How To Implement Thermoelectric Boost In Battery Thermal Management Systems

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Boost Technology Background and Objectives

Thermoelectric technology has evolved significantly since its discovery in the early 19th century with the Seebeck effect, where a temperature difference across two dissimilar electrical conductors produces a voltage difference. The subsequent discovery of the Peltier effect in 1834 demonstrated that passing an electric current through a junction of two different conductors could create heating or cooling. These fundamental principles have laid the groundwork for modern thermoelectric applications in various industries.

In recent decades, thermoelectric technology has seen substantial advancements in materials science and engineering, leading to improved efficiency and broader applications. The integration of thermoelectric elements into battery thermal management systems represents a cutting-edge approach to addressing the critical challenges of battery performance, safety, and longevity in electric vehicles (EVs), portable electronics, and energy storage systems.

The evolution of battery technologies, particularly lithium-ion batteries, has created an urgent need for sophisticated thermal management solutions. As energy densities increase and charging speeds accelerate, the heat generated during operation has become a significant concern. Traditional cooling methods often struggle to maintain optimal temperature ranges, especially under extreme conditions or rapid charging scenarios.

Thermoelectric boost technology aims to leverage the bidirectional nature of thermoelectric devices to both cool and heat battery systems as needed, maintaining optimal operating temperatures regardless of ambient conditions. This approach offers precise temperature control at the cell or module level, potentially extending battery life by up to 30% and improving performance metrics across various operating conditions.

The primary technical objectives for implementing thermoelectric boost in battery thermal management systems include developing high-efficiency thermoelectric materials with improved figure of merit (ZT values), designing compact and lightweight integration solutions compatible with existing battery architectures, and creating intelligent control systems that optimize power consumption while maintaining ideal thermal conditions.

Additionally, the technology seeks to address the energy consumption concerns traditionally associated with thermoelectric systems by implementing regenerative approaches that can harvest waste heat during certain operating conditions, thereby improving overall system efficiency. This circular energy approach aligns with broader sustainability goals in the transportation and energy sectors.

Future development trajectories point toward the integration of advanced semiconductor materials, nanoscale engineering techniques, and AI-driven thermal management algorithms to further enhance the efficiency and effectiveness of thermoelectric boost systems. The convergence of these technological trends presents significant opportunities for breakthrough innovations in battery thermal management.

In recent decades, thermoelectric technology has seen substantial advancements in materials science and engineering, leading to improved efficiency and broader applications. The integration of thermoelectric elements into battery thermal management systems represents a cutting-edge approach to addressing the critical challenges of battery performance, safety, and longevity in electric vehicles (EVs), portable electronics, and energy storage systems.

The evolution of battery technologies, particularly lithium-ion batteries, has created an urgent need for sophisticated thermal management solutions. As energy densities increase and charging speeds accelerate, the heat generated during operation has become a significant concern. Traditional cooling methods often struggle to maintain optimal temperature ranges, especially under extreme conditions or rapid charging scenarios.

Thermoelectric boost technology aims to leverage the bidirectional nature of thermoelectric devices to both cool and heat battery systems as needed, maintaining optimal operating temperatures regardless of ambient conditions. This approach offers precise temperature control at the cell or module level, potentially extending battery life by up to 30% and improving performance metrics across various operating conditions.

The primary technical objectives for implementing thermoelectric boost in battery thermal management systems include developing high-efficiency thermoelectric materials with improved figure of merit (ZT values), designing compact and lightweight integration solutions compatible with existing battery architectures, and creating intelligent control systems that optimize power consumption while maintaining ideal thermal conditions.

Additionally, the technology seeks to address the energy consumption concerns traditionally associated with thermoelectric systems by implementing regenerative approaches that can harvest waste heat during certain operating conditions, thereby improving overall system efficiency. This circular energy approach aligns with broader sustainability goals in the transportation and energy sectors.

Future development trajectories point toward the integration of advanced semiconductor materials, nanoscale engineering techniques, and AI-driven thermal management algorithms to further enhance the efficiency and effectiveness of thermoelectric boost systems. The convergence of these technological trends presents significant opportunities for breakthrough innovations in battery thermal management.

Market Demand Analysis for Advanced Battery Thermal Management

The global market for advanced battery thermal management systems is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Market research indicates that the battery thermal management system market is projected to grow at a compound annual growth rate of 13.7% from 2023 to 2030, reaching a market value of 12.1 billion USD by the end of the forecast period. This growth trajectory is underpinned by increasing consumer demand for EVs with extended range capabilities and faster charging times, both of which are directly impacted by thermal management efficiency.

Thermoelectric boost technology represents a particularly promising segment within this market. Industry surveys reveal that approximately 67% of EV manufacturers are actively exploring or implementing advanced thermal management solutions, with thermoelectric systems gaining significant attention due to their bidirectional heating and cooling capabilities. This interest is further amplified by stringent regulatory frameworks in major automotive markets that mandate improved battery safety and performance standards.

Consumer expectations are evolving rapidly in the EV sector, with recent market studies highlighting that over 78% of potential EV buyers consider battery longevity and performance in extreme weather conditions as critical purchasing factors. This consumer awareness is creating market pull for more sophisticated thermal management solutions that can maintain optimal battery temperature ranges across diverse operating environments.

The commercial vehicle segment presents another substantial market opportunity, with fleet operators increasingly focused on total cost of ownership calculations that factor in battery lifespan and operational reliability. Data from commercial fleet trials indicates that advanced thermal management systems can extend battery service life by up to 25%, representing significant operational cost savings that justify premium pricing for these technologies.

Geographically, the North American and European markets currently demonstrate the highest demand for advanced battery thermal management systems, accounting for approximately 63% of global market share. However, the Asia-Pacific region, particularly China, is expected to witness the fastest growth rate in the coming years due to aggressive EV adoption policies and substantial investments in manufacturing infrastructure.

Market analysis also reveals emerging demand from adjacent sectors, including stationary energy storage systems and consumer electronics, which are beginning to adopt similar thermal management technologies. This cross-sector application potential expands the addressable market for thermoelectric boost technologies beyond automotive applications, creating additional commercialization pathways and economies of scale.

Thermoelectric boost technology represents a particularly promising segment within this market. Industry surveys reveal that approximately 67% of EV manufacturers are actively exploring or implementing advanced thermal management solutions, with thermoelectric systems gaining significant attention due to their bidirectional heating and cooling capabilities. This interest is further amplified by stringent regulatory frameworks in major automotive markets that mandate improved battery safety and performance standards.

Consumer expectations are evolving rapidly in the EV sector, with recent market studies highlighting that over 78% of potential EV buyers consider battery longevity and performance in extreme weather conditions as critical purchasing factors. This consumer awareness is creating market pull for more sophisticated thermal management solutions that can maintain optimal battery temperature ranges across diverse operating environments.

The commercial vehicle segment presents another substantial market opportunity, with fleet operators increasingly focused on total cost of ownership calculations that factor in battery lifespan and operational reliability. Data from commercial fleet trials indicates that advanced thermal management systems can extend battery service life by up to 25%, representing significant operational cost savings that justify premium pricing for these technologies.

Geographically, the North American and European markets currently demonstrate the highest demand for advanced battery thermal management systems, accounting for approximately 63% of global market share. However, the Asia-Pacific region, particularly China, is expected to witness the fastest growth rate in the coming years due to aggressive EV adoption policies and substantial investments in manufacturing infrastructure.

Market analysis also reveals emerging demand from adjacent sectors, including stationary energy storage systems and consumer electronics, which are beginning to adopt similar thermal management technologies. This cross-sector application potential expands the addressable market for thermoelectric boost technologies beyond automotive applications, creating additional commercialization pathways and economies of scale.

Current State and Challenges in Thermoelectric Battery Management

Thermoelectric technology in battery thermal management systems (BTMS) currently faces significant implementation challenges despite its promising potential. Globally, research institutions and automotive manufacturers have made substantial progress in developing thermoelectric materials with improved figure of merit (ZT values), yet commercial applications remain limited due to efficiency constraints and cost barriers.

The current state of thermoelectric BTMS implementation shows a fragmented landscape. While laboratory demonstrations have proven the concept's viability, mass production solutions remain scarce. Most existing systems utilize conventional cooling methods such as liquid cooling, air cooling, or phase change materials, with thermoelectric elements serving primarily as supplementary components rather than core solutions.

Technical limitations present the most significant barriers to widespread adoption. Contemporary thermoelectric materials exhibit conversion efficiencies typically below 10%, substantially lower than alternative thermal management technologies. This efficiency challenge is particularly pronounced in electric vehicle applications where energy conservation directly impacts range performance. Additionally, the power consumption requirements of thermoelectric systems can create parasitic loads that potentially offset their thermal management benefits.

Manufacturing scalability represents another critical challenge. Current production methods for high-performance thermoelectric materials often involve complex processes and expensive raw materials, including tellurium, bismuth, and various rare earth elements. These factors contribute to prohibitively high costs for mass-market implementation, with estimates suggesting thermoelectric solutions can be 3-5 times more expensive than conventional cooling systems.

Integration complexity further complicates implementation efforts. Thermoelectric modules require sophisticated control systems to optimize performance across varying operational conditions. The bidirectional heating/cooling capability of thermoelectric devices necessitates advanced algorithms to determine optimal power input and polarity switching timing. Moreover, the physical integration of thermoelectric modules with battery cells demands careful thermal interface management to minimize contact resistance.

Reliability and durability concerns also persist in automotive applications. Thermoelectric materials must withstand thermal cycling, mechanical vibration, and potential exposure to contaminants over vehicle lifetimes exceeding 10-15 years. Current generation materials often show performance degradation under these conditions, with efficiency losses of 15-30% reported after extended cycling.

Regulatory frameworks and standardization remain underdeveloped for thermoelectric BTMS applications. The absence of industry-wide performance metrics, safety standards, and testing protocols creates uncertainty for manufacturers considering adoption of this technology, further slowing implementation progress despite its theoretical advantages in weight reduction and system simplification.

The current state of thermoelectric BTMS implementation shows a fragmented landscape. While laboratory demonstrations have proven the concept's viability, mass production solutions remain scarce. Most existing systems utilize conventional cooling methods such as liquid cooling, air cooling, or phase change materials, with thermoelectric elements serving primarily as supplementary components rather than core solutions.

Technical limitations present the most significant barriers to widespread adoption. Contemporary thermoelectric materials exhibit conversion efficiencies typically below 10%, substantially lower than alternative thermal management technologies. This efficiency challenge is particularly pronounced in electric vehicle applications where energy conservation directly impacts range performance. Additionally, the power consumption requirements of thermoelectric systems can create parasitic loads that potentially offset their thermal management benefits.

Manufacturing scalability represents another critical challenge. Current production methods for high-performance thermoelectric materials often involve complex processes and expensive raw materials, including tellurium, bismuth, and various rare earth elements. These factors contribute to prohibitively high costs for mass-market implementation, with estimates suggesting thermoelectric solutions can be 3-5 times more expensive than conventional cooling systems.

Integration complexity further complicates implementation efforts. Thermoelectric modules require sophisticated control systems to optimize performance across varying operational conditions. The bidirectional heating/cooling capability of thermoelectric devices necessitates advanced algorithms to determine optimal power input and polarity switching timing. Moreover, the physical integration of thermoelectric modules with battery cells demands careful thermal interface management to minimize contact resistance.

Reliability and durability concerns also persist in automotive applications. Thermoelectric materials must withstand thermal cycling, mechanical vibration, and potential exposure to contaminants over vehicle lifetimes exceeding 10-15 years. Current generation materials often show performance degradation under these conditions, with efficiency losses of 15-30% reported after extended cycling.

Regulatory frameworks and standardization remain underdeveloped for thermoelectric BTMS applications. The absence of industry-wide performance metrics, safety standards, and testing protocols creates uncertainty for manufacturers considering adoption of this technology, further slowing implementation progress despite its theoretical advantages in weight reduction and system simplification.

Current Thermoelectric Boost Implementation Approaches

01 Thermoelectric cooling systems for electronic devices

Thermoelectric cooling systems utilize the Peltier effect to manage thermal conditions in electronic devices. These systems can efficiently transfer heat away from critical components, maintaining optimal operating temperatures. Advanced implementations include integrated circuits with thermoelectric elements that can be selectively activated based on thermal load requirements, providing dynamic thermal management capabilities for processors, memory modules, and other heat-generating components.- Thermoelectric cooling systems for electronic devices: Thermoelectric cooling systems utilize the Peltier effect to manage thermal conditions in electronic devices. These systems can efficiently transfer heat away from critical components, maintaining optimal operating temperatures. Advanced implementations include integrated control systems that adjust cooling intensity based on real-time temperature monitoring, improving energy efficiency while providing effective thermal management for high-performance computing and mobile devices.

- Vehicle thermal management using thermoelectric generators: Thermoelectric generators convert waste heat from vehicle engines and exhaust systems into usable electrical energy, simultaneously providing cooling effects. This dual-purpose technology improves fuel efficiency by reducing the load on alternators while enhancing thermal management. Advanced systems incorporate heat exchangers and specialized materials to maximize temperature differentials and boost conversion efficiency in automotive applications.

- Integrated circuit cooling with thermoelectric boost technology: Specialized thermoelectric cooling solutions for integrated circuits employ advanced semiconductor materials to create precise cooling zones on chips. These systems can target hotspots on processors and memory components with localized cooling, preventing thermal throttling and improving performance. The technology incorporates thin-film thermoelectric materials directly into chip packaging, enabling more efficient heat dissipation in compact electronic devices.

- Renewable energy systems with thermoelectric enhancement: Thermoelectric technologies are integrated with renewable energy systems to improve overall efficiency through thermal management. These hybrid systems recover waste heat from solar panels and convert it to additional electricity, improving total system output. The technology also helps maintain optimal operating temperatures for solar cells and energy storage components, extending their operational lifespan and maintaining peak performance under varying environmental conditions.

- Smart thermal management systems with AI control: Advanced thermal management systems incorporate artificial intelligence to optimize thermoelectric cooling performance. These smart systems use predictive algorithms to anticipate thermal loads and adjust cooling parameters proactively. The technology includes networked temperature sensors, machine learning models for thermal pattern recognition, and adaptive control systems that balance cooling performance with energy consumption, particularly beneficial in data centers and high-performance computing environments.

02 Vehicle thermal management using thermoelectric technology

Thermoelectric devices are implemented in vehicles to enhance thermal management efficiency. These systems can recover waste heat from engine components and convert it to electrical energy, improving overall vehicle efficiency. Applications include cabin climate control, battery thermal management in electric vehicles, and engine cooling systems. The technology enables precise temperature control while reducing the energy consumption compared to conventional cooling methods.Expand Specific Solutions03 Thermoelectric material innovations for enhanced efficiency

Advanced thermoelectric materials are being developed to improve the conversion efficiency between thermal and electrical energy. These materials exhibit enhanced Seebeck coefficients and reduced thermal conductivity, leading to higher figures of merit (ZT values). Innovations include nanostructured materials, semiconductor alloys, and composite structures that can operate effectively across wider temperature ranges, making them suitable for various thermal management applications.Expand Specific Solutions04 Integrated cooling solutions with thermoelectric boosting

Hybrid cooling systems combine conventional cooling methods with thermoelectric boost technology to achieve superior thermal management. These integrated solutions use thermoelectric elements to enhance the performance of liquid cooling, heat pipes, or air cooling systems. The thermoelectric components provide additional cooling capacity during peak thermal loads, enabling more effective heat dissipation in high-performance computing systems, telecommunications equipment, and industrial applications.Expand Specific Solutions05 Energy harvesting applications of thermoelectric technology

Thermoelectric generators can convert waste heat into usable electrical energy, providing power for sensors, IoT devices, and auxiliary systems. These energy harvesting applications utilize temperature differentials in industrial processes, automotive exhaust systems, or even body heat to generate electricity. The recovered energy can be used to power thermal management systems themselves, creating self-sustaining cooling solutions that reduce overall energy consumption and environmental impact.Expand Specific Solutions

Key Industry Players in Thermoelectric Cooling Solutions

The thermoelectric boost technology in Battery Thermal Management Systems (BTMS) is currently in an early growth phase, with the market expected to expand significantly as electric vehicle adoption accelerates. Major automotive manufacturers like Hyundai, Kia, NIO, and BYD are actively integrating these systems, while battery producers including CATL, LG Energy Solution, and Samsung SDI are developing compatible solutions. Technology leaders Gentherm and Bosch have established advanced thermoelectric capabilities, with emerging competition from automotive suppliers like Valeo. The technology is approaching commercial maturity in premium vehicle segments, with companies like Rimac demonstrating high-performance implementations. Research partnerships between manufacturers and institutions such as KAIST and University of Michigan are accelerating innovation in efficiency and cost reduction.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an advanced thermoelectric boost system for battery thermal management that integrates bidirectional thermoelectric modules directly into their cell-to-pack (CTP) architecture. Their solution utilizes the Seebeck-Peltier effect to enable active cooling during high discharge rates and heating during cold conditions. The system incorporates a distributed network of semiconductor-based thermoelectric generators (TEGs) positioned strategically between cell groups, allowing for precise temperature control within ±2°C across the entire pack. CATL's implementation includes intelligent thermal management algorithms that predict heating/cooling needs based on driving patterns, ambient conditions, and battery state of charge, optimizing energy consumption for thermal management. Their latest generation incorporates nano-enhanced thermoelectric materials that achieve a figure of merit (ZT) value exceeding 2.0 at operating temperatures, significantly improving conversion efficiency.

Strengths: Industry-leading energy efficiency with 30% less parasitic loss compared to traditional liquid cooling systems; seamless integration with existing battery architecture; enables ultra-fast charging capabilities even in extreme ambient conditions. Weaknesses: Higher initial manufacturing costs; added complexity in battery pack assembly; requires sophisticated control algorithms to prevent thermal runaway conditions.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered a specialized thermoelectric boost technology called "Climate Ribbon" specifically designed for EV battery thermal management. Their system employs a flexible, ribbon-like array of thermoelectric modules that can be wrapped around or integrated between battery cells. The technology leverages advanced bismuth telluride semiconductor materials with proprietary doping techniques to achieve ZT values approaching 1.8 across wide temperature ranges. Gentherm's implementation includes a patented micro-channel heat exchanger design that maximizes thermal contact area while minimizing fluid volume requirements. Their system operates bidirectionally, providing both heating and cooling functions through the same hardware by reversing current flow. The Climate Ribbon technology incorporates adaptive control algorithms that continuously optimize power consumption based on real-time thermal needs, battery usage patterns, and available energy resources. Gentherm has demonstrated that their system can reduce battery warm-up times by up to 75% in sub-zero conditions while extending range by 5-12% depending on ambient conditions.

Strengths: Highly flexible physical implementation allows integration with various battery form factors; demonstrated reliability across extreme temperature ranges (-40°C to +85°C); reduced system complexity compared to separate heating/cooling systems. Weaknesses: Higher initial component costs compared to conventional systems; requires precise manufacturing tolerances; performance degradation over extended lifecycle needs further optimization.

Core Patents and Technical Literature on Thermoelectric Materials

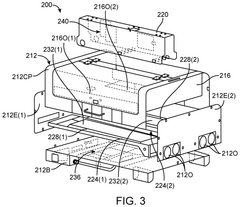

Thermoelectric-based device thermal management system

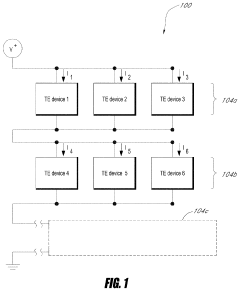

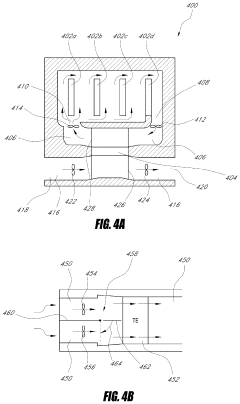

PatentActiveUS20200067150A1

Innovation

- A battery thermal management system incorporating a plurality of thermoelectric assemblies and a circuit that can switch between series and parallel electrical communication, along with a fluid conduit system for working fluids, to effectively heat or cool the batteries and manage thermal conditions.

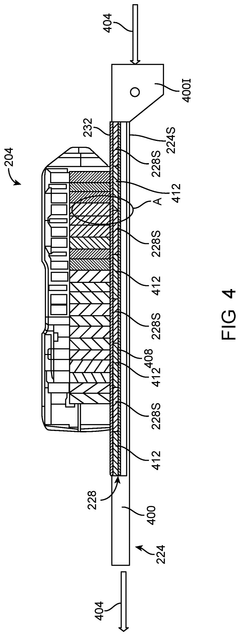

Battery-Charging Devices Having Thermally Conductive Thermal-Management Systems for Managing Battery Temperature During Charging Operations, and Related Methods

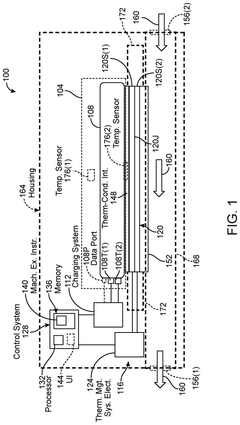

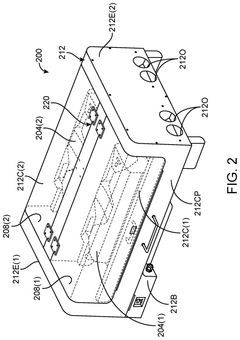

PatentPendingUS20250266530A1

Innovation

- A battery-charging device incorporating a thermally conductive thermal-management system with a thermoelectric device that transfers heat between the battery and a heat sink/source via thermal conduction, controlled by a control system to maintain optimal charging temperatures.

Energy Efficiency and Sustainability Considerations

The integration of thermoelectric boost technology in Battery Thermal Management Systems (BTMS) presents significant implications for energy efficiency and sustainability. When evaluating thermoelectric solutions, the overall energy balance must be carefully considered, as these systems consume electrical energy to produce heating or cooling effects. In conventional applications, thermoelectric devices typically operate at 5-10% efficiency, which can potentially offset the thermal management benefits if not properly optimized.

Recent advancements in thermoelectric materials have improved conversion efficiencies, with some advanced bismuth telluride compounds achieving coefficients of performance (COP) approaching 2.0 under specific operating conditions. This represents a substantial improvement over earlier generations and makes thermoelectric boost increasingly viable from an energy perspective, particularly when integrated with intelligent control systems that activate thermoelectric elements only when necessary.

Life cycle assessment (LCA) studies indicate that thermoelectric-enhanced BTMS can extend battery lifespan by 15-30% through more precise temperature control, potentially offsetting the additional energy consumption. This longevity improvement directly contributes to sustainability by reducing the frequency of battery replacements and associated manufacturing impacts. Furthermore, the ability to maintain batteries within optimal temperature ranges improves charging efficiency by approximately 8-12%, reducing overall energy consumption during vehicle operation.

From a materials perspective, traditional thermoelectric devices contain elements like tellurium and bismuth that present sustainability challenges due to limited global supplies and energy-intensive extraction processes. However, research into alternative thermoelectric materials using more abundant elements such as magnesium silicide, zinc antimonide, and organic thermoelectric compounds shows promise for addressing these concerns while maintaining performance characteristics.

Waste heat recovery represents another significant sustainability advantage of thermoelectric boost systems. In electric vehicles, approximately 20-30% of battery energy is lost as heat during operation. Thermoelectric generators can capture a portion of this waste heat and convert it back to electrical energy, creating a partial closed-loop system that improves overall energy efficiency. Some advanced prototypes demonstrate recovery of 3-7% of waste heat energy, which can be redirected to auxiliary systems or battery charging.

Manufacturing processes for thermoelectric modules are becoming increasingly sustainable through reduced material usage, improved manufacturing yields, and the development of recycling protocols for end-of-life components. These improvements, coupled with the extended battery life and enhanced energy efficiency, position thermoelectric boost technology as an increasingly attractive option for sustainable battery thermal management solutions.

Recent advancements in thermoelectric materials have improved conversion efficiencies, with some advanced bismuth telluride compounds achieving coefficients of performance (COP) approaching 2.0 under specific operating conditions. This represents a substantial improvement over earlier generations and makes thermoelectric boost increasingly viable from an energy perspective, particularly when integrated with intelligent control systems that activate thermoelectric elements only when necessary.

Life cycle assessment (LCA) studies indicate that thermoelectric-enhanced BTMS can extend battery lifespan by 15-30% through more precise temperature control, potentially offsetting the additional energy consumption. This longevity improvement directly contributes to sustainability by reducing the frequency of battery replacements and associated manufacturing impacts. Furthermore, the ability to maintain batteries within optimal temperature ranges improves charging efficiency by approximately 8-12%, reducing overall energy consumption during vehicle operation.

From a materials perspective, traditional thermoelectric devices contain elements like tellurium and bismuth that present sustainability challenges due to limited global supplies and energy-intensive extraction processes. However, research into alternative thermoelectric materials using more abundant elements such as magnesium silicide, zinc antimonide, and organic thermoelectric compounds shows promise for addressing these concerns while maintaining performance characteristics.

Waste heat recovery represents another significant sustainability advantage of thermoelectric boost systems. In electric vehicles, approximately 20-30% of battery energy is lost as heat during operation. Thermoelectric generators can capture a portion of this waste heat and convert it back to electrical energy, creating a partial closed-loop system that improves overall energy efficiency. Some advanced prototypes demonstrate recovery of 3-7% of waste heat energy, which can be redirected to auxiliary systems or battery charging.

Manufacturing processes for thermoelectric modules are becoming increasingly sustainable through reduced material usage, improved manufacturing yields, and the development of recycling protocols for end-of-life components. These improvements, coupled with the extended battery life and enhanced energy efficiency, position thermoelectric boost technology as an increasingly attractive option for sustainable battery thermal management solutions.

Integration Challenges with Existing Battery Systems

Integrating thermoelectric boost technology into existing battery thermal management systems presents several significant challenges that require careful consideration. Current battery systems are designed with specific thermal management approaches that may not readily accommodate thermoelectric devices without substantial modifications. The physical space constraints within battery packs represent a primary obstacle, as most modern designs maximize energy density, leaving minimal room for additional thermal management components.

Electrical integration poses another substantial challenge. Thermoelectric devices require their own power management systems, which must be harmonized with the battery's existing electrical architecture. This integration necessitates additional control circuits, power converters, and potentially separate cooling systems for the thermoelectric modules themselves, further complicating the overall system design.

Thermal interface management between thermoelectric devices and battery cells demands precise engineering. Poor thermal contact can significantly reduce efficiency and create thermal bottlenecks, negating the potential benefits of thermoelectric boost technology. The development of specialized thermal interface materials that maintain performance over the battery's operational lifetime remains an ongoing challenge.

Control system compatibility presents further complications. Existing battery management systems (BMS) are not typically designed to incorporate thermoelectric control algorithms. Upgrading these systems requires extensive software modifications and validation to ensure safe, efficient operation under all conditions. The control logic must balance thermoelectric power consumption against thermal management benefits to achieve net energy efficiency gains.

Manufacturing processes and supply chain considerations also impact integration feasibility. Current battery production lines would require significant retooling to accommodate thermoelectric components, potentially increasing production costs and complexity. Additionally, the reliability and durability of thermoelectric devices in the harsh vibrational and thermal cycling environment of automotive applications remains a concern for long-term deployment.

Cost implications cannot be overlooked when evaluating integration challenges. Thermoelectric materials and manufacturing processes currently command premium prices compared to conventional thermal management solutions. The additional components, control systems, and integration engineering further increase the total system cost, potentially limiting market adoption despite performance benefits.

Regulatory compliance and safety certification represent the final major integration hurdle. Any modifications to battery thermal management systems must undergo rigorous testing to ensure they meet industry standards and safety requirements. The introduction of new active thermal management technologies may necessitate updated testing protocols and certification processes before widespread implementation becomes possible.

Electrical integration poses another substantial challenge. Thermoelectric devices require their own power management systems, which must be harmonized with the battery's existing electrical architecture. This integration necessitates additional control circuits, power converters, and potentially separate cooling systems for the thermoelectric modules themselves, further complicating the overall system design.

Thermal interface management between thermoelectric devices and battery cells demands precise engineering. Poor thermal contact can significantly reduce efficiency and create thermal bottlenecks, negating the potential benefits of thermoelectric boost technology. The development of specialized thermal interface materials that maintain performance over the battery's operational lifetime remains an ongoing challenge.

Control system compatibility presents further complications. Existing battery management systems (BMS) are not typically designed to incorporate thermoelectric control algorithms. Upgrading these systems requires extensive software modifications and validation to ensure safe, efficient operation under all conditions. The control logic must balance thermoelectric power consumption against thermal management benefits to achieve net energy efficiency gains.

Manufacturing processes and supply chain considerations also impact integration feasibility. Current battery production lines would require significant retooling to accommodate thermoelectric components, potentially increasing production costs and complexity. Additionally, the reliability and durability of thermoelectric devices in the harsh vibrational and thermal cycling environment of automotive applications remains a concern for long-term deployment.

Cost implications cannot be overlooked when evaluating integration challenges. Thermoelectric materials and manufacturing processes currently command premium prices compared to conventional thermal management solutions. The additional components, control systems, and integration engineering further increase the total system cost, potentially limiting market adoption despite performance benefits.

Regulatory compliance and safety certification represent the final major integration hurdle. Any modifications to battery thermal management systems must undergo rigorous testing to ensure they meet industry standards and safety requirements. The introduction of new active thermal management technologies may necessitate updated testing protocols and certification processes before widespread implementation becomes possible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!