. Research into lower-temperature doping methods, including chemical vapor deposition and solution-based approaches, shows promise for reducing energy requirements while maintaining dopant effectiveness.

Quality control systems for large-scale production present unique challenges. Conventional characterization techniques used in research settings (such as Hall effect measurements and scanning electron microscopy) may be impractical for continuous production monitoring. Development of rapid, non-destructive testing methods capable of verifying dopant concentration and distribution represents an important frontier in manufacturing technology.

Environmental considerations increasingly influence manufacturing strategy development. Traditional doping processes may involve toxic precursors or generate hazardous waste streams. Sustainable manufacturing approaches emphasizing green chemistry principles, closed-loop material recovery, and reduced environmental footprint are gaining importance, particularly as regulatory frameworks evolve globally.

The transition from laboratory to industrial scale production requires careful attention to process repeatability and yield optimization. Statistical process control methodologies must be implemented to identify and mitigate sources of variation in dopant incorporation, ensuring consistent thermoelectric performance across production batches while minimizing material waste and manufacturing costs.

A key consideration in manufacturing scalability is the uniformity of dopant distribution throughout the host material. Non-uniform doping can create localized variations in electrical conductivity and Seebeck coefficient, resulting in suboptimal thermoelectric performance. Advanced mixing techniques such as mechanical alloying and solution-based processing have demonstrated improved homogeneity but require careful optimization to maintain consistency across larger batch sizes.

Cost factors significantly impact commercial viability of doped thermoelectric materials. Many high-performance dopants utilize rare earth elements or precious metals, which introduce substantial raw material costs. Manufacturing economics must balance material performance against production expenses, potentially necessitating compromise solutions that utilize more abundant dopant alternatives despite marginally reduced performance characteristics.

Energy consumption during manufacturing presents another critical consideration. Many current doping processes require extended high-temperature treatments, contributing significantly to production costs and environmental impact. Research into lower-temperature doping methods, including chemical vapor deposition and solution-based approaches, shows promise for reducing energy requirements while maintaining dopant effectiveness.

Quality control systems for large-scale production present unique challenges. Conventional characterization techniques used in research settings (such as Hall effect measurements and scanning electron microscopy) may be impractical for continuous production monitoring. Development of rapid, non-destructive testing methods capable of verifying dopant concentration and distribution represents an important frontier in manufacturing technology.

Environmental considerations increasingly influence manufacturing strategy development. Traditional doping processes may involve toxic precursors or generate hazardous waste streams. Sustainable manufacturing approaches emphasizing green chemistry principles, closed-loop material recovery, and reduced environmental footprint are gaining importance, particularly as regulatory frameworks evolve globally.

The transition from laboratory to industrial scale production requires careful attention to process repeatability and yield optimization. Statistical process control methodologies must be implemented to identify and mitigate sources of variation in dopant incorporation, ensuring consistent thermoelectric performance across production batches while minimizing material waste and manufacturing costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!