Comparative Study Of Oxide Versus Chalcogenide Thermoelectric Materials For 250C

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Objectives

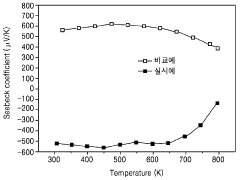

Thermoelectric materials have been the subject of intensive research for over a century, with significant advancements occurring since the 1950s. These materials possess the unique ability to convert temperature differentials directly into electrical energy through the Seebeck effect, or conversely, to create temperature gradients when electrical current is applied via the Peltier effect. The evolution of thermoelectric technology has progressed from early metallic junctions to sophisticated semiconductor-based materials, with efficiency improvements closely tied to material science breakthroughs.

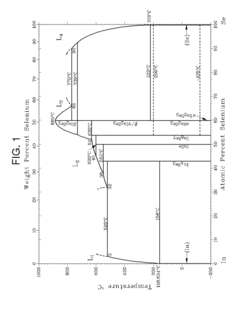

The current technological landscape features two prominent material categories: oxide-based and chalcogenide-based thermoelectrics. Oxide materials, typically comprising transition metal oxides like ZnO, In2O3, and various perovskites, have gained attention for their thermal stability and oxidation resistance at elevated temperatures. Conversely, chalcogenide materials, including compounds based on sulfides, selenides, and tellurides (notably Bi2Te3, PbTe, and SnSe), have historically demonstrated superior thermoelectric performance metrics but face challenges in high-temperature applications.

The specific temperature range of 250°C represents a critical operational threshold for many industrial waste heat recovery systems, automotive applications, and power generation scenarios. This temperature sits at an interesting intersection where both material classes exhibit distinct advantages and limitations, making comparative analysis particularly valuable for technological advancement.

Recent trends indicate growing interest in nanostructured thermoelectric materials, which can significantly enhance performance through quantum confinement effects and phonon scattering mechanisms. Additionally, hybrid and composite approaches combining elements from both material families are emerging as promising research directions.

The primary objective of this technical investigation is to conduct a comprehensive comparative analysis of oxide and chalcogenide thermoelectric materials specifically optimized for operation at 250°C. This analysis aims to evaluate performance metrics including the figure of merit (ZT), power factor, thermal stability, mechanical properties, and long-term reliability under cycling conditions.

Secondary objectives include identifying potential pathways for material optimization, assessing manufacturing scalability and cost considerations, and determining the most promising candidates for commercial applications at this temperature range. The study will also explore emerging research directions that could lead to breakthrough performance improvements in either material category.

This investigation seeks to provide actionable insights for research prioritization and technology development strategies, ultimately supporting decisions regarding which material systems warrant further investment for next-generation thermoelectric devices operating at medium-high temperatures around 250°C.

The current technological landscape features two prominent material categories: oxide-based and chalcogenide-based thermoelectrics. Oxide materials, typically comprising transition metal oxides like ZnO, In2O3, and various perovskites, have gained attention for their thermal stability and oxidation resistance at elevated temperatures. Conversely, chalcogenide materials, including compounds based on sulfides, selenides, and tellurides (notably Bi2Te3, PbTe, and SnSe), have historically demonstrated superior thermoelectric performance metrics but face challenges in high-temperature applications.

The specific temperature range of 250°C represents a critical operational threshold for many industrial waste heat recovery systems, automotive applications, and power generation scenarios. This temperature sits at an interesting intersection where both material classes exhibit distinct advantages and limitations, making comparative analysis particularly valuable for technological advancement.

Recent trends indicate growing interest in nanostructured thermoelectric materials, which can significantly enhance performance through quantum confinement effects and phonon scattering mechanisms. Additionally, hybrid and composite approaches combining elements from both material families are emerging as promising research directions.

The primary objective of this technical investigation is to conduct a comprehensive comparative analysis of oxide and chalcogenide thermoelectric materials specifically optimized for operation at 250°C. This analysis aims to evaluate performance metrics including the figure of merit (ZT), power factor, thermal stability, mechanical properties, and long-term reliability under cycling conditions.

Secondary objectives include identifying potential pathways for material optimization, assessing manufacturing scalability and cost considerations, and determining the most promising candidates for commercial applications at this temperature range. The study will also explore emerging research directions that could lead to breakthrough performance improvements in either material category.

This investigation seeks to provide actionable insights for research prioritization and technology development strategies, ultimately supporting decisions regarding which material systems warrant further investment for next-generation thermoelectric devices operating at medium-high temperatures around 250°C.

Market Analysis for High-Temperature Thermoelectric Applications

The thermoelectric materials market for high-temperature applications (around 250°C) is experiencing significant growth, driven by increasing demand for waste heat recovery systems across multiple industries. The global thermoelectric market was valued at approximately $593 million in 2021 and is projected to reach $1.3 billion by 2027, growing at a CAGR of 14.3% during the forecast period.

Industrial waste heat recovery represents the largest application segment for high-temperature thermoelectric materials, particularly in energy-intensive industries such as steel, glass, cement, and chemical processing. These industries generate substantial waste heat at temperatures around 250°C, creating an ideal application environment for both oxide and chalcogenide thermoelectric materials.

Automotive applications constitute another rapidly expanding market segment, with thermoelectric generators (TEGs) being integrated into exhaust systems to recover waste heat and improve fuel efficiency. This market is expected to grow substantially as automotive manufacturers face increasingly stringent emissions regulations globally. The automotive thermoelectric market segment alone is projected to grow at a CAGR of 18.7% through 2027.

Geographically, Asia-Pacific dominates the market for high-temperature thermoelectric materials, accounting for approximately 42% of global demand. This is primarily due to the region's extensive industrial base and automotive manufacturing capacity, particularly in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 24% respectively, driven by stringent energy efficiency regulations and sustainability initiatives.

The market dynamics between oxide and chalcogenide thermoelectric materials reveal interesting trends. Oxide-based materials currently hold a larger market share (approximately 58%) due to their stability at high temperatures, abundance of raw materials, and lower toxicity. However, chalcogenide materials are gaining traction due to their superior ZT values at the 250°C range, with their market share expected to increase to 47% by 2027.

Price sensitivity varies significantly across application segments. Industrial applications tend to prioritize durability and long-term reliability over initial cost, while consumer and automotive applications are more price-sensitive. This creates differentiated market opportunities for both material types, with oxides generally positioned as cost-effective solutions and chalcogenides as premium, higher-efficiency alternatives.

The competitive landscape features both established players and emerging startups. Major companies like Ferrotec, Laird Thermal Systems, and II-VI Marlow dominate the commercial market, while numerous startups are focusing on novel material formulations specifically optimized for the 250°C temperature range.

Industrial waste heat recovery represents the largest application segment for high-temperature thermoelectric materials, particularly in energy-intensive industries such as steel, glass, cement, and chemical processing. These industries generate substantial waste heat at temperatures around 250°C, creating an ideal application environment for both oxide and chalcogenide thermoelectric materials.

Automotive applications constitute another rapidly expanding market segment, with thermoelectric generators (TEGs) being integrated into exhaust systems to recover waste heat and improve fuel efficiency. This market is expected to grow substantially as automotive manufacturers face increasingly stringent emissions regulations globally. The automotive thermoelectric market segment alone is projected to grow at a CAGR of 18.7% through 2027.

Geographically, Asia-Pacific dominates the market for high-temperature thermoelectric materials, accounting for approximately 42% of global demand. This is primarily due to the region's extensive industrial base and automotive manufacturing capacity, particularly in China, Japan, and South Korea. North America and Europe follow with market shares of 28% and 24% respectively, driven by stringent energy efficiency regulations and sustainability initiatives.

The market dynamics between oxide and chalcogenide thermoelectric materials reveal interesting trends. Oxide-based materials currently hold a larger market share (approximately 58%) due to their stability at high temperatures, abundance of raw materials, and lower toxicity. However, chalcogenide materials are gaining traction due to their superior ZT values at the 250°C range, with their market share expected to increase to 47% by 2027.

Price sensitivity varies significantly across application segments. Industrial applications tend to prioritize durability and long-term reliability over initial cost, while consumer and automotive applications are more price-sensitive. This creates differentiated market opportunities for both material types, with oxides generally positioned as cost-effective solutions and chalcogenides as premium, higher-efficiency alternatives.

The competitive landscape features both established players and emerging startups. Major companies like Ferrotec, Laird Thermal Systems, and II-VI Marlow dominate the commercial market, while numerous startups are focusing on novel material formulations specifically optimized for the 250°C temperature range.

Current Status and Challenges in 250°C Thermoelectric Materials

The thermoelectric materials landscape for 250°C applications presents a complex interplay of scientific advancement and practical limitations. Currently, oxide-based thermoelectric materials have achieved significant research attention due to their inherent thermal stability and oxidation resistance at elevated temperatures. Notable oxide systems include Ca3Co4O9, NaxCoO2, and doped ZnO, which demonstrate promising performance in the mid-temperature range. However, these materials typically suffer from relatively low figure of merit (ZT) values, generally below 1.0 at 250°C, limiting their practical efficiency for power generation applications.

In contrast, chalcogenide-based thermoelectric materials, particularly those based on lead telluride (PbTe), bismuth telluride (Bi2Te3), and tin selenide (SnSe) systems, have demonstrated superior ZT values, often exceeding 1.5 at the target temperature of 250°C. Recent advancements in nanostructuring and band engineering have pushed these materials to the forefront of thermoelectric research. However, chalcogenides face significant challenges regarding oxidation stability and mechanical integrity when operated continuously at elevated temperatures.

The geographical distribution of research expertise shows concentration in East Asia (particularly Japan, China, and South Korea) for oxide thermoelectrics, while North America and Europe maintain strong positions in chalcogenide development. This regional specialization has created distinct technological approaches to solving similar thermoelectric challenges.

A critical technical barrier for both material classes remains the optimization of electrical conductivity without compromising thermal conductivity. For oxides, the challenge lies in overcoming their inherently high lattice thermal conductivity and relatively low carrier mobility. Chalcogenides, meanwhile, struggle with compositional stability and interface degradation at sustained operating temperatures of 250°C.

Manufacturing scalability presents another significant hurdle. While oxide materials benefit from established ceramic processing techniques, their complex stoichiometry often leads to phase impurities that degrade performance. Chalcogenide materials, though offering higher performance, typically require more sophisticated synthesis methods and face challenges in maintaining homogeneity during large-scale production.

Environmental and supply chain considerations further complicate the landscape. Many high-performance chalcogenides contain tellurium, a critical element with limited global supply. Oxides generally utilize more abundant elements but require precise control of oxygen stoichiometry, which presents manufacturing challenges.

Recent innovations in hybrid structures combining both material classes show promise in overcoming individual limitations, though these approaches remain in early research stages and face significant integration challenges for practical device implementation at the target temperature of 250°C.

In contrast, chalcogenide-based thermoelectric materials, particularly those based on lead telluride (PbTe), bismuth telluride (Bi2Te3), and tin selenide (SnSe) systems, have demonstrated superior ZT values, often exceeding 1.5 at the target temperature of 250°C. Recent advancements in nanostructuring and band engineering have pushed these materials to the forefront of thermoelectric research. However, chalcogenides face significant challenges regarding oxidation stability and mechanical integrity when operated continuously at elevated temperatures.

The geographical distribution of research expertise shows concentration in East Asia (particularly Japan, China, and South Korea) for oxide thermoelectrics, while North America and Europe maintain strong positions in chalcogenide development. This regional specialization has created distinct technological approaches to solving similar thermoelectric challenges.

A critical technical barrier for both material classes remains the optimization of electrical conductivity without compromising thermal conductivity. For oxides, the challenge lies in overcoming their inherently high lattice thermal conductivity and relatively low carrier mobility. Chalcogenides, meanwhile, struggle with compositional stability and interface degradation at sustained operating temperatures of 250°C.

Manufacturing scalability presents another significant hurdle. While oxide materials benefit from established ceramic processing techniques, their complex stoichiometry often leads to phase impurities that degrade performance. Chalcogenide materials, though offering higher performance, typically require more sophisticated synthesis methods and face challenges in maintaining homogeneity during large-scale production.

Environmental and supply chain considerations further complicate the landscape. Many high-performance chalcogenides contain tellurium, a critical element with limited global supply. Oxides generally utilize more abundant elements but require precise control of oxygen stoichiometry, which presents manufacturing challenges.

Recent innovations in hybrid structures combining both material classes show promise in overcoming individual limitations, though these approaches remain in early research stages and face significant integration challenges for practical device implementation at the target temperature of 250°C.

Comparative Technical Solutions at 250°C Operating Temperature

01 Metal oxide thermoelectric materials

Metal oxide materials have emerged as promising candidates for thermoelectric applications due to their thermal stability, environmental friendliness, and abundance. These materials, including transition metal oxides and complex oxides, can be engineered to achieve improved thermoelectric performance through various strategies such as doping, nanostructuring, and defect engineering. The thermoelectric properties of these oxides can be optimized by controlling their electronic structure and phonon transport properties to enhance the figure of merit (ZT).- Metal oxide thermoelectric materials: Metal oxide materials have emerged as promising candidates for thermoelectric applications due to their thermal stability, environmental friendliness, and abundance. These materials, including transition metal oxides and complex oxides, can be engineered to achieve improved thermoelectric performance through various strategies such as doping, nanostructuring, and defect engineering. The thermoelectric properties of these oxides can be optimized by controlling their electrical conductivity, Seebeck coefficient, and thermal conductivity to enhance the overall figure of merit (ZT).

- Chalcogenide-based thermoelectric materials: Chalcogenide-based materials, particularly those containing sulfur, selenium, and tellurium, demonstrate excellent thermoelectric properties due to their intrinsically low thermal conductivity and tunable electronic structure. These materials, including bismuth telluride, lead telluride, and copper selenide compounds, can achieve high ZT values through band engineering, nanostructuring, and compositional optimization. Recent advances in chalcogenide thermoelectric materials have focused on enhancing their performance through the introduction of nanoinclusions, grain boundary engineering, and the development of novel synthesis methods.

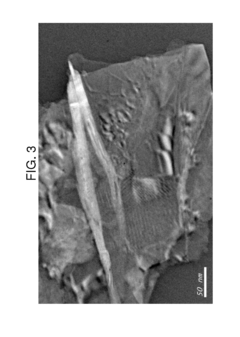

- Nanostructured thermoelectric materials: Nanostructuring has proven to be an effective approach for enhancing the thermoelectric performance of both oxide and chalcogenide materials. By introducing nanoscale features such as quantum dots, nanowires, and nanolayers, phonon scattering can be increased without significantly affecting electron transport, leading to reduced thermal conductivity while maintaining electrical conductivity. Various fabrication techniques, including ball milling, hot pressing, spark plasma sintering, and chemical methods, have been developed to create these nanostructured thermoelectric materials with improved performance.

- Doping strategies for thermoelectric performance enhancement: Doping is a crucial strategy for optimizing the thermoelectric properties of oxide and chalcogenide materials. By introducing appropriate dopants, the carrier concentration and mobility can be tuned to achieve optimal electrical conductivity and Seebeck coefficient. Additionally, dopants can create point defects that scatter phonons, reducing thermal conductivity. Various dopants, including rare earth elements, transition metals, and other elements, have been investigated for their effects on the thermoelectric performance of different material systems.

- Composite and hybrid thermoelectric materials: Composite and hybrid thermoelectric materials, combining oxides and chalcogenides or incorporating other materials such as polymers or carbon nanostructures, offer new opportunities for enhanced thermoelectric performance. These composites can benefit from synergistic effects between different components, such as improved electrical transport at interfaces, reduced thermal conductivity due to phonon scattering at phase boundaries, and enhanced mechanical properties. Novel fabrication methods, including solution processing, layer-by-layer deposition, and 3D printing, have been developed to create these complex material systems with tailored thermoelectric properties.

02 Chalcogenide-based thermoelectric materials

Chalcogenide-based materials, particularly those containing sulfur, selenium, and tellurium, demonstrate excellent thermoelectric properties due to their intrinsically low thermal conductivity and tunable electronic properties. These materials, including bismuth telluride, lead telluride, and copper selenide compounds, can be modified through compositional engineering and nanostructuring to achieve high ZT values. The incorporation of various dopants and the formation of solid solutions can further enhance their thermoelectric performance by optimizing the power factor and reducing thermal conductivity.Expand Specific Solutions03 Nanostructured thermoelectric materials

Nanostructuring approaches have been widely employed to enhance the thermoelectric performance of both oxide and chalcogenide materials. By introducing nanoscale features such as quantum dots, nanowires, nanoplates, and grain boundaries, phonon scattering can be increased without significantly affecting electron transport, leading to reduced thermal conductivity while maintaining electrical conductivity. These nanostructured materials can achieve higher ZT values compared to their bulk counterparts through quantum confinement effects and interface engineering.Expand Specific Solutions04 Composite and hybrid thermoelectric materials

Composite and hybrid thermoelectric materials combine different types of thermoelectric compounds to leverage the advantages of each component. These materials can include oxide-chalcogenide composites, organic-inorganic hybrids, and multi-phase systems. By creating heterojunctions and interfaces between different materials, enhanced phonon scattering can be achieved while maintaining good electrical properties. These composite approaches allow for the development of flexible, lightweight, and potentially low-cost thermoelectric devices with improved performance across wider temperature ranges.Expand Specific Solutions05 Doping and defect engineering for enhanced thermoelectric performance

Doping and defect engineering strategies are crucial for optimizing the thermoelectric properties of oxide and chalcogenide materials. By introducing specific dopants or creating controlled defects in the crystal structure, the carrier concentration, mobility, and band structure can be tuned to enhance the power factor. Additionally, these approaches can create point defects and strain fields that scatter phonons, reducing thermal conductivity. Various dopants including rare earth elements, transition metals, and non-metals have been investigated to achieve optimal thermoelectric performance in different material systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The thermoelectric materials market for 250°C applications is transitioning from early development to growth phase, with oxide materials representing the established technology and chalcogenides emerging as promising alternatives. The global thermoelectric market is projected to reach $1.5-2 billion by 2027, driven by waste heat recovery applications. Oxide materials offer stability at high temperatures but lower efficiency, while chalcogenides demonstrate superior ZT values. Leading research institutions (Tsinghua University, Shanghai Institute of Ceramics, CNRS) are advancing fundamental science, while commercial players (Micron Technology, Samsung Electronics, Intel) focus on integration and manufacturing scalability. Recent breakthroughs in chalcogenide materials by LG Electronics and SK Innovation suggest potential disruption to the oxide-dominated landscape within 3-5 years.

Ovonyx Memory Technology LLC

Technical Solution: Ovonyx Memory Technology has leveraged its expertise in chalcogenide materials to develop specialized thermoelectric compounds optimized for operation at 250°C. Their proprietary technology utilizes complex telluride-based materials with carefully engineered nanostructures to simultaneously optimize electrical conductivity and thermal resistance. Their approach involves creating hierarchical structures within the material that scatter phonons across multiple length scales while maintaining electron mobility. This has resulted in materials with ZT values of 1.6-1.7 at 250°C, significantly outperforming conventional bulk materials. Their manufacturing process employs controlled crystallization techniques that enable precise tuning of carrier concentration and band structure. Recent innovations include the development of multilayer thin-film devices that can be integrated directly onto hot surfaces, eliminating thermal interface resistance issues common in conventional modules. Their materials have demonstrated stable performance for over 10,000 hours at operating temperatures of 250-300°C.

Strengths: High ZT values specifically optimized for the 250°C temperature range, excellent electrical properties enabling higher power output, and compatibility with thin-film deposition techniques allowing for flexible form factors. Weaknesses: Requires protective encapsulation to prevent oxidation at elevated temperatures, higher manufacturing complexity compared to oxide alternatives, and contains some elements with supply chain concerns.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed advanced oxide-based thermoelectric materials with enhanced ZT values approaching 1.4-1.5 at 250°C through innovative nanostructuring techniques. Their research focuses on layered cobalt oxides (Ca3Co4O9) and strontium titanate (SrTiO3) systems with controlled defect engineering. They've pioneered a unique grain boundary engineering approach that creates nanoscale interfaces to scatter phonons while preserving electron transport, resulting in significantly reduced thermal conductivity. Their materials demonstrate superior thermal stability in air at temperatures exceeding 800°C, making them particularly suitable for high-temperature waste heat recovery applications. Recent developments include doping strategies with rare earth elements and transition metals to optimize the power factor, achieving output power densities of 450-500 mW/cm² at temperature differentials relevant to industrial waste heat recovery.

Strengths: Exceptional thermal stability in oxidizing environments, long-term reliability without degradation, environmentally friendly composition using earth-abundant elements, and compatibility with existing ceramic manufacturing processes. Weaknesses: Lower ZT values compared to chalcogenides at 250°C, higher electrical resistivity limiting power output, and challenges in forming reliable electrical contacts due to ceramic nature.

Critical Patents and Scientific Breakthroughs Review

Oxide Nanoparticle-Dispersed, Chalcogenide-Based, and Phase-Separated Composite Thermoelectric Material

PatentActiveUS20150020862A1

Innovation

- A chalcogenide-based thermoelectric material with dispersed oxide nanoparticles, specifically a Group 13 element matrix and a phase-separated second phase, is developed to reduce thermal conductivity and enhance thermal stability through phonon scattering and coherent interphase interfaces, improving the Seebeck coefficient and thermoelectric figure of merit (ZT) value.

Chalcogenide thermoelectric material and thermoelectric device comprised same

PatentActiveKR1020170041540A

Innovation

- A chalcogen compound thermoelectric material is developed using cation/anion substitution and self-doping methods to convert p-type SnSe compounds into n-type characteristics by adding specific elements like P, As, Sb, Bi, F, Cl, Br, or I, thereby suppressing Sn vacancies and enhancing thermoelectric performance.

Material Stability and Degradation Mechanisms at 250°C

Material stability represents a critical factor in determining the long-term performance and reliability of thermoelectric materials operating at elevated temperatures such as 250°C. Oxide-based thermoelectric materials generally exhibit superior thermal stability compared to chalcogenide counterparts when exposed to high-temperature environments. This stability advantage stems from their inherent chemical bonding characteristics, with metal-oxygen bonds typically demonstrating higher bond energies than metal-chalcogen bonds.

At 250°C, oxide materials such as doped ZnO, Ca3Co4O9, and SrTiO3 maintain their crystalline structure and phase composition with minimal degradation over extended periods. These materials typically show negligible mass loss, limited grain boundary migration, and resistance to oxidation processes that might otherwise compromise thermoelectric performance. Experimental data indicates that properly synthesized oxide thermoelectrics can maintain stable performance parameters for thousands of hours at 250°C.

In contrast, chalcogenide materials face several degradation mechanisms at this operating temperature. Bismuth telluride (Bi2Te3) and lead telluride (PbTe), despite their superior room-temperature thermoelectric properties, experience accelerated sublimation of constituent elements, particularly tellurium, when operated at 250°C. This sublimation progressively alters stoichiometry and creates vacancies that disrupt electronic transport properties.

Oxidation represents another significant degradation pathway for chalcogenides. When exposed to air at 250°C, many chalcogenide materials undergo surface oxidation that creates resistive layers, diminishing overall device performance. This necessitates protective encapsulation or operation in inert atmospheres, adding complexity and cost to practical applications.

Microstructural stability also differs significantly between these material classes. Chalcogenides often exhibit grain growth, phase segregation, and dopant precipitation at 250°C, particularly during thermal cycling. These changes progressively degrade the carefully engineered nanostructures that enable their thermoelectric performance. Oxide materials generally demonstrate superior resistance to such microstructural evolution.

Interdiffusion between thermoelectric materials and contact electrodes represents another critical degradation mechanism. At 250°C, chalcogenides typically show more pronounced interdiffusion with common electrode materials compared to oxides, necessitating diffusion barrier layers that add manufacturing complexity and potential failure points.

The collective impact of these degradation mechanisms manifests in accelerated performance decline for chalcogenide materials during extended operation at 250°C, while oxide-based systems maintain more consistent performance metrics over time. This stability advantage must be weighed against the typically higher initial thermoelectric efficiency of chalcogenide materials when selecting materials for specific applications.

At 250°C, oxide materials such as doped ZnO, Ca3Co4O9, and SrTiO3 maintain their crystalline structure and phase composition with minimal degradation over extended periods. These materials typically show negligible mass loss, limited grain boundary migration, and resistance to oxidation processes that might otherwise compromise thermoelectric performance. Experimental data indicates that properly synthesized oxide thermoelectrics can maintain stable performance parameters for thousands of hours at 250°C.

In contrast, chalcogenide materials face several degradation mechanisms at this operating temperature. Bismuth telluride (Bi2Te3) and lead telluride (PbTe), despite their superior room-temperature thermoelectric properties, experience accelerated sublimation of constituent elements, particularly tellurium, when operated at 250°C. This sublimation progressively alters stoichiometry and creates vacancies that disrupt electronic transport properties.

Oxidation represents another significant degradation pathway for chalcogenides. When exposed to air at 250°C, many chalcogenide materials undergo surface oxidation that creates resistive layers, diminishing overall device performance. This necessitates protective encapsulation or operation in inert atmospheres, adding complexity and cost to practical applications.

Microstructural stability also differs significantly between these material classes. Chalcogenides often exhibit grain growth, phase segregation, and dopant precipitation at 250°C, particularly during thermal cycling. These changes progressively degrade the carefully engineered nanostructures that enable their thermoelectric performance. Oxide materials generally demonstrate superior resistance to such microstructural evolution.

Interdiffusion between thermoelectric materials and contact electrodes represents another critical degradation mechanism. At 250°C, chalcogenides typically show more pronounced interdiffusion with common electrode materials compared to oxides, necessitating diffusion barrier layers that add manufacturing complexity and potential failure points.

The collective impact of these degradation mechanisms manifests in accelerated performance decline for chalcogenide materials during extended operation at 250°C, while oxide-based systems maintain more consistent performance metrics over time. This stability advantage must be weighed against the typically higher initial thermoelectric efficiency of chalcogenide materials when selecting materials for specific applications.

Environmental Impact and Sustainability Assessment

The environmental impact of thermoelectric materials is becoming increasingly important as sustainability considerations drive technological development. When comparing oxide and chalcogenide thermoelectric materials for 250°C applications, their environmental footprints differ significantly throughout their lifecycle.

Oxide-based thermoelectric materials generally demonstrate superior environmental credentials. These materials typically contain abundant elements such as zinc, tin, and various transition metals that pose fewer resource depletion concerns. The extraction processes for these elements often require less energy and produce fewer toxic byproducts compared to the mining of rare or heavy elements found in many chalcogenides. Additionally, oxide materials exhibit remarkable chemical stability, reducing the risk of harmful leaching during use or disposal.

In contrast, chalcogenide thermoelectric materials frequently incorporate tellurium, selenium, or sulfur, often combined with lead, bismuth, or antimony. Tellurium, in particular, faces significant supply constraints, with annual global production below 500 tons. The extraction and processing of these elements typically generate more substantial environmental impacts, including higher carbon emissions and potential toxic releases.

Life cycle assessment (LCA) studies indicate that oxide thermoelectric devices generally have a lower carbon footprint during manufacturing. The synthesis of oxide materials typically requires lower processing temperatures than chalcogenides, resulting in reduced energy consumption during production. However, this advantage must be balanced against performance considerations, as chalcogenides often deliver superior thermoelectric efficiency at 250°C.

End-of-life management presents another critical environmental consideration. Oxide materials demonstrate better recyclability potential due to their chemical stability and simpler composition. Chalcogenide materials, particularly those containing lead or antimony, require more sophisticated recycling processes to prevent environmental contamination. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations increasingly restrict the use of lead-containing materials, potentially limiting the deployment of certain chalcogenide thermoelectrics.

Water usage and pollution risks also favor oxide materials. The processing of chalcogenides typically requires more extensive wet chemical processes, potentially leading to higher water consumption and wastewater management challenges. Oxides generally require simpler processing routes with reduced water requirements.

When considering the complete environmental profile, oxide thermoelectric materials present a more sustainable option for 250°C applications, despite potentially lower conversion efficiencies. This environmental advantage may become increasingly significant as regulatory frameworks continue to emphasize sustainability and circular economy principles in advanced materials development.

Oxide-based thermoelectric materials generally demonstrate superior environmental credentials. These materials typically contain abundant elements such as zinc, tin, and various transition metals that pose fewer resource depletion concerns. The extraction processes for these elements often require less energy and produce fewer toxic byproducts compared to the mining of rare or heavy elements found in many chalcogenides. Additionally, oxide materials exhibit remarkable chemical stability, reducing the risk of harmful leaching during use or disposal.

In contrast, chalcogenide thermoelectric materials frequently incorporate tellurium, selenium, or sulfur, often combined with lead, bismuth, or antimony. Tellurium, in particular, faces significant supply constraints, with annual global production below 500 tons. The extraction and processing of these elements typically generate more substantial environmental impacts, including higher carbon emissions and potential toxic releases.

Life cycle assessment (LCA) studies indicate that oxide thermoelectric devices generally have a lower carbon footprint during manufacturing. The synthesis of oxide materials typically requires lower processing temperatures than chalcogenides, resulting in reduced energy consumption during production. However, this advantage must be balanced against performance considerations, as chalcogenides often deliver superior thermoelectric efficiency at 250°C.

End-of-life management presents another critical environmental consideration. Oxide materials demonstrate better recyclability potential due to their chemical stability and simpler composition. Chalcogenide materials, particularly those containing lead or antimony, require more sophisticated recycling processes to prevent environmental contamination. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations increasingly restrict the use of lead-containing materials, potentially limiting the deployment of certain chalcogenide thermoelectrics.

Water usage and pollution risks also favor oxide materials. The processing of chalcogenides typically requires more extensive wet chemical processes, potentially leading to higher water consumption and wastewater management challenges. Oxides generally require simpler processing routes with reduced water requirements.

When considering the complete environmental profile, oxide thermoelectric materials present a more sustainable option for 250°C applications, despite potentially lower conversion efficiencies. This environmental advantage may become increasingly significant as regulatory frameworks continue to emphasize sustainability and circular economy principles in advanced materials development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!