Thermoelectric Generator Thermal Management Using Phase Change Materials

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG and PCM Technology Background and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821. This phenomenon, where a temperature difference between two dissimilar electrical conductors produces a voltage difference, forms the fundamental principle of thermoelectric generation. The technology remained largely theoretical until the mid-20th century when semiconductor materials revolutionized the field, enabling practical applications of TEGs.

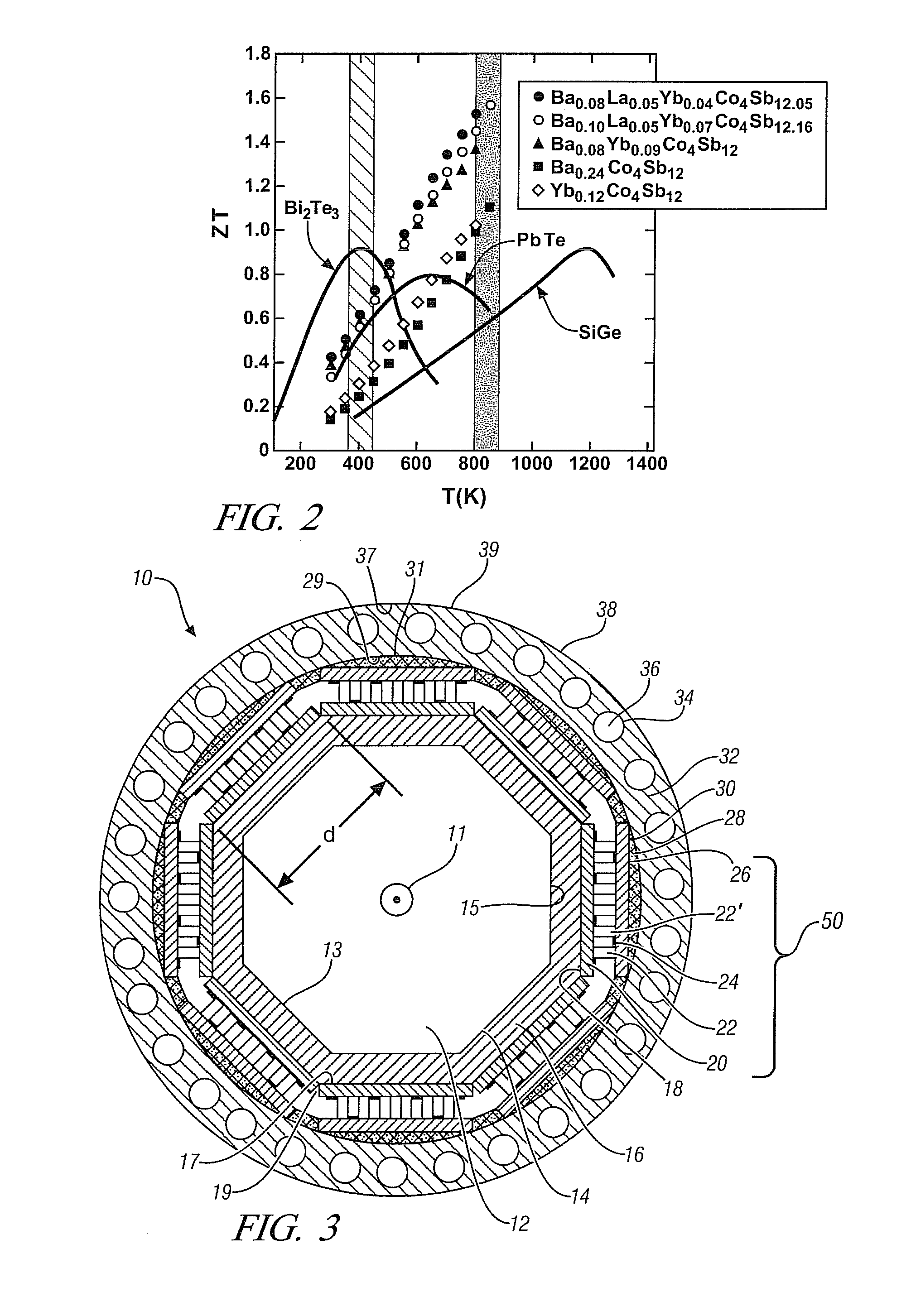

Over the past decades, TEG technology has progressed from simple, low-efficiency devices to more sophisticated systems capable of converting waste heat into usable electricity across various temperature ranges. The efficiency of these systems, measured by the figure of merit ZT, has seen steady improvement from less than 1.0 to values approaching 2.0 in laboratory settings, marking significant advancements in material science and device engineering.

Phase Change Materials (PCMs), on the other hand, represent a class of substances that can absorb, store, and release large amounts of energy during phase transitions. The development of PCMs dates back to the 1970s and 1980s when they were first explored for thermal energy storage applications. Since then, research has expanded to include various organic, inorganic, and eutectic PCMs with melting points ranging from sub-zero temperatures to several hundred degrees Celsius.

The integration of TEGs with PCMs represents a convergent evolution of these technologies, aimed at addressing one of the critical challenges in thermoelectric generation: thermal management. Effective heat dissipation and temperature regulation are essential for maintaining optimal TEG performance, as excessive temperatures can reduce efficiency and potentially damage the semiconductor materials.

The primary objective of this technological integration is to enhance the overall efficiency and reliability of thermoelectric generation systems through improved thermal management. By utilizing PCMs' latent heat storage capabilities, it becomes possible to stabilize temperature gradients across TEG modules, thereby optimizing power output and extending operational lifetimes. Additionally, this approach aims to enable more effective harvesting of intermittent or fluctuating waste heat sources, which are abundant in industrial processes, automotive applications, and renewable energy systems.

Further objectives include miniaturization of TEG systems for portable and wearable applications, development of passive cooling solutions that eliminate the need for active cooling components, and creation of self-regulating thermal management systems that can adapt to varying heat loads. The ultimate goal is to establish TEG-PCM systems as a viable, sustainable technology for distributed energy generation, contributing to global efforts in energy efficiency and carbon footprint reduction.

Over the past decades, TEG technology has progressed from simple, low-efficiency devices to more sophisticated systems capable of converting waste heat into usable electricity across various temperature ranges. The efficiency of these systems, measured by the figure of merit ZT, has seen steady improvement from less than 1.0 to values approaching 2.0 in laboratory settings, marking significant advancements in material science and device engineering.

Phase Change Materials (PCMs), on the other hand, represent a class of substances that can absorb, store, and release large amounts of energy during phase transitions. The development of PCMs dates back to the 1970s and 1980s when they were first explored for thermal energy storage applications. Since then, research has expanded to include various organic, inorganic, and eutectic PCMs with melting points ranging from sub-zero temperatures to several hundred degrees Celsius.

The integration of TEGs with PCMs represents a convergent evolution of these technologies, aimed at addressing one of the critical challenges in thermoelectric generation: thermal management. Effective heat dissipation and temperature regulation are essential for maintaining optimal TEG performance, as excessive temperatures can reduce efficiency and potentially damage the semiconductor materials.

The primary objective of this technological integration is to enhance the overall efficiency and reliability of thermoelectric generation systems through improved thermal management. By utilizing PCMs' latent heat storage capabilities, it becomes possible to stabilize temperature gradients across TEG modules, thereby optimizing power output and extending operational lifetimes. Additionally, this approach aims to enable more effective harvesting of intermittent or fluctuating waste heat sources, which are abundant in industrial processes, automotive applications, and renewable energy systems.

Further objectives include miniaturization of TEG systems for portable and wearable applications, development of passive cooling solutions that eliminate the need for active cooling components, and creation of self-regulating thermal management systems that can adapt to varying heat loads. The ultimate goal is to establish TEG-PCM systems as a viable, sustainable technology for distributed energy generation, contributing to global efforts in energy efficiency and carbon footprint reduction.

Market Analysis for TEG-PCM Integrated Systems

The global market for thermoelectric generator (TEG) systems integrated with phase change materials (PCMs) is experiencing significant growth, driven by increasing demand for efficient energy harvesting solutions across multiple industries. Current market valuations indicate that the TEG market reached approximately 460 million USD in 2022, with projections suggesting a compound annual growth rate of 8.2% through 2030. The integration of PCMs into these systems represents an emerging segment with particularly strong growth potential.

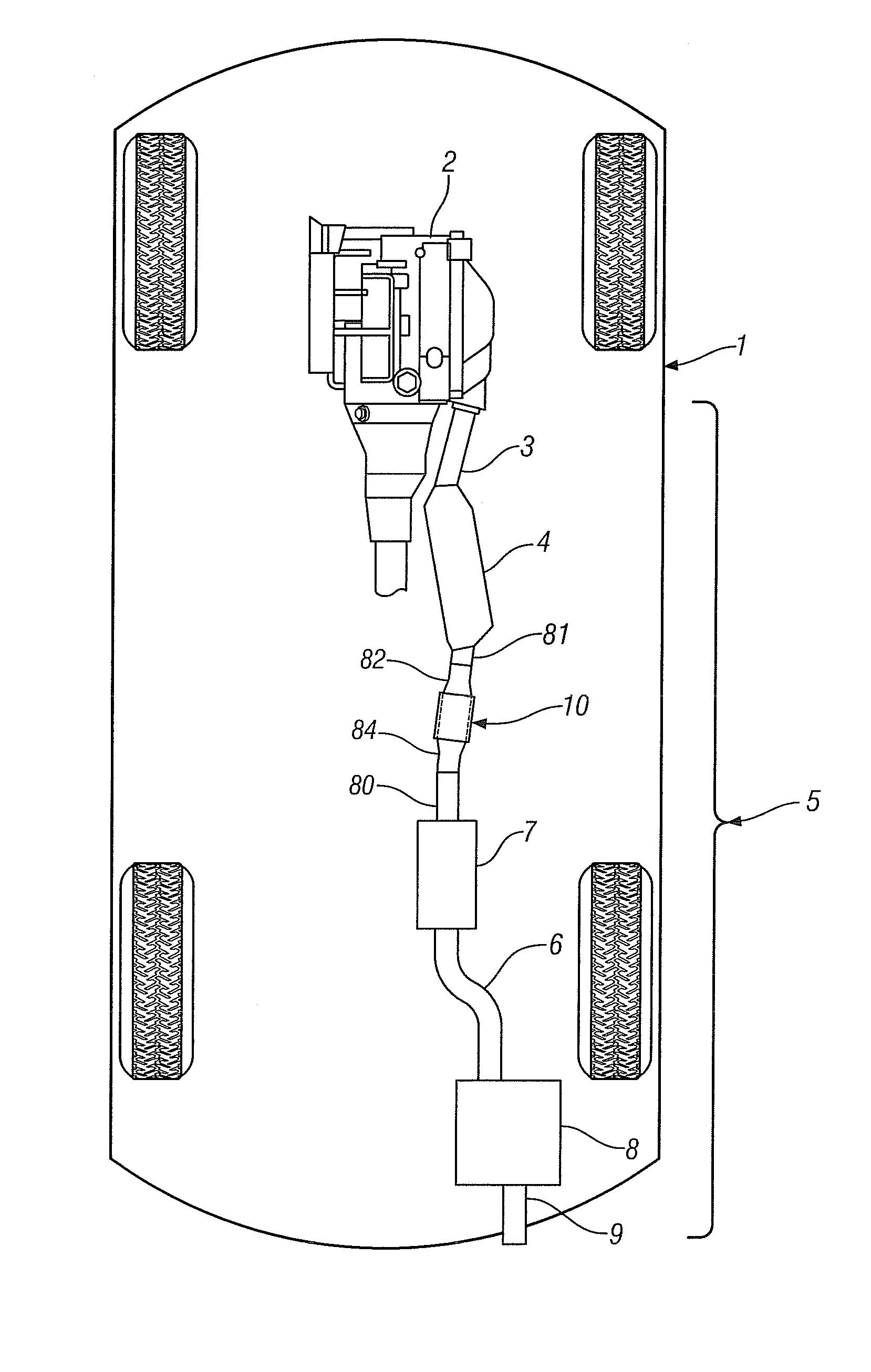

Industrial waste heat recovery applications currently dominate the market landscape, accounting for roughly 35% of total market share. This sector's prominence stems from stringent environmental regulations and corporate sustainability initiatives that incentivize the capture and conversion of waste heat into usable electricity. Automotive applications follow closely behind, representing approximately 30% of the market, with particular interest in exhaust heat recovery systems that can improve overall vehicle efficiency.

Consumer electronics represents the fastest-growing application segment, with annual growth rates exceeding 12%. This surge is primarily attributed to the increasing need for autonomous power sources for IoT devices and wearable technology. The aerospace and defense sectors, while smaller in overall market share at approximately 15%, command premium pricing due to specialized requirements and performance specifications.

Geographically, North America and Europe currently lead the market with combined market share of approximately 60%, largely due to advanced industrial infrastructure and supportive regulatory frameworks. However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, with China, Japan, and South Korea making substantial investments in thermoelectric technology development and manufacturing capabilities.

Market analysis reveals several key demand drivers for TEG-PCM integrated systems. Energy efficiency requirements across industries represent the primary catalyst, followed by the growing need for reliable power sources in remote or off-grid applications. The increasing focus on sustainable energy solutions and circular economy principles further strengthens market demand. Additionally, the miniaturization trend in electronics creates opportunities for compact, efficient thermal management solutions that TEG-PCM systems can provide.

Customer segmentation shows distinct requirements across different sectors. Industrial clients prioritize durability and return on investment, automotive manufacturers focus on weight, space efficiency, and reliability, while consumer electronics producers emphasize miniaturization and cost-effectiveness. This diversity in requirements is driving specialized product development within the TEG-PCM integration space.

Market barriers include relatively high initial costs compared to conventional technologies, limited awareness of TEG-PCM benefits among potential end-users, and technical challenges related to system integration and optimization. Despite these challenges, the market outlook remains highly positive, with technological advancements and economies of scale expected to address current limitations.

Industrial waste heat recovery applications currently dominate the market landscape, accounting for roughly 35% of total market share. This sector's prominence stems from stringent environmental regulations and corporate sustainability initiatives that incentivize the capture and conversion of waste heat into usable electricity. Automotive applications follow closely behind, representing approximately 30% of the market, with particular interest in exhaust heat recovery systems that can improve overall vehicle efficiency.

Consumer electronics represents the fastest-growing application segment, with annual growth rates exceeding 12%. This surge is primarily attributed to the increasing need for autonomous power sources for IoT devices and wearable technology. The aerospace and defense sectors, while smaller in overall market share at approximately 15%, command premium pricing due to specialized requirements and performance specifications.

Geographically, North America and Europe currently lead the market with combined market share of approximately 60%, largely due to advanced industrial infrastructure and supportive regulatory frameworks. However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, with China, Japan, and South Korea making substantial investments in thermoelectric technology development and manufacturing capabilities.

Market analysis reveals several key demand drivers for TEG-PCM integrated systems. Energy efficiency requirements across industries represent the primary catalyst, followed by the growing need for reliable power sources in remote or off-grid applications. The increasing focus on sustainable energy solutions and circular economy principles further strengthens market demand. Additionally, the miniaturization trend in electronics creates opportunities for compact, efficient thermal management solutions that TEG-PCM systems can provide.

Customer segmentation shows distinct requirements across different sectors. Industrial clients prioritize durability and return on investment, automotive manufacturers focus on weight, space efficiency, and reliability, while consumer electronics producers emphasize miniaturization and cost-effectiveness. This diversity in requirements is driving specialized product development within the TEG-PCM integration space.

Market barriers include relatively high initial costs compared to conventional technologies, limited awareness of TEG-PCM benefits among potential end-users, and technical challenges related to system integration and optimization. Despite these challenges, the market outlook remains highly positive, with technological advancements and economies of scale expected to address current limitations.

Current Challenges in TEG Thermal Management

Thermoelectric generators (TEGs) face significant thermal management challenges that limit their widespread adoption and efficiency. The primary challenge lies in the inherent temperature gradient requirement for TEG operation, which necessitates effective heat dissipation mechanisms to maintain optimal performance. Current thermal management systems often struggle with size constraints, weight limitations, and inadequate heat transfer capabilities, particularly in applications where space is limited or weight is critical.

Heat flux uniformity presents another major challenge, as uneven temperature distribution across TEG modules leads to reduced conversion efficiency and potential thermal stress damage. This non-uniformity can create localized hotspots that accelerate material degradation and reduce system lifespan. Additionally, many TEG applications experience transient or fluctuating heat sources, making it difficult to maintain stable temperature differentials necessary for consistent power generation.

The thermal contact resistance between TEG modules and heat exchangers significantly impacts overall system performance. Poor thermal interfaces can create substantial thermal barriers, reducing the effective temperature gradient across the thermoelectric materials. Current interface materials often represent a compromise between thermal conductivity, electrical isolation, and mechanical compliance, rarely achieving optimal performance in all three areas.

Material limitations further complicate thermal management efforts. Conventional heat sink materials may not provide sufficient thermal conductivity for high-flux applications, while advanced materials with superior properties often come with prohibitive costs or manufacturing challenges. The thermal expansion mismatch between different system components can lead to mechanical stress during thermal cycling, potentially causing physical damage or degradation of thermal interfaces over time.

Energy density considerations also pose significant challenges, particularly in portable or mobile applications where system volume and weight are strictly limited. Current thermal management solutions often fail to achieve the necessary balance between effective heat transfer and compact design, limiting TEG implementation in many promising applications.

Integration with existing systems presents additional complications, as TEG thermal management must often adapt to pre-existing thermal architectures rather than being designed from first principles. This constraint frequently results in sub-optimal thermal management solutions that fail to maximize potential power generation.

Environmental factors introduce further complexities, as TEG systems must operate reliably across varying ambient conditions. Temperature extremes, humidity, dust, and other environmental variables can significantly impact thermal management performance, requiring robust designs that maintain effectiveness across diverse operating environments.

Heat flux uniformity presents another major challenge, as uneven temperature distribution across TEG modules leads to reduced conversion efficiency and potential thermal stress damage. This non-uniformity can create localized hotspots that accelerate material degradation and reduce system lifespan. Additionally, many TEG applications experience transient or fluctuating heat sources, making it difficult to maintain stable temperature differentials necessary for consistent power generation.

The thermal contact resistance between TEG modules and heat exchangers significantly impacts overall system performance. Poor thermal interfaces can create substantial thermal barriers, reducing the effective temperature gradient across the thermoelectric materials. Current interface materials often represent a compromise between thermal conductivity, electrical isolation, and mechanical compliance, rarely achieving optimal performance in all three areas.

Material limitations further complicate thermal management efforts. Conventional heat sink materials may not provide sufficient thermal conductivity for high-flux applications, while advanced materials with superior properties often come with prohibitive costs or manufacturing challenges. The thermal expansion mismatch between different system components can lead to mechanical stress during thermal cycling, potentially causing physical damage or degradation of thermal interfaces over time.

Energy density considerations also pose significant challenges, particularly in portable or mobile applications where system volume and weight are strictly limited. Current thermal management solutions often fail to achieve the necessary balance between effective heat transfer and compact design, limiting TEG implementation in many promising applications.

Integration with existing systems presents additional complications, as TEG thermal management must often adapt to pre-existing thermal architectures rather than being designed from first principles. This constraint frequently results in sub-optimal thermal management solutions that fail to maximize potential power generation.

Environmental factors introduce further complexities, as TEG systems must operate reliably across varying ambient conditions. Temperature extremes, humidity, dust, and other environmental variables can significantly impact thermal management performance, requiring robust designs that maintain effectiveness across diverse operating environments.

State-of-the-Art PCM Integration Methods for TEGs

01 Integration of phase change materials with thermoelectric generators

Phase change materials (PCMs) can be integrated with thermoelectric generators to enhance thermal management. PCMs absorb and release thermal energy during phase transitions, helping to maintain optimal operating temperatures for thermoelectric devices. This integration improves energy conversion efficiency by stabilizing temperature gradients across thermoelectric elements and extending operational time during intermittent heat sources.- Integration of phase change materials with thermoelectric generators: Phase change materials (PCMs) can be integrated with thermoelectric generators to enhance thermal management. PCMs absorb and release thermal energy during phase transitions, which helps maintain optimal operating temperatures for thermoelectric devices. This integration improves energy conversion efficiency by stabilizing temperature gradients across the thermoelectric elements and extending the operational duration of the system.

- Heat dissipation and temperature regulation systems: Advanced heat dissipation systems incorporating phase change materials can effectively regulate the temperature of thermoelectric generators. These systems utilize the latent heat properties of PCMs to absorb excess heat during peak operation and release it during low-demand periods. This temperature regulation prevents overheating, reduces thermal stress on components, and maintains the temperature differential necessary for efficient thermoelectric conversion.

- Encapsulation techniques for phase change materials: Specialized encapsulation techniques for phase change materials enhance their integration with thermoelectric generators. These methods involve containing PCMs within thermally conductive shells or matrices that prevent leakage during phase transitions while maximizing heat transfer. Proper encapsulation ensures long-term stability, prevents material degradation, and optimizes the thermal contact between the PCM and thermoelectric elements.

- Hybrid thermal management systems: Hybrid thermal management systems combine phase change materials with other cooling technologies such as heat pipes, liquid cooling, or forced convection to optimize thermoelectric generator performance. These integrated approaches leverage the complementary strengths of different thermal management methods to handle varying heat loads and environmental conditions. Such hybrid systems provide more robust temperature control and can adapt to fluctuating operating conditions.

- Energy storage and recovery using phase change materials: Phase change materials in thermoelectric systems can serve dual purposes of thermal management and energy storage. During operation, excess thermal energy is stored in the PCM and can be later recovered to extend the generation capability during periods of low heat input. This approach improves overall system efficiency by capturing waste heat that would otherwise be lost and utilizing it to maintain power generation during thermal fluctuations.

02 Heat dissipation systems for thermoelectric generators using PCMs

Specialized heat dissipation systems incorporating phase change materials can effectively manage excess heat in thermoelectric generators. These systems utilize PCMs to absorb heat during peak generation periods and release it during low-load conditions, creating a more stable thermal environment. The heat dissipation mechanisms include heat sinks, heat pipes, and thermal interface materials combined with PCMs to optimize the temperature differential across thermoelectric modules.Expand Specific Solutions03 Temperature regulation mechanisms for thermoelectric efficiency

Advanced temperature regulation mechanisms using phase change materials can significantly improve thermoelectric generator efficiency. These mechanisms maintain the optimal temperature gradient across thermoelectric elements by absorbing excess heat during operation and releasing it when needed. The controlled thermal management prevents overheating and thermal cycling damage, extending the lifespan of thermoelectric devices while maintaining peak performance conditions.Expand Specific Solutions04 Encapsulation techniques for PCMs in thermoelectric systems

Innovative encapsulation techniques for phase change materials enhance their integration with thermoelectric generators. These methods include micro-encapsulation, macro-encapsulation, and composite formation with supporting materials to prevent leakage during phase transition. Properly encapsulated PCMs maintain their thermal properties over numerous cycles, prevent corrosion of thermoelectric elements, and allow for strategic placement within the thermoelectric system to maximize thermal management benefits.Expand Specific Solutions05 Hybrid energy harvesting systems combining PCMs and thermoelectric generators

Hybrid energy harvesting systems integrate phase change materials with thermoelectric generators and complementary technologies such as photovoltaics or waste heat recovery systems. These hybrid configurations utilize PCMs as thermal energy storage to balance intermittent heat sources and maintain consistent power output from thermoelectric generators. The combined approach maximizes energy conversion efficiency across varying environmental conditions and enables applications in remote locations, wearable devices, and industrial waste heat recovery.Expand Specific Solutions

Leading Companies and Research Institutions in TEG-PCM Field

The thermoelectric generator thermal management market using phase change materials is currently in a growth phase, with increasing applications in waste heat recovery systems. The global market is expanding steadily, driven by energy efficiency demands and sustainable technology adoption. Leading companies like Siemens AG, Intel Corp., and Robert Bosch GmbH are advancing the technology's maturity through significant R&D investments. Research institutions including Fraunhofer-Gesellschaft and SRI International are collaborating with industrial players such as BASF, Honeywell, and Gentherm to overcome thermal management challenges. The technology is progressing from laboratory demonstrations toward commercial applications, with companies like nanoCoolers and All Cell Technologies developing specialized solutions for automotive, electronics, and energy sectors.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has pioneered advanced thermoelectric generator thermal management systems utilizing novel phase change materials. Their research has yielded a sophisticated thermal regulation approach that combines nanostructured PCMs with optimized heat transfer interfaces specifically designed for high-efficiency TEGs. CEA's solution features custom-synthesized PCMs with precisely tailored melting points and latent heat capacities matched to specific TEG operating parameters. The system incorporates a multi-dimensional heat flow management architecture that directs thermal energy through optimized pathways to maintain ideal temperature differentials across thermoelectric elements. A key innovation is their development of graphene-enhanced PCM composites that dramatically improve thermal conductivity while maintaining high energy storage density. CEA has also created adaptive thermal management algorithms that continuously optimize the PCM's performance based on real-time temperature monitoring and predictive modeling. Their research demonstrates significant improvements in TEG conversion efficiency, with laboratory tests showing up to 38% increased power output compared to conventional cooling methods under variable thermal load conditions.

Strengths: Cutting-edge materials science expertise; highly optimized for maximum thermoelectric efficiency; sophisticated thermal modeling capabilities. Weaknesses: Some technologies remain at research/prototype stage; higher material costs for specialized PCM formulations; complex implementation requiring significant technical expertise.

Siemens AG

Technical Solution: Siemens has developed an industrial-scale thermoelectric generator thermal management system incorporating advanced phase change materials for power generation applications. Their solution features a modular design with specialized PCM composites engineered to operate efficiently within specific temperature ranges. The system employs a layered PCM architecture with varying thermal conductivities and melting points, strategically positioned to create optimal temperature gradients across the thermoelectric elements. Siemens' innovation includes a hybrid cooling approach that combines passive PCM thermal buffering with active cooling elements that engage only when thermal loads exceed the PCM's capacity. This intelligent thermal management strategy significantly reduces parasitic power losses while maintaining stable operating temperatures. The system incorporates advanced heat pipe technology to rapidly distribute heat across the PCM matrix, ensuring uniform temperature distribution and preventing localized hotspots that could degrade thermoelectric performance. Siemens has also developed proprietary PCM encapsulation techniques that enhance long-term stability and prevent material degradation even under thousands of thermal cycles.

Strengths: Scalable design suitable for industrial power generation; excellent long-term reliability; sophisticated thermal modeling and system integration capabilities. Weaknesses: Higher implementation costs compared to conventional cooling systems; requires significant engineering expertise for optimal deployment; system size may limit applications in space-constrained environments.

Critical Patents and Research on TEG-PCM Systems

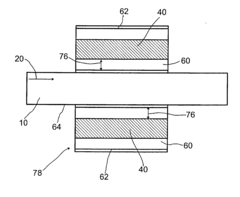

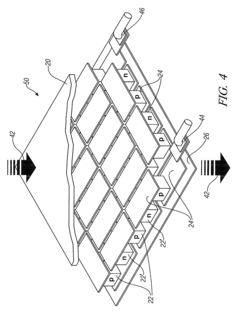

Temperature protection of a thermoelectric module and/or of a thermoelectric generator using phase change materials

PatentInactiveUS20120073619A1

Innovation

- Incorporating a layer of phase change material between the hot medium pipe and the thermoelectric module to absorb and store excess heat, protecting the module from high temperatures and releasing heat back when temperatures decrease, thus enhancing efficiency and eliminating the need for costly modifications.

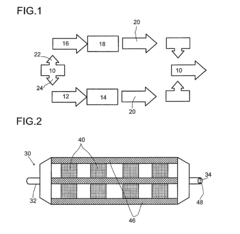

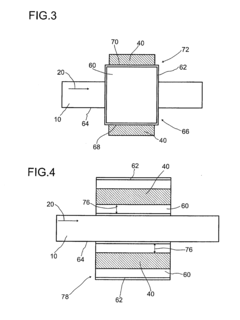

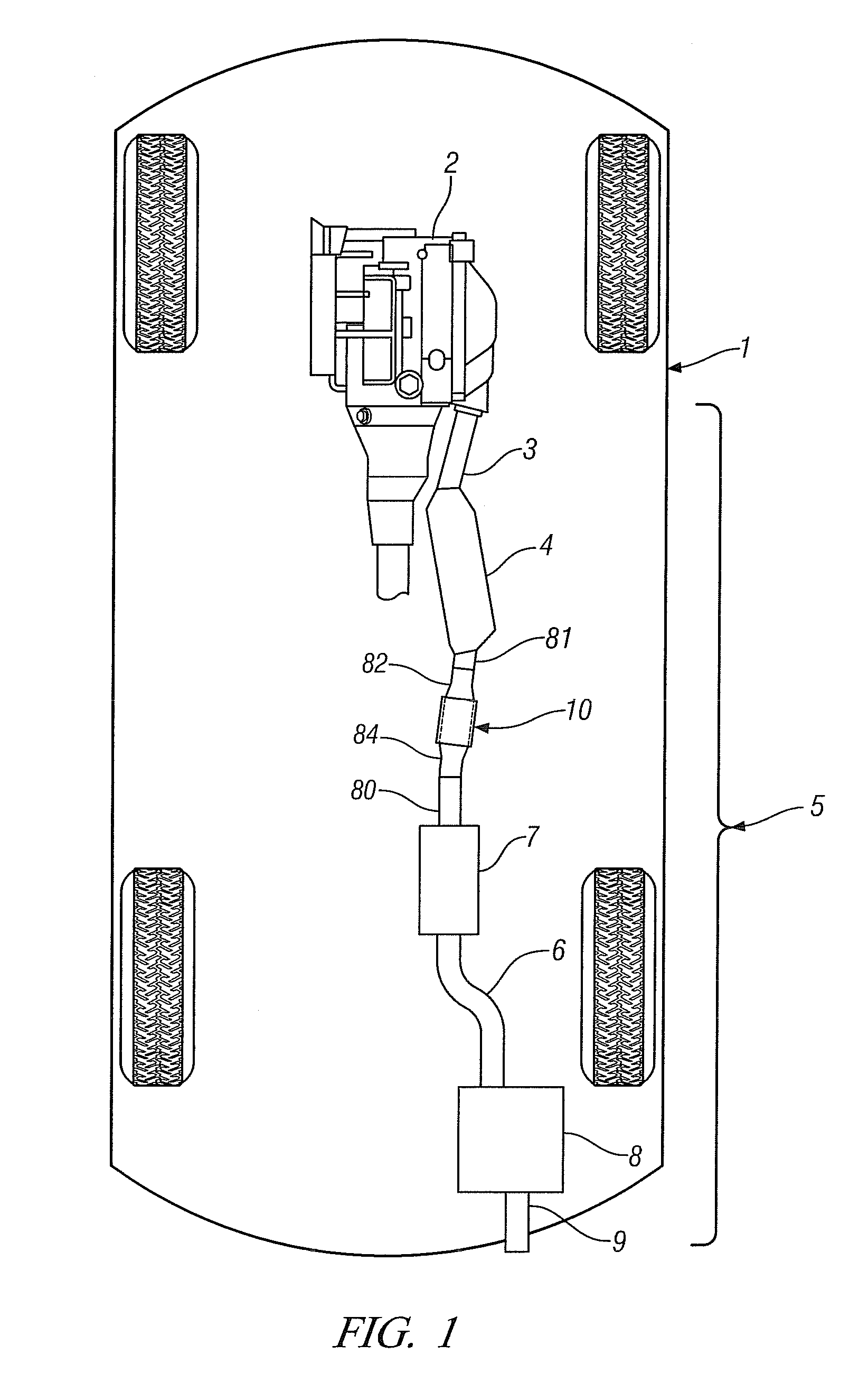

Thermoelectric generators incorporating phase-change materials for waste heat recovery from engine exhaust

PatentActiveUS20120073276A1

Innovation

- Integration of thermoelectric modules with phase-change materials in the exhaust conduit system to convert thermal energy from exhaust gases into electrical energy, using bypass pipes and air admittance to manage temperature and prevent overheating of thermoelectric modules.

Energy Efficiency and Performance Metrics

The evaluation of thermoelectric generators (TEGs) integrated with phase change materials (PCMs) requires comprehensive energy efficiency and performance metrics to quantify system effectiveness. The primary metric for TEG performance is the conversion efficiency, typically ranging from 3-8% for commercial systems. This efficiency is directly influenced by the temperature differential maintained across the TEG, which PCMs help optimize through thermal regulation.

Power density represents another critical metric, measuring electrical output per unit area (W/cm²) or volume (W/cm³). TEG-PCM systems demonstrate enhanced power density compared to conventional TEG setups, particularly in applications with fluctuating heat sources. Studies indicate that properly designed PCM integration can improve power density by 15-30% under intermittent thermal loading conditions.

Thermal management effectiveness is quantified through metrics such as thermal resistance (K/W), which measures the system's ability to transfer heat efficiently. The integration of PCMs introduces additional parameters including phase transition temperature range, latent heat capacity (J/g), and thermal conductivity (W/m·K). These properties directly impact the system's ability to maintain optimal temperature gradients across the thermoelectric elements.

Energy storage density of the PCM component plays a crucial role in determining the system's operational duration during periods of low or no external heat input. This metric, measured in Wh/kg or Wh/L, enables comparison between different PCM materials and system configurations. High-performance PCMs with energy storage densities of 150-300 Wh/kg can significantly extend the operational window of TEG systems.

Response time represents another key performance indicator, measuring how quickly the system can react to thermal fluctuations. PCM-enhanced TEGs typically exhibit longer thermal inertia compared to conventional systems, which can be advantageous for applications requiring stable power output despite variable heat sources.

Lifecycle performance metrics include degradation rates of both TEG and PCM components, thermal cycling stability, and long-term conversion efficiency maintenance. Current research indicates that properly engineered PCM-TEG systems can maintain over 90% of initial performance after 1000+ thermal cycles, significantly outperforming conventional TEG implementations.

Cost-performance ratios, including levelized cost of energy (LCOE) and payback period calculations, provide economic perspectives on TEG-PCM systems. While initial costs typically exceed those of conventional TEGs by 20-40%, the improved energy harvesting capabilities and extended operational lifetimes often result in more favorable long-term economics, particularly in waste heat recovery applications.

Power density represents another critical metric, measuring electrical output per unit area (W/cm²) or volume (W/cm³). TEG-PCM systems demonstrate enhanced power density compared to conventional TEG setups, particularly in applications with fluctuating heat sources. Studies indicate that properly designed PCM integration can improve power density by 15-30% under intermittent thermal loading conditions.

Thermal management effectiveness is quantified through metrics such as thermal resistance (K/W), which measures the system's ability to transfer heat efficiently. The integration of PCMs introduces additional parameters including phase transition temperature range, latent heat capacity (J/g), and thermal conductivity (W/m·K). These properties directly impact the system's ability to maintain optimal temperature gradients across the thermoelectric elements.

Energy storage density of the PCM component plays a crucial role in determining the system's operational duration during periods of low or no external heat input. This metric, measured in Wh/kg or Wh/L, enables comparison between different PCM materials and system configurations. High-performance PCMs with energy storage densities of 150-300 Wh/kg can significantly extend the operational window of TEG systems.

Response time represents another key performance indicator, measuring how quickly the system can react to thermal fluctuations. PCM-enhanced TEGs typically exhibit longer thermal inertia compared to conventional systems, which can be advantageous for applications requiring stable power output despite variable heat sources.

Lifecycle performance metrics include degradation rates of both TEG and PCM components, thermal cycling stability, and long-term conversion efficiency maintenance. Current research indicates that properly engineered PCM-TEG systems can maintain over 90% of initial performance after 1000+ thermal cycles, significantly outperforming conventional TEG implementations.

Cost-performance ratios, including levelized cost of energy (LCOE) and payback period calculations, provide economic perspectives on TEG-PCM systems. While initial costs typically exceed those of conventional TEGs by 20-40%, the improved energy harvesting capabilities and extended operational lifetimes often result in more favorable long-term economics, particularly in waste heat recovery applications.

Environmental Impact and Sustainability Considerations

The integration of Phase Change Materials (PCMs) in Thermoelectric Generator (TEG) thermal management systems presents significant environmental and sustainability advantages. PCMs enable more efficient heat recovery and utilization, directly contributing to reduced fossil fuel consumption and greenhouse gas emissions. By enhancing TEG efficiency through improved thermal regulation, these systems can generate more electricity from waste heat that would otherwise be released into the environment, representing a form of energy recovery that aligns with circular economy principles.

From a life cycle perspective, PCM-enhanced TEG systems demonstrate favorable environmental profiles compared to conventional cooling technologies. Most PCMs used in these applications are non-toxic and can be derived from renewable or biodegradable sources, such as bio-based fatty acids or salt hydrates. This reduces the environmental footprint associated with material extraction and end-of-life disposal. Additionally, the extended operational lifespan of TEGs resulting from better thermal management translates to fewer replacement cycles and reduced manufacturing-related environmental impacts.

The sustainability benefits extend to resource conservation as well. PCM-TEG systems typically require minimal water consumption during operation, unlike traditional cooling towers or water-cooled heat exchangers. This water-saving characteristic makes them particularly valuable in water-stressed regions. Furthermore, the passive nature of PCM thermal regulation reduces or eliminates the need for energy-intensive active cooling mechanisms, creating a self-sustaining system with minimal external energy requirements.

In industrial applications, PCM-enhanced TEG systems contribute to corporate sustainability goals by improving energy efficiency metrics and supporting regulatory compliance with emissions standards. The technology enables industries to monetize waste heat streams while simultaneously reducing their carbon footprint, creating both environmental and economic benefits that reinforce the business case for adoption.

Looking toward future developments, research into advanced bio-derived PCMs and environmentally benign thermoelectric materials promises to further enhance the sustainability profile of these systems. Emerging circular economy frameworks for the recovery and recycling of thermoelectric materials and PCMs at end-of-life will be crucial for maximizing the long-term environmental benefits of this technology. As climate policies increasingly favor carbon-neutral solutions, PCM-enhanced TEG systems stand to gain prominence as a sustainable approach to thermal energy management and distributed power generation.

From a life cycle perspective, PCM-enhanced TEG systems demonstrate favorable environmental profiles compared to conventional cooling technologies. Most PCMs used in these applications are non-toxic and can be derived from renewable or biodegradable sources, such as bio-based fatty acids or salt hydrates. This reduces the environmental footprint associated with material extraction and end-of-life disposal. Additionally, the extended operational lifespan of TEGs resulting from better thermal management translates to fewer replacement cycles and reduced manufacturing-related environmental impacts.

The sustainability benefits extend to resource conservation as well. PCM-TEG systems typically require minimal water consumption during operation, unlike traditional cooling towers or water-cooled heat exchangers. This water-saving characteristic makes them particularly valuable in water-stressed regions. Furthermore, the passive nature of PCM thermal regulation reduces or eliminates the need for energy-intensive active cooling mechanisms, creating a self-sustaining system with minimal external energy requirements.

In industrial applications, PCM-enhanced TEG systems contribute to corporate sustainability goals by improving energy efficiency metrics and supporting regulatory compliance with emissions standards. The technology enables industries to monetize waste heat streams while simultaneously reducing their carbon footprint, creating both environmental and economic benefits that reinforce the business case for adoption.

Looking toward future developments, research into advanced bio-derived PCMs and environmentally benign thermoelectric materials promises to further enhance the sustainability profile of these systems. Emerging circular economy frameworks for the recovery and recycling of thermoelectric materials and PCMs at end-of-life will be crucial for maximizing the long-term environmental benefits of this technology. As climate policies increasingly favor carbon-neutral solutions, PCM-enhanced TEG systems stand to gain prominence as a sustainable approach to thermal energy management and distributed power generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!