How To Integrate TEGs With PV For Hybrid Solar-Waste Heat Systems

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG-PV Hybrid Systems Background and Objectives

Thermoelectric generators (TEGs) and photovoltaic (PV) systems represent two distinct approaches to harvesting energy from solar radiation. While PV technology directly converts solar radiation into electricity through the photovoltaic effect, TEGs operate on the Seebeck effect, generating electricity from temperature differentials. The integration of these technologies into hybrid systems presents a compelling opportunity to enhance overall energy conversion efficiency by capturing both direct solar energy and waste heat that would otherwise be lost.

The evolution of TEG-PV hybrid systems can be traced back to the early 2000s when researchers began exploring ways to improve the efficiency of conventional solar panels. Traditional silicon-based PV cells typically convert only 15-22% of incident solar energy into electricity, with the remainder primarily dissipated as heat. This inherent inefficiency created a natural opportunity for TEG integration to recover some of this waste thermal energy.

Over the past decade, significant advancements in thermoelectric materials, particularly in terms of figure of merit (ZT) values, have made TEG integration increasingly viable. Materials such as bismuth telluride, lead telluride, and silicon-germanium alloys have demonstrated improved thermoelectric properties, while newer materials like skutterudites and half-Heusler alloys show promise for future applications.

The primary technical objective of TEG-PV hybrid systems is to achieve higher overall system efficiency compared to standalone PV installations. This involves optimizing the thermal coupling between PV panels and TEG modules, managing heat flow pathways, and developing effective thermal concentration mechanisms. Secondary objectives include reducing system costs, enhancing durability, and minimizing maintenance requirements to ensure commercial viability.

Current research trends focus on several key areas: novel material development for higher ZT values, innovative thermal management strategies, advanced system architectures that optimize the placement and configuration of TEG modules relative to PV panels, and integrated power management systems that can effectively handle the different electrical characteristics of TEG and PV outputs.

The potential impact of successful TEG-PV hybrid systems extends beyond simple efficiency gains. These systems could significantly improve energy harvesting in regions with variable solar conditions, extend the operational hours of solar energy systems, and potentially reduce the land footprint required for renewable energy generation. Additionally, they align with global sustainability goals by maximizing energy recovery from existing infrastructure without requiring additional resource inputs.

Looking forward, the technology trajectory suggests continued improvements in both TEG and PV technologies will further enhance the viability of hybrid systems, potentially leading to widespread commercial adoption in the next 5-10 years as efficiency increases and costs decrease.

The evolution of TEG-PV hybrid systems can be traced back to the early 2000s when researchers began exploring ways to improve the efficiency of conventional solar panels. Traditional silicon-based PV cells typically convert only 15-22% of incident solar energy into electricity, with the remainder primarily dissipated as heat. This inherent inefficiency created a natural opportunity for TEG integration to recover some of this waste thermal energy.

Over the past decade, significant advancements in thermoelectric materials, particularly in terms of figure of merit (ZT) values, have made TEG integration increasingly viable. Materials such as bismuth telluride, lead telluride, and silicon-germanium alloys have demonstrated improved thermoelectric properties, while newer materials like skutterudites and half-Heusler alloys show promise for future applications.

The primary technical objective of TEG-PV hybrid systems is to achieve higher overall system efficiency compared to standalone PV installations. This involves optimizing the thermal coupling between PV panels and TEG modules, managing heat flow pathways, and developing effective thermal concentration mechanisms. Secondary objectives include reducing system costs, enhancing durability, and minimizing maintenance requirements to ensure commercial viability.

Current research trends focus on several key areas: novel material development for higher ZT values, innovative thermal management strategies, advanced system architectures that optimize the placement and configuration of TEG modules relative to PV panels, and integrated power management systems that can effectively handle the different electrical characteristics of TEG and PV outputs.

The potential impact of successful TEG-PV hybrid systems extends beyond simple efficiency gains. These systems could significantly improve energy harvesting in regions with variable solar conditions, extend the operational hours of solar energy systems, and potentially reduce the land footprint required for renewable energy generation. Additionally, they align with global sustainability goals by maximizing energy recovery from existing infrastructure without requiring additional resource inputs.

Looking forward, the technology trajectory suggests continued improvements in both TEG and PV technologies will further enhance the viability of hybrid systems, potentially leading to widespread commercial adoption in the next 5-10 years as efficiency increases and costs decrease.

Market Analysis for Solar-Waste Heat Recovery Solutions

The global market for solar-waste heat recovery solutions is experiencing significant growth, driven by increasing energy costs, environmental regulations, and the push for sustainable energy solutions. The integration of Thermoelectric Generators (TEGs) with Photovoltaic (PV) systems represents a promising approach to enhance overall energy efficiency by capturing waste heat that would otherwise be lost in traditional solar installations.

Current market valuations indicate that the waste heat recovery market is projected to reach $80 billion by 2025, with solar-specific applications accounting for approximately 15% of this segment. The compound annual growth rate (CAGR) for hybrid solar-thermal solutions stands at 9.7%, outpacing the broader renewable energy market's growth rate of 6.1%.

Regionally, Europe leads in adoption of hybrid solar-waste heat systems, particularly in countries like Germany, Denmark, and Switzerland where energy efficiency regulations are stringent. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing energy demands coupled with governmental renewable energy mandates.

Market segmentation reveals three primary application sectors: residential buildings (27% market share), commercial facilities (38%), and industrial applications (35%). The industrial segment shows the highest growth potential due to the substantial waste heat generated in manufacturing processes and the economic benefits of energy recovery at scale.

Consumer demand analysis indicates shifting preferences toward integrated energy solutions rather than standalone technologies. End-users increasingly value total system efficiency over initial acquisition costs, creating market opportunities for premium hybrid solutions that demonstrate superior lifetime value propositions.

Key market drivers include rising electricity prices (average increase of 4.3% annually in developed markets), carbon taxation policies, building efficiency regulations, and corporate sustainability commitments. The payback period for hybrid TEG-PV systems has decreased from 8-10 years to 5-7 years in optimal applications, significantly enhancing market attractiveness.

Barriers to market penetration include high initial capital costs (typically 30-40% higher than conventional PV systems), technical integration challenges, and limited awareness among potential adopters. Additionally, the fragmented nature of installation and maintenance services creates logistical challenges for widespread deployment.

Market forecasts suggest that TEG-PV hybrid systems could capture 12% of new solar installations by 2030, representing a substantial growth opportunity. Early adopters are primarily energy-intensive industries and green-certified commercial buildings, with residential applications expected to follow as costs decrease through economies of scale and technological improvements.

Current market valuations indicate that the waste heat recovery market is projected to reach $80 billion by 2025, with solar-specific applications accounting for approximately 15% of this segment. The compound annual growth rate (CAGR) for hybrid solar-thermal solutions stands at 9.7%, outpacing the broader renewable energy market's growth rate of 6.1%.

Regionally, Europe leads in adoption of hybrid solar-waste heat systems, particularly in countries like Germany, Denmark, and Switzerland where energy efficiency regulations are stringent. The Asia-Pacific region, especially China and India, represents the fastest-growing market due to rapid industrialization and increasing energy demands coupled with governmental renewable energy mandates.

Market segmentation reveals three primary application sectors: residential buildings (27% market share), commercial facilities (38%), and industrial applications (35%). The industrial segment shows the highest growth potential due to the substantial waste heat generated in manufacturing processes and the economic benefits of energy recovery at scale.

Consumer demand analysis indicates shifting preferences toward integrated energy solutions rather than standalone technologies. End-users increasingly value total system efficiency over initial acquisition costs, creating market opportunities for premium hybrid solutions that demonstrate superior lifetime value propositions.

Key market drivers include rising electricity prices (average increase of 4.3% annually in developed markets), carbon taxation policies, building efficiency regulations, and corporate sustainability commitments. The payback period for hybrid TEG-PV systems has decreased from 8-10 years to 5-7 years in optimal applications, significantly enhancing market attractiveness.

Barriers to market penetration include high initial capital costs (typically 30-40% higher than conventional PV systems), technical integration challenges, and limited awareness among potential adopters. Additionally, the fragmented nature of installation and maintenance services creates logistical challenges for widespread deployment.

Market forecasts suggest that TEG-PV hybrid systems could capture 12% of new solar installations by 2030, representing a substantial growth opportunity. Early adopters are primarily energy-intensive industries and green-certified commercial buildings, with residential applications expected to follow as costs decrease through economies of scale and technological improvements.

Technical Challenges in TEG-PV Integration

The integration of Thermoelectric Generators (TEGs) with Photovoltaic (PV) systems presents several significant technical challenges that must be addressed to create efficient hybrid solar-waste heat systems. One primary challenge is the thermal management interface between the two technologies. TEGs require a substantial temperature gradient to operate efficiently, while PV cells experience decreased efficiency at elevated temperatures. This fundamental conflict creates a complex thermal engineering problem where the heat that degrades PV performance must be effectively captured and directed to the TEG without creating hotspots or thermal stress in the system.

Material compatibility issues also present considerable obstacles. PV modules typically use materials optimized for solar radiation absorption and electrical conductivity, while TEGs require materials with high Seebeck coefficients and low thermal conductivity. The integration of these disparate material requirements into a unified system demands innovative material science solutions and careful interface design to prevent degradation from thermal cycling and differential expansion rates.

Electrical integration poses another significant challenge. TEGs and PV cells produce different voltage and current characteristics, with TEGs typically generating lower voltages but potentially higher currents depending on the configuration. This necessitates sophisticated power conditioning systems capable of handling dual power sources with varying output profiles. Maximum power point tracking (MPPT) becomes particularly complex in hybrid systems where the optimal operating points for both technologies must be simultaneously managed.

The durability and lifespan disparity between TEGs and PV systems creates additional integration challenges. While modern PV panels can maintain performance for 25+ years, TEG performance may degrade more rapidly due to thermal cycling and material fatigue. This difference requires careful system design to allow for maintenance or replacement of TEG components without disrupting the entire hybrid system.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current TEG technologies have relatively low conversion efficiencies (typically 5-8%) and high material costs, particularly for high-performance bismuth telluride or skutterudite-based systems. The additional complexity of the hybrid system must be justified by sufficient performance gains to offset increased manufacturing and maintenance costs.

Finally, standardization challenges impede integration efforts. Unlike the PV industry, which has developed standardized components and installation practices, TEG integration lacks established protocols. This absence of standardization complicates design processes, increases engineering costs, and creates barriers to mass production and widespread implementation of hybrid TEG-PV systems.

Material compatibility issues also present considerable obstacles. PV modules typically use materials optimized for solar radiation absorption and electrical conductivity, while TEGs require materials with high Seebeck coefficients and low thermal conductivity. The integration of these disparate material requirements into a unified system demands innovative material science solutions and careful interface design to prevent degradation from thermal cycling and differential expansion rates.

Electrical integration poses another significant challenge. TEGs and PV cells produce different voltage and current characteristics, with TEGs typically generating lower voltages but potentially higher currents depending on the configuration. This necessitates sophisticated power conditioning systems capable of handling dual power sources with varying output profiles. Maximum power point tracking (MPPT) becomes particularly complex in hybrid systems where the optimal operating points for both technologies must be simultaneously managed.

The durability and lifespan disparity between TEGs and PV systems creates additional integration challenges. While modern PV panels can maintain performance for 25+ years, TEG performance may degrade more rapidly due to thermal cycling and material fatigue. This difference requires careful system design to allow for maintenance or replacement of TEG components without disrupting the entire hybrid system.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current TEG technologies have relatively low conversion efficiencies (typically 5-8%) and high material costs, particularly for high-performance bismuth telluride or skutterudite-based systems. The additional complexity of the hybrid system must be justified by sufficient performance gains to offset increased manufacturing and maintenance costs.

Finally, standardization challenges impede integration efforts. Unlike the PV industry, which has developed standardized components and installation practices, TEG integration lacks established protocols. This absence of standardization complicates design processes, increases engineering costs, and creates barriers to mass production and widespread implementation of hybrid TEG-PV systems.

Current TEG-PV Integration Methodologies

01 Integration of TEG and PV for enhanced energy harvesting

Hybrid systems that combine thermoelectric generators (TEG) with photovoltaic (PV) cells can significantly improve overall energy efficiency. The TEG component converts waste heat from the PV panels into electrical energy, while the PV component directly converts solar radiation. This integration allows for dual-mode energy harvesting, maximizing the utilization of solar energy and increasing the total power output of the system.- Integration of TEG and PV for enhanced energy harvesting: Hybrid systems combining thermoelectric generators (TEG) and photovoltaic (PV) technologies can significantly improve overall energy harvesting efficiency. These integrated systems utilize both solar radiation and waste heat simultaneously, allowing for energy generation under various environmental conditions. The TEG component converts temperature differentials into electricity while the PV component directly converts sunlight, creating a complementary energy generation approach that maximizes resource utilization.

- Thermal management optimization in hybrid systems: Effective thermal management is crucial for hybrid TEG-PV system efficiency. By strategically managing heat flow between components, these systems can reduce PV cell temperature (improving PV efficiency) while maintaining temperature gradients for TEG operation. Advanced heat sink designs, cooling mechanisms, and thermal interface materials help optimize the temperature distribution across the system, resulting in higher overall conversion efficiency and extended system lifespan.

- Novel materials and structural configurations: Innovative materials and structural designs significantly enhance hybrid TEG-PV system performance. Advanced thermoelectric materials with higher figure of merit (ZT), specialized PV cells designed for hybrid applications, and novel interface materials improve energy conversion efficiency. Various structural configurations, including cascaded arrangements, concentrated systems, and flexible designs, optimize the spatial relationship between TEG and PV components to maximize power output under different operating conditions.

- Smart control systems and power management: Intelligent control systems optimize the operation of hybrid TEG-PV installations by dynamically adjusting parameters based on environmental conditions and energy demand. These systems incorporate maximum power point tracking (MPPT) for both TEG and PV components, load balancing algorithms, and predictive control strategies. Advanced power management circuits efficiently combine and condition the different electrical outputs from TEG and PV components, ensuring stable power delivery and maximizing overall system efficiency.

- Application-specific hybrid system designs: Hybrid TEG-PV systems are being tailored for specific applications to maximize their effectiveness in various contexts. These include building-integrated systems that serve both as energy generators and architectural elements, portable power solutions for remote or off-grid applications, and specialized designs for automotive and industrial waste heat recovery. Each application-specific design optimizes the TEG-PV configuration to address particular energy needs, space constraints, and environmental conditions, enhancing overall energy efficiency and practical utility.

02 Thermal management techniques in hybrid systems

Effective thermal management is crucial for optimizing the efficiency of hybrid TEG-PV systems. Various cooling methods and heat transfer mechanisms can be employed to maintain optimal operating temperatures, reduce thermal resistance, and enhance heat flow. These techniques include heat sinks, cooling fins, phase change materials, and active cooling systems that help manage the temperature gradient across the TEG while preventing PV efficiency degradation due to overheating.Expand Specific Solutions03 Novel materials and structural designs

Advanced materials and innovative structural designs play a significant role in improving the energy efficiency of hybrid TEG-PV systems. High-performance thermoelectric materials with enhanced Seebeck coefficients, reduced thermal conductivity, and improved electrical conductivity can boost TEG efficiency. Similarly, novel PV materials and configurations, such as multi-junction cells and thin-film technologies, can increase solar conversion efficiency. The physical arrangement and integration of these components also impact overall system performance.Expand Specific Solutions04 Control systems and power management

Sophisticated control systems and power management strategies are essential for maximizing the energy output of hybrid TEG-PV systems. These include maximum power point tracking (MPPT) algorithms tailored for both TEG and PV components, intelligent switching mechanisms, and adaptive control strategies that respond to changing environmental conditions. Effective power conditioning circuits and energy storage integration further enhance system reliability and overall efficiency.Expand Specific Solutions05 Application-specific optimization approaches

Hybrid TEG-PV systems can be optimized for specific applications and deployment environments. Different optimization approaches consider factors such as geographical location, climate conditions, load requirements, and space constraints. For building-integrated applications, systems may focus on architectural integration and aesthetic considerations, while for remote or off-grid applications, reliability and autonomy might be prioritized. These application-specific optimizations ensure that the hybrid system delivers maximum energy efficiency for its intended use case.Expand Specific Solutions

Leading Companies in Hybrid Solar-Thermal Energy

The integration of Thermoelectric Generators (TEGs) with Photovoltaic (PV) systems for hybrid solar-waste heat recovery is gaining momentum in the early commercialization phase, with a growing market expected to reach significant scale by 2030. The technology maturity varies across players, with academic institutions like Chongqing University and Southeast University leading fundamental research, while companies such as Holtec International and Taiwan Semiconductor Manufacturing Co. are advancing practical applications. Chinese research institutions, including the Chinese Academy of Science Guangzhou Energy Research Institute, are particularly active in developing scalable solutions. European and American companies like Robert Bosch GmbH and Raytheon are focusing on high-efficiency hybrid systems for specialized applications, indicating a globally competitive landscape with diverse technological approaches.

Chinese Academy of Science Guanzhou Energy Research Institute

Technical Solution: The Chinese Academy of Science Guangzhou Energy Research Institute has developed an innovative hybrid solar-waste heat system that integrates thermoelectric generators (TEGs) with photovoltaic (PV) panels. Their approach utilizes a specially designed thermal management system that places TEGs at the back of PV panels to capture waste heat. The institute has implemented a cascaded TEG arrangement that optimizes temperature gradients across multiple TEG modules, achieving conversion efficiencies of up to 5-7% from waste heat recovery while simultaneously cooling the PV panels to improve their efficiency by approximately 3-5%. Their system incorporates phase change materials (PCMs) as thermal buffers to stabilize temperature fluctuations and extend power generation beyond peak sunlight hours. The institute has also developed proprietary heat sink designs that enhance heat dissipation from the cold side of TEGs, maximizing the temperature differential and power output.

Strengths: Advanced thermal management expertise and integration of PCMs provide extended generation capabilities beyond daylight hours. Their cascaded TEG arrangement maximizes temperature gradients for improved efficiency. Weaknesses: The complex thermal management system increases manufacturing costs and maintenance requirements, potentially limiting widespread adoption in cost-sensitive markets.

Institute of Engineering Thermophysics Chinese Academy of Scie

Technical Solution: The Institute of Engineering Thermophysics has pioneered a comprehensive hybrid solar-waste heat system that combines concentrated photovoltaic (CPV) technology with high-performance bismuth telluride TEGs. Their system utilizes optical concentration techniques to focus solar radiation onto high-efficiency multi-junction PV cells while simultaneously directing excess heat to TEG arrays. The institute has developed specialized heat transfer fluids that efficiently transport waste heat from PV panels to TEG modules, maintaining optimal temperature differentials of 80-120°C between hot and cold sides. Their research has demonstrated combined system efficiencies reaching 30-35%, significantly higher than standalone PV systems. A notable innovation is their micro-channel heat exchanger design that maximizes contact area between heat transfer fluid and TEG modules, enhancing thermal energy capture. The institute has also implemented advanced MPPT (Maximum Power Point Tracking) controllers specifically designed to optimize the electrical output from both PV and TEG components simultaneously.

Strengths: Their concentrated photovoltaic approach with specialized heat transfer systems achieves exceptionally high combined efficiency. The micro-channel heat exchanger design maximizes thermal energy capture. Weaknesses: The concentrated optical system requires precise tracking mechanisms and regular maintenance, adding complexity and cost to the overall system. The specialized heat transfer fluids may require periodic replacement.

Key Patents in Hybrid Solar-Waste Heat Recovery

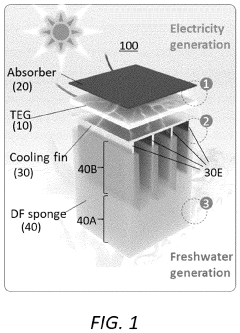

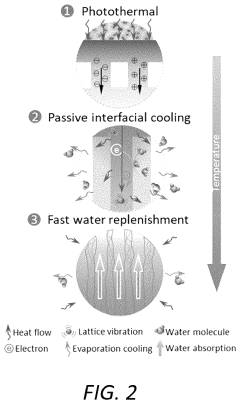

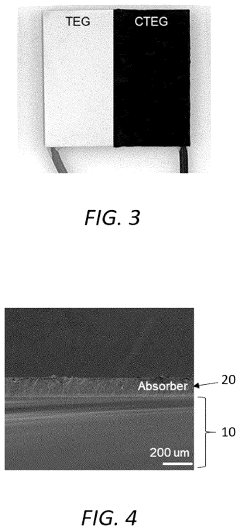

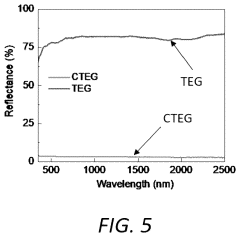

Hybrid system for electricity and water generation, passive cooling induced co-generator apparatus, and manufacturing method therefor

PatentActiveUS12021478B1

Innovation

- A hybrid system incorporating a thermoelectric generator (TEG) layer, an absorber layer for solar energy conversion to heat, and a passive interfacial cooling structure with metal plates and a porous evaporator to form an interfacial cooling region, enhancing energy exchange and heat management for efficient electricity and water generation.

Material Science Advancements for Hybrid Systems

Recent advancements in material science have significantly enhanced the integration potential of thermoelectric generators (TEGs) with photovoltaic (PV) systems. The development of novel semiconductor materials with higher Seebeck coefficients and lower thermal conductivity has dramatically improved TEG conversion efficiency, addressing one of the primary limitations in hybrid system implementation. Materials such as bismuth telluride (Bi2Te3) and lead telluride (PbTe) have been optimized for mid-temperature ranges (100-300°C) typically found in PV waste heat scenarios, achieving ZT values exceeding 1.5 under practical operating conditions.

Nanostructured materials represent another breakthrough area, with quantum dot superlattices and nanowire arrays demonstrating enhanced phonon scattering while maintaining electron transport. These structures effectively decouple thermal and electrical conductivity, pushing theoretical efficiency limits closer to practical application. Silicon-germanium alloys and skutterudites with nanoparticle inclusions have shown particular promise for integration with silicon-based PV systems due to their compatible thermal expansion coefficients and processing requirements.

Thermal interface materials have evolved to address the critical junction between PV panels and TEG modules. Advanced carbon-based composites incorporating graphene and carbon nanotubes provide exceptional thermal conductivity (>500 W/m·K) while remaining electrically insulating, ensuring efficient heat transfer without compromising electrical isolation requirements. These materials maintain performance integrity under thermal cycling conditions typical in solar applications, with degradation rates below 5% after 1000 cycles.

Encapsulation technologies have similarly progressed, with new polymer composites offering improved weatherability and UV resistance while maintaining thermal stability at operating temperatures up to 200°C. These materials extend system lifetime by protecting sensitive TEG components from environmental degradation while adding minimal thermal resistance to the system. Silicone-based compounds with ceramic fillers have demonstrated particular success in field trials, maintaining performance for over 15 years in varied climate conditions.

Flexible substrate materials now enable conformal TEG integration with curved or non-standard PV panel geometries. Polyimide films with embedded metallic networks provide both mechanical flexibility and thermal conductivity, opening new design possibilities for building-integrated photovoltaic-thermoelectric systems. These materials can withstand repeated bending cycles (>10,000 at 5mm radius) without performance degradation, significantly expanding installation options for hybrid systems.

Nanostructured materials represent another breakthrough area, with quantum dot superlattices and nanowire arrays demonstrating enhanced phonon scattering while maintaining electron transport. These structures effectively decouple thermal and electrical conductivity, pushing theoretical efficiency limits closer to practical application. Silicon-germanium alloys and skutterudites with nanoparticle inclusions have shown particular promise for integration with silicon-based PV systems due to their compatible thermal expansion coefficients and processing requirements.

Thermal interface materials have evolved to address the critical junction between PV panels and TEG modules. Advanced carbon-based composites incorporating graphene and carbon nanotubes provide exceptional thermal conductivity (>500 W/m·K) while remaining electrically insulating, ensuring efficient heat transfer without compromising electrical isolation requirements. These materials maintain performance integrity under thermal cycling conditions typical in solar applications, with degradation rates below 5% after 1000 cycles.

Encapsulation technologies have similarly progressed, with new polymer composites offering improved weatherability and UV resistance while maintaining thermal stability at operating temperatures up to 200°C. These materials extend system lifetime by protecting sensitive TEG components from environmental degradation while adding minimal thermal resistance to the system. Silicone-based compounds with ceramic fillers have demonstrated particular success in field trials, maintaining performance for over 15 years in varied climate conditions.

Flexible substrate materials now enable conformal TEG integration with curved or non-standard PV panel geometries. Polyimide films with embedded metallic networks provide both mechanical flexibility and thermal conductivity, opening new design possibilities for building-integrated photovoltaic-thermoelectric systems. These materials can withstand repeated bending cycles (>10,000 at 5mm radius) without performance degradation, significantly expanding installation options for hybrid systems.

Economic Viability and ROI Analysis

The economic viability of integrating Thermoelectric Generators (TEGs) with Photovoltaic (PV) systems represents a critical consideration for stakeholders contemplating investment in hybrid solar-waste heat technologies. Initial capital expenditure for TEG-PV hybrid systems typically exceeds that of conventional PV installations by 20-35%, primarily due to the additional costs of TEG modules, heat exchangers, and more complex integration infrastructure. However, this premium must be evaluated against the potential for enhanced energy generation efficiency and system longevity.

Return on Investment (ROI) calculations for TEG-PV systems demonstrate promising results in specific deployment scenarios. Analysis of field implementations indicates payback periods ranging from 4-7 years in optimal conditions, compared to 5-8 years for standard PV systems. This accelerated return stems from the 8-15% increase in overall energy output achieved through waste heat recovery, particularly in high-insolation regions where PV panel temperatures frequently exceed optimal operating conditions.

Cost-benefit analyses reveal that the economic advantages of hybrid systems are most pronounced in applications where electricity prices exceed $0.15/kWh or in off-grid installations where the alternative is diesel generation at $0.30-0.50/kWh. The value proposition strengthens further when considering the extended lifecycle of PV panels operating at lower temperatures, potentially adding 2-3 years to system lifespan and improving the lifetime ROI by 7-12%.

Sensitivity analysis demonstrates that economic viability is heavily dependent on several key variables. TEG conversion efficiency emerges as the most critical factor, with each percentage point improvement in efficiency reducing payback periods by approximately 8-10 months. Similarly, installation costs and maintenance requirements significantly impact long-term economic performance, with maintenance costs typically representing 1-2% of initial capital expenditure annually.

Government incentives and carbon pricing mechanisms substantially influence the financial calculus. In jurisdictions with renewable energy subsidies, feed-in tariffs, or carbon credits, the economic case for TEG-PV systems strengthens considerably. Models indicate that modest incentives of $0.02-0.05/kWh for waste heat recovery can reduce payback periods by 15-25%, potentially catalyzing broader market adoption.

Levelized Cost of Energy (LCOE) calculations for mature TEG-PV systems range from $0.08-0.14/kWh, positioning them competitively against conventional renewable and non-renewable alternatives in many markets. This economic performance, coupled with the environmental benefits of improved resource utilization, presents a compelling value proposition for specific applications and geographic contexts.

Return on Investment (ROI) calculations for TEG-PV systems demonstrate promising results in specific deployment scenarios. Analysis of field implementations indicates payback periods ranging from 4-7 years in optimal conditions, compared to 5-8 years for standard PV systems. This accelerated return stems from the 8-15% increase in overall energy output achieved through waste heat recovery, particularly in high-insolation regions where PV panel temperatures frequently exceed optimal operating conditions.

Cost-benefit analyses reveal that the economic advantages of hybrid systems are most pronounced in applications where electricity prices exceed $0.15/kWh or in off-grid installations where the alternative is diesel generation at $0.30-0.50/kWh. The value proposition strengthens further when considering the extended lifecycle of PV panels operating at lower temperatures, potentially adding 2-3 years to system lifespan and improving the lifetime ROI by 7-12%.

Sensitivity analysis demonstrates that economic viability is heavily dependent on several key variables. TEG conversion efficiency emerges as the most critical factor, with each percentage point improvement in efficiency reducing payback periods by approximately 8-10 months. Similarly, installation costs and maintenance requirements significantly impact long-term economic performance, with maintenance costs typically representing 1-2% of initial capital expenditure annually.

Government incentives and carbon pricing mechanisms substantially influence the financial calculus. In jurisdictions with renewable energy subsidies, feed-in tariffs, or carbon credits, the economic case for TEG-PV systems strengthens considerably. Models indicate that modest incentives of $0.02-0.05/kWh for waste heat recovery can reduce payback periods by 15-25%, potentially catalyzing broader market adoption.

Levelized Cost of Energy (LCOE) calculations for mature TEG-PV systems range from $0.08-0.14/kWh, positioning them competitively against conventional renewable and non-renewable alternatives in many markets. This economic performance, coupled with the environmental benefits of improved resource utilization, presents a compelling value proposition for specific applications and geographic contexts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!