How To Validate Lab-Scale TEG Gains In Pilot Plant Deployments

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Technology Background and Validation Objectives

Thermoelectric generators (TEGs) represent a significant advancement in waste heat recovery technology, converting temperature differentials directly into electrical energy through the Seebeck effect. The development of TEGs dates back to the early 19th century, but recent advancements in material science and manufacturing techniques have dramatically improved their efficiency and applicability in industrial settings. The evolution of TEG technology has been marked by continuous improvements in conversion efficiency, durability, and cost-effectiveness, making them increasingly viable for commercial applications.

The current technological trajectory of TEGs is focused on enhancing energy conversion efficiency, which typically ranges from 5-8% in commercial applications. Laboratory research has demonstrated promising results with efficiencies approaching 15-20% under controlled conditions, primarily through the development of novel thermoelectric materials and optimized device architectures. These laboratory gains represent a significant potential for industrial energy recovery systems if successfully translated to real-world environments.

The primary validation objective for TEG technology is to verify that the performance improvements observed in laboratory settings can be replicated in pilot plant deployments. This includes confirming the scalability of efficiency gains, durability under variable operating conditions, and economic viability when integrated into existing industrial processes. Specific validation metrics include power output consistency, thermal cycling resilience, and long-term performance stability under actual industrial conditions.

Another critical validation goal is to establish standardized testing protocols that bridge the gap between laboratory measurements and industrial performance expectations. Current laboratory testing often occurs under idealized conditions that may not accurately reflect the thermal fluctuations, vibrations, and chemical exposures present in industrial environments. Developing robust validation methodologies will enable more accurate predictions of real-world performance and accelerate industrial adoption.

The technical objectives also extend to validating system integration approaches, as TEGs must function effectively within complex industrial systems. This includes optimizing heat exchanger designs, electrical power conditioning systems, and physical mounting solutions that can withstand industrial environments while maintaining optimal thermal interfaces. Successful validation must demonstrate not only the performance of the TEG modules themselves but also their functional integration within existing plant infrastructure.

Finally, validation efforts must address the economic objectives that will ultimately determine commercial viability. This includes verifying projected return on investment timelines, maintenance requirements, and operational impacts on existing processes. The validation process must establish clear correlations between laboratory performance metrics and actual energy recovery in industrial settings, providing stakeholders with reliable data for investment decisions.

The current technological trajectory of TEGs is focused on enhancing energy conversion efficiency, which typically ranges from 5-8% in commercial applications. Laboratory research has demonstrated promising results with efficiencies approaching 15-20% under controlled conditions, primarily through the development of novel thermoelectric materials and optimized device architectures. These laboratory gains represent a significant potential for industrial energy recovery systems if successfully translated to real-world environments.

The primary validation objective for TEG technology is to verify that the performance improvements observed in laboratory settings can be replicated in pilot plant deployments. This includes confirming the scalability of efficiency gains, durability under variable operating conditions, and economic viability when integrated into existing industrial processes. Specific validation metrics include power output consistency, thermal cycling resilience, and long-term performance stability under actual industrial conditions.

Another critical validation goal is to establish standardized testing protocols that bridge the gap between laboratory measurements and industrial performance expectations. Current laboratory testing often occurs under idealized conditions that may not accurately reflect the thermal fluctuations, vibrations, and chemical exposures present in industrial environments. Developing robust validation methodologies will enable more accurate predictions of real-world performance and accelerate industrial adoption.

The technical objectives also extend to validating system integration approaches, as TEGs must function effectively within complex industrial systems. This includes optimizing heat exchanger designs, electrical power conditioning systems, and physical mounting solutions that can withstand industrial environments while maintaining optimal thermal interfaces. Successful validation must demonstrate not only the performance of the TEG modules themselves but also their functional integration within existing plant infrastructure.

Finally, validation efforts must address the economic objectives that will ultimately determine commercial viability. This includes verifying projected return on investment timelines, maintenance requirements, and operational impacts on existing processes. The validation process must establish clear correlations between laboratory performance metrics and actual energy recovery in industrial settings, providing stakeholders with reliable data for investment decisions.

Market Analysis for Industrial Waste Heat Recovery

The industrial waste heat recovery market is experiencing significant growth, driven by increasing energy costs and environmental regulations. Currently valued at approximately $53.8 billion globally, this market is projected to reach $114.7 billion by 2030, growing at a CAGR of 8.5%. The thermoelectric generator (TEG) segment specifically is expanding at an even faster rate of 11.2% annually, as industries seek cost-effective solutions for energy efficiency improvements.

Manufacturing sectors including steel, glass, cement, and chemical processing represent the largest potential market for TEG technology, collectively generating over 20-30% of their input energy as waste heat. In the steel industry alone, waste heat recovery potential is estimated at 1.2 quadrillion BTUs annually in the United States. The cement industry globally dissipates approximately 40% of its thermal energy input, representing a $10.2 billion opportunity for recovery technologies.

Regional analysis shows Europe leading adoption with 34% market share, driven by stringent efficiency regulations and carbon pricing mechanisms. North America follows at 28%, with Asia-Pacific representing the fastest-growing region at 12.3% annual growth, particularly in China and India where rapid industrialization coincides with new environmental policies.

Customer segmentation reveals three primary market tiers: large enterprises with waste heat exceeding 500°C (representing 42% of the market), mid-sized operations with medium-grade waste heat between 200-500°C (35%), and smaller facilities with low-grade waste heat below 200°C (23%). TEG solutions are particularly valuable in the medium and low-grade segments where traditional recovery methods prove less economical.

Market barriers include high initial capital costs, with industrial-scale TEG systems requiring $2,000-4,500 per kW of capacity installed. The average payback period currently stands at 3-5 years, though this varies significantly based on energy prices and utilization rates. Technical barriers include conversion efficiency limitations, with commercial TEGs typically achieving 5-8% efficiency, though laboratory prototypes have demonstrated up to 12-15% under optimal conditions.

Competitive analysis indicates traditional waste heat recovery technologies (ORC systems, heat exchangers) still dominate with 78% market share, while TEG solutions currently represent only 7% but are growing rapidly. This presents significant opportunity for TEG technologies that can demonstrate reliable performance scaling from laboratory to industrial environments.

Manufacturing sectors including steel, glass, cement, and chemical processing represent the largest potential market for TEG technology, collectively generating over 20-30% of their input energy as waste heat. In the steel industry alone, waste heat recovery potential is estimated at 1.2 quadrillion BTUs annually in the United States. The cement industry globally dissipates approximately 40% of its thermal energy input, representing a $10.2 billion opportunity for recovery technologies.

Regional analysis shows Europe leading adoption with 34% market share, driven by stringent efficiency regulations and carbon pricing mechanisms. North America follows at 28%, with Asia-Pacific representing the fastest-growing region at 12.3% annual growth, particularly in China and India where rapid industrialization coincides with new environmental policies.

Customer segmentation reveals three primary market tiers: large enterprises with waste heat exceeding 500°C (representing 42% of the market), mid-sized operations with medium-grade waste heat between 200-500°C (35%), and smaller facilities with low-grade waste heat below 200°C (23%). TEG solutions are particularly valuable in the medium and low-grade segments where traditional recovery methods prove less economical.

Market barriers include high initial capital costs, with industrial-scale TEG systems requiring $2,000-4,500 per kW of capacity installed. The average payback period currently stands at 3-5 years, though this varies significantly based on energy prices and utilization rates. Technical barriers include conversion efficiency limitations, with commercial TEGs typically achieving 5-8% efficiency, though laboratory prototypes have demonstrated up to 12-15% under optimal conditions.

Competitive analysis indicates traditional waste heat recovery technologies (ORC systems, heat exchangers) still dominate with 78% market share, while TEG solutions currently represent only 7% but are growing rapidly. This presents significant opportunity for TEG technologies that can demonstrate reliable performance scaling from laboratory to industrial environments.

Current TEG Validation Challenges and Limitations

The validation of lab-scale Thermoelectric Generator (TEG) performance in pilot plant environments presents significant challenges that impede the seamless transition from laboratory success to industrial implementation. One primary limitation is the substantial scale disparity between controlled laboratory conditions and real-world industrial settings. Laboratory TEGs typically operate with small temperature differentials and controlled heat sources, whereas pilot plants involve complex thermal profiles, fluctuating temperatures, and diverse heat sources that can dramatically alter performance metrics.

Measurement accuracy represents another critical challenge. Laboratory instrumentation provides precise data collection under ideal conditions, but pilot plant environments introduce electrical noise, thermal interference, and operational vibrations that compromise measurement integrity. This discrepancy often leads to overestimated efficiency projections that fail to materialize in actual deployments.

Environmental factors further complicate validation efforts. Pilot plants expose TEGs to humidity variations, dust accumulation, and chemical contaminants absent in laboratory settings. These factors accelerate material degradation and connection corrosion, significantly reducing operational lifespans and conversion efficiencies. Current validation methodologies inadequately account for these environmental stressors, creating unrealistic performance expectations.

Time-scale limitations also present substantial obstacles. Laboratory tests typically run for hours or days, while industrial applications require continuous operation for months or years. This temporal disconnect means that critical long-term performance factors—such as material degradation, thermal cycling fatigue, and connection stability—remain largely unexamined during laboratory validation, leading to premature system failures in pilot implementations.

Standardization deficiencies compound these challenges. The TEG industry lacks universally accepted testing protocols and performance metrics that bridge laboratory and industrial applications. This absence of standardization makes cross-comparison between different TEG technologies problematic and hinders meaningful validation of performance claims across varied deployment scenarios.

Economic validation frameworks remain similarly underdeveloped. Laboratory assessments typically focus on technical performance metrics like conversion efficiency and power density, while neglecting crucial industrial considerations such as installation costs, maintenance requirements, and system integration expenses. This disconnect creates unrealistic economic projections that fail to materialize in actual industrial implementations.

Integration challenges with existing industrial systems represent another significant limitation. Laboratory TEGs operate as standalone units, while pilot deployments must interface with complex industrial processes, control systems, and power management infrastructure. Current validation approaches inadequately address these integration requirements, leading to unexpected compatibility issues and suboptimal performance in real-world applications.

Measurement accuracy represents another critical challenge. Laboratory instrumentation provides precise data collection under ideal conditions, but pilot plant environments introduce electrical noise, thermal interference, and operational vibrations that compromise measurement integrity. This discrepancy often leads to overestimated efficiency projections that fail to materialize in actual deployments.

Environmental factors further complicate validation efforts. Pilot plants expose TEGs to humidity variations, dust accumulation, and chemical contaminants absent in laboratory settings. These factors accelerate material degradation and connection corrosion, significantly reducing operational lifespans and conversion efficiencies. Current validation methodologies inadequately account for these environmental stressors, creating unrealistic performance expectations.

Time-scale limitations also present substantial obstacles. Laboratory tests typically run for hours or days, while industrial applications require continuous operation for months or years. This temporal disconnect means that critical long-term performance factors—such as material degradation, thermal cycling fatigue, and connection stability—remain largely unexamined during laboratory validation, leading to premature system failures in pilot implementations.

Standardization deficiencies compound these challenges. The TEG industry lacks universally accepted testing protocols and performance metrics that bridge laboratory and industrial applications. This absence of standardization makes cross-comparison between different TEG technologies problematic and hinders meaningful validation of performance claims across varied deployment scenarios.

Economic validation frameworks remain similarly underdeveloped. Laboratory assessments typically focus on technical performance metrics like conversion efficiency and power density, while neglecting crucial industrial considerations such as installation costs, maintenance requirements, and system integration expenses. This disconnect creates unrealistic economic projections that fail to materialize in actual industrial implementations.

Integration challenges with existing industrial systems represent another significant limitation. Laboratory TEGs operate as standalone units, while pilot deployments must interface with complex industrial processes, control systems, and power management infrastructure. Current validation approaches inadequately address these integration requirements, leading to unexpected compatibility issues and suboptimal performance in real-world applications.

Scale-up Methodologies for TEG Implementation

01 Efficiency measurement and validation methods for TEGs

Various methods and systems are used to validate the efficiency gains of thermoelectric generators. These include specialized testing apparatus that can measure electrical output under controlled temperature differentials, performance validation under different operating conditions, and comparative analysis against theoretical models. These validation techniques help quantify the actual power generation capabilities and conversion efficiency of TEG systems in real-world applications.- TEG efficiency validation methods: Various methods and systems for validating the efficiency and performance gains of thermoelectric generators. These include specialized testing apparatus, measurement protocols, and comparative analysis techniques that can accurately determine the conversion efficiency of thermal energy to electrical energy. The validation methods often involve controlled temperature differentials and precise measurement of electrical output to calculate efficiency gains under different operating conditions.

- TEG material optimization for performance gains: Innovations in thermoelectric materials that enhance the efficiency and power output of TEGs. These include novel semiconductor compositions, nanostructured materials, and composite materials with improved Seebeck coefficients and reduced thermal conductivity. Material optimization focuses on increasing the figure of merit (ZT) of thermoelectric materials, which directly correlates with the efficiency of thermal to electrical energy conversion.

- TEG system integration and waste heat recovery: Integration of thermoelectric generators into various systems for effective waste heat recovery and energy harvesting. These implementations include automotive exhaust systems, industrial processes, and consumer appliances where significant heat is typically wasted. The designs focus on maximizing thermal contact, optimizing heat flow paths, and ensuring durability under thermal cycling conditions to validate real-world performance gains.

- TEG performance monitoring and control systems: Advanced monitoring and control systems designed to validate and optimize TEG performance in real-time. These systems include sensors for temperature, voltage, and current measurements, along with data acquisition and analysis tools. The control mechanisms can adjust operating parameters to maximize power output under varying conditions, providing continuous validation of performance gains and system efficiency.

- Novel TEG configurations and structural designs: Innovative structural designs and configurations of thermoelectric generators that enhance performance and efficiency. These include segmented TEGs, cascaded systems, and geometrically optimized structures that improve thermal management and electrical output. The novel configurations address issues such as thermal stress, contact resistance, and heat flow distribution to validate increased power generation capabilities.

02 TEG integration with waste heat recovery systems

Thermoelectric generators can be integrated with various waste heat recovery systems to validate energy gains. These implementations capture thermal energy from industrial processes, vehicle exhaust systems, or other heat-generating operations that would otherwise be lost. The validation of these integrated systems demonstrates how TEGs can convert waste heat into usable electricity, improving overall energy efficiency and reducing environmental impact.Expand Specific Solutions03 Material innovations for enhanced TEG performance

Advanced materials are being developed to enhance the performance of thermoelectric generators. These include novel semiconductor compounds, nanostructured materials, and composite structures that demonstrate improved Seebeck coefficients and reduced thermal conductivity. Validation studies confirm that these material innovations can significantly increase the power output and conversion efficiency of TEGs, making them more viable for commercial applications.Expand Specific Solutions04 TEG performance monitoring and control systems

Sophisticated monitoring and control systems are essential for validating the performance gains of thermoelectric generators in real-time. These systems include sensors for temperature measurement, power output tracking, and efficiency calculation. Advanced control algorithms can optimize operating conditions to maximize energy harvesting. The validation data collected through these systems provides valuable insights for further improvements in TEG design and implementation.Expand Specific Solutions05 Application-specific TEG validation frameworks

Different applications require specialized validation frameworks to accurately assess thermoelectric generator performance. These frameworks consider the unique operating conditions of automotive, industrial, wearable, or space applications. They include standardized testing protocols, simulation models, and field testing methodologies tailored to specific use cases. These validation approaches help determine the practical viability and economic benefits of implementing TEG technology in various sectors.Expand Specific Solutions

Leading TEG Manufacturers and Research Institutions

The thermoelectric generator (TEG) market is currently in a growth phase, with increasing interest in waste heat recovery applications across industrial sectors. Market size is projected to expand significantly as energy efficiency concerns drive adoption, though commercial-scale implementation remains limited. Technologically, TEGs are in a transitional stage between laboratory validation and industrial deployment, with varying maturity levels among key players. Research institutions like Georgia Tech, Technical University of Denmark, and California Institute of Technology are advancing fundamental science, while companies including Huawei, Boeing, and Sumitomo Chemical are developing application-specific solutions. IMEC and Applied Thermoelectric Solutions represent specialized players focused on bridging the lab-to-pilot gap. The primary challenge remains demonstrating that efficiency gains observed in controlled laboratory environments can be consistently reproduced in real-world industrial settings with fluctuating conditions.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech Research Corporation has pioneered an advanced validation framework for thermoelectric generators that systematically addresses the scaling challenges between laboratory and industrial implementations. Their methodology incorporates multi-physics modeling coupled with experimental validation across different scales. At the laboratory level, they utilize precision characterization equipment to measure Seebeck coefficients, electrical conductivity, and thermal conductivity of thermoelectric materials under controlled conditions. For pilot validation, they've developed modular test platforms that can be deployed in industrial environments while maintaining comprehensive data collection capabilities. Their approach includes real-time monitoring systems that track performance parameters including temperature distribution, power output stability, and conversion efficiency under dynamic operating conditions[2]. A distinguishing feature is their statistical validation protocol that quantifies uncertainty propagation from material properties to system-level performance, enabling more reliable predictions when scaling up. Georgia Tech has also developed specialized thermal interface materials and connection techniques that help preserve the performance advantages observed in laboratory settings when transitioning to larger industrial implementations.

Strengths: Robust scientific approach combining theoretical modeling with experimental validation, providing high confidence in scaling predictions. Their methodology includes uncertainty quantification that helps identify critical parameters affecting performance at scale. Weaknesses: The comprehensive approach requires significant technical expertise and specialized equipment that may not be readily available to all organizations. The validation process can be time-intensive, potentially slowing deployment timelines.

The Regents of the University of California

Technical Solution: The University of California has developed a sophisticated validation methodology for thermoelectric generators that addresses the critical gap between laboratory performance and real-world implementation. Their approach combines experimental testing with advanced computational modeling to predict TEG performance across different scales. At the laboratory level, they employ high-precision thermal and electrical characterization techniques to establish baseline performance metrics for thermoelectric materials and module configurations. Their validation protocol includes custom-designed test chambers that can simulate various industrial thermal environments while precisely controlling boundary conditions. For pilot deployments, they've developed a modular instrumentation package that can be integrated with industrial processes to collect operational data under actual working conditions. The UC system has pioneered techniques for in-situ performance monitoring that accounts for thermal cycling effects, degradation mechanisms, and system integration factors that typically impact scaled implementations[3]. Their methodology incorporates machine learning algorithms that analyze performance data across different scales to identify key parameters affecting efficiency and output when transitioning from laboratory to industrial settings. Additionally, they've developed standardized metrics for comparing laboratory and field performance that account for variations in operating conditions.

Strengths: Comprehensive approach that combines fundamental materials science with systems engineering to address scaling challenges. Their methodology includes advanced data analytics that can identify non-obvious factors affecting performance at scale. Weaknesses: The sophisticated modeling and instrumentation requirements may present barriers to implementation for organizations without advanced technical capabilities. The approach may require customization for specific industrial applications and heat source characteristics.

Critical Performance Metrics and Testing Protocols

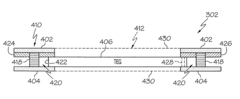

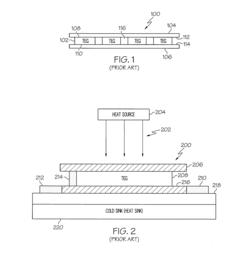

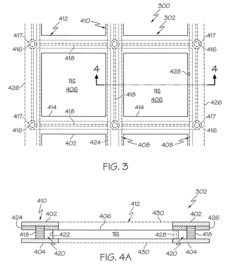

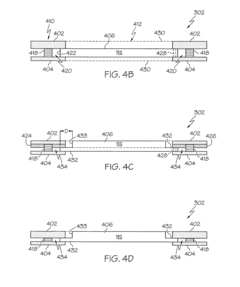

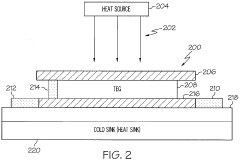

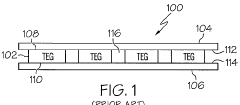

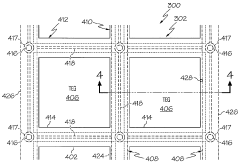

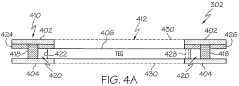

Thermoelectric generator assembly and system

PatentActiveUS20110108080A1

Innovation

- A thermoelectric generator assembly with a frame that includes a first and second frame member to retain TEG devices, a spacer for thermal expansion relief, and a power bus for electrical energy transmission, allowing for direct contact with heat sources and sinks without air gaps, and featuring a ledge on the TEG device for improved thermal contact and reduced thermal resistance.

Thermoelectric generator assembly and system

PatentWO2011056333A1

Innovation

- A thermoelectric generator assembly with a frame that includes a first and second frame member to retain TEG devices, a spacer for thermal expansion relief, and a power bus for efficient energy transfer, along with a ledge on the TEG device for direct contact and reduced thermal resistance, allowing for expansion and contraction without separate stress buffer layers.

Economic Feasibility and ROI Assessment Framework

Evaluating the economic viability of transitioning from lab-scale Thermoelectric Generator (TEG) systems to pilot plant deployments requires a comprehensive assessment framework that accounts for both direct costs and potential returns. This framework must consider the capital expenditure for scaling up TEG technology, including materials, manufacturing, installation, and integration costs within existing industrial processes.

The ROI assessment should incorporate multiple time horizons, typically analyzing short-term (1-2 years), medium-term (3-5 years), and long-term (5+ years) returns. For TEG implementations, the primary economic benefits derive from waste heat recovery and subsequent energy cost reductions, which must be quantified based on the specific thermal characteristics of the target industrial environment.

A sensitivity analysis forms a critical component of the economic feasibility study, examining how variations in key parameters—such as energy prices, TEG efficiency improvements, maintenance costs, and system degradation rates—impact the overall financial performance. This analysis helps identify economic thresholds where TEG implementation becomes financially viable across different industrial settings.

Payback period calculations should be standardized to enable comparison between different TEG configurations and deployment scenarios. For most industrial applications, a payback period of 2-4 years typically represents an attractive investment threshold, though this varies by industry and region based on energy costs and regulatory environments.

Non-monetary benefits must also be incorporated into the assessment framework, including regulatory compliance advantages, carbon emission reductions, and potential carbon credit opportunities. These factors increasingly influence investment decisions as environmental regulations tighten globally and organizations pursue sustainability targets.

Risk assessment methodologies should evaluate potential economic downsides, including technology obsolescence risk, maintenance cost uncertainties, and performance degradation scenarios. These risks should be quantified where possible and incorporated into Monte Carlo simulations to provide probability distributions of economic outcomes rather than single-point estimates.

Funding and financing options should be evaluated as part of the framework, including potential government incentives, green energy subsidies, and specialized financing mechanisms for energy efficiency projects. The availability of these options can significantly impact the economic feasibility of pilot deployments by reducing initial capital requirements and improving cash flow profiles.

The ROI assessment should incorporate multiple time horizons, typically analyzing short-term (1-2 years), medium-term (3-5 years), and long-term (5+ years) returns. For TEG implementations, the primary economic benefits derive from waste heat recovery and subsequent energy cost reductions, which must be quantified based on the specific thermal characteristics of the target industrial environment.

A sensitivity analysis forms a critical component of the economic feasibility study, examining how variations in key parameters—such as energy prices, TEG efficiency improvements, maintenance costs, and system degradation rates—impact the overall financial performance. This analysis helps identify economic thresholds where TEG implementation becomes financially viable across different industrial settings.

Payback period calculations should be standardized to enable comparison between different TEG configurations and deployment scenarios. For most industrial applications, a payback period of 2-4 years typically represents an attractive investment threshold, though this varies by industry and region based on energy costs and regulatory environments.

Non-monetary benefits must also be incorporated into the assessment framework, including regulatory compliance advantages, carbon emission reductions, and potential carbon credit opportunities. These factors increasingly influence investment decisions as environmental regulations tighten globally and organizations pursue sustainability targets.

Risk assessment methodologies should evaluate potential economic downsides, including technology obsolescence risk, maintenance cost uncertainties, and performance degradation scenarios. These risks should be quantified where possible and incorporated into Monte Carlo simulations to provide probability distributions of economic outcomes rather than single-point estimates.

Funding and financing options should be evaluated as part of the framework, including potential government incentives, green energy subsidies, and specialized financing mechanisms for energy efficiency projects. The availability of these options can significantly impact the economic feasibility of pilot deployments by reducing initial capital requirements and improving cash flow profiles.

Environmental Impact and Sustainability Benefits

Thermoelectric Generators (TEGs) represent a significant opportunity for sustainable energy recovery, particularly in industrial settings where waste heat is abundant. The environmental impact of implementing TEG technology in pilot plant deployments extends far beyond simple energy generation metrics, encompassing broader sustainability benefits that align with global climate goals and corporate environmental responsibilities.

The primary environmental benefit of TEG implementation lies in its ability to capture waste heat that would otherwise be released into the atmosphere. This waste heat recovery directly reduces the carbon footprint of industrial operations by decreasing the need for additional energy generation from fossil fuel sources. Quantitative assessments from lab-scale TEG implementations suggest that industrial-scale deployments could potentially reduce carbon emissions by 5-15% in energy-intensive industries such as steel manufacturing, glass production, and chemical processing.

Water conservation represents another critical environmental advantage of TEG technology. Unlike traditional power generation methods that often require significant water resources for cooling, TEGs operate without water consumption. This characteristic becomes increasingly valuable in regions facing water scarcity challenges, where industrial operations must balance production needs with environmental stewardship.

The lifecycle assessment of TEG systems reveals favorable sustainability metrics compared to alternative energy recovery technologies. The materials used in modern TEG construction, while including some rare earth elements, generally have lower environmental impact than comparable energy technologies when measured across full lifecycle analyses. Additionally, the long operational lifespan of properly maintained TEG systems—typically 15-20 years—enhances their sustainability profile through reduced replacement and maintenance requirements.

Regulatory compliance and environmental certification benefits also accompany successful TEG implementations. As global environmental regulations become increasingly stringent, particularly regarding emissions and energy efficiency, TEG technology offers industrial operations a pathway to meet or exceed compliance requirements. Several case studies from early adopters demonstrate that TEG deployments have contributed significantly to achieving ISO 14001 environmental management certification and similar standards.

The scalability of TEG technology further enhances its environmental value proposition. Modular TEG systems can be incrementally deployed as validation confirms their effectiveness, allowing for optimized environmental returns on investment. This scalability enables organizations to prioritize implementations in areas with the highest potential environmental impact, maximizing sustainability benefits while managing financial constraints.

The primary environmental benefit of TEG implementation lies in its ability to capture waste heat that would otherwise be released into the atmosphere. This waste heat recovery directly reduces the carbon footprint of industrial operations by decreasing the need for additional energy generation from fossil fuel sources. Quantitative assessments from lab-scale TEG implementations suggest that industrial-scale deployments could potentially reduce carbon emissions by 5-15% in energy-intensive industries such as steel manufacturing, glass production, and chemical processing.

Water conservation represents another critical environmental advantage of TEG technology. Unlike traditional power generation methods that often require significant water resources for cooling, TEGs operate without water consumption. This characteristic becomes increasingly valuable in regions facing water scarcity challenges, where industrial operations must balance production needs with environmental stewardship.

The lifecycle assessment of TEG systems reveals favorable sustainability metrics compared to alternative energy recovery technologies. The materials used in modern TEG construction, while including some rare earth elements, generally have lower environmental impact than comparable energy technologies when measured across full lifecycle analyses. Additionally, the long operational lifespan of properly maintained TEG systems—typically 15-20 years—enhances their sustainability profile through reduced replacement and maintenance requirements.

Regulatory compliance and environmental certification benefits also accompany successful TEG implementations. As global environmental regulations become increasingly stringent, particularly regarding emissions and energy efficiency, TEG technology offers industrial operations a pathway to meet or exceed compliance requirements. Several case studies from early adopters demonstrate that TEG deployments have contributed significantly to achieving ISO 14001 environmental management certification and similar standards.

The scalability of TEG technology further enhances its environmental value proposition. Modular TEG systems can be incrementally deployed as validation confirms their effectiveness, allowing for optimized environmental returns on investment. This scalability enables organizations to prioritize implementations in areas with the highest potential environmental impact, maximizing sustainability benefits while managing financial constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!