Mechanical Robustness And Vibration Resistance For Automotive TEG Modules

SEP 5, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Automotive TEG Technology Background and Objectives

Thermoelectric Generator (TEG) technology represents a promising solution for automotive energy recovery systems, converting waste heat from vehicle exhaust into usable electrical energy. The development of automotive TEG systems dates back to the early 2000s when major automotive manufacturers began exploring waste heat recovery technologies to improve fuel efficiency and reduce emissions. This technology leverages the Seebeck effect, discovered in the 19th century, which enables direct conversion of temperature differences into electrical voltage.

The evolution of automotive TEG technology has been marked by significant advancements in thermoelectric materials, from traditional bismuth telluride to more efficient and environmentally friendly alternatives. Recent years have witnessed a shift toward skutterudite-based and half-Heusler alloys, offering improved performance at the high temperatures typical of automotive exhaust systems. These developments align with the automotive industry's growing focus on sustainability and energy efficiency.

The primary objective of automotive TEG technology is to capture and convert waste heat from vehicle exhaust systems, which typically accounts for approximately 30-40% of fuel energy in conventional internal combustion engines. By harnessing this otherwise wasted energy, TEGs aim to reduce fuel consumption by 3-5% and correspondingly decrease CO2 emissions, contributing to meeting increasingly stringent environmental regulations worldwide.

A critical challenge in automotive TEG implementation is ensuring mechanical robustness and vibration resistance. Automotive environments subject components to extreme conditions, including temperature fluctuations ranging from -40°C to over 600°C at the exhaust interface, constant vibrations from engine operation and road conditions, and mechanical shocks from driving events. These conditions can compromise the structural integrity of TEG modules, particularly at critical interfaces between thermoelectric materials and heat exchangers.

The technical goals for automotive TEG modules focus on developing systems that maintain performance and structural integrity throughout the vehicle's lifecycle, typically 150,000-200,000 miles or 10-15 years. This requires innovative approaches to module design, material selection, and assembly techniques that can withstand the harsh automotive environment while maintaining efficient thermal-to-electrical energy conversion.

Current research trends are exploring advanced bonding technologies, flexible mechanical interfaces, and novel module architectures that can accommodate thermal expansion mismatches while resisting vibration-induced fatigue. Additionally, there is growing interest in developing standardized testing protocols specifically designed to evaluate the mechanical durability of automotive TEG systems under realistic operating conditions.

The evolution of automotive TEG technology has been marked by significant advancements in thermoelectric materials, from traditional bismuth telluride to more efficient and environmentally friendly alternatives. Recent years have witnessed a shift toward skutterudite-based and half-Heusler alloys, offering improved performance at the high temperatures typical of automotive exhaust systems. These developments align with the automotive industry's growing focus on sustainability and energy efficiency.

The primary objective of automotive TEG technology is to capture and convert waste heat from vehicle exhaust systems, which typically accounts for approximately 30-40% of fuel energy in conventional internal combustion engines. By harnessing this otherwise wasted energy, TEGs aim to reduce fuel consumption by 3-5% and correspondingly decrease CO2 emissions, contributing to meeting increasingly stringent environmental regulations worldwide.

A critical challenge in automotive TEG implementation is ensuring mechanical robustness and vibration resistance. Automotive environments subject components to extreme conditions, including temperature fluctuations ranging from -40°C to over 600°C at the exhaust interface, constant vibrations from engine operation and road conditions, and mechanical shocks from driving events. These conditions can compromise the structural integrity of TEG modules, particularly at critical interfaces between thermoelectric materials and heat exchangers.

The technical goals for automotive TEG modules focus on developing systems that maintain performance and structural integrity throughout the vehicle's lifecycle, typically 150,000-200,000 miles or 10-15 years. This requires innovative approaches to module design, material selection, and assembly techniques that can withstand the harsh automotive environment while maintaining efficient thermal-to-electrical energy conversion.

Current research trends are exploring advanced bonding technologies, flexible mechanical interfaces, and novel module architectures that can accommodate thermal expansion mismatches while resisting vibration-induced fatigue. Additionally, there is growing interest in developing standardized testing protocols specifically designed to evaluate the mechanical durability of automotive TEG systems under realistic operating conditions.

Market Analysis for Automotive TEG Applications

The global automotive thermoelectric generator (TEG) market is experiencing significant growth, driven by increasing demand for fuel-efficient vehicles and stringent emission regulations worldwide. The market was valued at approximately $550 million in 2022 and is projected to reach $1.2 billion by 2030, growing at a CAGR of 10.3% during the forecast period. This growth trajectory is primarily fueled by the automotive industry's shift towards sustainable technologies and energy recovery systems.

The passenger vehicle segment currently dominates the TEG market, accounting for nearly 65% of the total market share. However, commercial vehicles are expected to witness faster growth due to their higher waste heat generation and greater potential for energy recovery. Geographically, Europe leads the market with approximately 38% share, followed by North America and Asia-Pacific regions at 32% and 25% respectively.

Key market drivers include the increasing focus on vehicle electrification, rising fuel prices, and growing environmental concerns. TEG systems offer a compelling value proposition by converting waste heat from exhaust systems into usable electrical energy, potentially improving fuel efficiency by 3-5% in conventional vehicles. This efficiency gain translates to significant fuel savings and reduced emissions over a vehicle's lifetime.

The mechanical robustness and vibration resistance aspects of TEG modules represent a critical market differentiator. Automotive environments subject these modules to extreme conditions, including temperature fluctuations ranging from -40°C to 800°C, vibrations of up to 30G, and operational lifespans exceeding 10,000 hours. OEMs are increasingly prioritizing TEG solutions that demonstrate superior durability under these harsh conditions.

Market segmentation reveals distinct customer preferences across different vehicle categories. Luxury and premium vehicle manufacturers are early adopters, willing to pay premium prices for high-performance TEG systems. Mid-range vehicle manufacturers seek cost-effective solutions with proven reliability, while commercial vehicle manufacturers prioritize durability and long-term ROI.

The competitive landscape features both established automotive suppliers and specialized TEG technology companies. Tier-1 suppliers like Bosch, Continental, and Denso hold significant market share due to their established relationships with OEMs and manufacturing capabilities. However, specialized companies such as Gentherm, II-VI Marlow, and Thermonamic Electronics are gaining traction through technological innovation and focused R&D efforts.

Market challenges include high initial costs, with current TEG systems adding between $300-600 to vehicle production costs. Integration complexities and weight considerations also impact adoption rates. Nevertheless, the market outlook remains positive as technological advancements continue to improve performance while reducing costs, making TEG systems increasingly attractive for mainstream automotive applications.

The passenger vehicle segment currently dominates the TEG market, accounting for nearly 65% of the total market share. However, commercial vehicles are expected to witness faster growth due to their higher waste heat generation and greater potential for energy recovery. Geographically, Europe leads the market with approximately 38% share, followed by North America and Asia-Pacific regions at 32% and 25% respectively.

Key market drivers include the increasing focus on vehicle electrification, rising fuel prices, and growing environmental concerns. TEG systems offer a compelling value proposition by converting waste heat from exhaust systems into usable electrical energy, potentially improving fuel efficiency by 3-5% in conventional vehicles. This efficiency gain translates to significant fuel savings and reduced emissions over a vehicle's lifetime.

The mechanical robustness and vibration resistance aspects of TEG modules represent a critical market differentiator. Automotive environments subject these modules to extreme conditions, including temperature fluctuations ranging from -40°C to 800°C, vibrations of up to 30G, and operational lifespans exceeding 10,000 hours. OEMs are increasingly prioritizing TEG solutions that demonstrate superior durability under these harsh conditions.

Market segmentation reveals distinct customer preferences across different vehicle categories. Luxury and premium vehicle manufacturers are early adopters, willing to pay premium prices for high-performance TEG systems. Mid-range vehicle manufacturers seek cost-effective solutions with proven reliability, while commercial vehicle manufacturers prioritize durability and long-term ROI.

The competitive landscape features both established automotive suppliers and specialized TEG technology companies. Tier-1 suppliers like Bosch, Continental, and Denso hold significant market share due to their established relationships with OEMs and manufacturing capabilities. However, specialized companies such as Gentherm, II-VI Marlow, and Thermonamic Electronics are gaining traction through technological innovation and focused R&D efforts.

Market challenges include high initial costs, with current TEG systems adding between $300-600 to vehicle production costs. Integration complexities and weight considerations also impact adoption rates. Nevertheless, the market outlook remains positive as technological advancements continue to improve performance while reducing costs, making TEG systems increasingly attractive for mainstream automotive applications.

Current Challenges in TEG Mechanical Durability

Thermoelectric Generator (TEG) modules in automotive applications face significant mechanical durability challenges due to the harsh operating environment. The primary issue stems from the extreme temperature gradients these modules must withstand, often exceeding 600°C between the hot and cold sides. These thermal stresses induce mechanical strain that can lead to component fatigue and eventual failure, particularly at the interfaces between different materials.

Vibration presents another critical challenge for automotive TEG modules. Vehicles typically generate vibrations ranging from 10 to 500 Hz with acceleration forces up to 10g, creating continuous mechanical stress on TEG components. These vibrations can cause micro-fractures in thermoelectric materials, which are inherently brittle due to their semiconductor nature. Bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), commonly used in TEGs, exhibit particularly poor mechanical properties under vibrational stress.

Thermal cycling—the repeated heating and cooling during vehicle operation—compounds these issues by creating differential expansion between module components. The coefficient of thermal expansion (CTE) mismatch between thermoelectric materials, substrates, and interconnects leads to progressive mechanical degradation. Current data indicates that automotive TEGs may experience up to 10,000 thermal cycles during their operational lifetime, with each cycle potentially weakening the structural integrity.

Contact resistance stability represents another significant durability concern. The electrical connections between thermoelectric elements and metal interconnects must maintain consistent contact under thermal and mechanical stress. Research shows that contact resistance can increase by up to 30% after extended vibration exposure, dramatically reducing power output efficiency.

Sealing and encapsulation technologies present ongoing challenges. TEG modules require effective protection from environmental factors like moisture and oxidation while maintaining thermal performance. Current encapsulation methods often compromise either mechanical robustness or thermal efficiency, creating an engineering trade-off that limits overall system performance.

Manufacturing inconsistencies further exacerbate durability issues. Microscopic defects introduced during production can serve as failure initiation points under mechanical stress. Quality control data indicates that even state-of-the-art manufacturing processes produce thermoelectric elements with up to 5% variation in mechanical properties, creating unpredictable failure modes.

The integration of TEG modules into vehicle exhaust systems introduces additional challenges related to mounting and fixation. Current mounting solutions must balance thermal isolation requirements with mechanical stability, often resulting in compromised vibration resistance. Testing reveals that mounting points frequently become failure locations after extended road testing, particularly in off-road conditions where vibration profiles are more severe and unpredictable.

Vibration presents another critical challenge for automotive TEG modules. Vehicles typically generate vibrations ranging from 10 to 500 Hz with acceleration forces up to 10g, creating continuous mechanical stress on TEG components. These vibrations can cause micro-fractures in thermoelectric materials, which are inherently brittle due to their semiconductor nature. Bismuth telluride (Bi₂Te₃) and lead telluride (PbTe), commonly used in TEGs, exhibit particularly poor mechanical properties under vibrational stress.

Thermal cycling—the repeated heating and cooling during vehicle operation—compounds these issues by creating differential expansion between module components. The coefficient of thermal expansion (CTE) mismatch between thermoelectric materials, substrates, and interconnects leads to progressive mechanical degradation. Current data indicates that automotive TEGs may experience up to 10,000 thermal cycles during their operational lifetime, with each cycle potentially weakening the structural integrity.

Contact resistance stability represents another significant durability concern. The electrical connections between thermoelectric elements and metal interconnects must maintain consistent contact under thermal and mechanical stress. Research shows that contact resistance can increase by up to 30% after extended vibration exposure, dramatically reducing power output efficiency.

Sealing and encapsulation technologies present ongoing challenges. TEG modules require effective protection from environmental factors like moisture and oxidation while maintaining thermal performance. Current encapsulation methods often compromise either mechanical robustness or thermal efficiency, creating an engineering trade-off that limits overall system performance.

Manufacturing inconsistencies further exacerbate durability issues. Microscopic defects introduced during production can serve as failure initiation points under mechanical stress. Quality control data indicates that even state-of-the-art manufacturing processes produce thermoelectric elements with up to 5% variation in mechanical properties, creating unpredictable failure modes.

The integration of TEG modules into vehicle exhaust systems introduces additional challenges related to mounting and fixation. Current mounting solutions must balance thermal isolation requirements with mechanical stability, often resulting in compromised vibration resistance. Testing reveals that mounting points frequently become failure locations after extended road testing, particularly in off-road conditions where vibration profiles are more severe and unpredictable.

Existing Mechanical Robustness Solutions for TEG Modules

01 Structural design for vibration resistance in automotive TEG modules

Thermoelectric generator (TEG) modules for automotive applications require specialized structural designs to withstand vibration and mechanical stress. These designs include reinforced housing structures, shock-absorbing mounting systems, and flexible connections that can accommodate thermal expansion while maintaining structural integrity. Such robust designs ensure that the TEG modules can withstand the harsh vibration conditions present in automotive environments without performance degradation or physical damage.- Structural design for vibration resistance in automotive TEG modules: Thermoelectric generator (TEG) modules for automotive applications require specialized structural designs to withstand vibration. These designs include reinforced housing structures, shock-absorbing mounting systems, and flexible connectors that can absorb mechanical stress. The structural elements are engineered to maintain thermal contact under dynamic conditions while preventing component fatigue during continuous vehicle operation.

- Material selection for mechanical robustness in high-temperature environments: Advanced materials are crucial for TEG modules that must withstand both vibration and high-temperature differentials in automotive exhaust systems. These materials include high-temperature resistant ceramics, specialized metal alloys, and composite materials that maintain structural integrity while allowing efficient heat transfer. The selection of these materials directly impacts the longevity and reliability of the TEG modules under harsh automotive conditions.

- Vibration dampening and isolation techniques: Various dampening and isolation techniques are employed to protect TEG modules from vehicle vibrations. These include elastomeric mounts, spring-loaded fixtures, and specialized dampening materials that absorb vibrational energy. Some designs incorporate multi-layer isolation systems that filter different vibration frequencies, preventing resonance effects that could damage the thermoelectric elements or their electrical connections.

- Testing and validation methodologies for mechanical durability: Comprehensive testing protocols are essential to validate the mechanical robustness of automotive TEG modules. These include accelerated vibration testing, thermal cycling under load, and combined thermal-mechanical stress tests that simulate real-world automotive conditions. Advanced monitoring systems track performance degradation during testing, allowing for design optimization before field deployment. These methodologies ensure that TEG modules can withstand the rigorous demands of automotive applications.

- Integration systems for TEG modules in vehicle powertrains: Specialized integration systems are designed to mount TEG modules securely within vehicle powertrains while accommodating thermal expansion and vehicle movement. These systems include adaptive mounting brackets, heat distribution plates, and flexible electrical connections that maintain functionality during vehicle operation. Some designs incorporate active monitoring systems that can detect mechanical stresses and adjust operating parameters to prevent damage, ensuring long-term reliability in automotive applications.

02 Materials selection for mechanical robustness in TEG modules

The selection of appropriate materials plays a crucial role in enhancing the mechanical robustness of automotive TEG modules. High-temperature resistant alloys, advanced ceramics, and composite materials are utilized to create components that can withstand thermal cycling, mechanical shock, and continuous vibration. These materials are selected for their favorable combination of thermal conductivity, mechanical strength, and durability under automotive operating conditions, ensuring long-term reliability of the TEG system.Expand Specific Solutions03 Vibration isolation and damping systems for TEG modules

Specialized vibration isolation and damping systems are implemented to protect automotive TEG modules from the detrimental effects of vehicle vibrations. These systems include elastomeric mounts, spring-loaded supports, and multi-layer damping structures that absorb and dissipate vibrational energy. By effectively isolating the sensitive thermoelectric components from chassis vibrations, these systems significantly improve the operational lifespan and reliability of automotive TEG modules under real-world driving conditions.Expand Specific Solutions04 Testing and validation methods for mechanical robustness

Comprehensive testing and validation protocols are essential for ensuring the mechanical robustness of automotive TEG modules. These include accelerated vibration testing, thermal cycling under load, shock resistance evaluation, and long-term durability assessments. Advanced simulation techniques and real-world road testing are employed to verify that the TEG modules can withstand the combined effects of thermal stress, mechanical vibration, and environmental factors encountered in automotive applications.Expand Specific Solutions05 Interface design and bonding techniques for vibration resistance

The interfaces between different components of automotive TEG modules are critical for vibration resistance. Advanced bonding techniques such as high-temperature brazing, specialized soldering methods, and mechanical interlocking designs are employed to create robust connections. Flexible thermal interfaces and compliant electrical connections are designed to accommodate differential thermal expansion while maintaining electrical and thermal conductivity under vibration conditions, thereby enhancing the overall mechanical robustness of the TEG system.Expand Specific Solutions

Leading Manufacturers and Competitors in Automotive TEG

The automotive thermoelectric generator (TEG) module market is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The market size is projected to expand significantly as vehicle electrification accelerates, with estimates suggesting a compound annual growth rate of 15-20% over the next five years. Regarding technical maturity, major automotive suppliers like Robert Bosch, DENSO, and Continental are leading development efforts, focusing on solving mechanical robustness challenges in high-vibration automotive environments. Tier-1 suppliers ZF Friedrichshafen and Schaeffler are advancing vibration-resistant mounting solutions, while automakers including Hyundai, BYD, and Chery are integrating these technologies into vehicle development programs. Material innovation from companies like Hexcel Composites and Sumitomo Chemical is addressing thermal cycling durability issues that have historically limited TEG adoption in vehicles.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermoelectric generator (TEG) modules with enhanced mechanical robustness specifically designed for automotive applications. Their solution incorporates a multi-layered structural design with specialized shock-absorbing mounting systems that isolate the sensitive thermoelectric materials from vehicle vibrations. The company utilizes high-temperature resistant ceramic substrates with optimized thickness and flexibility to withstand thermal cycling while maintaining electrical connectivity. Bosch's TEG modules feature proprietary bonding techniques that create reliable connections between thermoelectric materials and metal contacts, reducing thermal expansion stress. Their design includes elastomeric damping elements strategically positioned to absorb vibrations across multiple frequency ranges commonly experienced in automotive environments, protecting the brittle semiconductor materials used in thermoelectric couples.

Strengths: Extensive automotive industry experience allows for practical implementation knowledge; comprehensive testing capabilities across various vehicle platforms; established manufacturing infrastructure for mass production. Weaknesses: Higher production costs compared to simpler designs; increased complexity may affect maintenance accessibility; potential weight penalties from robust protection systems.

DENSO Corp.

Technical Solution: DENSO has engineered a vibration-resistant TEG module system specifically for harsh automotive environments, featuring a patented flexible mounting architecture that accommodates thermal expansion while maintaining structural integrity. Their design incorporates specialized spring-loaded contact mechanisms that ensure continuous electrical connectivity despite mechanical stresses and vibrations. DENSO's TEG modules utilize segmented thermoelectric materials with gradient properties that reduce internal stress concentrations during thermal cycling and vibration events. The company has developed a proprietary encapsulation technology that hermetically seals the thermoelectric elements while allowing controlled flexibility, protecting against moisture ingress and oxidation while absorbing mechanical shocks. Their system includes integrated vibration dampening structures with resonance-avoiding geometries tuned to counteract typical automotive vibration frequencies.

Strengths: Superior thermal cycling durability validated through extensive field testing; excellent power density-to-weight ratio; proven reliability in production vehicles. Weaknesses: Higher initial manufacturing costs; more complex assembly process requiring specialized equipment; potential thermal interface degradation over extended vehicle lifetime.

Critical Patents in Vibration-Resistant TEG Design

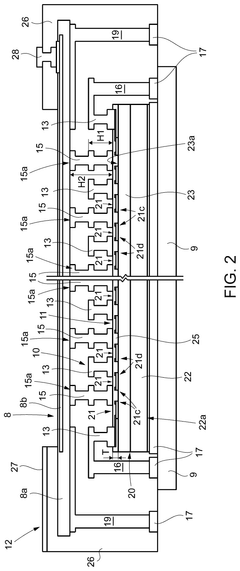

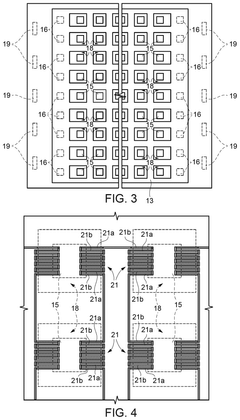

Thermoelectric generator and method for producing a thermoelectric generator

PatentInactiveEP3289620A1

Innovation

- Incorporating an electrically insulating support material between substrates to enhance mechanical and thermal resilience, allowing for easier integration and machining, while also using thermally conductive carrier substrates for improved thermal coupling and mechanical stability, and potentially removing the support material after encasing to maintain thermal performance.

Thermoelectric generator

PatentPendingUS20250133964A1

Innovation

- A thermoelectric generator design that includes a thermoelectric converter with a support body comprising a structural layer and a thermal insulation layer, and a thermal coupling structure that thermally couples the converter to a hot and a cold body, eliminating the need for membranes and simplifying the manufacturing process.

Thermal Cycling Reliability Assessment Methods

Thermal cycling reliability assessment for automotive thermoelectric generator (TEG) modules requires rigorous methodologies to ensure performance under extreme temperature fluctuations. Standard assessment protocols typically involve subjecting TEG modules to controlled temperature cycles that simulate real-world automotive conditions, ranging from -40°C to 150°C. These cycles must be executed at precisely controlled rates to accurately represent the thermal stresses experienced during vehicle operation.

The most widely adopted assessment method is the temperature shock test, where modules are rapidly transferred between extreme temperature environments. This approach effectively evaluates solder joint integrity and material interface stability under severe thermal gradients. Complementary to this is the thermal cycling chamber test, which implements more gradual temperature transitions to simulate normal driving conditions, with typical test durations ranging from 500 to 3000 cycles depending on automotive industry standards.

Accelerated life testing represents another critical assessment approach, wherein modules undergo intensified thermal cycling at elevated temperatures or with steeper temperature gradients. These tests employ mathematical models such as the Coffin-Manson relationship or the Arrhenius equation to extrapolate long-term reliability from accelerated test data. The acceleration factor calculation is crucial for translating accelerated test results to real-world performance expectations.

In-situ monitoring techniques have emerged as valuable assessment tools, allowing for real-time observation of electrical performance degradation during thermal cycling. Parameters such as internal resistance, open-circuit voltage, and power output are continuously measured to detect early signs of failure mechanisms. Advanced implementations incorporate acoustic emission sensors to detect microcrack formation before catastrophic failure occurs.

Finite element analysis (FEA) has become an indispensable component of thermal cycling reliability assessment, enabling simulation of thermomechanical stresses at critical interfaces. These computational models can predict failure modes and optimize design parameters before physical prototyping. When combined with experimental validation, FEA significantly reduces development cycles and improves reliability predictions.

Post-test analysis methodologies include cross-sectional microscopy, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDX) to characterize failure mechanisms at the microstructural level. These techniques reveal critical information about crack propagation patterns, intermetallic compound formation, and diffusion processes that contribute to performance degradation during thermal cycling.

Industry standards for automotive TEG modules typically require survival of at least 1000 thermal cycles with less than 10% degradation in power output to meet automotive-grade reliability requirements. The assessment results are commonly expressed using Weibull statistical analysis to determine failure probability distributions and mean time to failure metrics.

The most widely adopted assessment method is the temperature shock test, where modules are rapidly transferred between extreme temperature environments. This approach effectively evaluates solder joint integrity and material interface stability under severe thermal gradients. Complementary to this is the thermal cycling chamber test, which implements more gradual temperature transitions to simulate normal driving conditions, with typical test durations ranging from 500 to 3000 cycles depending on automotive industry standards.

Accelerated life testing represents another critical assessment approach, wherein modules undergo intensified thermal cycling at elevated temperatures or with steeper temperature gradients. These tests employ mathematical models such as the Coffin-Manson relationship or the Arrhenius equation to extrapolate long-term reliability from accelerated test data. The acceleration factor calculation is crucial for translating accelerated test results to real-world performance expectations.

In-situ monitoring techniques have emerged as valuable assessment tools, allowing for real-time observation of electrical performance degradation during thermal cycling. Parameters such as internal resistance, open-circuit voltage, and power output are continuously measured to detect early signs of failure mechanisms. Advanced implementations incorporate acoustic emission sensors to detect microcrack formation before catastrophic failure occurs.

Finite element analysis (FEA) has become an indispensable component of thermal cycling reliability assessment, enabling simulation of thermomechanical stresses at critical interfaces. These computational models can predict failure modes and optimize design parameters before physical prototyping. When combined with experimental validation, FEA significantly reduces development cycles and improves reliability predictions.

Post-test analysis methodologies include cross-sectional microscopy, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDX) to characterize failure mechanisms at the microstructural level. These techniques reveal critical information about crack propagation patterns, intermetallic compound formation, and diffusion processes that contribute to performance degradation during thermal cycling.

Industry standards for automotive TEG modules typically require survival of at least 1000 thermal cycles with less than 10% degradation in power output to meet automotive-grade reliability requirements. The assessment results are commonly expressed using Weibull statistical analysis to determine failure probability distributions and mean time to failure metrics.

Environmental and Regulatory Compliance Factors

Automotive thermoelectric generator (TEG) modules operate within a complex regulatory landscape that significantly impacts their design, manufacturing, and implementation. The Environmental Protection Agency (EPA) and National Highway Traffic Safety Administration (NHTSA) have established increasingly stringent emissions and fuel efficiency standards, which indirectly promote the adoption of waste heat recovery technologies like TEGs. These regulations create a favorable environment for TEG development while simultaneously imposing compliance requirements.

International standards such as ISO 16750 (Environmental conditions and testing for electrical and electronic equipment) and ISO 26262 (Functional safety for road vehicles) directly influence the mechanical robustness specifications for automotive TEG modules. These standards mandate specific vibration resistance levels and durability requirements that TEG systems must meet before vehicle integration. Additionally, the United Nations Economic Commission for Europe (UNECE) regulations on vehicle components provide further guidelines on mechanical integrity.

Material selection for TEG modules must comply with the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, limiting the use of certain hazardous materials. This regulatory framework has accelerated research into lead-free thermoelectric materials with comparable performance to traditional lead-telluride compounds, despite their typically lower efficiency.

Temperature extremes present another critical compliance challenge. Automotive TEG modules must maintain structural integrity and performance across temperature ranges from -40°C to over 600°C at the hot side. This requirement necessitates specialized material selection and connection technologies that can withstand thermal cycling while meeting environmental regulations. The SAE J2380 standard specifically addresses thermal cycling durability for automotive components.

Noise and vibration regulations further complicate TEG module design. As vehicles become quieter, particularly in hybrid and electric platforms where TEGs may find increasing application, any noise generated by TEG components due to vibration becomes more noticeable and must be addressed to meet vehicle noise regulations and customer expectations.

End-of-life considerations represent an emerging regulatory concern. The EU End-of-Life Vehicles Directive and similar regulations worldwide require automotive components to be designed for recyclability and proper disposal. This necessitates TEG designs that facilitate material recovery and minimize environmental impact, potentially influencing connection methods and material choices for vibration-resistant assemblies.

International standards such as ISO 16750 (Environmental conditions and testing for electrical and electronic equipment) and ISO 26262 (Functional safety for road vehicles) directly influence the mechanical robustness specifications for automotive TEG modules. These standards mandate specific vibration resistance levels and durability requirements that TEG systems must meet before vehicle integration. Additionally, the United Nations Economic Commission for Europe (UNECE) regulations on vehicle components provide further guidelines on mechanical integrity.

Material selection for TEG modules must comply with the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, limiting the use of certain hazardous materials. This regulatory framework has accelerated research into lead-free thermoelectric materials with comparable performance to traditional lead-telluride compounds, despite their typically lower efficiency.

Temperature extremes present another critical compliance challenge. Automotive TEG modules must maintain structural integrity and performance across temperature ranges from -40°C to over 600°C at the hot side. This requirement necessitates specialized material selection and connection technologies that can withstand thermal cycling while meeting environmental regulations. The SAE J2380 standard specifically addresses thermal cycling durability for automotive components.

Noise and vibration regulations further complicate TEG module design. As vehicles become quieter, particularly in hybrid and electric platforms where TEGs may find increasing application, any noise generated by TEG components due to vibration becomes more noticeable and must be addressed to meet vehicle noise regulations and customer expectations.

End-of-life considerations represent an emerging regulatory concern. The EU End-of-Life Vehicles Directive and similar regulations worldwide require automotive components to be designed for recyclability and proper disposal. This necessitates TEG designs that facilitate material recovery and minimize environmental impact, potentially influencing connection methods and material choices for vibration-resistant assemblies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!