How To Combine Thermoelectrics With Heat Pumps For Efficient Buildings

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric-Heat Pump Integration Background & Objectives

Thermoelectric (TE) technology and heat pumps represent two distinct approaches to thermal management that have evolved along separate technological trajectories over the past century. Thermoelectric devices, based on the Seebeck and Peltier effects discovered in the early 19th century, convert temperature differences directly into electrical voltage and vice versa. Heat pumps, meanwhile, have developed from basic refrigeration cycles first commercialized in the late 19th century into sophisticated heating and cooling systems widely deployed today.

The integration of these technologies presents a compelling opportunity to address the growing global challenge of building energy efficiency. Buildings account for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, with heating, ventilation, and air conditioning (HVAC) systems representing the largest portion of this energy use. As climate change accelerates and urbanization continues worldwide, the demand for more efficient building thermal management solutions becomes increasingly urgent.

Recent technological advancements have significantly improved the performance of both thermoelectric materials and heat pump systems. Thermoelectric materials have seen their figure of merit (ZT) increase from below 1.0 to over 2.0 in laboratory settings, while heat pumps have achieved coefficient of performance (COP) values exceeding 4.0 in optimal conditions. These improvements create new possibilities for hybrid systems that leverage the complementary strengths of each technology.

The primary objective of this technical research is to explore innovative approaches for combining thermoelectric devices with conventional heat pump systems to create integrated solutions that exceed the performance limitations of either technology used independently. Specifically, we aim to identify configurations that can improve overall system efficiency, reduce energy consumption, enable more precise temperature control, and minimize environmental impact in building applications.

Secondary objectives include evaluating the technical feasibility of various integration architectures, assessing the economic viability of hybrid systems compared to conventional alternatives, and identifying key research and development priorities to accelerate commercialization. We also seek to understand how these integrated systems might adapt to different building types, climate zones, and operational requirements.

The technological evolution trajectory suggests several promising directions, including cascade systems where thermoelectric devices handle fine temperature adjustments while heat pumps manage bulk thermal loads, waste heat recovery systems that convert thermal gradients within heat pump cycles into supplementary electrical power, and smart thermal management systems that dynamically optimize the operation of both technologies based on changing environmental conditions and user requirements.

The integration of these technologies presents a compelling opportunity to address the growing global challenge of building energy efficiency. Buildings account for approximately 40% of global energy consumption and 30% of greenhouse gas emissions, with heating, ventilation, and air conditioning (HVAC) systems representing the largest portion of this energy use. As climate change accelerates and urbanization continues worldwide, the demand for more efficient building thermal management solutions becomes increasingly urgent.

Recent technological advancements have significantly improved the performance of both thermoelectric materials and heat pump systems. Thermoelectric materials have seen their figure of merit (ZT) increase from below 1.0 to over 2.0 in laboratory settings, while heat pumps have achieved coefficient of performance (COP) values exceeding 4.0 in optimal conditions. These improvements create new possibilities for hybrid systems that leverage the complementary strengths of each technology.

The primary objective of this technical research is to explore innovative approaches for combining thermoelectric devices with conventional heat pump systems to create integrated solutions that exceed the performance limitations of either technology used independently. Specifically, we aim to identify configurations that can improve overall system efficiency, reduce energy consumption, enable more precise temperature control, and minimize environmental impact in building applications.

Secondary objectives include evaluating the technical feasibility of various integration architectures, assessing the economic viability of hybrid systems compared to conventional alternatives, and identifying key research and development priorities to accelerate commercialization. We also seek to understand how these integrated systems might adapt to different building types, climate zones, and operational requirements.

The technological evolution trajectory suggests several promising directions, including cascade systems where thermoelectric devices handle fine temperature adjustments while heat pumps manage bulk thermal loads, waste heat recovery systems that convert thermal gradients within heat pump cycles into supplementary electrical power, and smart thermal management systems that dynamically optimize the operation of both technologies based on changing environmental conditions and user requirements.

Building Energy Efficiency Market Analysis

The global building energy efficiency market is experiencing significant growth, driven by increasing energy costs, environmental concerns, and stringent regulatory frameworks. As of 2023, the market was valued at approximately $290 billion and is projected to reach $620 billion by 2030, representing a compound annual growth rate (CAGR) of 11.4%. This growth trajectory is particularly evident in regions with mature construction industries and strong environmental policies, such as North America, Europe, and parts of Asia-Pacific.

The demand for energy-efficient building solutions is primarily fueled by the fact that buildings account for nearly 40% of global energy consumption and 36% of carbon emissions. Within this context, heating and cooling systems represent the largest energy expenditure in buildings, consuming approximately 50-60% of total building energy. This creates a substantial market opportunity for innovative technologies like integrated thermoelectric-heat pump systems.

Commercial buildings constitute the largest market segment, accounting for 45% of the energy efficiency market, followed by residential (35%) and industrial buildings (20%). However, the residential sector is showing the fastest growth rate at 13.2% annually, driven by increasing homeowner awareness and government incentives for energy-efficient home improvements.

Regionally, Europe leads the market with a 38% share, supported by ambitious climate targets and progressive building codes. North America follows at 30%, while Asia-Pacific represents the fastest-growing region with a 15.3% annual growth rate, primarily driven by China and India's rapid urbanization and increasing environmental consciousness.

The market for specific thermoelectric and heat pump technologies is expanding rapidly within this broader context. Heat pump installations have increased by 34% globally between 2021 and 2023, with air-source heat pumps dominating the market (75% share). Thermoelectric solutions, though currently representing a smaller segment (approximately $3.5 billion), are projected to grow at 16.8% annually through 2030, indicating strong potential for combined thermoelectric-heat pump systems.

Key market drivers include government regulations and incentives, with over 70 countries implementing energy efficiency standards for buildings. The EU's Energy Performance of Buildings Directive and the U.S. Building Technologies Office programs are particularly influential. Additionally, rising energy costs, with electricity prices increasing by an average of 8.2% annually in developed nations, are pushing building owners toward more efficient solutions that offer demonstrable return on investment.

The demand for energy-efficient building solutions is primarily fueled by the fact that buildings account for nearly 40% of global energy consumption and 36% of carbon emissions. Within this context, heating and cooling systems represent the largest energy expenditure in buildings, consuming approximately 50-60% of total building energy. This creates a substantial market opportunity for innovative technologies like integrated thermoelectric-heat pump systems.

Commercial buildings constitute the largest market segment, accounting for 45% of the energy efficiency market, followed by residential (35%) and industrial buildings (20%). However, the residential sector is showing the fastest growth rate at 13.2% annually, driven by increasing homeowner awareness and government incentives for energy-efficient home improvements.

Regionally, Europe leads the market with a 38% share, supported by ambitious climate targets and progressive building codes. North America follows at 30%, while Asia-Pacific represents the fastest-growing region with a 15.3% annual growth rate, primarily driven by China and India's rapid urbanization and increasing environmental consciousness.

The market for specific thermoelectric and heat pump technologies is expanding rapidly within this broader context. Heat pump installations have increased by 34% globally between 2021 and 2023, with air-source heat pumps dominating the market (75% share). Thermoelectric solutions, though currently representing a smaller segment (approximately $3.5 billion), are projected to grow at 16.8% annually through 2030, indicating strong potential for combined thermoelectric-heat pump systems.

Key market drivers include government regulations and incentives, with over 70 countries implementing energy efficiency standards for buildings. The EU's Energy Performance of Buildings Directive and the U.S. Building Technologies Office programs are particularly influential. Additionally, rising energy costs, with electricity prices increasing by an average of 8.2% annually in developed nations, are pushing building owners toward more efficient solutions that offer demonstrable return on investment.

Current Challenges in Hybrid Thermal Technologies

Despite the promising potential of integrating thermoelectric devices with heat pumps for building efficiency, several significant technical challenges impede widespread adoption. The fundamental challenge lies in the relatively low efficiency of thermoelectric materials, with most commercial modules operating at only 5-8% conversion efficiency. This limitation makes standalone thermoelectric systems less competitive compared to conventional HVAC technologies in terms of energy performance.

Material constraints present another major hurdle. Current thermoelectric materials rely heavily on tellurium, bismuth, and other rare elements with limited global supply. The scarcity of these materials drives up costs and creates sustainability concerns for large-scale implementation in building systems. Additionally, many high-performance thermoelectric materials contain toxic elements like lead, raising environmental and regulatory compliance issues.

System integration complexity poses significant engineering challenges. Thermoelectric devices operate optimally under specific temperature differentials, while heat pumps have their own operational parameters. Creating control systems that can harmonize these different technologies to work efficiently together requires sophisticated algorithms and sensing capabilities that add complexity and cost to the overall system.

Thermal management issues further complicate hybrid system design. The interface between thermoelectric modules and heat pumps creates thermal resistance that can degrade overall system performance. Ensuring efficient heat transfer across components while minimizing losses requires advanced thermal interface materials and precise engineering that are difficult to standardize across different building applications.

Economic barriers remain substantial, with current hybrid thermoelectric-heat pump systems showing payback periods exceeding 10 years in most building applications. This extended return on investment discourages adoption, particularly in commercial buildings where shorter payback periods are typically required for technology investments.

Durability and reliability concerns also persist. Thermoelectric modules can experience performance degradation over time due to thermal cycling and mechanical stress. When integrated with heat pumps, these reliability issues become more complex as the failure of one component can compromise the entire system, increasing maintenance requirements and lifecycle costs.

Regulatory frameworks and building codes have not fully adapted to accommodate these hybrid technologies. The lack of standardized testing protocols and performance metrics for combined thermoelectric-heat pump systems creates uncertainty for manufacturers and hesitancy among building designers to specify these innovative but unproven solutions.

Material constraints present another major hurdle. Current thermoelectric materials rely heavily on tellurium, bismuth, and other rare elements with limited global supply. The scarcity of these materials drives up costs and creates sustainability concerns for large-scale implementation in building systems. Additionally, many high-performance thermoelectric materials contain toxic elements like lead, raising environmental and regulatory compliance issues.

System integration complexity poses significant engineering challenges. Thermoelectric devices operate optimally under specific temperature differentials, while heat pumps have their own operational parameters. Creating control systems that can harmonize these different technologies to work efficiently together requires sophisticated algorithms and sensing capabilities that add complexity and cost to the overall system.

Thermal management issues further complicate hybrid system design. The interface between thermoelectric modules and heat pumps creates thermal resistance that can degrade overall system performance. Ensuring efficient heat transfer across components while minimizing losses requires advanced thermal interface materials and precise engineering that are difficult to standardize across different building applications.

Economic barriers remain substantial, with current hybrid thermoelectric-heat pump systems showing payback periods exceeding 10 years in most building applications. This extended return on investment discourages adoption, particularly in commercial buildings where shorter payback periods are typically required for technology investments.

Durability and reliability concerns also persist. Thermoelectric modules can experience performance degradation over time due to thermal cycling and mechanical stress. When integrated with heat pumps, these reliability issues become more complex as the failure of one component can compromise the entire system, increasing maintenance requirements and lifecycle costs.

Regulatory frameworks and building codes have not fully adapted to accommodate these hybrid technologies. The lack of standardized testing protocols and performance metrics for combined thermoelectric-heat pump systems creates uncertainty for manufacturers and hesitancy among building designers to specify these innovative but unproven solutions.

Existing Hybrid Thermal System Architectures

01 Hybrid thermoelectric-heat pump systems for improved efficiency

Combining thermoelectric devices with conventional heat pumps creates hybrid systems that leverage the advantages of both technologies. These hybrid systems can achieve higher overall efficiency by using thermoelectric modules for precise temperature control while the heat pump handles bulk heating or cooling. The synergistic operation allows for better energy utilization across varying load conditions and can significantly improve the coefficient of performance compared to either technology operating independently.- Hybrid thermoelectric-heat pump systems for improved efficiency: Combining thermoelectric devices with conventional heat pumps creates hybrid systems that leverage the advantages of both technologies. These hybrid systems can achieve higher overall efficiency by using thermoelectric modules for precise temperature control while the heat pump handles the bulk heating or cooling load. The integration allows for better energy utilization across varying operating conditions and can significantly reduce energy consumption compared to standalone systems.

- Cascaded thermoelectric-heat pump configurations: Cascaded configurations involve arranging thermoelectric elements and heat pump components in series or parallel to optimize heat transfer across temperature gradients. This approach allows for more efficient operation by matching each technology to its optimal temperature range. The cascaded design enables heat recovery between stages, reducing energy waste and improving the coefficient of performance of the overall system.

- Waste heat recovery using thermoelectric-heat pump integration: Thermoelectric generators can be combined with heat pumps to recover waste heat from various processes. The thermoelectric elements convert temperature differentials into electrical energy, which can then power the heat pump or other components. This integration creates a self-sustaining system that improves overall energy efficiency by utilizing heat that would otherwise be lost to the environment.

- Advanced control systems for thermoelectric-heat pump combinations: Sophisticated control systems can dynamically adjust the operation of integrated thermoelectric and heat pump systems based on environmental conditions, load requirements, and energy availability. These intelligent controls optimize the performance of each component to maximize overall system efficiency. By continuously monitoring and adjusting operating parameters, these systems can maintain optimal efficiency across a wide range of conditions.

- Miniaturized and portable thermoelectric-heat pump applications: Compact designs combining thermoelectric devices with small-scale heat pumps enable efficient portable or localized heating and cooling solutions. These systems leverage the solid-state nature of thermoelectric devices and efficient heat pump cycles to create energy-efficient solutions for personal comfort, medical applications, or electronic device cooling. The miniaturized designs optimize space utilization while maintaining high efficiency in small-scale applications.

02 Cascaded thermoelectric-heat pump configurations

Cascaded configurations involve arranging thermoelectric devices and heat pump components in series or parallel to optimize heat transfer across multiple temperature differentials. This approach allows for more efficient operation across larger temperature gradients than either technology could handle alone. By strategically staging the heat transfer process, these systems can maintain efficiency even when operating between widely separated temperature reservoirs, making them particularly valuable for applications requiring extreme temperature differentials.Expand Specific Solutions03 Waste heat recovery and utilization systems

Systems that combine thermoelectric generators with heat pumps can effectively recover and utilize waste heat from various processes. The thermoelectric components convert temperature differentials directly into electricity, which can then power heat pumps for additional heating or cooling applications. This integrated approach improves overall system efficiency by capturing energy that would otherwise be lost, creating a more sustainable energy cycle and reducing primary energy consumption.Expand Specific Solutions04 Advanced control strategies for thermoelectric-heat pump integration

Sophisticated control algorithms and systems optimize the operation of combined thermoelectric and heat pump technologies. These control strategies dynamically adjust the power distribution between components based on real-time conditions, load requirements, and available energy sources. By intelligently managing the operation of both technologies, these systems can maximize efficiency across varying environmental conditions and usage patterns, resulting in significant energy savings compared to conventional systems with simpler controls.Expand Specific Solutions05 Miniaturized and specialized thermoelectric-heat pump applications

Compact and specialized applications combine thermoelectric devices with small-scale heat pumps for targeted thermal management. These systems are particularly valuable in electronics cooling, medical devices, and portable applications where space is limited but precise temperature control is essential. The integration allows for highly responsive temperature regulation in a compact form factor, with designs that can be tailored to specific thermal profiles and power constraints of specialized equipment.Expand Specific Solutions

Leading Companies in Thermoelectric-Heat Pump Solutions

The integration of thermoelectrics with heat pumps for efficient buildings represents an emerging market in the early growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 15-20%. The competitive landscape features a mix of established HVAC manufacturers (Carrier, Trane, Siemens), specialized thermoelectric technology companies (Gentherm, TE Technology, Fahrenheit GmbH), and academic research institutions (Southeast University, Tongji University). Technical maturity varies significantly across applications, with Siemens, Carrier, and Toshiba leading in commercial implementations, while Fahrenheit GmbH and Gentherm demonstrate innovative approaches in thermal management integration. Academic-industry partnerships, particularly involving Southeast University and Tongji University, are accelerating technology development toward market-ready solutions for next-generation energy-efficient building systems.

Fahrenheit GmbH

Technical Solution: Fahrenheit GmbH has developed an innovative adsorption cooling system that combines thermoelectric elements with heat pump technology for building applications. Their solution utilizes zeolite-water adsorption technology that can be powered by waste heat or solar thermal energy at temperatures as low as 55°C. The system incorporates thermoelectric generators (TEGs) that convert temperature differentials into electricity, which is then used to power the control systems and circulation pumps of the heat pump. This hybrid approach allows buildings to achieve cooling and heating with minimal external electricity input. Fahrenheit's modular design enables scalability from small residential to large commercial buildings, with reported primary energy savings of up to 80% compared to conventional HVAC systems. Their technology effectively addresses the intermittency issues of renewable energy sources by creating a self-sustaining system that can operate during periods of low solar radiation or fluctuating waste heat availability.

Strengths: Highly energy-efficient with minimal external power requirements; can utilize low-grade waste heat that would otherwise be discarded; modular and scalable design. Weaknesses: Higher initial capital investment compared to conventional systems; requires careful system integration; performance depends on consistent availability of waste heat or solar thermal energy.

Carrier Corp.

Technical Solution: Carrier Corporation has developed a hybrid thermoelectric-enhanced heat pump system for commercial and residential buildings that combines conventional vapor compression technology with thermoelectric modules at critical heat exchange points. Their approach integrates thermoelectric devices at the evaporator and condenser interfaces to enhance temperature differentials and improve overall system coefficient of performance (COP). The system utilizes advanced semiconductor materials with high ZT values (figure of merit for thermoelectric efficiency) to maximize energy conversion efficiency. Carrier's solution includes smart controls that dynamically adjust the power distribution between the heat pump and thermoelectric components based on external conditions and demand requirements. This adaptive approach allows for optimal performance across varying climate conditions, with field tests demonstrating energy savings of 15-30% compared to conventional heat pumps. The system also incorporates heat recovery mechanisms that capture waste heat from the thermoelectric cooling process and redirect it for space or water heating applications, further improving overall system efficiency.

Strengths: Leverages existing heat pump infrastructure while enhancing performance; adaptive control system optimizes energy usage based on conditions; applicable to both new construction and retrofits. Weaknesses: Complex integration requires specialized installation and maintenance; higher upfront costs than standard heat pumps; optimal performance depends on sophisticated control algorithms that may require periodic updates.

Key Patents in Thermoelectric-Heat Pump Integration

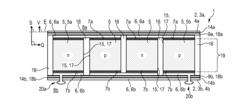

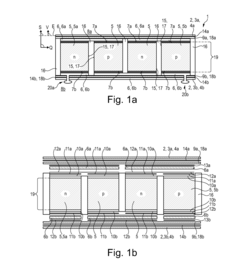

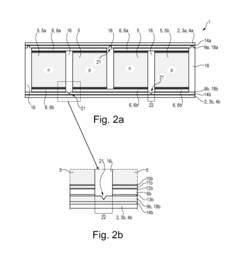

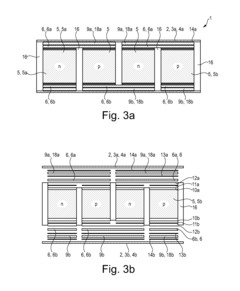

Thermoelectric device, in particular thermoelectric generator or heat pump

PatentActiveUS20160245556A1

Innovation

- The thermoelectric device employs an electrically conductive housing with two housing elements and electrical insulators, connected in a materially cohesive manner to conductor bridges, allowing for efficient thermal coupling and electrical insulation, and is arranged in a sandwich-like structure with thermoelectric elements and insulation foils for enhanced thermal and electrical performance.

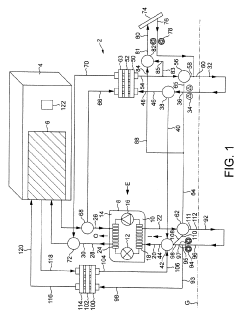

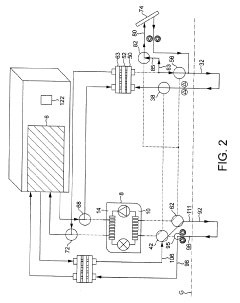

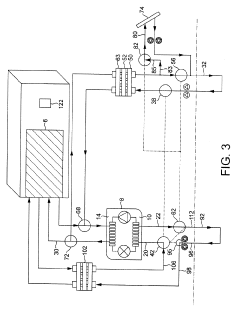

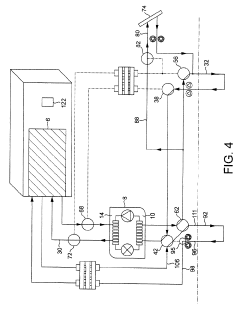

Thermal energy system and method of operation

PatentActiveUS20190309993A1

Innovation

- A thermal energy system that integrates a heat pump with two geothermal systems and switchable valve assemblies to selectively direct working fluids for heating and cooling, allowing for efficient energy transfer and reduced reliance on additional energy sources.

Energy Policy Impact on Hybrid Thermal Technologies

Energy policies across the globe are increasingly shaping the development and adoption of hybrid thermal technologies, particularly those combining thermoelectrics with heat pumps for building efficiency. The regulatory landscape has evolved significantly over the past decade, with many countries implementing stringent energy efficiency standards that directly influence technological innovation in this sector.

In the European Union, the Energy Performance of Buildings Directive (EPBD) has established comprehensive frameworks requiring near-zero energy buildings, creating a strong market pull for integrated thermal solutions. These policies have accelerated research funding and commercial deployment of thermoelectric-heat pump hybrid systems, particularly in countries like Germany and Denmark where renewable energy integration is prioritized.

The United States has approached policy differently, with a mix of federal tax incentives, state-level building codes, and utility rebate programs driving adoption. The Building Technologies Office within the Department of Energy has specifically targeted funding toward hybrid thermal technologies that can demonstrate significant efficiency improvements over conventional HVAC systems. This has resulted in several demonstration projects showcasing thermoelectric augmentation of heat pumps in various climate zones.

In Asia, particularly China and Japan, government-backed initiatives have focused on reducing urban heat island effects and meeting ambitious carbon reduction targets. These policies have stimulated substantial investment in manufacturing capacity for advanced thermoelectric materials, reducing costs and improving commercial viability of hybrid systems.

Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, have emerged as powerful drivers for hybrid thermal technology adoption. As the social cost of carbon becomes increasingly internalized in energy markets, the economic case for higher upfront investments in efficient building technologies strengthens considerably.

Building certification programs like LEED, BREEAM, and Passive House have also created market incentives that transcend direct regulation. These voluntary standards often reward innovative thermal solutions that can demonstrate superior performance metrics, creating premium market segments where thermoelectric-heat pump hybrids can command value despite higher initial costs.

Looking forward, policy trends suggest increasing emphasis on whole-building performance rather than component-level efficiency standards. This shift favors integrated approaches where thermoelectric elements can be strategically deployed to enhance conventional heat pump systems, particularly in addressing peak demand challenges and improving part-load performance.

In the European Union, the Energy Performance of Buildings Directive (EPBD) has established comprehensive frameworks requiring near-zero energy buildings, creating a strong market pull for integrated thermal solutions. These policies have accelerated research funding and commercial deployment of thermoelectric-heat pump hybrid systems, particularly in countries like Germany and Denmark where renewable energy integration is prioritized.

The United States has approached policy differently, with a mix of federal tax incentives, state-level building codes, and utility rebate programs driving adoption. The Building Technologies Office within the Department of Energy has specifically targeted funding toward hybrid thermal technologies that can demonstrate significant efficiency improvements over conventional HVAC systems. This has resulted in several demonstration projects showcasing thermoelectric augmentation of heat pumps in various climate zones.

In Asia, particularly China and Japan, government-backed initiatives have focused on reducing urban heat island effects and meeting ambitious carbon reduction targets. These policies have stimulated substantial investment in manufacturing capacity for advanced thermoelectric materials, reducing costs and improving commercial viability of hybrid systems.

Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, have emerged as powerful drivers for hybrid thermal technology adoption. As the social cost of carbon becomes increasingly internalized in energy markets, the economic case for higher upfront investments in efficient building technologies strengthens considerably.

Building certification programs like LEED, BREEAM, and Passive House have also created market incentives that transcend direct regulation. These voluntary standards often reward innovative thermal solutions that can demonstrate superior performance metrics, creating premium market segments where thermoelectric-heat pump hybrids can command value despite higher initial costs.

Looking forward, policy trends suggest increasing emphasis on whole-building performance rather than component-level efficiency standards. This shift favors integrated approaches where thermoelectric elements can be strategically deployed to enhance conventional heat pump systems, particularly in addressing peak demand challenges and improving part-load performance.

Cost-Benefit Analysis of Implementation Strategies

The implementation of combined thermoelectric and heat pump systems in buildings requires careful financial analysis to determine viability across different scenarios. Initial capital expenditure represents a significant barrier, with thermoelectric components adding approximately 15-30% to conventional heat pump installation costs. However, this premium varies substantially based on building scale, with larger commercial implementations benefiting from economies of scale that can reduce per-square-foot costs by up to 25% compared to residential applications.

Operational cost analysis reveals promising long-term economics. Energy consumption modeling indicates that hybrid systems can achieve 12-18% reduction in electricity usage compared to conventional heat pumps alone, with higher savings in extreme climate zones. When calculated over a 15-year operational lifespan, these systems typically reach financial break-even within 6-9 years in commercial settings and 8-11 years in residential applications, assuming current energy prices.

Implementation strategies significantly impact financial outcomes. The retrofit approach, integrating thermoelectric elements into existing heat pump infrastructure, offers the lowest initial investment but delivers more modest efficiency gains (7-10%). Conversely, purpose-built integrated systems require approximately 40% higher upfront investment but yield superior efficiency improvements (15-22%) and lower maintenance costs over time.

Maintenance considerations further influence the cost-benefit equation. Thermoelectric components demonstrate exceptional durability with minimal moving parts, reducing annual maintenance expenses by an estimated 8-12% compared to conventional systems. This advantage compounds over time, contributing significantly to favorable lifecycle cost calculations.

Financing mechanisms can substantially alter implementation feasibility. Energy performance contracting models, where installation costs are recovered through guaranteed energy savings, have proven particularly effective for commercial implementations, reducing initial capital barriers by 40-60%. Additionally, utility rebate programs in several regions offer incentives covering 10-25% of hybrid system costs, though these vary considerably by location.

Sensitivity analysis reveals that payback periods are most heavily influenced by energy price volatility, with a 20% increase in electricity costs accelerating break-even points by approximately 1.5 years. Climate zone also significantly impacts financial performance, with hybrid systems demonstrating superior cost-benefit ratios in regions experiencing extreme temperature differentials where conventional heat pumps struggle with efficiency.

Operational cost analysis reveals promising long-term economics. Energy consumption modeling indicates that hybrid systems can achieve 12-18% reduction in electricity usage compared to conventional heat pumps alone, with higher savings in extreme climate zones. When calculated over a 15-year operational lifespan, these systems typically reach financial break-even within 6-9 years in commercial settings and 8-11 years in residential applications, assuming current energy prices.

Implementation strategies significantly impact financial outcomes. The retrofit approach, integrating thermoelectric elements into existing heat pump infrastructure, offers the lowest initial investment but delivers more modest efficiency gains (7-10%). Conversely, purpose-built integrated systems require approximately 40% higher upfront investment but yield superior efficiency improvements (15-22%) and lower maintenance costs over time.

Maintenance considerations further influence the cost-benefit equation. Thermoelectric components demonstrate exceptional durability with minimal moving parts, reducing annual maintenance expenses by an estimated 8-12% compared to conventional systems. This advantage compounds over time, contributing significantly to favorable lifecycle cost calculations.

Financing mechanisms can substantially alter implementation feasibility. Energy performance contracting models, where installation costs are recovered through guaranteed energy savings, have proven particularly effective for commercial implementations, reducing initial capital barriers by 40-60%. Additionally, utility rebate programs in several regions offer incentives covering 10-25% of hybrid system costs, though these vary considerably by location.

Sensitivity analysis reveals that payback periods are most heavily influenced by energy price volatility, with a 20% increase in electricity costs accelerating break-even points by approximately 1.5 years. Climate zone also significantly impacts financial performance, with hybrid systems demonstrating superior cost-benefit ratios in regions experiencing extreme temperature differentials where conventional heat pumps struggle with efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!