Designing High-Efficiency Thermoelectric Generators For Automotive Exhaust Recovery

SEP 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery represents a significant opportunity in the automotive industry, where approximately 40% of fuel energy is lost through exhaust systems as waste heat. This technology has evolved considerably since the discovery of the Seebeck effect in 1821, which established that temperature differentials across certain materials could generate electrical voltage. The progression from basic thermoelectric principles to practical automotive applications has accelerated notably in the past two decades, driven by environmental regulations and efficiency demands.

The automotive sector's push toward reduced emissions and improved fuel economy has positioned thermoelectric generators (TEGs) as a promising technology for capturing waste thermal energy. Historical development shows a clear trajectory from laboratory-scale demonstrations to increasingly sophisticated prototypes integrated with vehicle exhaust systems. Early implementations in the 1990s achieved minimal efficiency, while contemporary systems can convert 5-8% of waste heat into usable electricity.

Current technological evolution is focused on enhancing the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency. Traditional bismuth telluride compounds are being supplemented or replaced by advanced materials including skutterudites, half-Heusler alloys, and nanostructured silicon-germanium composites. These materials show promising performance in the temperature ranges typical of automotive exhaust systems (200-600°C).

The primary objective of thermoelectric waste heat recovery research is to develop commercially viable systems that can generate 500W-1kW of electrical power from automotive exhaust, potentially reducing fuel consumption by 3-5%. Secondary goals include designing systems that maintain performance despite thermal cycling, vibration, and other automotive environmental challenges while achieving production costs below $1000 per kilowatt of generating capacity.

Technical objectives also extend to system integration challenges, including optimizing heat exchangers for maximum temperature differential across thermoelectric modules while minimizing backpressure on the engine exhaust system. Additional considerations include developing effective thermal management strategies and power conditioning electronics that can efficiently handle the variable output characteristics of thermoelectric generators under dynamic driving conditions.

Looking forward, the technology roadmap aims to achieve ZT values exceeding 2.0 for commercial materials by 2030, compared to current values of 1.0-1.5. This improvement would potentially double conversion efficiency and significantly enhance the economic viability of automotive thermoelectric generators, positioning them as standard components in future vehicle designs rather than specialized additions limited to premium or commercial vehicles.

The automotive sector's push toward reduced emissions and improved fuel economy has positioned thermoelectric generators (TEGs) as a promising technology for capturing waste thermal energy. Historical development shows a clear trajectory from laboratory-scale demonstrations to increasingly sophisticated prototypes integrated with vehicle exhaust systems. Early implementations in the 1990s achieved minimal efficiency, while contemporary systems can convert 5-8% of waste heat into usable electricity.

Current technological evolution is focused on enhancing the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency. Traditional bismuth telluride compounds are being supplemented or replaced by advanced materials including skutterudites, half-Heusler alloys, and nanostructured silicon-germanium composites. These materials show promising performance in the temperature ranges typical of automotive exhaust systems (200-600°C).

The primary objective of thermoelectric waste heat recovery research is to develop commercially viable systems that can generate 500W-1kW of electrical power from automotive exhaust, potentially reducing fuel consumption by 3-5%. Secondary goals include designing systems that maintain performance despite thermal cycling, vibration, and other automotive environmental challenges while achieving production costs below $1000 per kilowatt of generating capacity.

Technical objectives also extend to system integration challenges, including optimizing heat exchangers for maximum temperature differential across thermoelectric modules while minimizing backpressure on the engine exhaust system. Additional considerations include developing effective thermal management strategies and power conditioning electronics that can efficiently handle the variable output characteristics of thermoelectric generators under dynamic driving conditions.

Looking forward, the technology roadmap aims to achieve ZT values exceeding 2.0 for commercial materials by 2030, compared to current values of 1.0-1.5. This improvement would potentially double conversion efficiency and significantly enhance the economic viability of automotive thermoelectric generators, positioning them as standard components in future vehicle designs rather than specialized additions limited to premium or commercial vehicles.

Automotive TEG Market Analysis and Growth Potential

The global market for automotive thermoelectric generators (TEGs) is experiencing significant growth, driven by increasing environmental regulations and the automotive industry's push toward greater fuel efficiency. Current market valuations place automotive TEG technology at approximately 600 million USD in 2023, with projections indicating a compound annual growth rate of 14.5% through 2030, potentially reaching 1.5 billion USD by the end of the decade.

The primary market drivers include stringent emission regulations in Europe, North America, and Asia, particularly as countries implement policies aligned with the Paris Climate Agreement. Vehicle manufacturers are increasingly viewing waste heat recovery systems as a critical component in meeting these regulatory requirements while simultaneously improving fuel economy by 2-5% in conventional vehicles.

Market segmentation reveals distinct application categories within the automotive TEG sector. Passenger vehicles currently dominate the market share at 65%, followed by commercial vehicles at 25%, and specialty vehicles at 10%. Premium and luxury vehicle segments have shown the highest adoption rates, as these markets can more easily absorb the current high implementation costs.

Regional analysis indicates Europe leads in TEG adoption with approximately 40% market share, followed by North America (30%) and Asia-Pacific (25%). However, the Asia-Pacific region, particularly China and Japan, is expected to demonstrate the fastest growth rate over the next five years due to aggressive government incentives for green automotive technologies and substantial investments in manufacturing capabilities.

The economic value proposition of automotive TEGs continues to strengthen as technology advances. While current systems add between 800-1,200 USD to vehicle production costs, this premium is expected to decrease by 30-40% over the next five years as manufacturing scales and material innovations reduce expenses. The return on investment period for end-users is currently estimated at 3-4 years through fuel savings, with potential to decrease to 2-3 years by 2028.

Market penetration remains relatively low at 2-3% of new vehicles globally, indicating substantial growth potential. Industry analysts predict that by 2030, TEG systems could be present in up to 15% of new vehicles worldwide, with higher rates in premium segments and regions with strict emissions regulations.

Consumer awareness and demand for fuel-efficient technologies are also increasing, with market surveys indicating that 45% of new car buyers now consider fuel efficiency technologies among their top five purchasing factors, up from 30% five years ago. This shift in consumer preference represents a significant market opportunity for automotive manufacturers implementing TEG technology.

The primary market drivers include stringent emission regulations in Europe, North America, and Asia, particularly as countries implement policies aligned with the Paris Climate Agreement. Vehicle manufacturers are increasingly viewing waste heat recovery systems as a critical component in meeting these regulatory requirements while simultaneously improving fuel economy by 2-5% in conventional vehicles.

Market segmentation reveals distinct application categories within the automotive TEG sector. Passenger vehicles currently dominate the market share at 65%, followed by commercial vehicles at 25%, and specialty vehicles at 10%. Premium and luxury vehicle segments have shown the highest adoption rates, as these markets can more easily absorb the current high implementation costs.

Regional analysis indicates Europe leads in TEG adoption with approximately 40% market share, followed by North America (30%) and Asia-Pacific (25%). However, the Asia-Pacific region, particularly China and Japan, is expected to demonstrate the fastest growth rate over the next five years due to aggressive government incentives for green automotive technologies and substantial investments in manufacturing capabilities.

The economic value proposition of automotive TEGs continues to strengthen as technology advances. While current systems add between 800-1,200 USD to vehicle production costs, this premium is expected to decrease by 30-40% over the next five years as manufacturing scales and material innovations reduce expenses. The return on investment period for end-users is currently estimated at 3-4 years through fuel savings, with potential to decrease to 2-3 years by 2028.

Market penetration remains relatively low at 2-3% of new vehicles globally, indicating substantial growth potential. Industry analysts predict that by 2030, TEG systems could be present in up to 15% of new vehicles worldwide, with higher rates in premium segments and regions with strict emissions regulations.

Consumer awareness and demand for fuel-efficient technologies are also increasing, with market surveys indicating that 45% of new car buyers now consider fuel efficiency technologies among their top five purchasing factors, up from 30% five years ago. This shift in consumer preference represents a significant market opportunity for automotive manufacturers implementing TEG technology.

Global TEG Technology Status and Development Barriers

Thermoelectric generators (TEGs) for automotive exhaust heat recovery have gained significant attention globally, yet their widespread implementation faces substantial barriers. Current global TEG technology demonstrates conversion efficiencies ranging from 3-8% in real-world automotive applications, falling short of the theoretical maximum of approximately 15-20% for existing materials. This efficiency gap represents one of the primary technical barriers to commercial adoption.

Leading research institutions in North America, Europe, and East Asia have established different approaches to TEG development. North American efforts focus on advanced materials with higher figure of merit (ZT) values, while European research emphasizes system integration and manufacturing scalability. East Asian development, particularly in Japan and China, concentrates on cost reduction and mass production techniques.

Material limitations constitute a significant barrier, as conventional bismuth telluride (Bi2Te3) compounds offer limited temperature range suitability for automotive exhaust applications, which can reach temperatures exceeding 600°C. More temperature-appropriate materials such as skutterudites, half-Heusler alloys, and silicides often contain rare or expensive elements, creating cost and supply chain vulnerabilities.

Manufacturing complexity presents another substantial obstacle. Current TEG modules require precise assembly of multiple thermoelectric couples with minimal thermal and electrical contact resistance. The thermal cycling inherent in automotive applications causes mechanical stress at material interfaces, leading to degradation over time and reliability concerns that have prevented widespread adoption.

System integration challenges further complicate implementation. TEGs must interface effectively with existing exhaust systems without creating unacceptable back pressure that could reduce engine efficiency. Heat exchangers must maximize temperature differentials while withstanding corrosive exhaust environments and extreme temperature fluctuations.

Economic barriers remain perhaps the most significant impediment to commercialization. Current production costs for automotive-grade TEGs range from $20-40 per watt of generating capacity, far exceeding the target of $1-2 per watt considered necessary for mass-market adoption. This cost barrier is exacerbated by the relatively modest fuel economy improvements of 2-5% typically achieved in prototype systems.

Regulatory frameworks also influence development trajectories differently across regions. Stringent emissions standards in Europe have accelerated interest in TEG technology as part of comprehensive efficiency strategies, while North American regulations have provided less direct incentive for exhaust heat recovery systems. Asian markets, particularly China, have implemented policies specifically supporting waste heat recovery technologies, creating regional variations in development priorities.

Leading research institutions in North America, Europe, and East Asia have established different approaches to TEG development. North American efforts focus on advanced materials with higher figure of merit (ZT) values, while European research emphasizes system integration and manufacturing scalability. East Asian development, particularly in Japan and China, concentrates on cost reduction and mass production techniques.

Material limitations constitute a significant barrier, as conventional bismuth telluride (Bi2Te3) compounds offer limited temperature range suitability for automotive exhaust applications, which can reach temperatures exceeding 600°C. More temperature-appropriate materials such as skutterudites, half-Heusler alloys, and silicides often contain rare or expensive elements, creating cost and supply chain vulnerabilities.

Manufacturing complexity presents another substantial obstacle. Current TEG modules require precise assembly of multiple thermoelectric couples with minimal thermal and electrical contact resistance. The thermal cycling inherent in automotive applications causes mechanical stress at material interfaces, leading to degradation over time and reliability concerns that have prevented widespread adoption.

System integration challenges further complicate implementation. TEGs must interface effectively with existing exhaust systems without creating unacceptable back pressure that could reduce engine efficiency. Heat exchangers must maximize temperature differentials while withstanding corrosive exhaust environments and extreme temperature fluctuations.

Economic barriers remain perhaps the most significant impediment to commercialization. Current production costs for automotive-grade TEGs range from $20-40 per watt of generating capacity, far exceeding the target of $1-2 per watt considered necessary for mass-market adoption. This cost barrier is exacerbated by the relatively modest fuel economy improvements of 2-5% typically achieved in prototype systems.

Regulatory frameworks also influence development trajectories differently across regions. Stringent emissions standards in Europe have accelerated interest in TEG technology as part of comprehensive efficiency strategies, while North American regulations have provided less direct incentive for exhaust heat recovery systems. Asian markets, particularly China, have implemented policies specifically supporting waste heat recovery technologies, creating regional variations in development priorities.

Current Automotive Exhaust Heat Recovery Solutions

01 Material selection for improved thermoelectric efficiency

The selection of appropriate materials is crucial for enhancing the efficiency of thermoelectric generators. Materials with high Seebeck coefficient, high electrical conductivity, and low thermal conductivity are preferred. Advanced materials such as nanostructured semiconductors, skutterudites, and bismuth telluride compounds can significantly improve the figure of merit (ZT) of thermoelectric devices, leading to higher conversion efficiency. These materials can be engineered at the nanoscale to optimize their thermoelectric properties.- Material selection for improved thermoelectric efficiency: The choice of materials significantly impacts the efficiency of thermoelectric generators. Advanced materials with high Seebeck coefficients and low thermal conductivity can substantially improve conversion efficiency. Research focuses on semiconductor materials, nanostructured composites, and novel alloys that can maintain large temperature gradients while efficiently converting heat to electricity.

- Structural design optimization for thermoelectric generators: The physical configuration and structural design of thermoelectric generators play crucial roles in maximizing efficiency. Innovations include segmented leg designs, cascaded structures, and optimized heat exchanger interfaces. These structural improvements help to maintain temperature differentials and reduce thermal losses, thereby enhancing the overall conversion efficiency of the thermoelectric system.

- Temperature gradient management techniques: Maintaining and optimizing temperature differentials across thermoelectric elements is essential for high efficiency. Techniques include advanced heat sink designs, thermal isolation strategies, and heat flow control mechanisms. These approaches maximize the temperature gradient across the thermoelectric material, which directly correlates with increased power generation efficiency.

- Integration with waste heat recovery systems: Thermoelectric generators can be integrated with various waste heat sources to improve overall system efficiency. Applications include automotive exhaust systems, industrial processes, and power plants. These integrated systems capture thermal energy that would otherwise be lost, converting it into useful electricity and thereby increasing the net efficiency of the primary energy system.

- Circuit and power conditioning optimization: Electrical circuit design and power conditioning significantly impact the usable output from thermoelectric generators. Advanced maximum power point tracking systems, DC-DC converters with optimized impedance matching, and intelligent load management techniques help extract the maximum possible electrical energy from the thermal gradient. These electrical optimizations complement material and structural improvements to achieve higher system efficiency.

02 Structural design optimization for thermoelectric generators

The structural design of thermoelectric generators plays a significant role in determining their efficiency. Optimized designs include segmented or cascaded structures, which utilize different materials for different temperature ranges, and modular configurations that maximize heat transfer while minimizing thermal losses. Advanced geometries such as thin-film structures and micro-fabricated devices can also enhance performance by improving thermal management and reducing internal resistance. Proper thermal interfaces between components are essential for maintaining temperature gradients.Expand Specific Solutions03 Temperature gradient management techniques

Effective management of temperature gradients is essential for maximizing the efficiency of thermoelectric generators. This involves optimizing heat source coupling, implementing efficient heat sinks, and minimizing thermal resistance across the device. Techniques such as heat spreading, thermal concentration, and active cooling can help maintain optimal temperature differences across the thermoelectric elements. Proper insulation between hot and cold sides prevents unwanted heat transfer that would reduce the temperature gradient and consequently lower efficiency.Expand Specific Solutions04 Integration of thermoelectric generators with other energy systems

Integrating thermoelectric generators with other energy systems can significantly improve overall efficiency by utilizing waste heat from primary processes. Hybrid systems combining thermoelectric generators with solar panels, combustion engines, or industrial processes can capture otherwise wasted thermal energy. Co-generation approaches allow for more effective energy harvesting across different temperature ranges and operating conditions. These integrated systems can provide complementary power generation capabilities and enhance the overall energy conversion efficiency.Expand Specific Solutions05 Electronic control and power conditioning for efficiency optimization

Advanced electronic control systems and power conditioning circuits can optimize the operation of thermoelectric generators under varying conditions. Maximum power point tracking (MPPT) algorithms, DC-DC converters with adaptive control, and load matching techniques help extract the maximum available power from thermoelectric devices. Smart control systems can adjust operating parameters in response to changing temperature gradients or load requirements. Proper electrical interconnection of thermoelectric modules and efficient power management strategies minimize electrical losses and improve overall system efficiency.Expand Specific Solutions

Leading Automotive TEG Manufacturers and Research Institutions

The thermoelectric generator (TEG) market for automotive exhaust recovery is in its growth phase, with increasing adoption driven by stringent emission regulations and fuel efficiency demands. The market is projected to expand significantly as automotive manufacturers seek sustainable solutions. Technologically, the field shows varying maturity levels, with established players like Continental Emitec, Bosch, and Denso leading commercial applications, while academic institutions such as Wuhan University of Technology and South China University of Technology drive fundamental research. Major automakers including BMW, Hyundai, and Jaguar Land Rover are actively integrating TEGs into their vehicle development programs. The competitive landscape features collaboration between tier-1 suppliers (Faurecia, Valeo) and OEMs, with increasing focus on high-temperature materials, system integration, and cost reduction to improve conversion efficiency and commercial viability.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative thermoelectric generator system for automotive exhaust heat recovery that features a compact, lightweight design optimized for integration into their global vehicle platforms. Their approach utilizes a combination of skutterudite and silicide-based thermoelectric materials arranged in a radial configuration around a specially designed exhaust heat exchanger. This arrangement maximizes the temperature differential across the thermoelectric elements while maintaining a compact form factor. Hyundai's system incorporates a variable geometry heat exchanger that can adjust thermal contact based on exhaust flow rates and temperatures, optimizing performance across different driving conditions. Their TEG modules achieve peak conversion efficiencies of 4-6% and can generate up to 500W of electrical power during highway driving. A distinctive aspect of Hyundai's approach is their focus on manufacturing scalability, with automated assembly processes developed specifically for high-volume production. The system includes sophisticated thermal protection mechanisms that prevent overheating of thermoelectric materials during extreme operating conditions, and intelligent power management that integrates with Hyundai's hybrid and conventional powertrains to maximize fuel economy benefits.

Strengths: Hyundai's design achieves excellent power density and packaging efficiency, making it suitable for integration across multiple vehicle classes. Their focus on manufacturing processes has reduced production costs compared to competing systems. The variable geometry design maintains performance across a wider range of driving conditions. Weaknesses: The system shows somewhat lower peak efficiency compared to more complex multi-stage designs. The mechanical complexity of the variable geometry components may impact long-term reliability and increase maintenance requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced thermoelectric generator (TEG) system specifically designed for automotive exhaust heat recovery. Their solution integrates directly into the exhaust system between the catalytic converter and muffler, where exhaust temperatures are optimal for energy harvesting (250-500°C). The system utilizes bismuth telluride (Bi2Te3) based semiconductor materials arranged in a modular configuration that maximizes the temperature differential between the hot exhaust gas and engine coolant. Bosch's design incorporates a proprietary heat exchanger geometry that optimizes thermal contact while minimizing backpressure effects on engine performance. Their TEG modules achieve conversion efficiencies of 5-7% and can generate up to 600W of electrical power under optimal driving conditions, reducing fuel consumption by approximately 2-3%. The system includes intelligent power management electronics that integrate with the vehicle's electrical system to supplement alternator output and reduce engine load.

Strengths: Bosch's extensive automotive integration experience enables seamless compatibility with existing vehicle electrical systems. Their modular design allows for scalability across different vehicle platforms. Weaknesses: The system's relatively high production costs and complexity of installation in existing vehicle architectures limit widespread adoption. Performance is highly dependent on driving conditions, with reduced efficiency during city driving with frequent stops.

Critical Patents in High-Efficiency TEG Technology

Thermoelectric device

PatentInactiveEP2409341A2

Innovation

- A thermoelectric generator design featuring multiple thermoelectric devices with p- and n-doped semiconductor elements arranged between hot and cold flow paths, where the semiconductor elements are selectively interconnected and fixed on a flexible medium to manage thermal expansion and improve energy conversion efficiency, generating a voltage of 12 to 15 V when connected in series.

Thermoelectric power-generation device

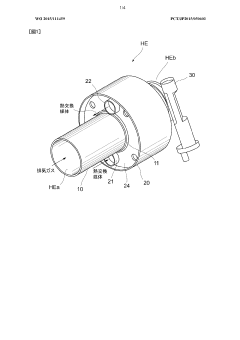

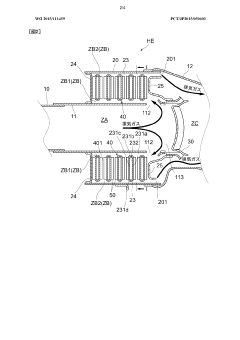

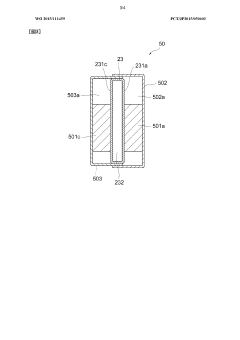

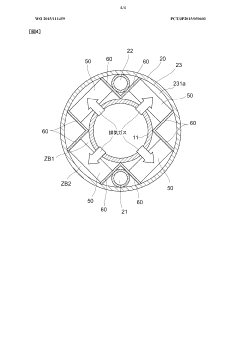

PatentWO2015111459A1

Innovation

- A thermoelectric generator design that includes an inner and outer cylinder forming a heat exchange flow path, with a heat exchanger surrounding the inner cylinder and a thermoelectric module positioned to maximize heat exchange, utilizing an exhaust gas guide to direct high-temperature exhaust gas radially from the inner to the outer heat exchange path, ensuring efficient heat transfer to the thermoelectric module.

Integration Challenges with Vehicle Powertrain Systems

The integration of thermoelectric generators (TEGs) into automotive exhaust systems presents significant engineering challenges that must be addressed to achieve optimal performance and reliability. The primary integration challenge stems from the complex thermal management requirements of TEGs when interfacing with existing powertrain components. Vehicle powertrain systems operate under dynamic conditions with frequent temperature fluctuations, creating difficulties in maintaining the optimal temperature gradient necessary for efficient thermoelectric conversion.

Mechanical integration poses another substantial hurdle, as TEG systems must be designed to withstand severe vibration, thermal cycling, and mechanical stress inherent in automotive environments. The physical space constraints within modern vehicle architectures further complicate integration efforts, requiring compact designs that do not compromise existing powertrain functionality or add excessive weight that could negatively impact fuel efficiency.

Electrical system integration presents additional complexities, as TEGs produce variable DC output that must be conditioned before connecting to the vehicle's electrical network. This necessitates sophisticated power electronics capable of handling fluctuating input while providing stable output compatible with the vehicle's 12V or 48V systems. The control algorithms must also seamlessly interface with existing engine control units (ECUs) to optimize power generation without disrupting critical engine management functions.

Material compatibility issues arise when integrating TEGs with exhaust systems constructed from different metals and alloys. The thermal expansion coefficients of these materials must be carefully matched to prevent mechanical failure during thermal cycling. Additionally, the high-temperature environment of exhaust systems accelerates material degradation, requiring specialized coatings and joining techniques to ensure long-term durability.

Manufacturing and assembly considerations represent another significant challenge, as TEG integration must be compatible with existing automotive production processes. The complexity of TEG systems, with their numerous interconnected components, demands precise assembly techniques that can be scaled for mass production while maintaining quality and reliability standards expected in the automotive industry.

Maintenance and serviceability concerns must also be addressed, as TEG systems should ideally be designed for the entire vehicle lifecycle with minimal maintenance requirements. Access points for inspection and potential replacement must be incorporated into the design without compromising structural integrity or thermal performance. The integration strategy must balance these competing requirements while ensuring compliance with increasingly stringent emissions regulations and safety standards.

Mechanical integration poses another substantial hurdle, as TEG systems must be designed to withstand severe vibration, thermal cycling, and mechanical stress inherent in automotive environments. The physical space constraints within modern vehicle architectures further complicate integration efforts, requiring compact designs that do not compromise existing powertrain functionality or add excessive weight that could negatively impact fuel efficiency.

Electrical system integration presents additional complexities, as TEGs produce variable DC output that must be conditioned before connecting to the vehicle's electrical network. This necessitates sophisticated power electronics capable of handling fluctuating input while providing stable output compatible with the vehicle's 12V or 48V systems. The control algorithms must also seamlessly interface with existing engine control units (ECUs) to optimize power generation without disrupting critical engine management functions.

Material compatibility issues arise when integrating TEGs with exhaust systems constructed from different metals and alloys. The thermal expansion coefficients of these materials must be carefully matched to prevent mechanical failure during thermal cycling. Additionally, the high-temperature environment of exhaust systems accelerates material degradation, requiring specialized coatings and joining techniques to ensure long-term durability.

Manufacturing and assembly considerations represent another significant challenge, as TEG integration must be compatible with existing automotive production processes. The complexity of TEG systems, with their numerous interconnected components, demands precise assembly techniques that can be scaled for mass production while maintaining quality and reliability standards expected in the automotive industry.

Maintenance and serviceability concerns must also be addressed, as TEG systems should ideally be designed for the entire vehicle lifecycle with minimal maintenance requirements. Access points for inspection and potential replacement must be incorporated into the design without compromising structural integrity or thermal performance. The integration strategy must balance these competing requirements while ensuring compliance with increasingly stringent emissions regulations and safety standards.

Environmental Impact and Emission Reduction Benefits

The implementation of high-efficiency thermoelectric generators (TEGs) in automotive exhaust systems represents a significant opportunity for environmental improvement and emission reduction. Vehicle exhaust systems typically waste approximately 30-40% of fuel energy as heat, contributing substantially to overall inefficiency and increased carbon emissions. By capturing and converting this waste heat into usable electricity, TEGs directly reduce the load on conventional vehicle alternators, decreasing fuel consumption by an estimated 2-5% depending on driving conditions and system integration.

This fuel efficiency improvement translates to proportional reductions in greenhouse gas emissions. For a typical passenger vehicle, this could mean a reduction of 20-50 grams of CO2 per kilometer traveled. When scaled across global automotive fleets, the potential environmental impact becomes substantial, potentially reducing annual CO2 emissions by millions of tons if widely adopted.

Beyond carbon dioxide, TEG systems can contribute to reducing other harmful emissions. By optimizing engine operation through reduced alternator load, there can be measurable decreases in nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. Studies have shown potential reductions of 3-7% in these pollutants when TEG systems are properly integrated with engine management systems.

The environmental benefits extend throughout the vehicle lifecycle. While the manufacturing of thermoelectric materials does have an environmental footprint, lifecycle assessments indicate that this impact is typically offset within 1-2 years of vehicle operation through emission reductions. Most thermoelectric materials used in automotive applications have lifespans matching or exceeding vehicle life expectancy, minimizing replacement waste.

Additionally, TEG systems align with increasingly stringent global emissions regulations. In regions implementing carbon taxation or strict emission standards like Euro 7 or California's LEV III, TEG technology offers manufacturers a pathway to compliance while providing economic benefits to consumers through fuel savings. The technology becomes particularly valuable in hybrid electric vehicles, where waste heat recovery can extend electric-only driving range.

From a circular economy perspective, many thermoelectric materials can be recovered and recycled at end-of-life, further reducing the environmental impact. Research indicates recovery rates of 70-85% for key materials like bismuth telluride and lead telluride are achievable with appropriate recycling infrastructure, though this remains an area requiring further development.

This fuel efficiency improvement translates to proportional reductions in greenhouse gas emissions. For a typical passenger vehicle, this could mean a reduction of 20-50 grams of CO2 per kilometer traveled. When scaled across global automotive fleets, the potential environmental impact becomes substantial, potentially reducing annual CO2 emissions by millions of tons if widely adopted.

Beyond carbon dioxide, TEG systems can contribute to reducing other harmful emissions. By optimizing engine operation through reduced alternator load, there can be measurable decreases in nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. Studies have shown potential reductions of 3-7% in these pollutants when TEG systems are properly integrated with engine management systems.

The environmental benefits extend throughout the vehicle lifecycle. While the manufacturing of thermoelectric materials does have an environmental footprint, lifecycle assessments indicate that this impact is typically offset within 1-2 years of vehicle operation through emission reductions. Most thermoelectric materials used in automotive applications have lifespans matching or exceeding vehicle life expectancy, minimizing replacement waste.

Additionally, TEG systems align with increasingly stringent global emissions regulations. In regions implementing carbon taxation or strict emission standards like Euro 7 or California's LEV III, TEG technology offers manufacturers a pathway to compliance while providing economic benefits to consumers through fuel savings. The technology becomes particularly valuable in hybrid electric vehicles, where waste heat recovery can extend electric-only driving range.

From a circular economy perspective, many thermoelectric materials can be recovered and recycled at end-of-life, further reducing the environmental impact. Research indicates recovery rates of 70-85% for key materials like bismuth telluride and lead telluride are achievable with appropriate recycling infrastructure, though this remains an area requiring further development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!