Heat Sink And Heat Exchanger Design For Maximizing TEG Output Power

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Power Generation Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for converting waste heat directly into electrical energy through the Seebeck effect. The history of thermoelectric materials dates back to the early 19th century when Thomas Johann Seebeck first discovered the phenomenon in 1821. However, significant technological advancements in this field have only materialized in recent decades, driven by growing concerns about energy efficiency and environmental sustainability.

The evolution of TEG technology has been marked by continuous improvements in material science, particularly in developing materials with higher figure of merit (ZT), which directly correlates with conversion efficiency. Traditional bismuth telluride (Bi2Te3) based TEGs have been the industry standard for low to medium temperature applications, while newer materials such as skutterudites, half-Heusler alloys, and silicon-germanium alloys are expanding the temperature range and efficiency of thermoelectric conversion.

Current global energy consumption patterns reveal that approximately 60% of primary energy is wasted as heat during various industrial processes, transportation, and power generation. This represents an enormous untapped resource that TEGs could potentially harness. The ability to convert even a small fraction of this waste heat into usable electricity presents a significant opportunity for energy conservation and reduction of greenhouse gas emissions.

The primary technical objective in TEG development is to maximize power output through optimized heat sink and heat exchanger designs. This involves creating thermal management systems that can efficiently capture heat from the source, maintain a substantial temperature gradient across the TEG modules, and effectively dissipate heat from the cold side. The challenge lies in balancing thermal resistance, material constraints, size limitations, and cost considerations.

Specific goals include developing heat sink designs that minimize thermal resistance while maintaining structural integrity, creating heat exchangers capable of operating efficiently across varying temperature ranges and environmental conditions, and integrating these components into compact, reliable systems suitable for diverse applications ranging from automotive exhaust systems to industrial processes.

Additionally, there is a growing focus on addressing the inherent limitations of current TEG systems, such as relatively low conversion efficiency (typically 5-8% for commercial systems) and high material costs. Research aims to develop cost-effective thermal management solutions that can enhance overall system performance without significantly increasing complexity or manufacturing expenses.

The ultimate objective is to establish TEGs as a viable, mainstream technology for waste heat recovery across multiple sectors, contributing to global energy efficiency goals and supporting the transition toward more sustainable energy systems. This requires not only technical innovations in heat sink and heat exchanger design but also considerations of scalability, reliability, and economic feasibility.

The evolution of TEG technology has been marked by continuous improvements in material science, particularly in developing materials with higher figure of merit (ZT), which directly correlates with conversion efficiency. Traditional bismuth telluride (Bi2Te3) based TEGs have been the industry standard for low to medium temperature applications, while newer materials such as skutterudites, half-Heusler alloys, and silicon-germanium alloys are expanding the temperature range and efficiency of thermoelectric conversion.

Current global energy consumption patterns reveal that approximately 60% of primary energy is wasted as heat during various industrial processes, transportation, and power generation. This represents an enormous untapped resource that TEGs could potentially harness. The ability to convert even a small fraction of this waste heat into usable electricity presents a significant opportunity for energy conservation and reduction of greenhouse gas emissions.

The primary technical objective in TEG development is to maximize power output through optimized heat sink and heat exchanger designs. This involves creating thermal management systems that can efficiently capture heat from the source, maintain a substantial temperature gradient across the TEG modules, and effectively dissipate heat from the cold side. The challenge lies in balancing thermal resistance, material constraints, size limitations, and cost considerations.

Specific goals include developing heat sink designs that minimize thermal resistance while maintaining structural integrity, creating heat exchangers capable of operating efficiently across varying temperature ranges and environmental conditions, and integrating these components into compact, reliable systems suitable for diverse applications ranging from automotive exhaust systems to industrial processes.

Additionally, there is a growing focus on addressing the inherent limitations of current TEG systems, such as relatively low conversion efficiency (typically 5-8% for commercial systems) and high material costs. Research aims to develop cost-effective thermal management solutions that can enhance overall system performance without significantly increasing complexity or manufacturing expenses.

The ultimate objective is to establish TEGs as a viable, mainstream technology for waste heat recovery across multiple sectors, contributing to global energy efficiency goals and supporting the transition toward more sustainable energy systems. This requires not only technical innovations in heat sink and heat exchanger design but also considerations of scalability, reliability, and economic feasibility.

Market Analysis for TEG Applications

The global market for Thermoelectric Generator (TEG) applications has been experiencing steady growth, driven primarily by increasing demand for waste heat recovery systems and energy harvesting solutions. The TEG market was valued at approximately $460 million in 2020 and is projected to reach $741 million by 2025, growing at a CAGR of 10.0% during the forecast period. This growth trajectory is supported by rising energy costs, stringent environmental regulations, and the push for greater energy efficiency across industries.

Industrial waste heat recovery represents the largest application segment for TEGs, accounting for nearly 38% of the total market share. Manufacturing facilities, power plants, and chemical processing industries are increasingly adopting TEG systems to convert waste heat into usable electricity, thereby improving overall energy efficiency and reducing operational costs. The automotive sector follows closely, with approximately 25% market share, where TEGs are being integrated into vehicle exhaust systems to harvest waste heat and reduce fuel consumption.

Consumer electronics and wearable technology constitute an emerging market segment with significant growth potential. The miniaturization of TEG devices has enabled their integration into various portable electronic devices, providing extended battery life through body heat or ambient temperature differentials. This segment is expected to grow at the highest CAGR of 12.5% through 2025.

Geographically, North America and Europe currently dominate the TEG market, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate due to rapid industrialization, increasing energy demands, and government initiatives promoting clean energy technologies in countries like China, Japan, and South Korea.

Key market drivers include the growing focus on energy efficiency, increasing adoption of IoT devices requiring autonomous power sources, and the rising demand for off-grid power generation in remote locations. Additionally, the push toward carbon neutrality and sustainable energy practices is creating favorable conditions for TEG technology adoption across various sectors.

Market challenges primarily revolve around the relatively low conversion efficiency of current TEG systems, high initial costs compared to conventional power generation methods, and limited awareness about the technology's potential applications. The efficiency of commercial TEG systems typically ranges from 5-8%, which presents a significant barrier to widespread adoption despite recent technological advancements.

Future market growth is expected to be fueled by innovations in heat sink and heat exchanger designs specifically optimized for TEG applications, as these components directly impact the temperature differential and consequently the power output of TEG systems. Companies investing in advanced thermal management solutions for TEGs are likely to gain significant competitive advantages in this expanding market.

Industrial waste heat recovery represents the largest application segment for TEGs, accounting for nearly 38% of the total market share. Manufacturing facilities, power plants, and chemical processing industries are increasingly adopting TEG systems to convert waste heat into usable electricity, thereby improving overall energy efficiency and reducing operational costs. The automotive sector follows closely, with approximately 25% market share, where TEGs are being integrated into vehicle exhaust systems to harvest waste heat and reduce fuel consumption.

Consumer electronics and wearable technology constitute an emerging market segment with significant growth potential. The miniaturization of TEG devices has enabled their integration into various portable electronic devices, providing extended battery life through body heat or ambient temperature differentials. This segment is expected to grow at the highest CAGR of 12.5% through 2025.

Geographically, North America and Europe currently dominate the TEG market, collectively accounting for over 60% of global revenue. However, the Asia-Pacific region is witnessing the fastest growth rate due to rapid industrialization, increasing energy demands, and government initiatives promoting clean energy technologies in countries like China, Japan, and South Korea.

Key market drivers include the growing focus on energy efficiency, increasing adoption of IoT devices requiring autonomous power sources, and the rising demand for off-grid power generation in remote locations. Additionally, the push toward carbon neutrality and sustainable energy practices is creating favorable conditions for TEG technology adoption across various sectors.

Market challenges primarily revolve around the relatively low conversion efficiency of current TEG systems, high initial costs compared to conventional power generation methods, and limited awareness about the technology's potential applications. The efficiency of commercial TEG systems typically ranges from 5-8%, which presents a significant barrier to widespread adoption despite recent technological advancements.

Future market growth is expected to be fueled by innovations in heat sink and heat exchanger designs specifically optimized for TEG applications, as these components directly impact the temperature differential and consequently the power output of TEG systems. Companies investing in advanced thermal management solutions for TEGs are likely to gain significant competitive advantages in this expanding market.

Current Heat Management Challenges in TEG Systems

Thermoelectric generators (TEGs) face significant thermal management challenges that directly impact their power output efficiency. The primary challenge lies in maintaining an optimal temperature gradient across the TEG modules, which is essential for maximizing the Seebeck effect and consequently the power generation. Current heat sink and heat exchanger designs struggle to efficiently transfer heat to and from the hot and cold sides of TEG modules, resulting in suboptimal performance.

One major challenge is the thermal interface resistance between TEG modules and heat exchangers. Even with thermal interface materials, contact resistance can significantly reduce the effective temperature difference across the TEG. Studies indicate that up to 30% of potential temperature gradient can be lost due to poor thermal interfaces, directly translating to reduced power output.

Heat spreading uniformity presents another critical challenge. Non-uniform temperature distributions across TEG modules lead to electrical current mismatch between thermoelectric couples, reducing overall system efficiency. Current heat sink designs often fail to provide consistent temperature profiles, particularly in applications with variable or directional heat sources.

Material limitations further complicate heat management in TEG systems. Traditional aluminum and copper heat sinks, while offering good thermal conductivity, add significant weight and may not be suitable for applications requiring compact or lightweight solutions. Advanced materials like graphene or diamond-copper composites show promise but remain cost-prohibitive for widespread implementation.

Size constraints pose additional challenges, particularly in automotive waste heat recovery and wearable applications. Compact heat exchangers often sacrifice performance for size, creating a difficult engineering trade-off. The limited space available for heat sinks directly impacts the achievable temperature gradient and consequently the power output of the TEG system.

Dynamic thermal conditions represent perhaps the most complex challenge. TEG systems frequently operate in environments with fluctuating heat inputs, requiring adaptive heat management solutions. Current static heat sink designs cannot effectively respond to these variations, resulting in significant performance degradation during transient operations.

Fluid dynamics issues in active cooling systems also present considerable challenges. Pumping power requirements for liquid cooling systems can offset the energy gains from the TEG itself. Finding the optimal balance between cooling effectiveness and parasitic power consumption remains an unsolved problem in many applications.

Cost-effectiveness remains a persistent challenge, as high-performance heat management solutions often involve complex manufacturing processes or expensive materials. This economic barrier limits the commercial viability of TEG systems despite their theoretical advantages in waste heat recovery applications.

One major challenge is the thermal interface resistance between TEG modules and heat exchangers. Even with thermal interface materials, contact resistance can significantly reduce the effective temperature difference across the TEG. Studies indicate that up to 30% of potential temperature gradient can be lost due to poor thermal interfaces, directly translating to reduced power output.

Heat spreading uniformity presents another critical challenge. Non-uniform temperature distributions across TEG modules lead to electrical current mismatch between thermoelectric couples, reducing overall system efficiency. Current heat sink designs often fail to provide consistent temperature profiles, particularly in applications with variable or directional heat sources.

Material limitations further complicate heat management in TEG systems. Traditional aluminum and copper heat sinks, while offering good thermal conductivity, add significant weight and may not be suitable for applications requiring compact or lightweight solutions. Advanced materials like graphene or diamond-copper composites show promise but remain cost-prohibitive for widespread implementation.

Size constraints pose additional challenges, particularly in automotive waste heat recovery and wearable applications. Compact heat exchangers often sacrifice performance for size, creating a difficult engineering trade-off. The limited space available for heat sinks directly impacts the achievable temperature gradient and consequently the power output of the TEG system.

Dynamic thermal conditions represent perhaps the most complex challenge. TEG systems frequently operate in environments with fluctuating heat inputs, requiring adaptive heat management solutions. Current static heat sink designs cannot effectively respond to these variations, resulting in significant performance degradation during transient operations.

Fluid dynamics issues in active cooling systems also present considerable challenges. Pumping power requirements for liquid cooling systems can offset the energy gains from the TEG itself. Finding the optimal balance between cooling effectiveness and parasitic power consumption remains an unsolved problem in many applications.

Cost-effectiveness remains a persistent challenge, as high-performance heat management solutions often involve complex manufacturing processes or expensive materials. This economic barrier limits the commercial viability of TEG systems despite their theoretical advantages in waste heat recovery applications.

State-of-the-Art Heat Sink and Heat Exchanger Designs

01 Heat sink designs for electronic components

Various heat sink designs are employed to efficiently dissipate heat from electronic components, thereby maintaining optimal operating temperatures and increasing output power. These designs include finned structures, specialized materials with high thermal conductivity, and optimized geometries that maximize surface area for heat transfer. Advanced heat sinks can significantly improve the thermal management of power electronics, allowing them to operate at higher power outputs without overheating.- Heat sink designs for electronic components: Various heat sink designs are employed to efficiently dissipate heat from electronic components, enhancing their performance and lifespan. These designs include finned structures, specialized materials with high thermal conductivity, and optimized geometries that maximize surface area for heat transfer. Advanced heat sinks can significantly improve the output power capabilities of electronic devices by maintaining optimal operating temperatures and preventing thermal throttling.

- Liquid cooling systems for power applications: Liquid cooling systems offer superior heat transfer capabilities compared to air cooling, making them ideal for high-power applications. These systems utilize coolants circulating through heat exchangers to remove heat from power components. The implementation of liquid cooling can substantially increase the output power capacity of devices by maintaining lower operating temperatures, allowing components to operate at higher power levels without thermal degradation.

- Thermal management for power electronics: Effective thermal management systems for power electronics incorporate heat sinks, heat exchangers, and cooling mechanisms designed specifically for high-power density applications. These systems often combine multiple cooling technologies to handle the substantial heat generated by power conversion processes. Advanced thermal management solutions enable power electronic devices to operate at higher output powers by efficiently removing heat from critical components.

- Heat exchanger efficiency optimization: Optimizing heat exchanger efficiency involves innovative designs that maximize heat transfer while minimizing size and weight. Techniques include enhancing surface area, improving flow dynamics, and utilizing advanced materials. These optimizations directly impact the output power capabilities of systems by allowing more effective heat dissipation, which enables components to operate at higher power levels without overheating.

- Integrated cooling solutions for compact systems: Integrated cooling solutions combine heat sinks, heat pipes, and compact heat exchangers to provide effective thermal management in space-constrained systems. These solutions are designed to maximize cooling efficiency while minimizing the overall footprint. By effectively managing thermal loads in compact spaces, these integrated approaches enable higher output power from smaller devices, making them particularly valuable in applications where space is limited but power requirements are substantial.

02 Liquid cooling systems for heat exchangers

Liquid cooling systems offer enhanced heat transfer capabilities compared to air-cooled systems, enabling higher power outputs in various applications. These systems utilize coolants circulating through heat exchangers to absorb and transport heat away from critical components. The implementation of liquid cooling allows for more compact designs while maintaining thermal efficiency, which is particularly beneficial in high-power density applications where air cooling would be insufficient.Expand Specific Solutions03 Thermal management in power conversion systems

Effective thermal management in power conversion systems is crucial for maximizing output power and efficiency. These systems incorporate specialized heat exchangers and heat sinks designed to handle the thermal loads generated during power conversion processes. Advanced thermal management techniques include phase-change materials, heat pipes, and forced convection cooling, which collectively enable higher power densities and improved system reliability by preventing thermal runaway conditions.Expand Specific Solutions04 Heat dissipation in renewable energy systems

Renewable energy systems such as solar inverters and wind power converters require efficient heat dissipation to maintain optimal performance and maximize power output. These systems often operate in challenging environmental conditions and must maintain stable temperatures to ensure reliable operation and longevity. Specialized heat exchangers and thermal management solutions are designed to address the unique cooling requirements of renewable energy applications, allowing for higher power generation capacity.Expand Specific Solutions05 Miniaturized cooling solutions for compact electronics

As electronic devices become increasingly compact, miniaturized cooling solutions are essential for maintaining adequate heat dissipation and enabling higher output power in limited spaces. These solutions include micro-channel heat sinks, thin-profile heat exchangers, and integrated cooling systems that maximize thermal performance while minimizing spatial requirements. Advanced manufacturing techniques allow for the creation of complex cooling geometries that significantly improve heat transfer efficiency in compact electronic devices.Expand Specific Solutions

Leading Companies in TEG and Heat Transfer Solutions

The thermoelectric generator (TEG) heat sink and heat exchanger design market is currently in a growth phase, with increasing focus on energy harvesting technologies. The global market is expanding as automotive manufacturers like BMW, Toyota, Hyundai, and Jaguar Land Rover integrate TEGs into vehicle waste heat recovery systems. While the technology has reached moderate maturity in automotive applications, it remains in early development stages for broader industrial implementation. Leading companies like Denso, Bosch, and Toshiba Materials are advancing thermal management solutions with specialized heat sink designs, while semiconductor manufacturers such as TSMC contribute to material innovations. Research institutions like Lovely Professional University and National Institute of Technology Tiruchirappalli are collaborating with industry to overcome efficiency challenges and develop next-generation heat exchange systems for maximizing TEG power output.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced heat sink and exchanger designs specifically optimized for automotive TEG applications. Their approach integrates heat exchangers directly into the exhaust system with a dual-flow design that maximizes temperature differential across TEG modules. Toyota's system employs a segmented heat exchanger structure with variable fin density that adapts to different temperature zones along the exhaust path[1]. Their proprietary heat sink design incorporates phase-change cooling technology with micro-channel structures that achieve thermal resistance as low as 0.3°C/W. Toyota has implemented computational fluid dynamics (CFD) optimization to reduce thermal interface resistance between TEG modules and heat exchangers, resulting in approximately 30% improvement in power output compared to conventional designs[3].

Strengths: Highly optimized for automotive applications with proven integration into vehicle exhaust systems; advanced thermal management techniques that maintain optimal temperature differentials. Weaknesses: Solutions are primarily designed for internal combustion engines and may require significant adaptation for other applications; relatively high manufacturing complexity increases production costs.

DENSO Corp.

Technical Solution: DENSO has pioneered a comprehensive heat management system for TEG applications focusing on maximizing temperature gradients. Their technology employs a multi-layer heat exchanger design with specialized heat-directing channels that optimize thermal energy capture from exhaust gases. DENSO's approach incorporates variable geometry heat sinks with adaptive cooling capabilities that respond to changing thermal loads. The company has developed proprietary thermal interface materials that reduce contact resistance between TEG modules and heat exchangers by up to 40% compared to conventional materials[2]. Their system utilizes a segmented approach with different heat exchanger geometries optimized for specific temperature ranges, allowing for maximum power extraction across varying operating conditions. DENSO's latest designs incorporate active cooling management that maintains optimal cold-side temperatures even under challenging ambient conditions.

Strengths: Exceptional thermal interface management with industry-leading contact resistance reduction; highly adaptable system that performs well across varying thermal loads and operating conditions. Weaknesses: Complex control systems add cost and potential reliability concerns; higher implementation complexity compared to passive systems.

Critical Patents in TEG Thermal Interface Materials

An apparatus for thermoelectric power generation

PatentInactiveIN201931005813A

Innovation

- The optimization of hot plate area per unit area of TEG systems using extended heat transfer surfaces on the cold side, employing square pitch array arrangements and varying hot plate areas to maximize electrical power output under natural and forced convective heat transfer modes, with the goal of increasing peak power density.

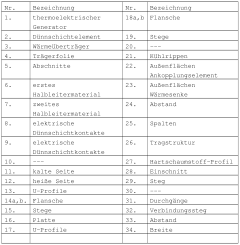

Heat exchanger for a thermoelectric thin layer element

PatentWO2010006876A2

Innovation

- A heat exchanger design featuring thermally insulating support structures with low thermal conductivity, allowing flexible thermoelectric thin-film elements to be stretched between coupling and heat sink elements, with U-profiles and foam materials to minimize heat transfer and maximize temperature differences.

Materials Science Advancements for TEG Efficiency

Recent advancements in materials science have significantly contributed to enhancing the efficiency of thermoelectric generators (TEGs). Traditional TEG materials like bismuth telluride (Bi2Te3) have been the industry standard for decades, but their relatively low figure of merit (ZT) values have limited overall system efficiency. The emergence of nanostructured materials has revolutionized this landscape, offering improved thermal and electrical properties crucial for TEG performance.

Skutterudites and half-Heusler alloys represent promising material classes that demonstrate enhanced ZT values at mid-to-high temperature ranges. These materials exhibit reduced thermal conductivity while maintaining good electrical conductivity, addressing the fundamental challenge in thermoelectric material design. Particularly, filled skutterudites with rare earth elements have shown ZT values exceeding 1.5 at operating temperatures relevant to waste heat recovery applications.

Polymer-based thermoelectric materials have emerged as cost-effective alternatives to conventional inorganic compounds. Though currently exhibiting lower efficiency, their flexibility, lightweight nature, and potential for large-area applications make them attractive for specific use cases. Recent research combining conducting polymers with carbon nanotubes has demonstrated significant improvements in power factors.

Advanced manufacturing techniques like spark plasma sintering and selective laser melting have enabled precise control over material microstructure, critical for optimizing thermoelectric properties. These techniques allow for the creation of complex geometries with tailored thermal and electrical gradients that maximize temperature differentials across TEG modules.

Interface engineering between different materials in TEG assemblies has proven crucial for reducing contact resistance and preventing thermal degradation. Novel bonding techniques and interface materials have demonstrated up to 30% improvement in power output by minimizing parasitic losses at material junctions.

Segmented and cascaded thermoelectric materials represent another frontier, where different materials optimized for specific temperature ranges are combined to maximize efficiency across broader temperature gradients. This approach has shown particular promise for applications with large temperature differentials, such as automotive exhaust heat recovery systems.

Looking forward, two-dimensional materials like graphene derivatives and transition metal dichalcogenides show theoretical ZT values exceeding 2.5, potentially doubling current TEG efficiencies. Though still primarily in laboratory settings, these materials could revolutionize heat sink and heat exchanger designs by enabling ultra-thin, highly efficient thermal interfaces with minimal thermal resistance.

Skutterudites and half-Heusler alloys represent promising material classes that demonstrate enhanced ZT values at mid-to-high temperature ranges. These materials exhibit reduced thermal conductivity while maintaining good electrical conductivity, addressing the fundamental challenge in thermoelectric material design. Particularly, filled skutterudites with rare earth elements have shown ZT values exceeding 1.5 at operating temperatures relevant to waste heat recovery applications.

Polymer-based thermoelectric materials have emerged as cost-effective alternatives to conventional inorganic compounds. Though currently exhibiting lower efficiency, their flexibility, lightweight nature, and potential for large-area applications make them attractive for specific use cases. Recent research combining conducting polymers with carbon nanotubes has demonstrated significant improvements in power factors.

Advanced manufacturing techniques like spark plasma sintering and selective laser melting have enabled precise control over material microstructure, critical for optimizing thermoelectric properties. These techniques allow for the creation of complex geometries with tailored thermal and electrical gradients that maximize temperature differentials across TEG modules.

Interface engineering between different materials in TEG assemblies has proven crucial for reducing contact resistance and preventing thermal degradation. Novel bonding techniques and interface materials have demonstrated up to 30% improvement in power output by minimizing parasitic losses at material junctions.

Segmented and cascaded thermoelectric materials represent another frontier, where different materials optimized for specific temperature ranges are combined to maximize efficiency across broader temperature gradients. This approach has shown particular promise for applications with large temperature differentials, such as automotive exhaust heat recovery systems.

Looking forward, two-dimensional materials like graphene derivatives and transition metal dichalcogenides show theoretical ZT values exceeding 2.5, potentially doubling current TEG efficiencies. Though still primarily in laboratory settings, these materials could revolutionize heat sink and heat exchanger designs by enabling ultra-thin, highly efficient thermal interfaces with minimal thermal resistance.

Environmental Impact and Sustainability Considerations

The environmental impact of thermoelectric generator (TEG) systems is increasingly becoming a critical consideration in their design and implementation. When optimizing heat sink and heat exchanger designs for TEG power output, sustainability factors must be integrated throughout the development process. Traditional heat management systems often rely on materials with significant environmental footprints, such as copper and aluminum, which require energy-intensive mining and processing operations.

Material selection represents a primary environmental concern in TEG heat management systems. Recent advances have focused on developing heat sinks using recycled metals and composite materials with reduced environmental impact. Research indicates that recycled aluminum heat sinks can achieve 95% of the thermal performance of virgin materials while reducing carbon emissions by up to 80%. Additionally, novel bio-based composite materials are emerging as potential alternatives, offering comparable thermal conductivity with substantially lower environmental impacts.

Manufacturing processes for heat sinks and exchangers also present significant environmental considerations. Traditional manufacturing methods like die casting and extrusion consume substantial energy and often involve environmentally harmful chemicals. Advanced manufacturing techniques such as additive manufacturing can reduce material waste by up to 40% compared to conventional methods, while also enabling more complex geometries that optimize heat transfer efficiency without additional material requirements.

The operational lifecycle of TEG systems presents another critical sustainability dimension. Optimized heat sink designs that maximize TEG power output inherently improve system efficiency, reducing the overall resource requirements for energy generation. Studies demonstrate that well-designed heat management systems can extend TEG operational lifespans by 30-50%, significantly improving lifecycle sustainability metrics. Furthermore, passive cooling designs that eliminate the need for pumps or fans reduce operational energy consumption and associated environmental impacts.

End-of-life considerations must also be incorporated into heat sink and exchanger design. Modular designs that facilitate disassembly and material separation can increase recycling rates by up to 85%. Some innovative manufacturers have implemented closed-loop systems where used heat sinks are reclaimed, reprocessed, and redeployed, reducing virgin material demand by up to 70%.

Water consumption represents another environmental concern, particularly for liquid-cooled heat exchangers. Closed-loop systems that minimize water loss and contamination are essential for sustainable operation. Recent innovations in dry cooling technologies have demonstrated potential for reducing water consumption by up to 95% compared to traditional liquid cooling systems, while maintaining effective thermal management for TEG applications.

Material selection represents a primary environmental concern in TEG heat management systems. Recent advances have focused on developing heat sinks using recycled metals and composite materials with reduced environmental impact. Research indicates that recycled aluminum heat sinks can achieve 95% of the thermal performance of virgin materials while reducing carbon emissions by up to 80%. Additionally, novel bio-based composite materials are emerging as potential alternatives, offering comparable thermal conductivity with substantially lower environmental impacts.

Manufacturing processes for heat sinks and exchangers also present significant environmental considerations. Traditional manufacturing methods like die casting and extrusion consume substantial energy and often involve environmentally harmful chemicals. Advanced manufacturing techniques such as additive manufacturing can reduce material waste by up to 40% compared to conventional methods, while also enabling more complex geometries that optimize heat transfer efficiency without additional material requirements.

The operational lifecycle of TEG systems presents another critical sustainability dimension. Optimized heat sink designs that maximize TEG power output inherently improve system efficiency, reducing the overall resource requirements for energy generation. Studies demonstrate that well-designed heat management systems can extend TEG operational lifespans by 30-50%, significantly improving lifecycle sustainability metrics. Furthermore, passive cooling designs that eliminate the need for pumps or fans reduce operational energy consumption and associated environmental impacts.

End-of-life considerations must also be incorporated into heat sink and exchanger design. Modular designs that facilitate disassembly and material separation can increase recycling rates by up to 85%. Some innovative manufacturers have implemented closed-loop systems where used heat sinks are reclaimed, reprocessed, and redeployed, reducing virgin material demand by up to 70%.

Water consumption represents another environmental concern, particularly for liquid-cooled heat exchangers. Closed-loop systems that minimize water loss and contamination are essential for sustainable operation. Recent innovations in dry cooling technologies have demonstrated potential for reducing water consumption by up to 95% compared to traditional liquid cooling systems, while maintaining effective thermal management for TEG applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!