Integration Strategies For TEGs In Marine And Heavy-Duty Engine Applications

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Marine Integration Background and Objectives

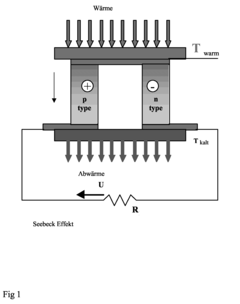

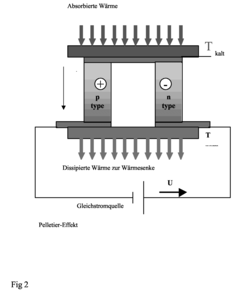

Thermoelectric generators (TEGs) have emerged as a promising technology for waste heat recovery in various applications, with marine and heavy-duty engines representing particularly significant opportunities. The evolution of TEG technology in marine applications can be traced back to early experimental implementations in the 1990s, though meaningful commercial development only gained momentum in the past decade as material science advancements improved conversion efficiencies.

The marine and heavy-duty engine sectors present unique waste heat recovery challenges and opportunities due to their continuous operation profiles and substantial thermal energy losses. Approximately 40-60% of fuel energy in marine diesel engines is typically lost as waste heat through exhaust gases and cooling systems, representing a vast untapped energy resource that TEGs could potentially convert into usable electricity.

Current technological trends indicate a shift toward modular TEG designs specifically engineered for the harsh operating conditions of marine environments, including resistance to vibration, corrosion, and thermal cycling. Simultaneously, research efforts are increasingly focused on developing high-temperature TEG materials capable of operating efficiently within the temperature ranges common to marine exhaust systems (300-500°C).

The primary technical objective for TEG integration in marine applications is to achieve a cost-effective waste heat recovery system that can generate supplementary electrical power while maintaining minimal impact on engine performance and vessel operations. Specific goals include developing integration strategies that achieve conversion efficiencies exceeding 5-8% in real-world marine conditions, with system costs below $5/W to ensure economic viability.

Secondary objectives encompass designing TEG systems that can withstand the unique challenges of marine environments, including salt exposure, constant vibration, and limited installation space. Additionally, these systems must demonstrate operational longevity of at least 40,000 hours to align with typical marine maintenance schedules and provide meaningful return on investment.

From a regulatory perspective, TEG integration aligns with increasingly stringent emissions regulations, including the International Maritime Organization's targets for reducing greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 levels. This regulatory landscape creates additional incentives for waste heat recovery technologies like TEGs that can improve overall vessel efficiency without requiring fundamental changes to propulsion systems.

The ultimate goal of TEG marine integration research is to develop standardized, scalable integration approaches that can be adapted across various vessel classes and engine types, thereby accelerating industry adoption and maximizing environmental and economic benefits.

The marine and heavy-duty engine sectors present unique waste heat recovery challenges and opportunities due to their continuous operation profiles and substantial thermal energy losses. Approximately 40-60% of fuel energy in marine diesel engines is typically lost as waste heat through exhaust gases and cooling systems, representing a vast untapped energy resource that TEGs could potentially convert into usable electricity.

Current technological trends indicate a shift toward modular TEG designs specifically engineered for the harsh operating conditions of marine environments, including resistance to vibration, corrosion, and thermal cycling. Simultaneously, research efforts are increasingly focused on developing high-temperature TEG materials capable of operating efficiently within the temperature ranges common to marine exhaust systems (300-500°C).

The primary technical objective for TEG integration in marine applications is to achieve a cost-effective waste heat recovery system that can generate supplementary electrical power while maintaining minimal impact on engine performance and vessel operations. Specific goals include developing integration strategies that achieve conversion efficiencies exceeding 5-8% in real-world marine conditions, with system costs below $5/W to ensure economic viability.

Secondary objectives encompass designing TEG systems that can withstand the unique challenges of marine environments, including salt exposure, constant vibration, and limited installation space. Additionally, these systems must demonstrate operational longevity of at least 40,000 hours to align with typical marine maintenance schedules and provide meaningful return on investment.

From a regulatory perspective, TEG integration aligns with increasingly stringent emissions regulations, including the International Maritime Organization's targets for reducing greenhouse gas emissions from international shipping by at least 50% by 2050 compared to 2008 levels. This regulatory landscape creates additional incentives for waste heat recovery technologies like TEGs that can improve overall vessel efficiency without requiring fundamental changes to propulsion systems.

The ultimate goal of TEG marine integration research is to develop standardized, scalable integration approaches that can be adapted across various vessel classes and engine types, thereby accelerating industry adoption and maximizing environmental and economic benefits.

Market Analysis for Waste Heat Recovery in Marine Engines

The marine engine waste heat recovery market is experiencing significant growth, driven by stringent environmental regulations and increasing fuel efficiency demands. The global marine waste heat recovery system market was valued at approximately $2.5 billion in 2021 and is projected to reach $3.8 billion by 2027, growing at a CAGR of 7.2%. This growth is primarily fueled by IMO 2020 regulations limiting sulfur content in marine fuels and upcoming carbon intensity reduction targets.

Marine vessels represent an ideal application for thermoelectric generators (TEGs) due to their continuous operation and substantial waste heat production. Large container ships and cargo vessels can reject up to 50% of fuel energy as waste heat, presenting a considerable opportunity for energy recovery. The potential fuel savings from effective waste heat recovery systems range from 5% to 15%, translating to millions of dollars in operational cost reduction for shipping companies over a vessel's lifetime.

Regional analysis indicates Europe leads the market with approximately 35% share, driven by stringent emission regulations and strong maritime industry presence. Asia-Pacific follows closely at 32%, with rapid growth expected due to expanding shipbuilding activities in China, South Korea, and Japan. North America accounts for 25% of the market, with increasing adoption in both commercial and military marine applications.

Customer segmentation reveals three primary market segments: commercial shipping (65%), naval/military vessels (20%), and offshore support vessels (15%). Within commercial shipping, container vessels and tankers show the highest adoption rates due to their size and operational profiles. The retrofit market currently dominates at 60% of installations, while new builds account for 40% but are growing faster as manufacturers integrate waste heat recovery systems during construction.

Key market drivers include fuel cost volatility, with marine fuel prices fluctuating between $300-700 per ton in recent years, creating strong economic incentives for efficiency technologies. Environmental regulations, particularly IMO's goal to reduce carbon intensity by 40% by 2030, are accelerating adoption. Additionally, technological advancements in TEG materials and system integration are expanding the application range and improving ROI metrics.

Market barriers include high initial capital costs, with marine-grade TEG systems typically requiring $1,000-2,500 per kW of capacity installed. Technical integration challenges in retrofitting existing vessels and space constraints remain significant obstacles. Furthermore, the relatively long payback periods of 3-5 years can deter adoption in an industry accustomed to shorter investment horizons.

Marine vessels represent an ideal application for thermoelectric generators (TEGs) due to their continuous operation and substantial waste heat production. Large container ships and cargo vessels can reject up to 50% of fuel energy as waste heat, presenting a considerable opportunity for energy recovery. The potential fuel savings from effective waste heat recovery systems range from 5% to 15%, translating to millions of dollars in operational cost reduction for shipping companies over a vessel's lifetime.

Regional analysis indicates Europe leads the market with approximately 35% share, driven by stringent emission regulations and strong maritime industry presence. Asia-Pacific follows closely at 32%, with rapid growth expected due to expanding shipbuilding activities in China, South Korea, and Japan. North America accounts for 25% of the market, with increasing adoption in both commercial and military marine applications.

Customer segmentation reveals three primary market segments: commercial shipping (65%), naval/military vessels (20%), and offshore support vessels (15%). Within commercial shipping, container vessels and tankers show the highest adoption rates due to their size and operational profiles. The retrofit market currently dominates at 60% of installations, while new builds account for 40% but are growing faster as manufacturers integrate waste heat recovery systems during construction.

Key market drivers include fuel cost volatility, with marine fuel prices fluctuating between $300-700 per ton in recent years, creating strong economic incentives for efficiency technologies. Environmental regulations, particularly IMO's goal to reduce carbon intensity by 40% by 2030, are accelerating adoption. Additionally, technological advancements in TEG materials and system integration are expanding the application range and improving ROI metrics.

Market barriers include high initial capital costs, with marine-grade TEG systems typically requiring $1,000-2,500 per kW of capacity installed. Technical integration challenges in retrofitting existing vessels and space constraints remain significant obstacles. Furthermore, the relatively long payback periods of 3-5 years can deter adoption in an industry accustomed to shorter investment horizons.

Current TEG Technology Status and Implementation Barriers

Thermoelectric Generator (TEG) technology has evolved significantly over the past decade, yet its widespread implementation in marine and heavy-duty engine applications remains limited. Current TEG systems typically achieve conversion efficiencies between 5-8%, significantly lower than other waste heat recovery technologies. This efficiency limitation represents a primary barrier to commercial adoption, as it directly impacts the cost-benefit ratio of implementation.

Material constraints constitute another significant challenge. State-of-the-art TEGs predominantly utilize bismuth telluride (Bi2Te3) for low-temperature applications and lead telluride (PbTe) or silicon-germanium alloys for higher temperatures. These materials face limitations in durability when subjected to the harsh operating conditions characteristic of marine and heavy-duty engines, including thermal cycling, vibration, and corrosive environments.

Integration complexity presents substantial engineering challenges. Current TEG systems require sophisticated heat exchangers to capture waste heat effectively while maintaining optimal temperature differentials across thermoelectric modules. The physical space constraints in engine compartments further complicate integration, often necessitating custom designs that increase implementation costs and complexity.

Economic barriers remain particularly prohibitive. The current production cost of high-quality thermoelectric materials ranges from $200-500 per kilogram, resulting in system costs of approximately $20-30 per watt of generating capacity. This high capital expenditure extends payback periods beyond acceptable thresholds for most commercial operators, especially when compared with alternative technologies.

Reliability and maintenance concerns persist in practical applications. Field data indicates that TEG performance degradation occurs at rates of 1-2% annually under typical operating conditions, with accelerated degradation in marine environments due to salt exposure and humidity. The sealed nature of most TEG systems makes maintenance challenging, often requiring complete module replacement rather than component repair.

Regulatory frameworks and standardization remain underdeveloped for TEG integration in these applications. Unlike other energy recovery systems, TEGs lack comprehensive industry standards for performance metrics, safety requirements, and integration protocols. This regulatory uncertainty increases development risks and complicates certification processes for marine applications subject to international maritime regulations.

Manufacturing scalability represents another implementation barrier. Current production methods for high-performance thermoelectric materials involve complex processes including zone melting, hot pressing, and spark plasma sintering. These techniques are difficult to scale economically, creating bottlenecks in supply chains and limiting production capacity to approximately 100-200 kW of generating capacity annually per manufacturer.

Material constraints constitute another significant challenge. State-of-the-art TEGs predominantly utilize bismuth telluride (Bi2Te3) for low-temperature applications and lead telluride (PbTe) or silicon-germanium alloys for higher temperatures. These materials face limitations in durability when subjected to the harsh operating conditions characteristic of marine and heavy-duty engines, including thermal cycling, vibration, and corrosive environments.

Integration complexity presents substantial engineering challenges. Current TEG systems require sophisticated heat exchangers to capture waste heat effectively while maintaining optimal temperature differentials across thermoelectric modules. The physical space constraints in engine compartments further complicate integration, often necessitating custom designs that increase implementation costs and complexity.

Economic barriers remain particularly prohibitive. The current production cost of high-quality thermoelectric materials ranges from $200-500 per kilogram, resulting in system costs of approximately $20-30 per watt of generating capacity. This high capital expenditure extends payback periods beyond acceptable thresholds for most commercial operators, especially when compared with alternative technologies.

Reliability and maintenance concerns persist in practical applications. Field data indicates that TEG performance degradation occurs at rates of 1-2% annually under typical operating conditions, with accelerated degradation in marine environments due to salt exposure and humidity. The sealed nature of most TEG systems makes maintenance challenging, often requiring complete module replacement rather than component repair.

Regulatory frameworks and standardization remain underdeveloped for TEG integration in these applications. Unlike other energy recovery systems, TEGs lack comprehensive industry standards for performance metrics, safety requirements, and integration protocols. This regulatory uncertainty increases development risks and complicates certification processes for marine applications subject to international maritime regulations.

Manufacturing scalability represents another implementation barrier. Current production methods for high-performance thermoelectric materials involve complex processes including zone melting, hot pressing, and spark plasma sintering. These techniques are difficult to scale economically, creating bottlenecks in supply chains and limiting production capacity to approximately 100-200 kW of generating capacity annually per manufacturer.

Current TEG Integration Methods for Marine Engines

01 Vehicle integration of thermoelectric generators

Thermoelectric generators can be integrated into vehicle systems to harvest waste heat from engines and exhaust systems, converting it into usable electrical energy. These integration strategies focus on optimizing placement near heat sources such as exhaust manifolds while ensuring proper thermal management. The recovered energy can supplement the vehicle's electrical system, reducing alternator load and improving fuel efficiency. Various mounting configurations and heat exchanger designs are employed to maximize temperature differentials and power generation efficiency.- Vehicle integration of thermoelectric generators: Thermoelectric generators can be integrated into vehicle systems to harvest waste heat from engines and exhaust systems, converting it into useful electrical energy. These integration strategies focus on optimizing placement near heat sources such as exhaust manifolds, catalytic converters, or engine blocks while ensuring proper thermal management. The recovered energy can supplement the vehicle's electrical system, reducing alternator load and improving fuel efficiency.

- Wearable and portable TEG applications: Integration strategies for wearable and portable thermoelectric generators focus on harvesting body heat or environmental temperature differentials to power small electronic devices. These designs emphasize flexibility, lightweight construction, and comfort while maintaining efficient thermal contact with heat sources. Applications include powering health monitoring devices, mobile electronics, and IoT sensors in remote locations where conventional power sources are unavailable.

- Building and infrastructure TEG integration: Thermoelectric generators can be integrated into building systems and infrastructure to harvest waste heat from HVAC systems, industrial processes, or solar thermal collectors. These integration strategies focus on embedding TEGs within building materials, incorporating them into existing thermal management systems, or designing dedicated heat recovery systems. The generated electricity can power building management systems, sensors, or be fed back into the grid.

- Advanced materials and manufacturing for TEG integration: Novel materials and manufacturing techniques enable better integration of thermoelectric generators into various applications. These approaches include flexible substrates, printable thermoelectric materials, and advanced thermal interface materials that improve contact between heat sources and TEGs. Additive manufacturing and microfabrication techniques allow for customized TEG designs that conform to complex geometries and optimize heat flow paths, enhancing overall system efficiency.

- Hybrid energy harvesting systems with TEGs: Integration strategies for hybrid energy systems combine thermoelectric generators with other energy harvesting technologies such as photovoltaics, piezoelectrics, or triboelectrics. These systems leverage multiple energy sources to improve overall power output and reliability. The integration approaches focus on shared thermal management, complementary power conditioning circuits, and intelligent power management to optimize energy capture across varying environmental conditions.

02 Wearable and portable TEG applications

Integration strategies for wearable and portable thermoelectric generators focus on harvesting body heat or environmental temperature differentials to power small electronic devices. These designs emphasize flexibility, lightweight construction, and ergonomic considerations to ensure user comfort while maximizing power output. Special attention is given to thermal interface materials that efficiently transfer body heat to the TEG while maintaining comfort. Applications include powering health monitoring devices, communication equipment, and other low-power portable electronics in remote or off-grid scenarios.Expand Specific Solutions03 Industrial waste heat recovery systems

Integration strategies for industrial thermoelectric generators focus on capturing waste heat from manufacturing processes, furnaces, and industrial equipment. These systems typically involve large-scale TEG arrays with specialized heat exchangers designed to withstand harsh industrial environments and high temperatures. The integration approach emphasizes modularity to facilitate maintenance and scalability. Advanced thermal management techniques are employed to maintain optimal temperature differentials across the thermoelectric materials, maximizing conversion efficiency and power output while ensuring system longevity in continuous operation scenarios.Expand Specific Solutions04 Building and infrastructure integration

Thermoelectric generators can be integrated into building systems and infrastructure to harvest thermal energy from HVAC systems, solar heating, and geothermal sources. These integration strategies focus on incorporating TEGs into walls, roofing materials, windows, or building mechanical systems to generate supplementary power. The approaches emphasize aesthetic integration, durability, and long-term reliability while maintaining building structural integrity. Some designs combine TEGs with other renewable energy systems like solar photovoltaics to create hybrid energy harvesting solutions for buildings and infrastructure.Expand Specific Solutions05 Advanced materials and manufacturing techniques

Integration strategies leveraging advanced materials and manufacturing techniques focus on improving TEG performance through novel thermoelectric materials, flexible substrates, and innovative fabrication methods. These approaches include thin-film deposition, 3D printing of thermoelectric components, and nanomaterial integration to enhance power density and efficiency. Manufacturing techniques such as roll-to-roll processing enable cost-effective production of flexible TEGs that can conform to irregular surfaces. Special attention is given to interface engineering between different materials to minimize thermal resistance and electrical contact losses, thereby improving overall system performance.Expand Specific Solutions

Leading Companies in Marine TEG Technology

The integration of Thermoelectric Generators (TEGs) in marine and heavy-duty engine applications is currently in an early growth phase, with the market expanding as industries seek waste heat recovery solutions for improved efficiency and emissions reduction. The global market size for TEG applications in these sectors is estimated to reach $250-300 million by 2025, driven by stringent environmental regulations. Leading companies like Robert Bosch GmbH, BMW, and Ford Global Technologies are advancing technical maturity through significant R&D investments, while specialized players such as Yanmar and CIMC Ocean Engineering focus on marine-specific implementations. Academic institutions including Shanghai Jiao Tong University and Wuhan University of Technology are collaborating with industry to overcome key challenges in thermal management, durability in harsh environments, and system integration efficiency.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced TEG systems specifically for marine and heavy-duty applications that capture waste heat from exhaust systems and convert it to usable electricity. Their approach integrates TEGs directly into the exhaust gas recirculation (EGR) systems, utilizing high-temperature differentials between exhaust gases (400-500°C) and coolant systems. Bosch's solution incorporates specialized heat exchangers with optimized fin designs to maximize thermal transfer while minimizing back pressure effects on engine performance. Their systems typically achieve 3-5% fuel efficiency improvements in heavy-duty diesel engines, with power generation capacity ranging from 0.5-2kW depending on engine load conditions. The integration strategy includes sophisticated power conditioning electronics that stabilize voltage output across varying engine operating conditions.

Strengths: Highly optimized integration with existing engine control systems; robust design suitable for harsh marine environments; proven reliability in field testing with major engine manufacturers. Weaknesses: Higher initial cost compared to conventional systems; requires precise thermal management to prevent overheating of TEG modules; performance benefits diminish at low engine loads.

Yanmar Co., Ltd.

Technical Solution: Yanmar has pioneered a comprehensive TEG integration approach specifically designed for their marine diesel engines. Their system places TEG modules at strategic locations along the exhaust pathway, with primary focus on the turbocharger outlet where temperatures reach optimal ranges (350-450°C) for thermoelectric conversion. Yanmar's approach incorporates a dual-stage heat exchanger design that first extracts heat for the TEG modules, then routes remaining thermal energy to other ship systems like water heating. Their proprietary module mounting system accommodates the significant thermal expansion and vibration inherent in marine applications while maintaining consistent thermal contact pressure. Yanmar's integrated control system dynamically adjusts coolant flow rates to maintain optimal temperature differentials across TEG modules, achieving conversion efficiencies of 4-6% and generating 1-3kW of supplementary electrical power in typical marine applications. The recovered electricity is integrated directly into the vessel's electrical system, reducing generator fuel consumption.

Strengths: Purpose-built for marine environments with corrosion-resistant materials; seamless integration with existing marine power systems; minimal impact on engine back pressure. Weaknesses: Significant weight addition that must be factored into vessel design; requires dedicated cooling circuits; performance varies significantly with sea conditions and engine operating profiles.

Key Patents in Marine Thermoelectric Generation

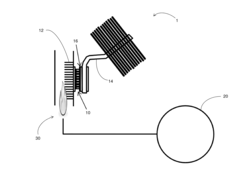

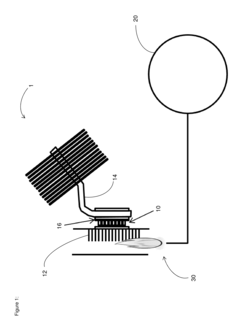

Thermoelectric generator for use with integrated functionality

PatentInactiveUS20130340802A1

Innovation

- A thermoelectric system comprising a thermoelectric generator with a cold-side and hot-side heat exchanger, where waste heat is transferred to a combustible fluid or engine lubricant, preheating it before combustion or use, thereby improving energy efficiency and reducing emissions.

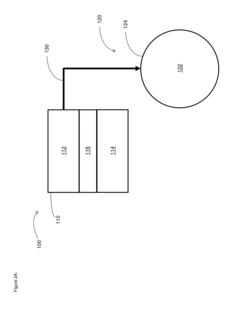

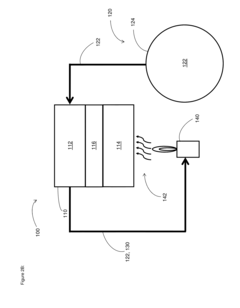

System and method for controlling the temperature of an internal combustion engine exhaust gas temperature

PatentInactiveEP1500808A1

Innovation

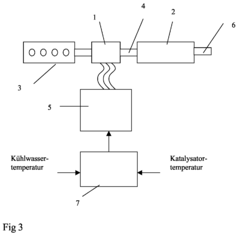

- A thermoelectric generator (TEG) is integrated into the engine exhaust line upstream of the catalytic converter, utilizing its heat pump effect to actively control exhaust gas temperature by reversing voltage polarity, and is powered by the engine's generator during warm-up to enhance catalyst and engine warm-up performance.

Environmental Impact and Emissions Reduction Potential

The integration of Thermoelectric Generators (TEGs) in marine and heavy-duty engine applications presents significant potential for environmental impact reduction, particularly in emissions control. These industries are under increasing regulatory pressure to minimize their carbon footprint and pollutant emissions, making TEG technology an attractive supplementary solution for environmental compliance.

TEG systems can capture waste heat from engine exhaust and cooling systems, converting it into usable electricity. This energy recovery process directly reduces fuel consumption by 2-5% in typical marine and heavy-duty applications, with some advanced implementations reporting up to 8% improvement. Each percentage point of fuel reduction translates to proportional decreases in CO2, NOx, SOx, and particulate matter emissions, addressing key environmental concerns in these sectors.

For marine applications specifically, TEG integration aligns with the International Maritime Organization's (IMO) increasingly stringent emissions regulations, including the 2020 global sulfur cap and the Energy Efficiency Design Index (EEDI). By reducing the operational load on conventional generators, TEGs contribute to meeting these standards without compromising vessel performance or requiring extensive retrofitting of existing propulsion systems.

In heavy-duty engine applications, TEG systems complement other emissions reduction technologies such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF). The electricity generated can power these aftertreatment systems, improving their efficiency while reducing the parasitic load they typically place on the engine. This synergistic effect amplifies the overall emissions reduction potential beyond what either technology could achieve independently.

Life cycle assessment studies indicate that despite the environmental impact associated with manufacturing thermoelectric materials (particularly those containing tellurium, bismuth, and other rare elements), the net environmental benefit over a typical 10-15 year operational lifespan is substantially positive. The emissions reduction achieved during operation outweighs production impacts by a factor of 8-12, depending on application specifics and operational profiles.

Furthermore, TEG systems enable more efficient operation of auxiliary systems in both marine vessels and heavy-duty vehicles. By providing localized power generation, they reduce transmission losses and enable more precise control of cooling systems, further enhancing fuel efficiency. This "cascade effect" of efficiency improvements compounds the direct emissions reduction benefits, potentially adding another 1-2% in overall emissions reduction.

As regulatory frameworks continue to evolve toward stricter emissions standards globally, the value proposition of TEG integration becomes increasingly compelling from both environmental compliance and economic perspectives, positioning this technology as an important component in the emissions reduction strategy for these challenging transportation sectors.

TEG systems can capture waste heat from engine exhaust and cooling systems, converting it into usable electricity. This energy recovery process directly reduces fuel consumption by 2-5% in typical marine and heavy-duty applications, with some advanced implementations reporting up to 8% improvement. Each percentage point of fuel reduction translates to proportional decreases in CO2, NOx, SOx, and particulate matter emissions, addressing key environmental concerns in these sectors.

For marine applications specifically, TEG integration aligns with the International Maritime Organization's (IMO) increasingly stringent emissions regulations, including the 2020 global sulfur cap and the Energy Efficiency Design Index (EEDI). By reducing the operational load on conventional generators, TEGs contribute to meeting these standards without compromising vessel performance or requiring extensive retrofitting of existing propulsion systems.

In heavy-duty engine applications, TEG systems complement other emissions reduction technologies such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF). The electricity generated can power these aftertreatment systems, improving their efficiency while reducing the parasitic load they typically place on the engine. This synergistic effect amplifies the overall emissions reduction potential beyond what either technology could achieve independently.

Life cycle assessment studies indicate that despite the environmental impact associated with manufacturing thermoelectric materials (particularly those containing tellurium, bismuth, and other rare elements), the net environmental benefit over a typical 10-15 year operational lifespan is substantially positive. The emissions reduction achieved during operation outweighs production impacts by a factor of 8-12, depending on application specifics and operational profiles.

Furthermore, TEG systems enable more efficient operation of auxiliary systems in both marine vessels and heavy-duty vehicles. By providing localized power generation, they reduce transmission losses and enable more precise control of cooling systems, further enhancing fuel efficiency. This "cascade effect" of efficiency improvements compounds the direct emissions reduction benefits, potentially adding another 1-2% in overall emissions reduction.

As regulatory frameworks continue to evolve toward stricter emissions standards globally, the value proposition of TEG integration becomes increasingly compelling from both environmental compliance and economic perspectives, positioning this technology as an important component in the emissions reduction strategy for these challenging transportation sectors.

Cost-Benefit Analysis of TEG Implementation

The implementation of Thermoelectric Generators (TEGs) in marine and heavy-duty engine applications requires careful economic assessment to determine viability. Initial capital expenditure for TEG systems remains significant, with costs ranging from $5-15 per watt of generating capacity depending on system scale and materials used. For large marine engines, total implementation costs typically range between $50,000-200,000 per installation, representing a substantial investment for fleet operators.

Operating cost reductions present the primary economic benefit, with fuel savings of 3-5% commonly reported in field trials. For vessels consuming 30-50 tons of fuel daily, this translates to annual savings of $150,000-300,000 at current fuel prices. Additional maintenance cost reductions of approximately $15,000-25,000 annually per vessel can be realized through decreased thermal stress on engine components.

Return on investment (ROI) calculations indicate payback periods of 2-4 years for most marine applications, with heavy-duty land transport applications showing slightly longer periods of 3-5 years. These timeframes align favorably with industry equipment upgrade cycles, enhancing adoption feasibility.

Lifecycle cost analysis reveals that TEG systems maintain approximately 85% of their initial efficiency over a 10-year operational period, with gradual performance degradation thereafter. Maintenance requirements remain minimal, typically requiring inspection and potential module replacement every 25,000-30,000 operating hours.

Environmental compliance benefits provide additional economic value through reduced carbon taxation and regulatory compliance costs. With carbon pricing mechanisms expanding globally, TEG systems can reduce carbon tax liabilities by $30,000-70,000 annually for large vessel operators.

Sensitivity analysis indicates that TEG economic viability increases proportionally with fuel prices and engine size. Systems become particularly attractive for engines exceeding 5MW output or in regions with fuel prices above global averages. Conversely, smaller engines or operations in regions with subsidized fuel prices may experience extended payback periods.

Comparative analysis against alternative waste heat recovery technologies shows TEGs offering superior economic performance in applications where space constraints are significant and maintenance accessibility is limited. While Organic Rankine Cycle systems may provide higher theoretical efficiency, their higher complexity and maintenance requirements often result in less favorable lifetime economic performance in marine environments.

Operating cost reductions present the primary economic benefit, with fuel savings of 3-5% commonly reported in field trials. For vessels consuming 30-50 tons of fuel daily, this translates to annual savings of $150,000-300,000 at current fuel prices. Additional maintenance cost reductions of approximately $15,000-25,000 annually per vessel can be realized through decreased thermal stress on engine components.

Return on investment (ROI) calculations indicate payback periods of 2-4 years for most marine applications, with heavy-duty land transport applications showing slightly longer periods of 3-5 years. These timeframes align favorably with industry equipment upgrade cycles, enhancing adoption feasibility.

Lifecycle cost analysis reveals that TEG systems maintain approximately 85% of their initial efficiency over a 10-year operational period, with gradual performance degradation thereafter. Maintenance requirements remain minimal, typically requiring inspection and potential module replacement every 25,000-30,000 operating hours.

Environmental compliance benefits provide additional economic value through reduced carbon taxation and regulatory compliance costs. With carbon pricing mechanisms expanding globally, TEG systems can reduce carbon tax liabilities by $30,000-70,000 annually for large vessel operators.

Sensitivity analysis indicates that TEG economic viability increases proportionally with fuel prices and engine size. Systems become particularly attractive for engines exceeding 5MW output or in regions with fuel prices above global averages. Conversely, smaller engines or operations in regions with subsidized fuel prices may experience extended payback periods.

Comparative analysis against alternative waste heat recovery technologies shows TEGs offering superior economic performance in applications where space constraints are significant and maintenance accessibility is limited. While Organic Rankine Cycle systems may provide higher theoretical efficiency, their higher complexity and maintenance requirements often result in less favorable lifetime economic performance in marine environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!