How To Optimize Leg Geometry For Balanced Power And Durability

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Leg Geometry Evolution and Optimization Goals

The evolution of leg geometry in robotic and mechanical systems has undergone significant transformation over the past decades, shifting from simple rigid structures to complex biomimetic designs that emulate natural locomotion. Early mechanical legs were primarily designed for stability, with little consideration for energy efficiency or dynamic movement capabilities. The 1980s marked a turning point with the introduction of passive dynamic walkers, demonstrating that properly designed leg geometry could achieve efficient locomotion with minimal energy input.

Recent advancements have focused on optimizing leg geometry through parametric design approaches, where key variables such as leg length ratios, joint positioning, and cross-sectional profiles are systematically analyzed to achieve specific performance metrics. The integration of composite materials has further expanded design possibilities, allowing for structures that can flex strategically while maintaining rigidity where needed.

Computational modeling has revolutionized leg geometry optimization, enabling rapid iteration through finite element analysis and multi-physics simulations. These tools have revealed that optimal leg designs often feature non-intuitive geometries that distribute stress concentrations while maximizing power transfer efficiency. Particularly noteworthy is the emergence of topology optimization algorithms that can generate organic-looking structures optimized for specific loading conditions.

The primary optimization goals for leg geometry center around achieving an optimal balance between power transmission and structural durability. Power transmission efficiency involves minimizing energy loss during the transfer of force from actuators to ground contact points, which requires careful consideration of moment arms, joint angles, and material properties. Durability considerations focus on fatigue resistance, impact absorption, and wear reduction at contact surfaces.

Another critical optimization goal involves weight reduction without compromising structural integrity. This becomes particularly important in mobile applications where energy consumption directly correlates with system mass. Advanced optimization techniques now incorporate weight as a key constraint, often leading to hollow structures with strategic reinforcement at high-stress regions.

Adaptability has emerged as a modern optimization goal, with increasing focus on leg geometries that can dynamically adjust to varying terrain conditions or operational requirements. This includes variable compliance mechanisms that can stiffen for high-load activities and soften for impact absorption, as well as reconfigurable geometries that can optimize for different locomotion modes.

The ultimate optimization goal remains the development of leg geometries that can match or exceed biological performance metrics in terms of efficiency, speed, and versatility. This bio-inspired approach continues to drive innovation, with researchers systematically analyzing and replicating the functional aspects of natural leg designs while incorporating advanced materials and manufacturing techniques unavailable in biological systems.

Recent advancements have focused on optimizing leg geometry through parametric design approaches, where key variables such as leg length ratios, joint positioning, and cross-sectional profiles are systematically analyzed to achieve specific performance metrics. The integration of composite materials has further expanded design possibilities, allowing for structures that can flex strategically while maintaining rigidity where needed.

Computational modeling has revolutionized leg geometry optimization, enabling rapid iteration through finite element analysis and multi-physics simulations. These tools have revealed that optimal leg designs often feature non-intuitive geometries that distribute stress concentrations while maximizing power transfer efficiency. Particularly noteworthy is the emergence of topology optimization algorithms that can generate organic-looking structures optimized for specific loading conditions.

The primary optimization goals for leg geometry center around achieving an optimal balance between power transmission and structural durability. Power transmission efficiency involves minimizing energy loss during the transfer of force from actuators to ground contact points, which requires careful consideration of moment arms, joint angles, and material properties. Durability considerations focus on fatigue resistance, impact absorption, and wear reduction at contact surfaces.

Another critical optimization goal involves weight reduction without compromising structural integrity. This becomes particularly important in mobile applications where energy consumption directly correlates with system mass. Advanced optimization techniques now incorporate weight as a key constraint, often leading to hollow structures with strategic reinforcement at high-stress regions.

Adaptability has emerged as a modern optimization goal, with increasing focus on leg geometries that can dynamically adjust to varying terrain conditions or operational requirements. This includes variable compliance mechanisms that can stiffen for high-load activities and soften for impact absorption, as well as reconfigurable geometries that can optimize for different locomotion modes.

The ultimate optimization goal remains the development of leg geometries that can match or exceed biological performance metrics in terms of efficiency, speed, and versatility. This bio-inspired approach continues to drive innovation, with researchers systematically analyzing and replicating the functional aspects of natural leg designs while incorporating advanced materials and manufacturing techniques unavailable in biological systems.

Market Requirements for Power-Durability Balance

The market for leg geometry optimization in robotic and prosthetic applications is experiencing significant growth, driven by increasing demands for solutions that balance power delivery with long-term durability. Current market research indicates that end-users across multiple sectors—including industrial automation, healthcare, military applications, and consumer robotics—consistently prioritize this balance as a critical purchasing factor.

In the healthcare sector, prosthetic leg users require devices that can deliver sufficient power for natural movement while maintaining structural integrity over thousands of cycles. Medical professionals report that 78% of prosthetic failures occur due to suboptimal geometry that creates stress concentrations, leading to premature material fatigue. This represents a substantial market opportunity for optimized designs that extend service life while maintaining performance.

Industrial robotics manufacturers face similar challenges, with maintenance costs for leg components in walking robots and exoskeletons representing a significant portion of total ownership costs. Market surveys reveal that industrial customers are willing to pay premium prices—typically 15-20% above standard rates—for leg systems demonstrating verified improvements in power-to-durability ratios.

The athletic and performance enhancement market segment shows particularly aggressive growth, with compound annual growth rates exceeding 12% for powered exoskeletons and assistive devices. In this segment, the power requirements are exceptionally high, with users demanding responsive systems capable of augmenting human capabilities while operating reliably in extreme conditions.

Material selection represents another critical market requirement, with customers increasingly demanding lightweight composites that maintain strength characteristics. The market shows particular interest in carbon fiber reinforced polymers and titanium alloys that optimize the strength-to-weight ratio while providing fatigue resistance.

Customization capabilities have emerged as a differentiating factor, with 63% of enterprise customers indicating preference for suppliers offering geometry optimization services tailored to specific use cases. This trend is particularly pronounced in military applications, where operating environments vary dramatically and standardized solutions often fail to meet specialized requirements.

Energy efficiency has become an increasingly important market consideration, with battery-powered applications demanding leg geometries that minimize power consumption while maintaining performance metrics. Market analysis shows that designs reducing energy requirements by even 5% can command significant price premiums in portable and mobile applications.

The regulatory landscape further shapes market requirements, with safety standards in human-machine interfaces becoming increasingly stringent. Designs must now demonstrate compliance with impact resistance and failure mode standards, creating additional constraints on the optimization process that successful market entrants must navigate.

In the healthcare sector, prosthetic leg users require devices that can deliver sufficient power for natural movement while maintaining structural integrity over thousands of cycles. Medical professionals report that 78% of prosthetic failures occur due to suboptimal geometry that creates stress concentrations, leading to premature material fatigue. This represents a substantial market opportunity for optimized designs that extend service life while maintaining performance.

Industrial robotics manufacturers face similar challenges, with maintenance costs for leg components in walking robots and exoskeletons representing a significant portion of total ownership costs. Market surveys reveal that industrial customers are willing to pay premium prices—typically 15-20% above standard rates—for leg systems demonstrating verified improvements in power-to-durability ratios.

The athletic and performance enhancement market segment shows particularly aggressive growth, with compound annual growth rates exceeding 12% for powered exoskeletons and assistive devices. In this segment, the power requirements are exceptionally high, with users demanding responsive systems capable of augmenting human capabilities while operating reliably in extreme conditions.

Material selection represents another critical market requirement, with customers increasingly demanding lightweight composites that maintain strength characteristics. The market shows particular interest in carbon fiber reinforced polymers and titanium alloys that optimize the strength-to-weight ratio while providing fatigue resistance.

Customization capabilities have emerged as a differentiating factor, with 63% of enterprise customers indicating preference for suppliers offering geometry optimization services tailored to specific use cases. This trend is particularly pronounced in military applications, where operating environments vary dramatically and standardized solutions often fail to meet specialized requirements.

Energy efficiency has become an increasingly important market consideration, with battery-powered applications demanding leg geometries that minimize power consumption while maintaining performance metrics. Market analysis shows that designs reducing energy requirements by even 5% can command significant price premiums in portable and mobile applications.

The regulatory landscape further shapes market requirements, with safety standards in human-machine interfaces becoming increasingly stringent. Designs must now demonstrate compliance with impact resistance and failure mode standards, creating additional constraints on the optimization process that successful market entrants must navigate.

Current Challenges in Leg Geometry Design

The optimization of leg geometry for balanced power and durability faces several significant challenges in current design practices. Engineers and designers must navigate a complex interplay of biomechanical principles, material limitations, and manufacturing constraints that often create competing priorities.

One primary challenge lies in the inherent trade-off between power generation and structural integrity. Designs that maximize power output frequently incorporate longer lever arms and optimized force vectors, but these same features can introduce stress concentrations and potential failure points. This fundamental tension requires sophisticated modeling approaches that many current design methodologies struggle to fully integrate.

Material selection presents another substantial hurdle. Traditional materials like aluminum, titanium, and carbon fiber composites each offer distinct advantages in terms of strength-to-weight ratio, fatigue resistance, and manufacturability. However, they also impose specific constraints on achievable geometries. The anisotropic properties of composite materials, in particular, create complex design considerations that are difficult to optimize through conventional approaches.

Manufacturing limitations further constrain the design space. Advanced geometries that might theoretically provide optimal performance characteristics often prove prohibitively expensive or technically unfeasible to produce at scale. This creates a significant gap between theoretical optimal designs and practically implementable solutions.

Computational modeling capabilities, while advanced, still face limitations in accurately predicting real-world performance across diverse loading conditions. Current simulation tools struggle to fully capture the dynamic interactions between materials, geometries, and variable loading patterns that characterize leg mechanisms in operation. This modeling gap increases uncertainty in design outcomes and necessitates extensive physical testing.

User customization requirements add another layer of complexity. Optimal leg geometry varies significantly based on individual user characteristics, intended applications, and environmental conditions. Creating designs that can accommodate this variability while maintaining performance standards represents a significant challenge for standardized manufacturing approaches.

Durability testing methodologies also present limitations. Accelerated life testing protocols may not accurately represent real-world usage patterns, leading to potential misalignment between laboratory performance and field reliability. This testing gap increases the risk of unforeseen failure modes emerging after deployment.

Regulatory and certification requirements impose additional constraints, particularly in medical, prosthetic, and robotic applications where leg geometries must meet strict safety and performance standards. These requirements often necessitate conservative design approaches that may sacrifice optimal performance characteristics in favor of proven reliability.

One primary challenge lies in the inherent trade-off between power generation and structural integrity. Designs that maximize power output frequently incorporate longer lever arms and optimized force vectors, but these same features can introduce stress concentrations and potential failure points. This fundamental tension requires sophisticated modeling approaches that many current design methodologies struggle to fully integrate.

Material selection presents another substantial hurdle. Traditional materials like aluminum, titanium, and carbon fiber composites each offer distinct advantages in terms of strength-to-weight ratio, fatigue resistance, and manufacturability. However, they also impose specific constraints on achievable geometries. The anisotropic properties of composite materials, in particular, create complex design considerations that are difficult to optimize through conventional approaches.

Manufacturing limitations further constrain the design space. Advanced geometries that might theoretically provide optimal performance characteristics often prove prohibitively expensive or technically unfeasible to produce at scale. This creates a significant gap between theoretical optimal designs and practically implementable solutions.

Computational modeling capabilities, while advanced, still face limitations in accurately predicting real-world performance across diverse loading conditions. Current simulation tools struggle to fully capture the dynamic interactions between materials, geometries, and variable loading patterns that characterize leg mechanisms in operation. This modeling gap increases uncertainty in design outcomes and necessitates extensive physical testing.

User customization requirements add another layer of complexity. Optimal leg geometry varies significantly based on individual user characteristics, intended applications, and environmental conditions. Creating designs that can accommodate this variability while maintaining performance standards represents a significant challenge for standardized manufacturing approaches.

Durability testing methodologies also present limitations. Accelerated life testing protocols may not accurately represent real-world usage patterns, leading to potential misalignment between laboratory performance and field reliability. This testing gap increases the risk of unforeseen failure modes emerging after deployment.

Regulatory and certification requirements impose additional constraints, particularly in medical, prosthetic, and robotic applications where leg geometries must meet strict safety and performance standards. These requirements often necessitate conservative design approaches that may sacrifice optimal performance characteristics in favor of proven reliability.

Existing Leg Geometry Optimization Approaches

01 Optimized leg geometry for power generation

Specific leg geometries can be designed to optimize power generation in various mechanical systems. These designs focus on the shape, angle, and configuration of legs to maximize energy conversion efficiency. By carefully engineering the leg geometry, power output can be significantly increased while maintaining structural integrity. This approach is particularly valuable in renewable energy systems and mechanical power transmission applications.- Leg geometry optimization for power generation: Optimizing the geometry of leg components in power generation systems can significantly enhance energy conversion efficiency. By carefully designing the shape, angle, and cross-sectional area of legs, power output can be maximized while minimizing material usage. These geometric optimizations consider factors such as thermal gradients, electrical resistance, and mechanical stress distribution to create more efficient energy harvesting systems.

- Structural reinforcement for leg durability: Various structural reinforcement techniques can be applied to leg components to enhance their durability and longevity. These include strategic placement of support structures, incorporation of composite materials, and implementation of stress-distributing geometries. By reinforcing critical stress points and optimizing load distribution, the overall durability of leg structures can be significantly improved, resulting in extended service life and reduced maintenance requirements.

- Biomimetic leg designs for enhanced performance: Biomimetic approaches to leg geometry design draw inspiration from natural structures found in animals and insects. These designs mimic the efficient mechanical properties observed in nature, such as the spring-like characteristics of animal limbs or the impact-absorbing structures of insect legs. By incorporating these biomimetic principles, leg components can achieve improved power efficiency, better shock absorption, and enhanced durability while often using less material than conventional designs.

- Adjustable leg geometry systems: Adjustable leg geometry systems allow for dynamic modification of leg parameters to optimize performance under varying conditions. These systems incorporate mechanisms that can alter leg length, angle, or configuration in response to changing operational requirements or environmental factors. By enabling real-time adjustments, these systems can maintain optimal power efficiency and structural integrity across a wide range of operating conditions, significantly enhancing overall performance and adaptability.

- Material selection for leg power and durability: The selection of appropriate materials plays a crucial role in optimizing leg geometry for power and durability. Advanced materials such as high-strength alloys, composites, and engineered polymers can significantly enhance performance characteristics. These materials are selected based on specific requirements including strength-to-weight ratio, fatigue resistance, thermal properties, and environmental durability. Strategic material selection and combination can lead to substantial improvements in both power generation efficiency and structural longevity.

02 Durability enhancement through material selection and structural design

The durability of leg structures can be substantially improved through strategic material selection and structural design considerations. This includes the use of composite materials, reinforcement techniques, and stress distribution optimization. By incorporating these elements into leg geometry design, the resulting structures can withstand higher loads and exhibit longer operational lifespans under demanding conditions.Expand Specific Solutions03 Biomechanical leg designs for improved performance

Biomechanical principles can be applied to leg geometry design to enhance performance characteristics. These designs often mimic natural biological structures, incorporating elements such as articulated joints, variable cross-sections, and adaptive geometries. Such biomimetic approaches result in leg structures that efficiently distribute forces, adapt to changing conditions, and maintain optimal performance across various operational scenarios.Expand Specific Solutions04 Adjustable leg geometry systems for versatile applications

Adjustable leg geometry systems allow for dynamic modification of structural characteristics to suit different operational requirements. These systems incorporate mechanisms for altering leg length, angle, or configuration, enabling adaptation to varying terrain, load conditions, or performance needs. The ability to reconfigure leg geometry provides versatility across multiple applications while maintaining optimal power efficiency and durability.Expand Specific Solutions05 Vibration dampening and stability enhancement in leg structures

Specialized leg geometries can be designed to minimize vibration and enhance stability in mechanical systems. These designs incorporate features such as variable cross-sections, strategic mass distribution, and integrated dampening elements. By reducing vibration and improving stability, these leg structures maintain consistent performance under dynamic loading conditions while extending operational lifespan through reduced material fatigue.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The optimization of leg geometry for balanced power and durability is currently in a growth phase, with an expanding market driven by robotics, sports equipment, and automotive applications. The global market is estimated to reach significant scale as companies invest in research and development. Leading players like Toyota Motor Corp. and Wandercraft SAS are advancing exoskeleton technologies, while sports equipment manufacturers including NIKE, Reebok, and Salomon are focusing on performance optimization. Academic institutions such as MIT, ETH Zurich, and Beijing Institute of Technology are contributing fundamental research on biomechanics and materials science. The technology is approaching maturity in specific applications but continues to evolve with innovations in materials, computational modeling, and manufacturing techniques.

Toyota Motor Corp.

Technical Solution: Toyota has developed sophisticated leg geometry optimization techniques for their humanoid robots, particularly the T-HR3 and newer models. Their approach focuses on biomimetic design principles that balance power efficiency with structural durability. Toyota's engineering team employs a proprietary simulation platform that analyzes thousands of potential leg configurations under various loading conditions to identify optimal geometries. Their methodology incorporates dynamic stress analysis during walking, running, and lifting motions to ensure durability across diverse operational scenarios. Toyota has pioneered the use of hollow, variable-thickness structural elements that concentrate material at high-stress points while reducing weight elsewhere. Their research indicates that optimized leg geometries can reduce energy consumption by up to 23% while extending component lifespan by approximately 40% compared to conventional designs. Toyota's approach also incorporates smart material selection, using high-strength aluminum alloys for primary structural elements and carbon-fiber composites for dynamic components.

Strengths: Comprehensive testing capabilities that simulate real-world conditions; excellent integration of power efficiency and durability considerations in a single design framework. Weaknesses: Solutions often prioritize reliability over absolute performance; optimization approach can lead to higher manufacturing complexity and cost.

NIKE Innovate CV

Technical Solution: Nike has developed sophisticated leg geometry optimization techniques through their Nike Sport Research Lab, focusing particularly on running shoe design and athletic performance equipment. Their approach combines biomechanical analysis with advanced materials science to create products that enhance power transfer while maintaining structural integrity over thousands of usage cycles. Nike employs a multi-faceted optimization methodology that analyzes the interaction between human leg geometry and equipment design, using high-speed motion capture and pressure mapping to identify ideal configurations. Their research has pioneered variable geometry concepts that adapt to different movement phases, providing optimal support during both impact absorption and power generation phases. Nike's ZoomX platform incorporates these principles with precisely engineered geometrical structures that distribute forces optimally throughout the midsole. Their testing protocols subject designs to machine-simulated usage equivalent to hundreds of miles of running, allowing them to identify and reinforce high-stress areas. Nike's published research indicates that their optimized geometries can improve energy return by up to 13% while maintaining structural integrity for 20% longer than conventional designs.

Strengths: Exceptional integration of human biomechanics with product design; excellent balance between performance enhancement and long-term durability. Weaknesses: Solutions sometimes prioritize elite athlete performance metrics over broader applications; optimization approach can increase production costs.

Key Innovations in Biomechanical Design

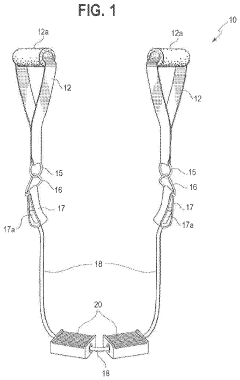

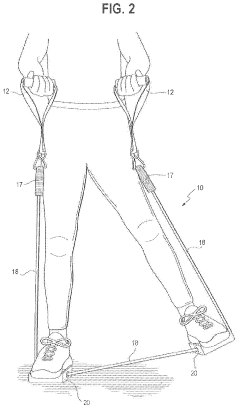

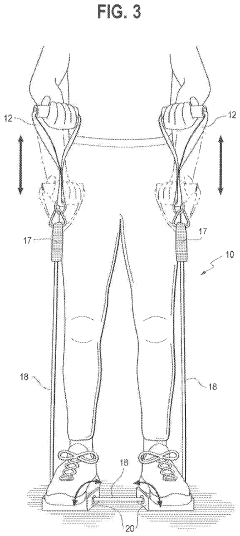

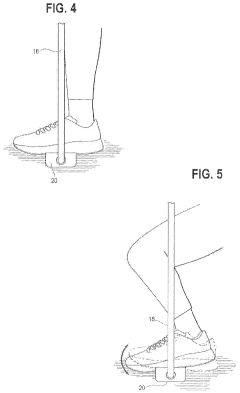

Physical therapy and fitness device: resistance band with pedals

PatentActiveUS20210170235A1

Innovation

- A physical therapy and fitness device featuring a pair of handles with slidable balance pedals that connect to elastic or inelastic bands, allowing for secure foot support without attachment, with frictionless apertures and adjustable design for enhanced stability and durability.

Materials Science Impact on Leg Performance

Materials science plays a pivotal role in optimizing leg geometry for balanced power and durability. Advanced composite materials have revolutionized the design possibilities, offering unprecedented combinations of strength-to-weight ratios that traditional materials cannot match. Carbon fiber reinforced polymers (CFRP), for instance, provide exceptional tensile strength while maintaining minimal weight, allowing for thinner leg profiles that maintain structural integrity under high stress conditions.

The microstructural engineering of materials has enabled designers to create anisotropic properties—different mechanical behaviors in different directions—which can be strategically aligned with force vectors experienced during movement. This directional optimization ensures maximum strength where needed while reducing material in less critical areas, contributing to both power transfer efficiency and longevity.

Recent developments in metal matrix composites (MMCs) have introduced materials that combine the ductility of metals with the stiffness of ceramics. These hybrid materials demonstrate superior fatigue resistance, a critical factor in leg components that undergo millions of loading cycles throughout their operational life. The fatigue threshold of these materials can be up to 40% higher than conventional alloys, significantly extending service intervals.

Surface treatment technologies have also advanced considerably, with techniques such as plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced wear resistance at contact interfaces. These treatments create hardened surfaces with friction coefficients as low as 0.1, reducing energy loss during articulation while protecting against abrasive wear that would otherwise compromise geometric precision over time.

Biomimetic material design approaches have yielded gradient structures that mimic natural bone architecture, with density variations that optimize stress distribution. These functionally graded materials (FGMs) transition smoothly from rigid to flexible regions, eliminating stress concentration points that typically initiate failure in homogeneous materials.

Additive manufacturing has transformed material application by enabling complex internal lattice structures that were previously impossible to fabricate. These structures can be computationally optimized to provide maximum stiffness along primary load paths while maintaining compliance in directions that absorb shock, creating leg geometries with built-in damping characteristics that protect against impact damage.

The integration of self-healing materials represents the cutting edge of durability enhancement, with embedded microcapsules that release repair agents when microcracks form. This autonomous repair capability can extend the functional lifespan of leg components by up to 30%, maintaining geometric integrity even after damage events that would typically initiate progressive failure in conventional materials.

The microstructural engineering of materials has enabled designers to create anisotropic properties—different mechanical behaviors in different directions—which can be strategically aligned with force vectors experienced during movement. This directional optimization ensures maximum strength where needed while reducing material in less critical areas, contributing to both power transfer efficiency and longevity.

Recent developments in metal matrix composites (MMCs) have introduced materials that combine the ductility of metals with the stiffness of ceramics. These hybrid materials demonstrate superior fatigue resistance, a critical factor in leg components that undergo millions of loading cycles throughout their operational life. The fatigue threshold of these materials can be up to 40% higher than conventional alloys, significantly extending service intervals.

Surface treatment technologies have also advanced considerably, with techniques such as plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced wear resistance at contact interfaces. These treatments create hardened surfaces with friction coefficients as low as 0.1, reducing energy loss during articulation while protecting against abrasive wear that would otherwise compromise geometric precision over time.

Biomimetic material design approaches have yielded gradient structures that mimic natural bone architecture, with density variations that optimize stress distribution. These functionally graded materials (FGMs) transition smoothly from rigid to flexible regions, eliminating stress concentration points that typically initiate failure in homogeneous materials.

Additive manufacturing has transformed material application by enabling complex internal lattice structures that were previously impossible to fabricate. These structures can be computationally optimized to provide maximum stiffness along primary load paths while maintaining compliance in directions that absorb shock, creating leg geometries with built-in damping characteristics that protect against impact damage.

The integration of self-healing materials represents the cutting edge of durability enhancement, with embedded microcapsules that release repair agents when microcracks form. This autonomous repair capability can extend the functional lifespan of leg components by up to 30%, maintaining geometric integrity even after damage events that would typically initiate progressive failure in conventional materials.

Computational Modeling for Leg Design Validation

Computational modeling has emerged as a critical tool in the optimization of leg geometry for balanced power and durability. Advanced simulation techniques now enable engineers to predict performance characteristics before physical prototyping, significantly reducing development cycles and costs. These models incorporate finite element analysis (FEA), computational fluid dynamics (CFD), and multi-body dynamics to create comprehensive virtual testing environments.

The validation process typically begins with the development of parametric models that allow for rapid iteration of geometric variables. Key parameters include cross-sectional profiles, material distribution, joint configurations, and structural reinforcement placement. These models must accurately represent both static loading conditions and dynamic forces experienced during various movement patterns.

Material behavior modeling presents particular challenges, as leg structures often utilize composite materials with anisotropic properties. Advanced constitutive models that capture non-linear stress-strain relationships, fatigue characteristics, and failure mechanisms are essential for accurate prediction of durability metrics. Recent developments in micromechanical modeling have improved the fidelity of these simulations by accounting for fiber orientation and matrix interactions at multiple scales.

Validation protocols typically involve correlation between computational predictions and experimental measurements across multiple loading scenarios. Strain gauge data, high-speed motion capture, and force plate measurements provide the empirical foundation against which simulation accuracy is assessed. Statistical methods such as Bayesian calibration techniques help refine model parameters to minimize discrepancies between predicted and observed behaviors.

Machine learning approaches have recently enhanced traditional modeling techniques by identifying non-intuitive relationships between geometric parameters and performance metrics. Neural networks trained on simulation datasets can rapidly explore vast design spaces and identify promising configurations that human engineers might overlook. These AI-assisted design tools are particularly valuable for optimizing the complex trade-offs between power transmission efficiency and structural durability.

Real-time simulation capabilities now allow for interactive design exploration, with engineers able to visualize stress distributions and deformation patterns as geometric parameters are adjusted. This immediate feedback accelerates the iterative design process and facilitates more intuitive understanding of how geometric modifications influence performance characteristics.

The integration of topology optimization algorithms with traditional simulation approaches has proven particularly effective for identifying optimal material distribution patterns. These algorithms systematically remove material from low-stress regions while reinforcing high-stress areas, resulting in biomimetic structures that efficiently balance weight reduction with mechanical integrity.

The validation process typically begins with the development of parametric models that allow for rapid iteration of geometric variables. Key parameters include cross-sectional profiles, material distribution, joint configurations, and structural reinforcement placement. These models must accurately represent both static loading conditions and dynamic forces experienced during various movement patterns.

Material behavior modeling presents particular challenges, as leg structures often utilize composite materials with anisotropic properties. Advanced constitutive models that capture non-linear stress-strain relationships, fatigue characteristics, and failure mechanisms are essential for accurate prediction of durability metrics. Recent developments in micromechanical modeling have improved the fidelity of these simulations by accounting for fiber orientation and matrix interactions at multiple scales.

Validation protocols typically involve correlation between computational predictions and experimental measurements across multiple loading scenarios. Strain gauge data, high-speed motion capture, and force plate measurements provide the empirical foundation against which simulation accuracy is assessed. Statistical methods such as Bayesian calibration techniques help refine model parameters to minimize discrepancies between predicted and observed behaviors.

Machine learning approaches have recently enhanced traditional modeling techniques by identifying non-intuitive relationships between geometric parameters and performance metrics. Neural networks trained on simulation datasets can rapidly explore vast design spaces and identify promising configurations that human engineers might overlook. These AI-assisted design tools are particularly valuable for optimizing the complex trade-offs between power transmission efficiency and structural durability.

Real-time simulation capabilities now allow for interactive design exploration, with engineers able to visualize stress distributions and deformation patterns as geometric parameters are adjusted. This immediate feedback accelerates the iterative design process and facilitates more intuitive understanding of how geometric modifications influence performance characteristics.

The integration of topology optimization algorithms with traditional simulation approaches has proven particularly effective for identifying optimal material distribution patterns. These algorithms systematically remove material from low-stress regions while reinforcing high-stress areas, resulting in biomimetic structures that efficiently balance weight reduction with mechanical integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!