How To Improve High-Temperature Stability Of Thermoelectric Materials

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Objectives

Thermoelectric materials have emerged as a promising solution for direct conversion between thermal and electrical energy, offering significant potential for waste heat recovery and environmentally friendly power generation. The development of these materials dates back to the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821, followed by the Peltier effect in 1834. However, it wasn't until the mid-20th century that substantial progress was made in understanding and enhancing their performance characteristics.

The evolution of thermoelectric technology has been marked by several key milestones, including the development of semiconductor-based thermoelectric materials in the 1950s, the introduction of nanostructured materials in the 1990s, and recent advancements in complex crystal structures and composite materials. These developments have progressively improved the figure of merit (ZT), which quantifies thermoelectric efficiency, from less than 1 to values approaching 2.5 in laboratory settings.

Despite these advances, the widespread commercial adoption of thermoelectric technology remains constrained by several factors, with high-temperature stability being one of the most critical challenges. Many promising thermoelectric materials exhibit excellent performance at moderate temperatures but suffer from significant degradation when exposed to elevated operating conditions, limiting their practical applications in high-temperature waste heat recovery systems.

The primary technical objective in this field is to develop thermoelectric materials that maintain structural integrity, chemical stability, and optimal electronic and thermal transport properties at temperatures exceeding 600°C. This involves addressing issues such as oxidation, sublimation, phase transitions, and interface degradation that commonly occur at high temperatures.

Current research trends focus on several approaches, including the exploration of intrinsically stable material systems like skutterudites, half-Heusler alloys, and silicides; the development of protective coatings and encapsulation techniques; and the engineering of compositionally graded structures that can withstand thermal cycling and temperature gradients.

The technological trajectory suggests a growing emphasis on multifunctional thermoelectric systems that combine high-temperature stability with other desirable properties such as mechanical robustness, cost-effectiveness, and environmental compatibility. Emerging research directions also include the investigation of novel synthesis methods, defect engineering strategies, and interface design principles to enhance high-temperature performance.

Achieving breakthroughs in high-temperature thermoelectric materials would unlock significant opportunities in automotive exhaust heat recovery, industrial process optimization, and advanced power generation systems, potentially contributing to global energy efficiency goals and carbon emission reduction targets.

The evolution of thermoelectric technology has been marked by several key milestones, including the development of semiconductor-based thermoelectric materials in the 1950s, the introduction of nanostructured materials in the 1990s, and recent advancements in complex crystal structures and composite materials. These developments have progressively improved the figure of merit (ZT), which quantifies thermoelectric efficiency, from less than 1 to values approaching 2.5 in laboratory settings.

Despite these advances, the widespread commercial adoption of thermoelectric technology remains constrained by several factors, with high-temperature stability being one of the most critical challenges. Many promising thermoelectric materials exhibit excellent performance at moderate temperatures but suffer from significant degradation when exposed to elevated operating conditions, limiting their practical applications in high-temperature waste heat recovery systems.

The primary technical objective in this field is to develop thermoelectric materials that maintain structural integrity, chemical stability, and optimal electronic and thermal transport properties at temperatures exceeding 600°C. This involves addressing issues such as oxidation, sublimation, phase transitions, and interface degradation that commonly occur at high temperatures.

Current research trends focus on several approaches, including the exploration of intrinsically stable material systems like skutterudites, half-Heusler alloys, and silicides; the development of protective coatings and encapsulation techniques; and the engineering of compositionally graded structures that can withstand thermal cycling and temperature gradients.

The technological trajectory suggests a growing emphasis on multifunctional thermoelectric systems that combine high-temperature stability with other desirable properties such as mechanical robustness, cost-effectiveness, and environmental compatibility. Emerging research directions also include the investigation of novel synthesis methods, defect engineering strategies, and interface design principles to enhance high-temperature performance.

Achieving breakthroughs in high-temperature thermoelectric materials would unlock significant opportunities in automotive exhaust heat recovery, industrial process optimization, and advanced power generation systems, potentially contributing to global energy efficiency goals and carbon emission reduction targets.

Market Analysis for High-Temperature Thermoelectric Applications

The global market for high-temperature thermoelectric applications is experiencing significant growth, driven by increasing demand for waste heat recovery systems and energy efficiency solutions across various industries. The market value for thermoelectric generators capable of operating at elevated temperatures (>400°C) reached approximately $520 million in 2022 and is projected to grow at a compound annual growth rate of 8.3% through 2030.

Automotive and industrial manufacturing sectors represent the largest market segments, collectively accounting for over 60% of the current demand. The automotive industry's push toward more fuel-efficient vehicles has created substantial opportunities for thermoelectric materials that can convert exhaust heat into usable electricity. Major automotive manufacturers have begun integrating thermoelectric generators into their vehicle designs, with BMW and Ford leading commercial implementations.

The aerospace sector presents another rapidly expanding market, with an estimated growth rate of 12.7% annually. Space exploration applications require thermoelectric materials capable of withstanding extreme temperature gradients while maintaining structural integrity and conversion efficiency. NASA and other space agencies have increased their investment in high-temperature thermoelectric research by approximately 35% over the past five years.

Power generation and heavy industries represent significant untapped potential, particularly in regions with stringent emissions regulations. The European Union's carbon neutrality goals have accelerated adoption of waste heat recovery technologies, creating a market estimated at $180 million annually for high-temperature thermoelectric solutions.

Geographic distribution of market demand shows North America leading with 38% market share, followed by Asia-Pacific (32%) and Europe (24%). China has emerged as the fastest-growing market with annual growth exceeding 15%, driven by government initiatives promoting energy efficiency and industrial modernization.

Customer requirements analysis reveals three primary market drivers: temperature stability (cited by 87% of potential customers), conversion efficiency (82%), and long-term reliability (79%). Cost considerations, while important, rank below these performance metrics for high-temperature applications, indicating a premium market segment where performance outweighs price sensitivity.

Market barriers include high initial implementation costs, integration challenges with existing systems, and limited awareness of thermoelectric technology benefits. The average return on investment period currently stands at 3.2 years for industrial applications, a timeframe that needs reduction to accelerate broader market adoption.

Emerging application areas showing promising growth include concentrated solar power, nuclear energy, and deep geothermal systems, all of which require materials capable of maintaining stability and performance at temperatures exceeding 700°C. These applications could potentially expand the market by an additional $300 million by 2028.

Automotive and industrial manufacturing sectors represent the largest market segments, collectively accounting for over 60% of the current demand. The automotive industry's push toward more fuel-efficient vehicles has created substantial opportunities for thermoelectric materials that can convert exhaust heat into usable electricity. Major automotive manufacturers have begun integrating thermoelectric generators into their vehicle designs, with BMW and Ford leading commercial implementations.

The aerospace sector presents another rapidly expanding market, with an estimated growth rate of 12.7% annually. Space exploration applications require thermoelectric materials capable of withstanding extreme temperature gradients while maintaining structural integrity and conversion efficiency. NASA and other space agencies have increased their investment in high-temperature thermoelectric research by approximately 35% over the past five years.

Power generation and heavy industries represent significant untapped potential, particularly in regions with stringent emissions regulations. The European Union's carbon neutrality goals have accelerated adoption of waste heat recovery technologies, creating a market estimated at $180 million annually for high-temperature thermoelectric solutions.

Geographic distribution of market demand shows North America leading with 38% market share, followed by Asia-Pacific (32%) and Europe (24%). China has emerged as the fastest-growing market with annual growth exceeding 15%, driven by government initiatives promoting energy efficiency and industrial modernization.

Customer requirements analysis reveals three primary market drivers: temperature stability (cited by 87% of potential customers), conversion efficiency (82%), and long-term reliability (79%). Cost considerations, while important, rank below these performance metrics for high-temperature applications, indicating a premium market segment where performance outweighs price sensitivity.

Market barriers include high initial implementation costs, integration challenges with existing systems, and limited awareness of thermoelectric technology benefits. The average return on investment period currently stands at 3.2 years for industrial applications, a timeframe that needs reduction to accelerate broader market adoption.

Emerging application areas showing promising growth include concentrated solar power, nuclear energy, and deep geothermal systems, all of which require materials capable of maintaining stability and performance at temperatures exceeding 700°C. These applications could potentially expand the market by an additional $300 million by 2028.

Current Challenges in High-Temperature Thermoelectric Stability

Despite significant advancements in thermoelectric materials, their high-temperature stability remains a critical challenge that limits widespread industrial application. The primary issue stems from the inherent material degradation that occurs under sustained high-temperature operation, particularly above 600°C. This degradation manifests through several mechanisms, including oxidation, sublimation, phase separation, and microstructural changes that progressively reduce conversion efficiency and operational lifespan.

Oxidation represents one of the most severe challenges, especially for telluride-based materials which rapidly oxidize when exposed to air at elevated temperatures. This chemical transformation fundamentally alters the material's electronic properties and thermal conductivity, rendering it increasingly ineffective for thermoelectric conversion. Even in vacuum or inert environments, many high-performance thermoelectric compounds experience sublimation, where constituent elements volatilize at different rates, disrupting the carefully engineered stoichiometry.

Thermal cycling between ambient and operating temperatures induces mechanical stress that leads to microcracking and interfacial delamination in multi-component systems. These structural defects create thermal and electrical resistance barriers that significantly degrade device performance over time. Additionally, the thermal expansion mismatch between different components in thermoelectric modules exacerbates mechanical failure modes during temperature fluctuations.

Dopant precipitation and migration represent another significant stability challenge. At high temperatures, dopant atoms become increasingly mobile and tend to cluster or migrate toward interfaces, resulting in non-uniform carrier concentration and compromised electronic properties. Similarly, interdiffusion between adjacent materials in thermoelectric modules creates unwanted interfacial phases with poor thermoelectric properties.

The metastability of many high-performance thermoelectric materials presents further complications. Materials optimized for room temperature performance often undergo phase transformations at elevated temperatures, transitioning to structures with less favorable thermoelectric properties. This phase instability fundamentally limits the temperature range for efficient operation.

Contact resistance issues also become more pronounced at high temperatures. The electrical and thermal interfaces between thermoelectric materials and metal electrodes deteriorate over time due to interdiffusion and formation of intermetallic compounds with high electrical resistivity. These interface degradation mechanisms significantly reduce overall system efficiency and reliability.

Addressing these challenges requires interdisciplinary approaches combining materials science, solid-state chemistry, and engineering solutions to develop inherently stable materials or effective protection strategies that can maintain performance under extreme thermal conditions.

Oxidation represents one of the most severe challenges, especially for telluride-based materials which rapidly oxidize when exposed to air at elevated temperatures. This chemical transformation fundamentally alters the material's electronic properties and thermal conductivity, rendering it increasingly ineffective for thermoelectric conversion. Even in vacuum or inert environments, many high-performance thermoelectric compounds experience sublimation, where constituent elements volatilize at different rates, disrupting the carefully engineered stoichiometry.

Thermal cycling between ambient and operating temperatures induces mechanical stress that leads to microcracking and interfacial delamination in multi-component systems. These structural defects create thermal and electrical resistance barriers that significantly degrade device performance over time. Additionally, the thermal expansion mismatch between different components in thermoelectric modules exacerbates mechanical failure modes during temperature fluctuations.

Dopant precipitation and migration represent another significant stability challenge. At high temperatures, dopant atoms become increasingly mobile and tend to cluster or migrate toward interfaces, resulting in non-uniform carrier concentration and compromised electronic properties. Similarly, interdiffusion between adjacent materials in thermoelectric modules creates unwanted interfacial phases with poor thermoelectric properties.

The metastability of many high-performance thermoelectric materials presents further complications. Materials optimized for room temperature performance often undergo phase transformations at elevated temperatures, transitioning to structures with less favorable thermoelectric properties. This phase instability fundamentally limits the temperature range for efficient operation.

Contact resistance issues also become more pronounced at high temperatures. The electrical and thermal interfaces between thermoelectric materials and metal electrodes deteriorate over time due to interdiffusion and formation of intermetallic compounds with high electrical resistivity. These interface degradation mechanisms significantly reduce overall system efficiency and reliability.

Addressing these challenges requires interdisciplinary approaches combining materials science, solid-state chemistry, and engineering solutions to develop inherently stable materials or effective protection strategies that can maintain performance under extreme thermal conditions.

State-of-the-Art High-Temperature Stability Solutions

01 High-temperature stable thermoelectric materials composition

Specific material compositions have been developed to maintain thermoelectric performance at elevated temperatures. These include advanced semiconductor alloys, nanostructured composites, and doped materials that resist degradation under thermal stress. These compositions are engineered to maintain their crystal structure, electrical conductivity, and Seebeck coefficient at high temperatures, which is crucial for power generation applications in extreme environments.- High-temperature stable thermoelectric materials composition: Specific material compositions have been developed to enhance the thermal stability of thermoelectric materials at high temperatures. These compositions include various alloys, compounds, and doped materials that maintain their thermoelectric properties even when subjected to elevated temperatures. The materials are engineered with specific crystal structures and chemical bonds that resist degradation, phase changes, or oxidation at high temperatures, making them suitable for applications in harsh thermal environments.

- Protective coatings and encapsulation techniques: Various protective coatings and encapsulation methods have been developed to enhance the high-temperature stability of thermoelectric materials. These techniques involve applying layers of thermally resistant materials that prevent oxidation, sublimation, or other degradation mechanisms that occur at elevated temperatures. The protective layers can be ceramic, metallic, or composite materials that form a barrier between the thermoelectric material and the surrounding environment, thereby extending the operational temperature range and lifetime of the thermoelectric devices.

- Nanostructured thermoelectric materials for thermal stability: Nanostructuring approaches have been employed to enhance the high-temperature stability of thermoelectric materials. By engineering materials at the nanoscale, researchers have created structures that can better withstand thermal expansion and contraction cycles while maintaining their thermoelectric performance. These nanostructured materials often feature grain boundaries, interfaces, or inclusions that impede thermal conductivity while allowing electrical conductivity, resulting in improved thermoelectric efficiency and stability at elevated temperatures.

- Testing and characterization methods for high-temperature stability: Specialized testing and characterization methods have been developed to evaluate the high-temperature stability of thermoelectric materials. These techniques include accelerated aging tests, thermal cycling, and in-situ measurements of thermoelectric properties at elevated temperatures. Advanced analytical tools such as high-temperature X-ray diffraction, thermal analysis, and electron microscopy are used to monitor structural changes, phase transitions, and degradation mechanisms that affect the long-term stability and performance of thermoelectric materials under high-temperature operating conditions.

- Device designs for high-temperature thermoelectric applications: Innovative device designs have been created specifically for high-temperature thermoelectric applications. These designs incorporate structural elements that accommodate thermal expansion, reduce thermal stress, and protect the thermoelectric materials from degradation. Features such as specialized electrical contacts, thermal barriers, and mechanical support structures are integrated to ensure the thermoelectric modules maintain their integrity and performance at elevated temperatures. The designs also consider heat transfer optimization and system integration aspects to maximize efficiency in high-temperature environments.

02 Protective coatings and encapsulation techniques

Various protective coatings and encapsulation methods have been developed to shield thermoelectric materials from oxidation and degradation at high temperatures. These include ceramic barriers, glass seals, and specialized metal oxide layers that prevent sublimation and maintain material integrity. These protection systems allow thermoelectric devices to operate reliably in high-temperature environments while preserving their electrical and thermal properties.Expand Specific Solutions03 Nanostructured thermoelectric materials for thermal stability

Nanostructuring approaches have been implemented to enhance the thermal stability of thermoelectric materials. By incorporating nanoscale features such as quantum dots, nanowires, or grain boundaries, these materials can better withstand thermal cycling and high-temperature operation. The nanostructures help reduce thermal conductivity while maintaining electrical conductivity, leading to improved thermoelectric performance and stability at elevated temperatures.Expand Specific Solutions04 Interface engineering for high-temperature thermoelectric devices

Interface engineering techniques focus on optimizing the boundaries between different materials in thermoelectric devices to enhance high-temperature stability. This includes developing specialized contact materials, diffusion barriers, and gradient structures that minimize thermal stress and prevent interdiffusion at elevated temperatures. These engineered interfaces maintain electrical connectivity and structural integrity during thermal cycling and prolonged high-temperature operation.Expand Specific Solutions05 Testing and characterization methods for high-temperature stability

Advanced testing and characterization methodologies have been developed to evaluate the thermal stability of thermoelectric materials. These include accelerated aging tests, in-situ high-temperature measurements, and thermal cycling protocols that assess performance degradation over time. Analytical techniques such as high-temperature X-ray diffraction, electron microscopy, and spectroscopic methods help identify failure mechanisms and validate the long-term stability of thermoelectric materials under extreme conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric materials high-temperature stability market is in a growth phase, with increasing demand driven by energy efficiency needs across automotive, industrial, and power generation sectors. The global market is projected to expand significantly as applications in waste heat recovery systems gain traction. Technologically, the field shows moderate maturity with ongoing innovation focused on improving performance at elevated temperatures. Key players include established electronics corporations like Toshiba, LG Electronics, and Panasonic, alongside specialized companies such as Hangzhou Dahe Thermo-Magnetics. Academic institutions (MIT, Waseda University) collaborate with industrial leaders (DENSO, Siemens) to advance material science breakthroughs, particularly in nanostructuring and composite development for enhanced thermal stability and efficiency at high temperatures.

Mitsubishi Materials Corp.

Technical Solution: Mitsubishi Materials has developed advanced thermoelectric materials with enhanced high-temperature stability through their proprietary metallurgical processing techniques. Their approach focuses on skutterudite and silicide-based compounds engineered for industrial waste heat recovery applications. Mitsubishi's research team has pioneered a multi-phase sintering process that creates controlled grain boundaries, effectively limiting grain growth at elevated temperatures while maintaining electrical performance. Their materials incorporate carefully selected dopants that form thermodynamically stable precipitates at operating temperatures, creating a self-stabilizing microstructure. Mitsubishi has also developed specialized protective coatings using refractory metal silicides that prevent oxidation and sublimation at temperatures exceeding 700°C. Their latest generation materials feature gradient structures with composition varying throughout the thermoelectric elements, strategically distributing thermal stresses during temperature cycling. This approach has demonstrated stable performance for over 10,000 hours at temperatures up to 650°C in industrial testing environments, with degradation rates below 5% - a significant improvement over conventional materials.

Strengths: Exceptional expertise in metallurgical processing techniques; strong focus on long-term stability rather than peak performance; excellent capabilities for large-scale manufacturing. Weaknesses: Solutions often involve complex processing steps increasing production costs; approaches typically sacrifice some peak ZT value to achieve stability; limited success with very high temperature (>800°C) applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered innovative approaches to improve high-temperature stability of thermoelectric materials through nanostructuring techniques. Their research focuses on creating complex nanostructured materials that can maintain structural integrity at elevated temperatures while simultaneously reducing thermal conductivity. MIT researchers have developed a method involving controlled precipitation of nanoscale phases within bulk thermoelectric materials, creating interfaces that scatter phonons without significantly affecting electron transport. This approach has demonstrated remarkable stability at temperatures exceeding 800°C in skutterudite and half-Heusler compounds. Additionally, MIT has explored the use of rare-earth element doping to create point defects that enhance phonon scattering while maintaining electrical conductivity. Their recent work on phase-change materials with self-healing capabilities shows promise for applications requiring thermal cycling, as these materials can repair microcracks that typically form during temperature fluctuations.

Strengths: Superior nanostructuring expertise allowing precise control of material interfaces; strong integration of theoretical modeling with experimental validation; access to advanced characterization facilities. Weaknesses: Solutions often involve expensive rare-earth elements; scaling manufacturing processes from lab to industrial scale remains challenging; some approaches require complex processing techniques that may limit commercial viability.

Critical Patents and Research on Thermal Degradation Prevention

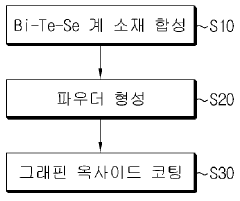

Bi-Te-Se based thermoelectric powder and materials with improved thermostability and manufacturing methods thereof

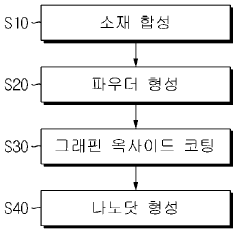

PatentInactiveKR1020170065308A

Innovation

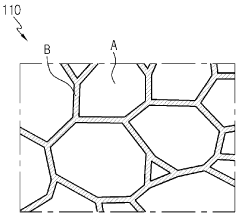

- A Bi-Te-Se-based thermoelectric material coated with a graphene oxide shell to enhance thermal stability, preventing volatilization and diffusion, and incorporating graphene oxide at grain boundaries to improve thermal conductivity and electrical properties.

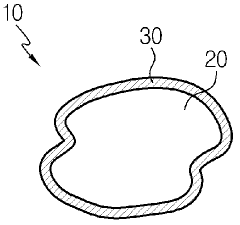

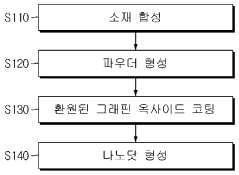

Thermoelectric powder and materials with improved thermostability and thermoelectric properties and manufacturing methods thereof

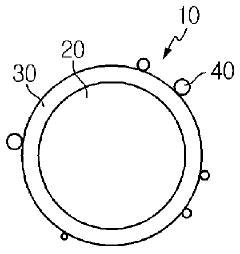

PatentInactiveKR1020170097432A

Innovation

- A thermoelectric powder composed of a thermoelectric material core coated with reduced graphene oxide and nano dots is used, where the core includes skutterudite particles, and the shell is made of reduced graphene oxide with nano dots formed on its surface, enhancing thermal stability and thermoelectric properties.

Material Characterization and Testing Methodologies

Comprehensive characterization and rigorous testing methodologies are essential for evaluating the high-temperature stability of thermoelectric materials. X-ray diffraction (XRD) serves as a primary technique for monitoring phase stability and structural changes during thermal cycling, allowing researchers to identify phase transitions or decomposition that may occur at elevated temperatures. The detection of secondary phases or structural degradation through XRD provides critical insights into material stability boundaries.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enables detailed microstructural analysis and elemental mapping, revealing grain boundary evolution, elemental diffusion, and potential segregation effects that impact long-term stability. These techniques are particularly valuable for identifying sublimation or oxidation processes that commonly occur at high temperatures.

Thermal conductivity measurements under sustained high-temperature conditions represent another crucial testing methodology. Laser flash analysis (LFA) and steady-state techniques can track thermal transport property changes over extended periods, with particular attention to hysteresis effects during heating and cooling cycles. These measurements must be conducted in controlled atmospheres to distinguish intrinsic material degradation from environmental reactions.

Electrical property characterization through temperature-dependent Seebeck coefficient and electrical conductivity measurements provides direct evidence of electronic structure stability. Advanced setups capable of simultaneous measurement of multiple thermoelectric parameters at temperatures exceeding 800°C are increasingly becoming standard for comprehensive evaluation.

Thermogravimetric analysis (TGA) combined with differential scanning calorimetry (DSC) offers quantitative assessment of mass changes and phase transitions during thermal cycling. These techniques can detect subtle decomposition processes, volatilization of components, or oxidation reactions that might not be immediately apparent in performance testing but significantly impact long-term stability.

Accelerated aging tests represent perhaps the most practical methodology for stability assessment. Materials are subjected to thermal cycling or extended high-temperature exposure under conditions that simulate or exceed operational parameters. Post-aging characterization using the aforementioned techniques provides a comprehensive picture of degradation mechanisms and stability limitations.

Advanced spectroscopic methods including Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) offer complementary information about bonding changes and surface chemistry alterations at high temperatures. These techniques are particularly valuable for understanding oxidation processes and interface stability in complex thermoelectric systems.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDX) enables detailed microstructural analysis and elemental mapping, revealing grain boundary evolution, elemental diffusion, and potential segregation effects that impact long-term stability. These techniques are particularly valuable for identifying sublimation or oxidation processes that commonly occur at high temperatures.

Thermal conductivity measurements under sustained high-temperature conditions represent another crucial testing methodology. Laser flash analysis (LFA) and steady-state techniques can track thermal transport property changes over extended periods, with particular attention to hysteresis effects during heating and cooling cycles. These measurements must be conducted in controlled atmospheres to distinguish intrinsic material degradation from environmental reactions.

Electrical property characterization through temperature-dependent Seebeck coefficient and electrical conductivity measurements provides direct evidence of electronic structure stability. Advanced setups capable of simultaneous measurement of multiple thermoelectric parameters at temperatures exceeding 800°C are increasingly becoming standard for comprehensive evaluation.

Thermogravimetric analysis (TGA) combined with differential scanning calorimetry (DSC) offers quantitative assessment of mass changes and phase transitions during thermal cycling. These techniques can detect subtle decomposition processes, volatilization of components, or oxidation reactions that might not be immediately apparent in performance testing but significantly impact long-term stability.

Accelerated aging tests represent perhaps the most practical methodology for stability assessment. Materials are subjected to thermal cycling or extended high-temperature exposure under conditions that simulate or exceed operational parameters. Post-aging characterization using the aforementioned techniques provides a comprehensive picture of degradation mechanisms and stability limitations.

Advanced spectroscopic methods including Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) offer complementary information about bonding changes and surface chemistry alterations at high temperatures. These techniques are particularly valuable for understanding oxidation processes and interface stability in complex thermoelectric systems.

Environmental Impact and Sustainability Considerations

The environmental implications of thermoelectric materials development extend far beyond their immediate applications. As these materials gain prominence in waste heat recovery systems, their environmental footprint becomes increasingly significant. The production of conventional thermoelectric materials often involves rare earth elements and heavy metals such as tellurium, bismuth, and lead, which present substantial environmental concerns during extraction, processing, and disposal phases. Mining operations for these elements typically generate significant land disruption, water pollution, and energy consumption, contributing to broader ecological degradation.

The high-temperature stability improvements in thermoelectric materials offer promising environmental benefits through enhanced energy efficiency. By converting waste heat into usable electricity at higher operating temperatures, these materials can significantly reduce primary energy consumption across industrial sectors. For instance, thermoelectric generators installed in automotive exhaust systems can improve fuel efficiency by 3-5%, translating to substantial reductions in greenhouse gas emissions when implemented at scale.

Life cycle assessment studies indicate that the environmental payback period for thermoelectric systems depends heavily on material stability and operational lifetime. High-temperature stable materials that maintain performance over extended periods (>100,000 hours) demonstrate significantly better environmental profiles than those requiring frequent replacement. This underscores the importance of stability improvements not just for performance but also for sustainability metrics.

Recent advances in nano-structured thermoelectric materials present both opportunities and challenges from an environmental perspective. While these structures enhance performance characteristics, their production often involves energy-intensive processes and specialized chemicals. Additionally, the potential environmental and health impacts of nanoparticle release during manufacturing, use, or disposal remain inadequately understood and require further investigation.

The recyclability of thermoelectric materials represents another critical sustainability consideration. Current high-performance thermoelectric devices often utilize complex material compositions and configurations that complicate end-of-life recovery. Research into design-for-disassembly approaches and recovery methodologies for valuable elements could significantly improve the circular economy potential of these technologies, reducing their overall environmental impact.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials, including restrictions on hazardous substances. Future development of high-temperature thermoelectric materials must navigate these evolving regulations, potentially accelerating the transition toward more environmentally benign compositions that maintain performance without relying on toxic or scarce elements.

The high-temperature stability improvements in thermoelectric materials offer promising environmental benefits through enhanced energy efficiency. By converting waste heat into usable electricity at higher operating temperatures, these materials can significantly reduce primary energy consumption across industrial sectors. For instance, thermoelectric generators installed in automotive exhaust systems can improve fuel efficiency by 3-5%, translating to substantial reductions in greenhouse gas emissions when implemented at scale.

Life cycle assessment studies indicate that the environmental payback period for thermoelectric systems depends heavily on material stability and operational lifetime. High-temperature stable materials that maintain performance over extended periods (>100,000 hours) demonstrate significantly better environmental profiles than those requiring frequent replacement. This underscores the importance of stability improvements not just for performance but also for sustainability metrics.

Recent advances in nano-structured thermoelectric materials present both opportunities and challenges from an environmental perspective. While these structures enhance performance characteristics, their production often involves energy-intensive processes and specialized chemicals. Additionally, the potential environmental and health impacts of nanoparticle release during manufacturing, use, or disposal remain inadequately understood and require further investigation.

The recyclability of thermoelectric materials represents another critical sustainability consideration. Current high-performance thermoelectric devices often utilize complex material compositions and configurations that complicate end-of-life recovery. Research into design-for-disassembly approaches and recovery methodologies for valuable elements could significantly improve the circular economy potential of these technologies, reducing their overall environmental impact.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced materials, including restrictions on hazardous substances. Future development of high-temperature thermoelectric materials must navigate these evolving regulations, potentially accelerating the transition toward more environmentally benign compositions that maintain performance without relying on toxic or scarce elements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!